Vành Hợp Kim Nhôm Vs Thép: Lợi Ích Thực Tế, Những Điểm Đánh Đổi

Bánh Xe Hợp Kim Nhôm – Giải Nghĩa và Giải Mã

Khi bạn đi mua bánh xe mới, việc lựa chọn giữa bánh xe hợp kim nhôm và bánh xe thép có thể khiến bạn cảm thấy bối rối. Bánh xe hợp kim là gì, và tại sao nhiều phương tiện hiện đại lại trang bị chúng như tiêu chuẩn? Hãy cùng phân tích những điểm khác biệt chính, làm rõ các thuật ngữ quan trọng và xác định kỳ vọng thực tế về hiệu suất, an toàn và bảo trì.

Ghế hợp kim là gì?

Nói một cách đơn giản, bánh xe hợp kim là loại bánh xe được làm từ hỗn hợp các kim loại—chủ yếu là nhôm, thường có thêm một lượng nhỏ magiê, niken hoặc silicon để tăng độ bền và khả năng chống ăn mòn. Đây chính là ý nghĩa đằng sau cụm từ ý nghĩa bánh xe hợp kim : một chiếc bánh không chỉ làm từ một loại kim loại duy nhất, mà là sự kết hợp nhiều kim loại được tính toán kỹ lưỡng. Ngược lại, bánh xe thép được làm từ những tấm thép cacbon ép dập, mang lại cấu trúc đơn giản và chắc chắn hơn.

Nhờ thành phần cấu tạo của chúng, lốp hợp kim nhôm nhẹ hơn bánh xe thép. Việc giảm trọng lượng này trực tiếp mang lại lợi ích cho khả năng vận hành, hiệu suất nhiên liệu và cả vẻ ngoài của xe. Chúng thường được sản xuất bằng phương pháp đúc hoặc rèn, những quy trình cho phép tạo ra các thiết kế phức tạp và phong cách hơn so với kiểu dáng đơn giản, nặng nề của bánh xe thép (AZoM) .

Ưu điểm và nhược điểm của bánh xe hợp kim nhôm

Tại sao các nhà sản xuất ô tô và người lái xe ngày càng lựa chọn lốp hợp kim nhôm ? Hãy tưởng tượng bạn đang di chuyển trên đường phố thành phố hoặc chạy trên đường cao tốc – bạn sẽ nhận thấy sự khác biệt về chất lượng lái xe, hiệu suất và cả lực phanh. Nhưng không phải tất cả đều là ưu điểm. Dưới đây là cái nhìn nhanh về các lợi ích chính và hạn chế:

- Trọng lượng nhẹ làm giảm khối lượng không được treo, cải thiện khả năng tăng tốc, phanh và xử lý

- Khả năng tản nhiệt tốt hơn, hỗ trợ hiệu suất phanh ổn định hơn

- Linh hoạt hơn trong thiết kế để tạo ra các kiểu dáng và lớp hoàn thiện tùy chỉnh

- Có thể cải thiện hiệu suất nhiên liệu nhờ khối lượng quay thấp hơn

- Dễ bị tổn thương về mặt thẩm mỹ như trầy xước do va quệt

- Yêu cầu chăm sóc kỹ hơn để duy trì lớp hoàn thiện (sơn, phủ bóng hoặc đánh bóng)

- Thông thường chi phí ban đầu cao hơn so với vành thép

- Có thể kém bền hơn thép khi sử dụng ở điều kiện off-road khắc nghiệt hoặc tải trọng lớn

Việc lựa chọn giữa vành hợp kim hay vành thép là sự cân bằng phù hợp—những chiếc vành nhẹ hơn, hiệu suất tốt hơn thường đi kèm với những điểm hạn chế về chi phí và bảo dưỡng. Hãy ưu tiên những yếu tố quan trọng nhất đối với phong cách lái xe và môi trường sử dụng của bạn.

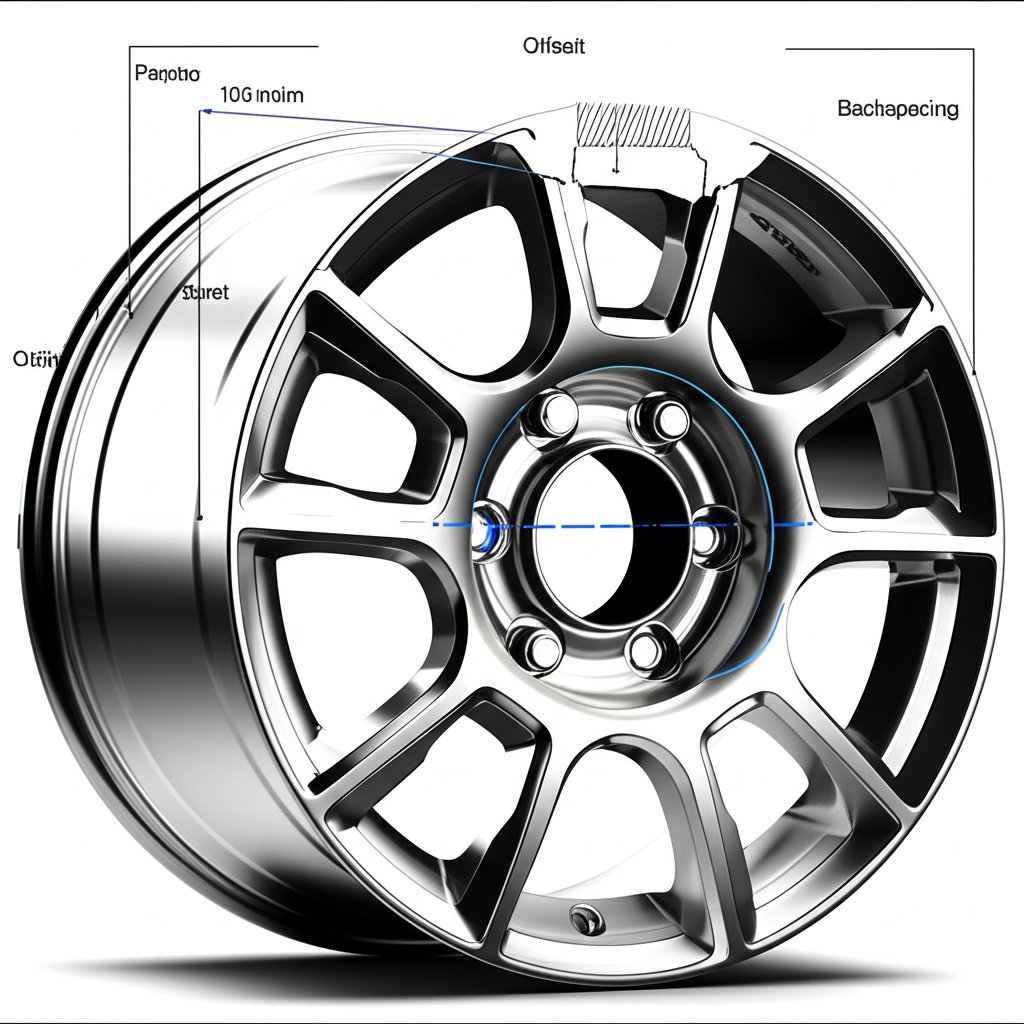

Các thông số kỹ thuật quan trọng người lái cần biết: PCD, độ lệch (offset), khả năng chịu tải

Dù bạn nâng cấp để cải thiện hiệu suất, kiểu dáng, hoặc cả hai, bạn cần hiểu rõ một vài thông số kỹ thuật chính sau:

- PCD (Pitch Circle Diameter): Số lượng và khoảng cách giữa các lỗ bắt bu lông—yếu tố quan trọng để đảm bảo lắp vừa khít

- Độ lệch (Offset): Khoảng cách từ bề mặt lắp đặt của bánh xe đến đường tâm của nó—ảnh hưởng đến tư thế đứng và khoảng hở

- Đánh giá tải trọng: Trọng lượng tối đa mà mỗi bánh xe có thể chịu được một cách an toàn – yếu tố quan trọng đối với sự an toàn

Luôn kiểm tra các thông số này với hướng dẫn sử dụng xe hoặc dữ liệu của nhà sản xuất gốc (OEM). SAE J328 tiêu chuẩn nêu rõ các yêu cầu hiệu suất tối thiểu cho bánh xe của xe du lịch và xe tải nhẹ, đảm bảo an toàn và độ tin cậy.

Tại sao chất lượng chuỗi cung ứng lại quan trọng

Bánh xe không hoạt động độc lập. Độ tin cậy của chúng phụ thuộc vào chất lượng các bộ phận liền kề – ví dụ như giá đỡ phanh, khớp cầu treo và các chi tiết định hình bảo vệ liên kết mọi thứ với nhau. Các chi tiết phụ kiện nhôm ép nuôi chất lượng cao là yếu tố nền tảng để đảm bảo hệ thống bánh xe hoạt động an toàn và ổn định, đặc biệt khi các thiết kế ngày càng nhẹ hơn và tiên tiến hơn. Các nhà cung cấp như Nhà cung cấp phụ tùng kim loại Shaoyi mang đến chuyên môn trong việc sản xuất các chi tiết định hình chính xác hỗ trợ độ bền vững cho các bộ bánh xe hiện đại.

Tóm lại, lốp hợp kim nhôm đem đến sự kết hợp ấn tượng giữa độ nhẹ, phong cách và hiệu suất, nhưng cần được lựa chọn và bảo dưỡng cẩn thận. Việc hiểu rõ những nguyên tắc cơ bản này sẽ giúp bạn đưa ra quyết định sáng suốt khi tìm hiểu các phần tiếp theo của hướng dẫn này.

Phương Pháp Sản Xuất Thay Đổi Hiệu Suất Như Thế Nào

Bạn có bao giờ tự hỏi tại sao một số la-zăng có giá chỉ vài trăm đô la, trong khi những chiếc khác lại lên tới hàng nghìn đô la không? Câu trả lời nằm ở cách chúng được chế tạo. Hãy cùng phân tích các phương pháp sản xuất chính — đúc, tạo hình dòng chảy và rèn — để làm rõ cách mỗi phương pháp ảnh hưởng đến độ bền, trọng lượng và giá trị của la-zăng hợp kim nhôm.

La-zăng Đúc: Đúc Trọng Lực vs Đúc Áp Suất Thấp vs Đúc Áp Suất Cao

La-zăng đúc là nền tảng phổ biến trên thị trường phụ tùng và OEM. Quy trình bắt đầu bằng việc đổ nhôm nóng chảy vào khuôn. Nghe có vẻ đơn giản, nhưng các chi tiết lại rất quan trọng:

- Đúc trọng lực: Dựa vào trọng lực để điền đầy khuôn. Đây là phương pháp tiết kiệm chi phí nhất nhưng có thể dẫn đến độ xốp cao hơn—những túi khí nhỏ có thể làm giảm độ bền. Bánh đúc trọng lực phù hợp nhất cho việc lái xe hàng ngày cơ bản, nơi ngân sách và kiểu dáng là yếu tố ưu tiên.

- Đúc áp suất thấp: Sử dụng áp suất không khí để đẩy nhôm nóng chảy vào khuôn. Phương pháp này tạo ra cấu trúc đặc hơn và đồng nhất hơn so với đúc trọng lực, mang lại độ bền và độ tin cậy tốt hơn. Phần lớn các bánh xe nhôm đúc ở cấp cơ bản bánh xe nhôm đúc được sản xuất theo cách này, tạo sự cân bằng giữa chi phí, chất lượng và tùy chọn hoàn thiện.

- Đúc áp suất cao: (đôi khi gọi là đúc khuôn ép) ít được sử dụng hơn cho bánh xe do chi phí thiết bị cao hơn, nhưng có thể cải thiện thêm độ đặc và giảm khuyết tật. Tuy nhiên, phương pháp này thường chỉ dành cho các ứng dụng chuyên biệt.

Trong khi tùy chọn bánh đúc rất đa dạng và giá cả phải chăng, nhưng chúng thường nặng hơn và dễ bị nứt hơn dưới tác động của lực căng mạnh. Tuy nhiên, đối với hầu hết các phương tiện lưu thông trên đường phố, bánh xe nhôm đúc hoàn toàn đầy đủ.

Thân mâm Flow Formed: Quy trình chế tạo cải thiện vành mâm

Flow forming (còn gọi là rotary forging hoặc spun forging) là một quy trình lai. Nó bắt đầu với một tâm mâm được đúc áp suất thấp, sau đó thân vành mâm được nung nóng và quay, trong khi các con lăn kéo giãn và nén ép kim loại ra ngoài. Thao tác cơ học này:

- Giảm trọng lượng nhờ sử dụng ít vật liệu hơn

- Cải thiện cấu trúc hạt kim loại, dẫn đến độ bền cao hơn và khả năng chịu va đập tốt hơn

- Tăng khả năng chịu tải và giảm độ xốp so với các mâm đúc tiêu chuẩn

Theo các nguồn trong ngành, mâm flow formed thường có trọng lượng nhẹ hơn 15–25% so với mâm đúc và mang lại sự cân bằng tốt giữa độ bền, trọng lượng và chi phí. Đây là lựa chọn yêu thích của những người đam mê muốn hiệu suất tốt hơn mà không phải trả chi phí cao như mâm rèn nguyên khối.

Mâm nhôm rèn: Các yếu tố về độ bền và chi phí

Vành đúc nguyên khối là tiêu chuẩn vàng về hiệu suất. Quy trình sản xuất bắt đầu bằng một thanh nhôm đặc, được nung nóng, sau đó áp dụng áp lực cực lớn để định hình. Điều này giúp sắp xếp cấu trúc hạt kim loại theo hình dạng của vành, tạo ra:

- Độ bền vượt trội và khả năng chống nứt, chống móp

- Trọng lượng nhẹ hơn cho cùng kích thước so với vành đúc hoặc vành định hình bằng ép chảy

- Độ bền cao hơn, đặc biệt trong điều kiện tải nặng hoặc đua xe thể thao

Vành đúc cũng cung cấp độ linh hoạt cao về thiết kế và nhiều tùy chọn tùy chỉnh, nhưng đi kèm với giá thành cao hơn và thời gian chờ đợi lâu hơn. Đối với hầu hết người lái xe, lợi ích của bánh xe nhôm đúc hoặc vành nhôm đúc sẽ được phát huy tốt nhất trong môi trường hiệu suất cao hoặc công nghiệp nặng.

| Quy trình | Trọng lượng điển hình | Độ bền/Độ nguyên vẹn | Nguy cơ khuyết tật | Tự do thiết kế | Các tùy chọn hoàn thiện | Các Trường Hợp Sử Dụng Phổ Biến |

|---|---|---|---|---|---|---|

| Đúc trọng lực | Nặng hơn | Cơ bản | Độ xốp cao hơn | LIMITED | Tiêu chuẩn | Lái hàng ngày, nâng cấp ngân sách |

| Đúc áp lực thấp | Trung bình | Cải tiến hơn phương pháp trọng lực | Độ xốp thấp hơn | Nhiều tùy chọn | Đa dạng | Hiệu suất cơ bản hàng ngày |

| Đúc xoay | Nhẹ hơn (ít hơn 15–25%) | Cao | Thấp | Tốt | Phạm vi rộng | Đường phố hiệu suất, đường đua, đua xe nhẹ |

| Đúc | Nhẹ nhất | Đứng trên | Rất Thấp | Tùy chỉnh, mở rộng | Premium | Thể thao động cơ, hạng nặng, cao cấp |

Việc lựa chọn phương pháp sản xuất vành xe phù hợp là để cân đối các ưu tiên của bạn - chi phí, độ bền, trọng lượng và kiểu dáng - với nhu cầu lái xe thực tế. Đối với hầu hết người dùng, vành nhôm đúc hoặc vành định hình dòng chảy là lựa chọn cân bằng lý tưởng. Với hiệu suất cao không khoan nhượng, vành nhôm rèn mang lại lợi ích vượt trội.

Bây giờ bạn đã hiểu rõ cách các quy trình sản xuất khác nhau định hình hiệu suất và giá trị của vành hợp kim nhôm, hãy cùng khám phá cách những lựa chọn kỹ thuật này ảnh hưởng đến trải nghiệm lái xe thực tế - tác động đến khả năng điều khiển, phanh và chất lượng vận hành tổng thể.

Cách Lựa Chọn Kỹ Thuật Định Hình Trải Nghiệm Lái Xe Của Bạn

Tác Động Của Trọng Lượng Vành Xe Đến Khả Năng Điều Khiển, Phanh Và Hiệu Quả Kinh Tế

Khi bạn thay thế vành xe của mình bằng những chiếc nhẹ hơn, bạn có thể tự hỏi - liệu sự khác biệt có thực sự đáng kể không? Câu trả lời là hoàn toàn có, và lý do nằm ở hai khái niệm sau: khối lượng không được treo và quán tính quay . Hãy tưởng tượng việc lái xe với một quả bóng bowling được gắn ở mỗi góc xe so với một quả bóng rổ. Bánh xe càng nhẹ thì hệ thống treo càng dễ dàng giữ cho lốp bám đường, dẫn đến khả năng đánh lái chính xác hơn và cảm giác lái nhạy bén hơn.

Ví dụ, việc giảm trọng lượng bánh xe chỉ 5–10 pound mỗi góc có thể khiến xe của bạn trở nên linh hoạt hơn, cải thiện khả năng vào cua và cảm giác lái nhẹ nhàng hơn. Các bài kiểm tra thực tế cho thấy việc giảm 12 pound mỗi bánh xe giúp chiếc Mazda Miata tăng tốc từ 0–60 mph nhanh hơn 0,29 giây. Ngay cả những người lái xe hàng ngày cũng nhận thấy điều này. bánh xe nhẹ và bánh xe xe tải nhẹ giúp quá trình tăng tốc và phanh xe trở nên nhanh nhạy hơn, đồng thời thậm chí còn mang lại những cải thiện nhỏ về hiệu suất nhiên liệu — một bài kiểm tra ghi nhận mức cải thiện 3% về mpg sau khi chuyển sang sử dụng bánh xe nhẹ hơn.

Nhưng không chỉ đơn thuần là tổng trọng lượng. Vị trí của trọng lượng đó đặt ở đâu cũng rất quan trọng. Bánh xe có khối lượng tập trung gần vành ngoài sẽ có quán tính quay cao hơn, khiến chúng khó tăng tốc hoặc giảm tốc hơn. Đó là lý do tại sao các thiết kế tập trung khối lượng gần trục bánh xe thường được ưa chuộng trong các ứng dụng hiệu suất cao và vành xe tải bằng nhôm tương tự.

Tản nhiệt và hiện tượng giảm hiệu quả phanh khi lái xe mạnh

Bạn đã từng nhận thấy hệ thống phanh có vẻ kém hiệu quả sau một loạt phanh gấp hoặc sau một đoạn đường dài xuống dốc chưa? Đó là hiện tượng giảm phanh (brake fade) - khi nhiệt độ tăng cao làm giảm hiệu suất phanh. Trong trường hợp này, vật liệu và thiết kế của bánh xe đóng vai trò then chốt. Vành hợp kim nhôm, và đặc biệt là vành bằng hợp kim magiê hoặc vành bằng hợp kim magiê , thường có khả năng tản nhiệt tốt hơn so với vành thép. Điều này có nghĩa là hệ thống phanh có thể nguội nhanh hơn, duy trì hiệu suất ổn định trong quá trình lái xe mạnh hoặc kéo tải nặng.

Tuy nhiên, có một sự đánh đổi. Theo các nghiên cứu trong phòng thí nghiệm, mặc dù vành nhôm giúp phanh hoạt động mát hơn (nhiệt độ phanh thấp hơn 5,6°C khi phanh mạnh so với thép), chúng có thể truyền nhiều nhiệt hơn tới lốp xe, có thể làm tăng nhiệt độ lốp lên tới 16% (Tạp chí SAGE) . Đối với việc sử dụng hàng ngày và hầu hết các ứng dụng hiệu suất, lợi ích của việc giảm phanh mòn nhiều hơn làm cân bằng rủi ro này - nhưng đây là yếu tố cần cân nhắc đối với việc lái xe tải trọng nặng hoặc liên tục xuống dốc, đặc biệt là với cấu hình bánh đơn.

Độ cứng, chất lượng lái và các yếu tố tiếng ồn

Độ cứng là một yếu tố khác ảnh hưởng đến trải nghiệm lái xe của bạn. Các thiết kế la-zăng nhẹ, đặc biệt là những mẫu làm từ nhôm hoặc magie rèn, thường cứng hơn so với các phiên bản đúc. Độ cứng gia tăng này có thể làm cho phản ứng lái sắc nét hơn và giảm độ uốn cong khi vào cua. Tuy nhiên, có một mặt trái: la-zăng quá cứng có thể truyền nhiều tiếng ồn và rung động từ mặt đường vào cabin hơn, điều mà một số tài xế cảm thấy mệt mỏi khi di chuyển trên những mặt đường xấu. Điểm cân bằng lý tưởng đối với hầu hết người lái là một bánh xe nhẹ mẫu có trọng lượng nhẹ vừa phải nhưng vẫn đủ độ linh hoạt để mang lại sự thoải mái.

| Thuộc Tính La-zăng | Nhẹ Hơn / Cứng Hơn | Nặng Hơn / Linh Hoạt Hơn |

|---|---|---|

| Xử Lý & Lái Xe | Sắc nét, phản ứng nhanh hơn | Phản ứng chậm hơn, cảm giác nặng hơn |

| Hiệu Suất Phanh | Cải thiện, ít suy giảm hơn | Dễ phai màu hơn |

| Tiết kiệm nhiên liệu | Có thể tốt hơn (đặc biệt là lái trong thành phố) | Thấp hơn, đặc biệt khi dừng và khởi động liên tục |

| Sự Thoải Mái Khi Lái Xe | Có thể cải thiện (giảm khối lượng không được treo), nhưng có thể làm tăng tiếng ồn | Mượt mà hơn trên đường xấu, yên tĩnh hơn |

| Mòn lốp | Phân bố đều hơn (tiếp xúc tốt hơn) | Có thể phân bố không đều hơn (gây áp lực lên hệ thống treo) |

Tìm sự cân bằng phù hợp giữa khối lượng nhẹ và độ bền là yếu tố quan trọng — hãy chọn la-zăng nâng cao trải nghiệm lái xe của bạn mà không làm giảm sự thoải mái hay độ tin cậy. La-zăng tốt nhất vành nhôm là những chiếc phù hợp với nhu cầu của xe bạn và thực tế hàng ngày của bạn.

Tiếp theo, chúng ta sẽ phân tích các yếu tố lắp đặt quan trọng đảm bảo rằng la-zăng mới của bạn không chỉ hoạt động tốt mà còn vừa vặn an toàn và mượt mà trên xe hoặc xe tải của bạn.

Những Điều Cơ Bản Về Khoảng Cách Lắp Ráp Mà Mọi Người Mua Đều Phải Nắm Rõ

Đã bao giờ bạn mua một bộ la-zăng, chỉ để phát hiện ra chúng cọ vào vòm bánh hoặc gây ra vấn đề lái xe chưa? Bạn không đơn độc đâu. Việc lắp ráp đúng cách quan trọng không kém việc chọn kiểu dáng phù hợp. Nếu bạn từng tự hỏi, " khoảng cách lệch tâm của bánh xe là gì ?" hoặc các thuật ngữ như mẫu bu-lông và lỗ trung tâm bảo vệ chiếc xe của bạn ra sao, phần này sẽ là kim chỉ nam giúp bạn nâng cấp an toàn và mượt mà.

Khoảng Cách Lệch Tâm Của Bánh Xe Là Gì Và Tại Sao Nó Ảnh Hưởng Đến Khoảng Trống

Hãy bắt đầu với những điều cơ bản. Khoảng cách lệch tâm của bánh xe là khoảng cách (tính bằng milimét) từ bề mặt lắp ráp của bánh xe đến đường trung tâm của nó. Hãy tưởng tượng nó giống như yếu tố xác định bánh xe của bạn nằm trong hay ngoài vòm bánh xe bao nhiêu. Nghe phức tạp à? Hãy nhìn từ phía sau xe của bạn: khoảng lệch tâm cao sẽ đẩy bánh xe vào bên trong, trong khi khoảng lệch thấp sẽ đưa nó ra bên ngoài. Khoảng cách lệch tâm vành đảm bảo bánh xe không chạm vào các bộ phận treo hoặc nhô ra ngoài một cách bất tiện. Hầu hết các xe sử dụng hàng ngày dùng độ lệch từ +30 đến +50 mm, trong khi xe tải và các thiết kế mạnh mẽ có thể sử dụng độ lệch thấp hơn hoặc thậm chí là âm. Việc lựa chọn độ lệch phù hợp là rất quan trọng cho cả vẻ ngoài lẫn an toàn.

- Độ lệch (Offset): Khoảng cách từ bề mặt gắn bánh xe đến đường tâm; ảnh hưởng đến tư thế đứng, khoảng hở phanh và an toàn hệ thống treo.

- Backspacing: Khoảng cách từ bề mặt gắn đến mép trong của bánh xe; giúp hình dung khoảng cách phía trong, đặc biệt đối với phanh lớn hoặc bánh xe sâu (deep-dish).

- Bolt Pattern (PCD): Số lượng chốt (lug) × đường kính vòng tròn (ví dụ: bánh xe 5x114.3 hoặc bánh xe 5x120 ); phải khớp chính xác với trục của xe bạn.

- Center Bore: Lỗ ở giữa vành xe vừa khớp với trục xe của bạn; rất quan trọng để lắp đặt không bị rung lắc.

Giải thích về Khoảng cách từ mép vành đến mặt lắp ráp và Đường kính lỗ trung tâm

Khoảng cách từ mép vành đến mặt lắp ráp (backspacing) và đường kính lỗ trung tâm (center bore) thường bị bỏ qua nhưng lại có thể quyết định sự phù hợp của vành. Backspacing, được đo từ mặt lắp ráp của vành đến mép bên trong của vành, cho bạn biết vành lồi vào trong bao xa. Nếu backspacing quá lớn, bạn có nguy cơ chạm vào các bộ phận treo hoặc phanh. Nếu quá nhỏ? Bánh xe của bạn có thể bị nhô ra ngoài hoặc gây thêm tải lên các ổ bi.

Center bore là đường kính của lỗ vừa khớp với trục xe. Nếu nó quá nhỏ, vành sẽ không lắp vừa. Nếu quá lớn? Bạn sẽ cần các vòng đệm cân tâm để tránh rung lắc. Ví dụ, nhiều dòng xe BMW sử dụng center bore 72,6 mm, trong khi các dòng xe bán tải phổ biến như vành cho xe Tacoma thường yêu cầu kích thước khác. Hãy luôn kiểm tra thông số kỹ thuật của xe hoặc tham khảo sách hướng dẫn sử dụng để lựa chọn đúng kích thước.

- Backspacing: Quan trọng cho khoảng cách giữa phanh và hệ thống treo; nếu quá lớn có thể gây cản trở.

- Center Bore: Đảm bảo bánh xe được đặt chính xác tại trung tâm moay-ơ; sự không tương thích về kích thước có thể gây rung lắc ở tốc độ cao.

Hub Centric (định tâm moay-ơ) so với Lug Centric (định tâm bằng bu-lông) và Cách chọn phụ kiện phù hợp

Bánh xe được lắp lên xe của bạn theo hai cách chính:

- Bánh xe Hub-centric: Lỗ trung tâm khớp chính xác với moay-ơ, giúp định tâm bánh xe cho chuyến đi êm ái. Hầu hết các bánh xe OEM đều là loại hub-centric.

- Bánh xe Lug-centric: Bánh xe được định tâm bằng các con ốc (lug nuts), chứ không phải bằng moay-ơ. Hầu hết các bánh xe aftermarket đều là lug-centric để phù hợp với nhiều dòng xe khác nhau, nhưng có thể cần vòng định tâm moay-ơ để đạt chất lượng lái tốt nhất.

Việc sử dụng vòng định tâm moay-ơ với bánh xe lug-centric sẽ lấp đầy khoảng hở và giúp loại bỏ rung lắc. Điều này đặc biệt quan trọng nếu bạn chuyển sang dùng bánh xe aftermarket hoặc đổi giữa các thương hiệu.

Các thuật ngữ liên quan đến độ lắp ráp (Fitment) - Tổng quan nhanh

- Độ lệch (Offset): Vị trí hướng vào/ra của bánh xe (mm)

- Backspacing: Bề mặt lắp đặt đến mép trong của bánh xe (inch)

- Bolt Pattern (PCD): Số lượng lug × đường kính vòng tròn (ví dụ: bánh xe 5x120)

- Center Bore: Đường kính lỗ trung tâm của bánh xe (mm)

- Tâm bánh xe theo trục (hub-centric): Bánh xe định tâm theo trục

- Tâm bánh xe theo đinh tán (lug-centric): Bánh xe định tâm bằng đinh tán

- Kiểm tra thông số bánh xe gốc của xe bạn (sách hướng dẫn sử dụng hoặc tài liệu tham khảo đáng tin cậy).

- Xác minh mẫu bu lông (ví dụ: bánh xe 5x114.3 hoặc bánh xe 5x120).

- Đo hoặc xác nhận đường kính lỗ trung tâm.

- Chọn đúng độ lệch/khoảng cách lùi phù hợp với hệ thống treo và phanh của bạn.

- Quyết định xem bạn có cần vòng định tâm trục cho la-zăng độ hay không.

Thay đổi độ lệch của bánh xe—even by a few millimeters—có thể làm tăng tải trọng lên ổ bi và thay đổi bán kính ma sát của xe bạn. Luôn kiểm tra sự phù hợp để bảo vệ khả năng vận hành, mài mòn lốp và an toàn lâu dài.

Nắm vững các nguyên tắc cơ bản về sự phù hợp này sẽ giúp bạn tránh những sai lầm tốn kém và đảm bảo rằng bộ la-zăng mới của bạn mang lại cả phong cách và độ an toàn. Tiếp theo, chúng ta sẽ cùng đi qua các bước thực tế để đo kiểm tra sự phù hợp ngay tại nhà, để bạn có thể mua sắm với sự tự tin tuyệt đối.

Hướng dẫn từng bước đo đạc và kiểm tra thực tế

Đã sẵn sàng nâng cấp la-zăng nhưng lo lắng về việc lắp không vừa? Bạn không đơn độc đâu. Ngay cả những người chơi xe lâu năm cũng có thể bị nhầm lẫn bởi mẫu bu-lông, lỗ trung tâm hoặc khoảng hở phanh. Hãy cùng đi qua một quy trình đơn giản, ít dụng cụ để đo và kiểm tra sự phù hợp ngay tại nhà—để bạn có thể tự tin lựa chọn đúng sản phẩm lốp hợp kim nhôm hoặc bất kỳ kiểu dáng nào bạn yêu thích.

Đo chính xác mẫu bulông bằng các công cụ cơ bản

Đầu tiên, hãy bắt đầu với mẫu bulông—thường được biểu thị bằng hai con số, ví dụ như 5x112 bánh xe hoặc 4x100 . Số đầu tiên là số lỗ bắt bulông, và số thứ hai là đường kính vòng tròn mà các lỗ này tạo thành (tính bằng milimét hoặc inch). Nhưng bạn sẽ đo nó như thế nào?

- Mẫu bulông chẵn (ví dụ: 4, 6, 8 bulông): Đo từ tâm của một chốt bulông trực tiếp sang tâm của chốt đối diện. Ví dụ, với vành 4x100, hãy đo từ một lỗ bulông đến lỗ đối diện—rất đơn giản (Apex Wheels) .

- Mẫu bulông lẻ (ví dụ: 5 bulông): Đo khoảng cách giữa hai tâm lỗ bulông liền kề (ký hiệu là X), sau đó tính toán bằng công thức PCD = X / 0.5878. Phương pháp đơn giản và đáng tin cậy nhất là sử dụng thước đo PCD chuyên dụng.

Kiểm tra độ rộng tâm và chọn vòng định tâm trục (Hub Centric Rings)

Tiếp theo: lỗ trung tâm (center bore). Đây là lỗ ở giữa vành xe, được thiết kế vừa khít với trục bánh xe của xe bạn. Tại sao điều này quan trọng? Nếu lỗ trung tâm quá nhỏ, vành sẽ không lắp vừa. Nếu quá lớn, bạn sẽ cần các vòng đệm trung tâm (hub-centric rings) để tránh rung giật.

- Đo lường: Dùng thước hoặc thước kẹp để đo chính xác đường kính thực tế của lỗ trung tâm vành - không chỉ đo phần mép vát. Hầu hết các vành hợp kim nhôm được thiết kế với lỗ trung tâm rõ ràng, phẳng để phục vụ cho việc đo đạc này.

- Vòng đệm trung tâm (Hub-centric rings): Nếu vành mới của bạn có lỗ trung tâm lớn hơn trục bánh xe của xe bạn, các vòng đệm này sẽ lấp đầy khoảng trống, giúp vành lắp vừa khít và không bị rung giật. Luôn kiểm tra thông số kỹ thuật trước khi mua.

Xác nhận khoảng hở phanh (brake clearance) và độ sâu mặt sau nan hoa (spoke backpad depth)

Bạn đã từng nghe thấy tiếng kêu lạch cạch sau khi lắp vành mới chưa? Đó thường là do vấn đề về khoảng hở của kẹp phanh (brake caliper). Đây là cách để tránh điều đó:

- Kiểm tra bằng mắt thường: Khi bánh xe đã tháo ra, đo từ bề mặt lắp đặt trục đến phần ngoài cùng của kẹp phanh (brake caliper). Sau đó so sánh giá trị này với độ sâu backpad của vành mới bạn mua.

- Hình dạng nan hoa (Spoke profile): Một số thiết kế—đặc biệt là kiểu dáng sâu hoặc nan hoa phức tạp—có thể gây cản trở với kẹp phanh lớn. Nếu bạn không chắc chắn, hãy thử lắp ráp bằng cách sử dụng mẫu giấy bìa hoặc kiểm tra sơ đồ từ nhà sản xuất.

- Chiều rộng mặt lốp: Đặt lốp dự định sử dụng xuống phẳng và đo chiều rộng mặt lốp để đảm bảo nó sẽ không cọ vào các bộ phận treo hoặc lớp lót chắn bùn.

- Xác định mẫu bulông hiện tại của bạn (ví dụ: bánh xe 5x112, 6x5, hoặc 5x4).

- Đo đường kính lỗ trung tâm của bánh xe và trục xe hiện tại.

- Kiểm tra khoảng cách giữa kẹp phanh và bề mặt sau của bánh xe cũng như hình dạng nan hoa.

- Thử mô phỏng chiều rộng mặt lốp và đường kính tổng thể để kiểm tra khoảng trống.

- So sánh chéo tất cả các kích thước với bảng thông số kỹ thuật từ nhà sản xuất hoặc các thông số in trên bánh xe.

| Trường thông số | Nơi Tìm Thông Tin |

|---|---|

| PCD (Mẫu bu lông) | Được đóng dấu ở mặt sau của bánh xe, bảng thông số kỹ thuật hoặc sách hướng dẫn sử dụng |

| Lỗ trung tâm (Center Bore) | Bảng thông số kỹ thuật, đo trực tiếp bằng thước kẹp/thước thẳng |

| Trục xuất | Độ lệch tâm (Offset) được in trên bánh xe (ví dụ: ET35), bảng thông số kỹ thuật |

| Đánh giá tải | Bảng thông số kỹ thuật, đôi khi được đóng dấu trên bánh xe |

Ví dụ về bảng thông số kỹ thuật giả (cho vành bánh xe nhôm tiêu biểu):

Mẫu Vành: Apex Flow Formed PCD: 5x112 Center Bore: 66.6 mm Offset: ET35 Tải trọng: 690 kg

Không bao giờ cố gắng lắp đặt một chiếc bánh xe không phù hợp với mẫu bu lông, lỗ trung tâm hoặc độ lệch tâm của xe bạn. Ngay cả những sự không khớp nhỏ cũng có thể gây ra rung giật, xử lý không an toàn hoặc hỏng hóc linh kiện.

Bằng cách làm theo quy trình thực tế này, bạn sẽ hiểu rõ hơn về vành bánh xe là gì, tự tin hơn khi lựa chọn các tùy chọn vành nhôm, đồng thời tránh được những sai lầm tốn kém và gây khó chịu. Tiếp theo, chúng tôi sẽ hướng dẫn bạn cách lắp đặt an toàn và kiểm tra sau khi lắp đặt - để những chiếc bánh mới của bạn không chỉ đẹp mà còn hoạt động hoàn hảo trên mọi hành trình.

Trình Tự Lắp Đặt và Kiểm Tra Sau Lắp

Khi bạn đã chọn được sản phẩm hoàn hảo lốp hợp kim nhôm - dù là cho chiếc xe hàng ngày, xe địa hình mâm xe jeep , hay một bộ vành kép - việc lắp đặt đúng cách là yếu tố then chốt đảm bảo hiệu suất và an toàn. Nghe có vẻ phức tạp? Không hề, nếu bạn tuân theo một trình tự đã được kiểm chứng và chú ý đến từng chi tiết. Dưới đây là cách để đảm bảo chiếc gói vành và lốp mang lại trải nghiệm vận hành ổn định, bất kể bạn đang lắp vành xe 17 inch hay vành khóa lốp chuyên dụng.

Chuẩn Bị: Công Cụ, An Toàn và Hỗ Trợ Xe

Trước khi bắt đầu, hãy chuẩn bị đầy đủ các dụng cụ cơ bản sau:

- Cờ lê momen xoắn chất lượng (kiểu thanh hoặc kiểu nhả)

- Cờ lê socket ốc bánh xe đúng kích cỡ (tránh dùng súng siết lực va đập để siết cuối cùng)

- Kích và giá đỡ kích có tải trọng phù hợp với xe của bạn

- Chổi sắt hoặc dụng cụ làm sạch ren để vệ sinh bu-lông

- Chất bôi trơn chống dính cho trung tâm moay-ơ (không dùng cho ren ốc bánh xe)

- Nêm chặn bánh xe để tăng độ ổn định

Kiểm tra tất cả các bu-lông bánh xe để phát hiện hư hỏng hoặc biến dạng. Nếu ren bị gỉ, bẩn hoặc đã từng siết quá lực, hãy làm sạch hoặc thay thế chúng—không bao giờ được mạo hiểm sử dụng lại các chi tiết đã bị ảnh hưởng. Luôn sử dụng ốc bánh xe mới khi lắp bánh xe mới nếu có thể, đặc biệt khi chuyển sang loại sau thị trường với kiểu ghế tiếp xúc khác (OnAllCylinders) .

Trình tự lắp và kiểu momen xoắn cho ốc bánh xe

- Thử lắp từng bánh xe: Xác nhận mẫu bulông, tiếp xúc đầy đủ với moay-ơ và khoảng cách đủ cho phanh và hệ thống treo.

- Vặn chặt đai ốc bằng tay: Vặn từng đai ốc bằng tay để tránh tuôn ren. Đảm bảo tất cả các đai ốc đều xoay trơn tru.

- Xiết chặt bulông theo kiểu hình sao: Xiết tất cả các bulông đến khoảng một nửa lực xiết cuối cùng theo trình tự chéo (hình sao). Điều này giúp bánh xe được định tâm và tránh biến dạng.

- Lực xiết cuối cùng: Khi hạ xe xuống đủ thấp để bánh xe chạm đất, sử dụng cờ lê lực để xiết từng bulông đến mức lực được nhà sản xuất khuyến nghị, cũng theo kiểu hình sao. (Kiểm tra sách hướng dẫn sử dụng xe hoặc các nguồn đáng tin cậy để biết giá trị chính xác. Không bao giờ dựa vào các con số chung trừ khi không có thông số của nhà sản xuất.)

- Kiểm tra lại chiều quay: Quay bánh xe bằng tay để đảm bảo bánh quay tự do và không bị cản.

Mẹo: Không bao giờ sử dụng súng bắn hơi để xiết chặt cuối cùng—điều này có thể dễ dàng gây ra lực xiết quá mức hoặc làm hỏng các chi tiết và bề mặt bánh xe.

Cân bằng, Thử nghiệm trên đường và Xiết lại sau khi lắp đặt

Sau khi gắn bánh xe, hãy đảm bảo chúng được cân bằng đúng cách để tránh rung giật. Nếu bạn đang lắp đặt bánh xe khóa bi (beadlock) hoặc các thiết kế đặc biệt, hãy kiểm tra kỹ tất cả các vòng khóa và bulông đã được xiết đúng theo hướng dẫn của nhà sản xuất. Đừng quên kiểm tra cảm biến hệ thống giám sát áp suất lốp (TPMS) để đảm bảo vị trí và chức năng hoạt động chính xác.

Sau khi chạy xe được 80–160 km đầu tiên, hãy kiểm tra lại lực xiết của đai ốc bánh xe khi bánh xe đã nguội đến nhiệt độ môi trường. Sự nén kim loại và chu kỳ thay đổi nhiệt độ có thể gây ra hiện tượng lún ban đầu, vì vậy bước này rất quan trọng đối với các lắp đặt mới hoặc sau khi thay thế các linh kiện mới.

- Nên làm: Xiết lại đai ốc sau những dặm đầu tiên và kiểm tra xem có rung hoặc cọ sát không

- Nên làm: Kiểm tra áp suất lốp và chức năng TPMS

- Nên làm: Chú ý các âm thanh bất thường hoặc hiện tượng kéo lái khi lái xe lần đầu

- Không nên: Bỏ qua các dấu hiệu rung hoặc lỏng các bộ phận cơ khí

- Không nên: Giả định lực xiết tiêu chuẩn cho tất cả—luôn tham khảo thông số kỹ thuật của xe bạn

| Lỗi lắp đặt phổ biến | Triệu chứng có thể gặp |

|---|---|

| Lực xiết không đúng (quá chặt/quá lỏng) | Bánh xe rung, đĩa phanh cong vênh, bánh xe lỏng |

| Ren bẩn hoặc đã bôi trơn | Lực xiết không chính xác, nguy cơ mất bánh xe |

| Bỏ qua kiểu xiết hình sao | Bánh xe không được định tâm, kẹp không đều, rung lắc |

| Quên xiết lại sau giai đoạn chạy rà | Bu lông bánh xe lỏng theo thời gian, nguy cơ mất an toàn |

| Bỏ qua căn chỉnh cảm biến TPMS | Đèn cảnh báo, mất dữ liệu áp suất lốp |

Hãy luôn tuân thủ các thông số mô-men xoắn và khoảng thời gian xiết lại bulông do nhà sản xuất xe quy định. Việc bỏ qua các bước này có thể gây ra nguy cơ rung giật, hư hỏng linh kiện và giảm an toàn — bất kể lựa chọn la-zăng của bạn tiên tiến đến mức nào.

Sau khi lắp đặt và kiểm tra la-zăng mới xong, bạn đã sẵn sàng tận hưởng hiệu suất và phong cách vượt trội. Nhưng đừng dừng lại ở đó — bảo dưỡng định kỳ là bước tiếp theo để bảo vệ khoản đầu tư của bạn và đảm bảo mọi chuyến đi đều mượt mà. Hãy cùng tìm hiểu các phương pháp tốt nhất để vệ sinh, kiểm tra và nhận biết khi nào cần sửa chữa hoặc thay thế.

Bảo dưỡng, sửa chữa và các phương pháp tối ưu trong vòng đời của la-zăng hợp kim nhôm

Lịch trình và sản phẩm vệ sinh an toàn cho lớp hoàn thiện

Khi bạn đầu tư vào la-zăng hợp kim nhôm — đặc biệt là các tùy chọn cao cấp như vành nhôm đánh bóng hoặc vành nhôm sọc mờ — việc chăm sóc định kỳ là rất quan trọng để giữ độ sáng bóng và độ bền cấu trúc. Nghe có vẻ nhiều việc? Không hẳn, nếu bạn tuân thủ quy trình vệ sinh đơn giản, phù hợp với từng loại lớp hoàn thiện:

- Kiểm tra trước khi vệ sinh: Sử dụng ánh sáng tốt để phát hiện hiện tượng oxy hóa, rỗ bề mặt hoặc bụi phanh. Dùng tay di chuyển trên vành xe để kiểm tra các điểm gồ ghề hoặc mảnh vụn bám vào.

- Tráng sạch mảnh vụn bám lỏng lẻo: Sử dụng nước sạch, đã qua lọc và bàn chải mềm để nhẹ nhàng loại bỏ bụi và cát. Không bao giờ chà mạnh vành xe khi còn khô – điều này có thể làm xước lớp phủ.

- Sử dụng chất tẩy rửa an toàn cho nhôm: Chọn các sản phẩm được pha chế dành riêng cho bề mặt nhôm. Tránh sử dụng các chất tẩy có tính axit hoặc kiềm, vì chúng có thể làm hỏng lớp phủ trong suốt và kim loại lộ thiên.

- Khuấy nhẹ: Dùng bàn chải lông mềm hoặc khăn microfiber, tập trung vào những vết bẩn cứng đầu. Đối với vành nhôm mạ bóng dành cho xe tải , cần cẩn thận hơn – làm việc từng khu vực nhỏ và tránh chà xát mạnh.

- Tráng kỹ và làm khô: Xả kỹ để loại bỏ hoàn toàn cặn chất tẩy rửa, sau đó lau khô bằng khăn sợi nhỏ cao cấp để tránh để lại vết nước.

- Đánh bóng (nếu cần): Đối với vành xe không có lớp phủ bảo vệ, hãy sử dụng sản phẩm đánh bóng vành nhôm chuyên dụng . Đối với vành có lớp phủ, hãy sử dụng các chất bảo vệ không mài mòn.

Không bao giờ rửa vành xe khi còn nóng, và tránh các trạm rửa xe tự động có ray định vị, vì có thể làm trầy xước hoặc bong tróc lớp hoàn thiện của vành.

Chống ăn mòn cho mùa đông hoặc sử dụng ở khu vực ven biển

Vành xe hợp kim nhôm, đặc biệt là vành nhôm mạ bóng dành cho xe tải , dễ bị ăn mòn do muối đường, độ ẩm và không khí ven biển. Dưới đây là cách bạn có thể bảo vệ khoản đầu tư của mình quanh năm:

- Rửa vành xe thường xuyên vào mùa đông hoặc sau khi tiếp xúc với muối và nước muối.

- Áp dụng chất bịt kín hoặc sáp không mài mòn được chế tạo dành cho nhôm để tạo ra lớp bảo vệ chống lại các chất gây ô nhiễm.

- Kiểm tra các vết sứt mẻ hoặc trầy xước trên lớp hoàn thiện – xử lý ngay các vết này để ngăn ngừa hiện tượng oxy hóa.

- Bảo quản la-zăng ở nơi mát mẻ và khô ráo nếu bạn thay bằng lốp mùa đông. Làm sạch và lau khô kỹ trước khi bảo quản.

Hãy nhớ rằng, vành mạ crôm và mâm xe đen các loại la-zăng có lớp hoàn thiện sơn hoặc phủ bột cũng được hưởng lợi từ những bước bảo vệ này, mặc dù chúng có thể yêu cầu các loại chất làm sạch và đánh bóng khác nhau.

Các Bước Sửa Chữa Curb Rash Cơ Bản và Giới Hạn An Toàn

Ngay cả những tài xế cẩn thận cũng có thể gặp phải tình trạng curb rash – những vết trầy xước khó chịu dọc theo mép la-zăng. Bạn tự hỏi liệu có thể tự sửa chữa tại nhà được không? Dưới đây là quy trình phân loại đơn giản:

- Đánh giá mức độ hư hại: Nếu móng tay của bạn bị vướng vào vết trầy xước, thì đó có thể là vết trầy mức độ trung bình hoặc nghiêm trọng (The Rim Guy) .

- Tự sửa chữa tại nhà cho các vết trầy nhẹ: Chà nhám nhẹ khu vực bị hư hỏng, nếu cần thì trám vá, sau đó sơn lớp sơn phủ hoặc lớp bảo vệ trong suốt phù hợp. Phương pháp này phù hợp để xử lý các vết trầy xước nhỏ trên vành nhôm sọc mờ hoặc các bề mặt đã sơn.

- Sửa chữa chuyên nghiệp cho các vết trầy sâu: Nếu bạn thấy kim loại bị lộ ra, có vết nứt hoặc hư hỏng lan rộng, hãy tìm đến một cơ sở sửa chữa vành chuyên nghiệp. Họ có thể khôi phục lại lớp hoàn thiện và kiểm tra các vấn đề cấu trúc ẩn.

| Tự sửa chữa | Sửa chữa chuyên nghiệp | |

|---|---|---|

| Ưu điểm | Chi phí thấp hơn, chủ động về thời gian, cảm giác hài lòng cá nhân | Lớp hoàn thiện được đảm bảo, kiểm tra cấu trúc, khớp màu sơn |

| Nhược điểm | Nguy cơ lớp hoàn thiện không đều, có thể bỏ sót hư hỏng nghiêm trọng hơn | Chi phí cao hơn, thời gian xe ngừng sử dụng |

Đối với vành xe bị trầy xước nặng do va quệt, về lâu dài sẽ tiết kiệm hơn nếu bạn bắt đầu bằng việc sửa chữa chuyên nghiệp, đặc biệt nếu bạn muốn duy trì giá trị và vẻ ngoài của vành hợp kim nhôm đánh bóng hoặc các lớp hoàn thiện đặc biệt khác.

Phát Hiện Vết Nứt và Quyết Định Thay Thế

Vết nứt hoặc hư hỏng cấu trúc nghiêm trọng không bao giờ chỉ là vấn đề thẩm mỹ. Nếu bạn phát hiện thấy vết nứt, chỗ phồng rộp hoặc mất kim loại, biện pháp an toàn nhất là đưa đi kiểm tra chuyên nghiệp ngay lập tức. Các xưởng sửa chữa có thể sửa chữa những vết nứt nhỏ, nhưng hầu hết các tiêu chuẩn và nhà sản xuất đều khuyến nghị thay thế toàn bộ nếu độ bền cấu trúc bị ảnh hưởng (AWRS Wheel Repair) .

Đừng bao giờ bỏ qua vết nứt cấu trúc – việc kiểm tra chuyên nghiệp hoặc thay thế là lựa chọn an toàn duy nhất. Bánh xe của bạn là một bộ phận an toàn quan trọng, không chỉ là một phụ kiện nâng cấp phong cách.

Với những phương pháp chăm sóc và sửa chữa này, các bánh xe hợp kim nhôm của bạn – dù là vành nhôm mạ bóng dành cho xe tải , cổ điển vành mạ crôm , hay hiện đại mâm xe đen —sẽ luôn trông và hoạt động tốt nhất trong nhiều năm. Tiếp theo, chúng ta sẽ cùng tìm hiểu cách xử lý các vấn đề phổ biến liên quan đến cảm giác lái và lắp đặt, để bạn biết khi nào cần sự giúp đỡ và làm thế nào để mọi chuyến đi đều an toàn và mượt mà.

Xử lý sự cố về lắp đặt và cảm giác lái

Bạn đã từng để ý thấy vô lăng rung, xe bị lệch về một bên, hoặc một đèn báo mới trên bảng điều khiển bật sáng sau khi thay thế bộ vành bánh xe bằng nhôm ? Những vấn đề này có thể gây khó chịu, nhưng hầu hết đều có nguyên nhân rõ ràng — và giải pháp cũng đơn giản. Việc hiểu rõ vành xe là gì và cách chúng tương tác với các hệ thống của xe là yếu tố quan trọng để có một chuyến đi an toàn và mượt mà. Hãy cùng đi qua quy trình xử lý sự cố từng bước để bạn có thể nhanh chóng xác định và giải quyết các vấn đề phổ biến về lắp đặt và cảm giác lái.

Rung giật sau khi lắp đặt: Quy trình chẩn đoán

Cảm giác rung giật, đặc biệt là ở tốc độ cao, là một trong những phàn nàn phổ biến nhất sau khi lắp đặt bộ vành bánh xe mới . Dưới đây là danh sách kiểm tra logic để xác định nguyên nhân:

- Kiểm tra cân bằng bánh xe: Bánh xe mất cân bằng là nguyên nhân hàng đầu gây ra rung lắc, thường cảm nhận rõ khi vận tốc trên 50 dặm/giờ. Nếu bạn cảm thấy vô lăng hoặc toàn bộ xe bị rung giật, hãy mang xe đến thợ chuyên nghiệp để cân lại bánh xe.

- Kiểm tra ổ trục và phụ kiện lắp ráp: Đảm bảo các bánh xe được lắp khít hoàn toàn vào trục và tất cả các bu-lông bánh xe được xiết đúng thứ tự. Việc lắp không đúng vị trí hoặc xiết bu-lông không đều có thể gây rung lắc và nguy hiểm khi lái xe.

- Tìm kiếm vành bị cong hoặc hư hỏng: Va chạm với ổ gà hoặc mép đường có thể làm cong vành bánh xe , dẫn đến hiện tượng bánh xe lắc lư và mòn lốp không đều. Hãy kiểm tra bằng mắt thường từng vành để phát hiện cong vênh hoặc nứt.

- Kiểm tra tình trạng lốp xe: Các vết bẹp, mòn không đều hoặc lỗi sản xuất của lốp xe đều có thể gây rung lắc. Hãy đảo vị trí hoặc thay thế các lốp nghi ngờ bị lỗi khi cần thiết.

- Kiểm tra độ chụm bánh xe: Nếu cảm giác rung đi kèm với hiện tượng lệch hướng hoặc mòn lốp không đều, hãy kiểm tra độ chụm bánh xe. Tình trạng lệch độ chụm thường xảy ra do va chạm hoặc lắp đặt không đúng cách.

Lệch hướng, tiếng kêu roto phanh, hoặc cảnh báo hệ thống giám sát áp suất lốp (TPMS)

Các vấn đề khác có thể phát sinh sau khi thay bánh xe - ví dụ như xe bị lệch về một phía, tiếng ồn từ phanh hoặc cảnh báo TPMS liên tục. Dưới đây là cách xử lý:

- Xe bị lệch hướng hoặc đánh lái không đều: Thường liên quan đến vấn đề độ chụm hoặc sự không tương thích của độ lệch tâm lốp . Hãy kiểm tra kỹ xem bánh xe mới có khớp với thông số kỹ thuật của nhà sản xuất và áp suất lốp ở tất cả các bánh có được cân bằng hay không.

- Tiếng kêu roto phanh hoặc ma sát: Mới vành bánh xe bằng nhôm độ lệch tâm không đúng hoặc khoảng cách tới càng phanh quá hẹp có thể gây ra tiếng cọ sát hoặc rít. Kiểm tra xem có sự tiếp xúc vật lý giữa vành và các bộ phận phanh hay không.

- Cảnh báo hệ thống giám sát áp suất lốp (TPMS): Những vấn đề này có thể xảy ra do lắp đặt cảm biến không đúng cách, không hiệu chỉnh lại cảm biến, hoặc thậm chí là do cảm biến bị hư hỏng trong quá trình thay lốp. Luôn hiệu chỉnh lại hoặc cài đặt lại hệ thống giám sát áp suất lốp (TPMS) sau khi thay đổi la-zăng và kiểm tra xem cảm biến có bị hư hỏng hay không nếu cảnh báo vẫn tiếp diễn (Wheelbase Garage) .

Khi Nào Cần Yêu Cầu Kỹ Thuật Viên Chuyên Nghiệp Kiểm Tra

Một số triệu chứng nên được xử lý bởi các kỹ thuật viên được chứng nhận, đặc biệt nếu bạn nhận thấy:

- Rung mạnh kéo dài ở tốc độ cao (có thể cho thấy vấn đề nghiêm trọng về vành hoặc hệ thống treo)

- Âm thanh bất thường (kêu lách cách, rít, hoặc lạch bạch) sau khi lắp đặt

- Cảnh báo TPMS không thể đặt lại sau khi cài đặt lại cảm biến

- Các vết nứt nhìn thấy được, cong vênh hoặc ăn mòn trên vành bánh xe mới

- Xe mất ổn định, bị lệch hướng, hoặc thay đổi đột ngột trong khả năng vận hành

Kỹ thuật viên được chứng nhận có thể thực hiện chẩn đoán nâng cao, kiểm tra các vấn đề ẩn của hệ thống treo hoặc trục xe, và đảm bảo rằng chiếc vành xe ô tô an toàn và đủ điều kiện lưu thông.

| Triệu chứng | Nguyên nhân phổ biến | Bước tiếp theo |

|---|---|---|

| Rung lắc ở tốc độ cao | Bánh xe mất cân bằng, vành cong, lốp mòn | Cân bằng bánh xe, kiểm tra cong vênh, đảo/thay lốp |

| Lái xe bị giật | Lệch độ chụm, áp suất lốp không đều, độ lệch tâm không khớp | Kiểm tra độ chụm, điều chỉnh áp suất lốp, xác minh độ lệch tâm |

| Tiếng ồn/ma sát phanh | Khe hở càng phanh không đủ, lắp đặt không đúng cách | Kiểm tra xem có cản trở không, lắp đặt lại đúng cách |

| Cảnh báo hệ thống giám sát áp suất lốp (TPMS) | Cảm biến chưa được học lại, cảm biến bị hư hỏng, áp suất không đúng | Học lại/đặt lại hệ thống TPMS, kiểm tra/thay thế cảm biến, điều chỉnh áp suất |

| Mòn lốp bất thường | Lệch độ chụm, vành bị cong, hệ thống treo bị mài mòn | Kiểm tra chuyên nghiệp, đảo lốp/thay thế lốp |

Không bao giờ được bỏ qua hiện tượng rung giật ở tốc độ cao—đây có thể là dấu hiệu của các vấn đề nghiêm trọng liên quan đến bánh xe, lốp hoặc hệ thống treo. Hãy xử lý các sự cố này kịp thời để bảo vệ bản thân và những người khác trên đường.

Bằng cách làm theo quy trình này, bạn sẽ có thể nhanh chóng giải quyết hầu hết các vấn đề với lốp hợp kim nhôm và tận hưởng chuyến đi mượt mà, an toàn hơn. Tiếp theo, chúng tôi sẽ kết thúc bằng một hướng dẫn đưa ra quyết định mua sắm thông minh và kết nối với các nguồn uy tín để đáp ứng mọi nhu cầu về hệ thống bánh xe của bạn.

Quyết định mua sắm thông minh và các nguồn đáng tin cậy

Lựa chọn theo trường hợp sử dụng: Hàng ngày, Hiệu suất, Kéo xe hoặc Mùa đông

Khi nói đến việc lựa chọn la-zăng hợp kim nhôm, lựa chọn tốt nhất luôn bắt đầu từ cách bạn lái xe. Nghe có vẻ phức tạp? Không nhất thiết phải như vậy. Hãy cùng phân tích theo từng trường hợp sử dụng để bạn có thể tự tin thu hẹp các tùy chọn của mình — cho dù bạn đang tìm mua la-zăng xe tải, mâm xe 20 inch phong cách hay các loại mâm Method chuyên dụng cho các chuyến phiêu lưu ngoài đường trường.

- Dùng hàng ngày: Ưu tiên độ bền, bảo trì thấp và lớp hoàn thiện phù hợp với môi trường của bạn. Các mâm xe tiêu chuẩn 18 inch thường mang lại sự cân bằng giữa sự thoải mái và phong cách cho việc sử dụng hàng ngày.

- Hiệu suất: Thiết kế nhẹ như mâm xe đua Weld hoặc mâm xe Raceline cải thiện khả năng điều khiển và tăng tốc. Hãy tìm các loại mâm nhôm đúc theo dòng (flow formed) hoặc rèn (forged) để đạt được lợi ích tối đa.

- Kéo xe/Đường trường: Vành xe hostile và phương pháp được thiết kế để có khả năng chịu tải cao hơn và phù hợp với địa hình gồ ghề. Tập trung vào độ bền, nan hoa được gia cố và lớp hoàn thiện chống trầy xước và chống ăn mòn.

- Mùa đông: Hãy cân nhắc một bộ vành mustang chuyên dụng hoặc hợp kim cơ bản với lớp hoàn thiện đơn giản, dễ làm sạch. Tránh các thiết kế bóng hoặc phức tạp vì khó bảo quản trong điều kiện khắc nghiệt.

Đọc bảng thông số kỹ thuật của vành xe và xác minh trước khi mua

Hãy tưởng tượng bạn tìm được bộ vành 20 inch hoàn hảo—chỉ để nhận ra chúng không phù hợp với xe của bạn. Để tránh bất ngờ, hãy luôn kiểm tra kỹ bảng thông số. Dưới đây là danh sách kiểm tra nhanh giúp bạn không bị bỏ sót:

- Xác nhận mẫu bulông (PCD) khớp với xe của bạn—ví dụ: 5x114.3 hoặc 6x139.7 cho nhiều dòng xe bán tải.

- Kiểm tra kích thước lỗ trung tâm—đảm bảo nó vừa với trục xe hoặc dự trù vòng định tâm trục.

- Xác minh độ lệch tâm (offset) và khoảng cách từ mặt lắp bánh đến mép trong cùng của vành (backspacing)—các thông số này ảnh hưởng đến khoảng hở dành cho phanh, hệ thống treo và chắn bùn.

- Xem xét khả năng chịu tải—đảm bảo vượt quá trọng lượng trục xe của bạn, đặc biệt khi kéo rơ-moóc hoặc chạy off-road.

- Kiểm tra yêu cầu hoàn thiện và chăm sóc - chọn những gì phù hợp với khí hậu và thói quen bảo dưỡng của bạn.

Tham khảo sách hướng dẫn sử dụng, dữ liệu của nhà sản xuất (OEM), hoặc chuyên gia phụ kiện uy tín trước khi hoàn tất mua hàng. Nhiều thương hiệu đáng tin cậy, bao gồm raceline wheels và method wheels, cung cấp bảng thông số chi tiết trực tuyến hoặc thông qua các đại lý được ủy quyền.

Đối Tác Uy Tín Cho Các Bộ Phận Hệ Thống Bánh Xe

Việc lựa chọn bánh xe đúng đắn chỉ là một phần trong phương trình. Để đạt được độ tin cậy thực sự, hãy lưu ý đến chất lượng của tất cả các bộ phận trong hệ thống bánh xe - như giá đỡ phanh, khớp xoay, và đặc biệt là các thanh định hình hỗ trợ cụm bánh xe của bạn. Chất lượng cao phụ kiện nhôm ép nuôi rất cần thiết để duy trì độ bền cấu trúc và an toàn cho bánh xe của bạn, đặc biệt khi thiết kế ngày càng nhẹ hơn và tiên tiến hơn. Shaoyi Metal Parts Supplier, nhà cung cấp hàng đầu Trung Quốc chuyên về các bộ phận kim loại ô tô chính xác, chuyên sản xuất các chi tiết định hình kỹ thuật hỗ trợ trực tiếp hiệu suất và độ tin cậy của bánh xe hợp kim nhôm. Chuyên môn của họ trong việc sản xuất các bộ phận định hình nhôm được chứng nhận IATF 16949 theo yêu cầu khách hàng đảm bảo rằng mỗi thành phần hệ thống bánh xe đều đáp ứng các tiêu chuẩn cao nhất cho các ứng dụng quan trọng về an toàn.

- Kiểm tra xem có chứng nhận IATF 16949 hoặc tương đương cho các bộ phận liên quan đến an toàn

- Hỏi về khả năng chế tạo mẫu nhanh và phân tích thiết kế cho các sản phẩm tùy chỉnh

- Ưu tiên các nhà cung cấp có kinh nghiệm đã được chứng minh trong lĩnh vực định hình nhôm ô tô

Việc mua mâm xe thông minh có nghĩa là xác định nhu cầu của bạn và lựa chọn thông số kỹ thuật phù hợp, kiểm tra độ tương thích, đồng thời lựa chọn các đối tác đáng tin cậy cho từng thành phần. Một bộ mâm hợp kim nhôm được lựa chọn cẩn thận – đi kèm với các bộ phận hệ thống chất lượng – sẽ mang lại những cải thiện rõ rệt về hiệu suất, an toàn và phong cách mà không phải đánh đổi điều gì.

Dù bạn bị thu hút bởi mâm hàn đua cho đường đua, mâm raceline cho những chuyến phiêu lưu địa hình hay mâm hostile cho vẻ ngoài mạnh mẽ, quy trình lựa chọn đều giống nhau: xác định rõ nhu cầu sử dụng, kiểm tra thông số kỹ thuật và hợp tác với các nhà cung cấp đã được chứng minh. Bằng cách làm theo những bước này, bạn sẽ luôn tự tin và hài lòng mỗi khi cầm lái.

Các Câu hỏi Thường gặp Về Mâm Xe Hợp Kim Nhôm

1. Mâm xe hợp kim nhôm là gì và điểm khác biệt của chúng so với mâm thép là gì?

Vành hợp kim nhôm được làm từ hỗn hợp nhôm và các kim loại khác, mang lại trọng lượng nhẹ hơn và khả năng tản nhiệt tốt hơn so với vành thép truyền thống. Điều này dẫn đến khả năng điều khiển tốt hơn, tiết kiệm nhiên liệu và nhiều lựa chọn thiết kế hơn. Ngược lại, vành thép nặng hơn và bền hơn trong điều kiện khắc nghiệt nhưng lại có ít lựa chọn thiết kế hơn.

2. Các phương pháp sản xuất như đúc, tạo hình dòng chảy và rèn ảnh hưởng như thế nào đến hiệu suất của vành xe?

Đúc, tạo hình dòng chảy và rèn đều ảnh hưởng đến trọng lượng, độ bền và chi phí của vành xe. Vành đúc có giá thành thấp và phù hợp cho sử dụng hàng ngày, vành tạo hình dòng chảy mang lại sự cân bằng giữa độ bền và trọng lượng nhẹ, còn vành rèn cung cấp độ bền cao nhất và trọng lượng nhẹ nhất, lý tưởng cho các ứng dụng hiệu suất cao hoặc tải nặng.

3. Tôi nên kiểm tra những gì để đảm bảo vành mới lắp vừa xe của mình một cách an toàn?

Kiểm tra mẫu bulông (PCD), đường kính lỗ trung tâm, độ lệch vành xe (offset), và khả năng chịu tải. Các thông số này phải phù hợp với yêu cầu của xe bạn được nêu trong sổ tay hướng dẫn sử dụng hoặc tài liệu của nhà sản xuất gốc (OEM). Đảm bảo lắp đặt chính xác để tránh hiện tượng cọ sát, rung lắc và các vấn đề an toàn.

4. Làm thế nào để bảo dưỡng và bảo vệ vành hợp kim nhôm, đặc biệt là trong mùa đông hoặc môi trường ven biển?

Làm sạch vành xe thường xuyên bằng các sản phẩm an toàn cho nhôm, phủ lớp chất bảo vệ, và rửa xe thường xuyên sau khi tiếp xúc với muối hoặc nước mặn. Kiểm tra các vết trầy xước hoặc vết nứt và xử lý kịp thời để ngăn ngừa ăn mòn. Bảo quản vành xe ở nơi khô ráo trong những mùa không sử dụng để kéo dài tuổi thọ.

5. Tại sao chất lượng các bộ phận nhôm ép đùn lại quan trọng đối với hệ thống vành xe?

Các bộ phận đúc ép nhôm chất lượng cao, như những bộ phận từ Nhà cung cấp Linh kiện Kim loại Shaoyi, đảm bảo độ bền cấu trúc của các cụm bánh xe. Các linh kiện này hỗ trợ độ tin cậy của hệ thống bánh xe, đặc biệt khi các bánh xe trở nên nhẹ hơn và tiên tiến hơn, đồng thời giúp duy trì an toàn trong các ứng dụng ô tô quan trọng.

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —

Sản xuất với số lượng nhỏ, tiêu chuẩn cao. Dịch vụ tạo nguyên mẫu nhanh của chúng tôi giúp việc kiểm chứng trở nên nhanh chóng và dễ dàng hơn —