Aqlli tushirilgan qism dizayni bilan CNC ishlash xarajatlarini kamaytiring

Qisqacha

Ishlov berish xarajatlarini kamaytirish uchun qismlarni optimallashtirish Ishlanuvchanlik uchun dizayn (DFM) tamoyillarini qo'llashga bog'liq. Bu qism geometriyasini soddalashtirishni, ichki burchaklarga keng radiuslar qo'shishni, teshiklar va taykalar uchun standart o'lchamlardan foydalanishni hamda imkon qadar noaniq to'g'riliklarni belgilashni o'z ichiga oladi. Ishlov berish xarajatlarini, murakkablik darajasini va umumiy xarajatlarni minimal darajada saqlash uchun arzon, yuqori darajadagi ishlanuvchanlikka ega materiallarni tanlash ham muhim strategiyadir.

Ishlanuvchanlik uchun dizayn (DFM) ning asosiy tamoyillari

Maxfiy dizayn o'zgarishlariga e'tibor qaratishdan oldin, xarajatlarni kamaytirishning asosiy strategiyasini tushunish muhim: Ishlanuvchanlik uchun dizayn (DFM). DFM - bu komponentlarni imkon qadar samarali va oddiy usulda ishlab chiqarish imkonini beradigan qilib maqsadli ravishada loyihalash jarayonidir. Maqsad faqatgina CNC mashinasida biron bir detalni ishlash vaqtini emas, balki dastlabki sozlashdan tortib oxirgi to'plamgacha bo'lgan butun ishlab chiqarish jarayonining murakkabligini ham minimallashtirishdir. Dizayn bosqichida qilinadigan har bir qaror bevosita va ko'pincha sezilarli darajada yakuniy narxga ta'sir qiladi.

DFM ning asosiy tamoyillari ikkita asosiy maqsad atrofida jamlanadi: ishlash vaqtini qisqartirish va operatsiyalar sonini kamaytirish. Ishlash vaqti ko'pincha asosiy xarajat omilidir, shu sababli tezroq kesish tezligi va kamroq o'tishlar bilan amalga oshiriladigan dizaynlarning narxi doim arzon bo'ladi. Buni yuqori ishlanuvchanlikka ega materiallarni tanlash yoki kattaroq, mustahkamroq asboblar bilan yaratilishi mumkin bo'lgan elementlarni loyihalash orqali amalga oshirish mumkin. Qo'llanmada batafsil bayon etilganidek, Protolabs Network , burchak radiusini oshirish kabi hatto kichik sozlamalar ham mashinaning tezroq va samaraliroq ishlashiga imkon beradi.

Shu bilan birga, mashina sozlanishlar sonini minimal darajada saqlash ham muhim. Sozlanish — qismning turli tomonlariga kirish uchun qayta qo'lda joylashtirilishi yoki qayta mahkamlanishi kerak bo'lganda har bir holat tushuniladi. Har bir sozlanish mehnat xarajatlarini qo'shadi va xatoga yo'l qo'yish ehtimolini keltirib chiqaradi. Olti tomonida ham elementlari bo'lgan murakkab qism oltita alohida sozlanishni talab qilishi mumkin, bu esa barcha elementlarni bitta tomondan ishlash mumkin bo'lgan soddaroq qismlar bilan taqqoslaganda uning narxini keskin oshiradi. Shunday qilib, DFM (ishlab chiqarish uchun dizayn) strategiyasining asosiy jihatlari — qismlarni imkon qadar kamroq sozlanishda, eng ma'qul holi — faqat bittada tugallash imkonini beradigan qilib loyihalashdir.

Narxlarni pasaytirish uchun asosiy geometrik optimallashtirishlar

Bir qismning geometriyasi uning ishlov berish xarajatlariga ta'sir ko'rsatadigan eng muhim omillardan biridir. Murakkab shakl, chuqur cho'ntaklar va nozik xususiyatlar ko'proq vaqt, maxsus vositalar va ehtiyotkorlik bilan ishlashni talab qiladi, bu esa narxni oshiradi. qism geometriyasiga strategik optimallashtirishlar kiritish orqali muhandislar funktsionalligini buzmasdan katta xarajatlarni tejashga erishishlari mumkin.

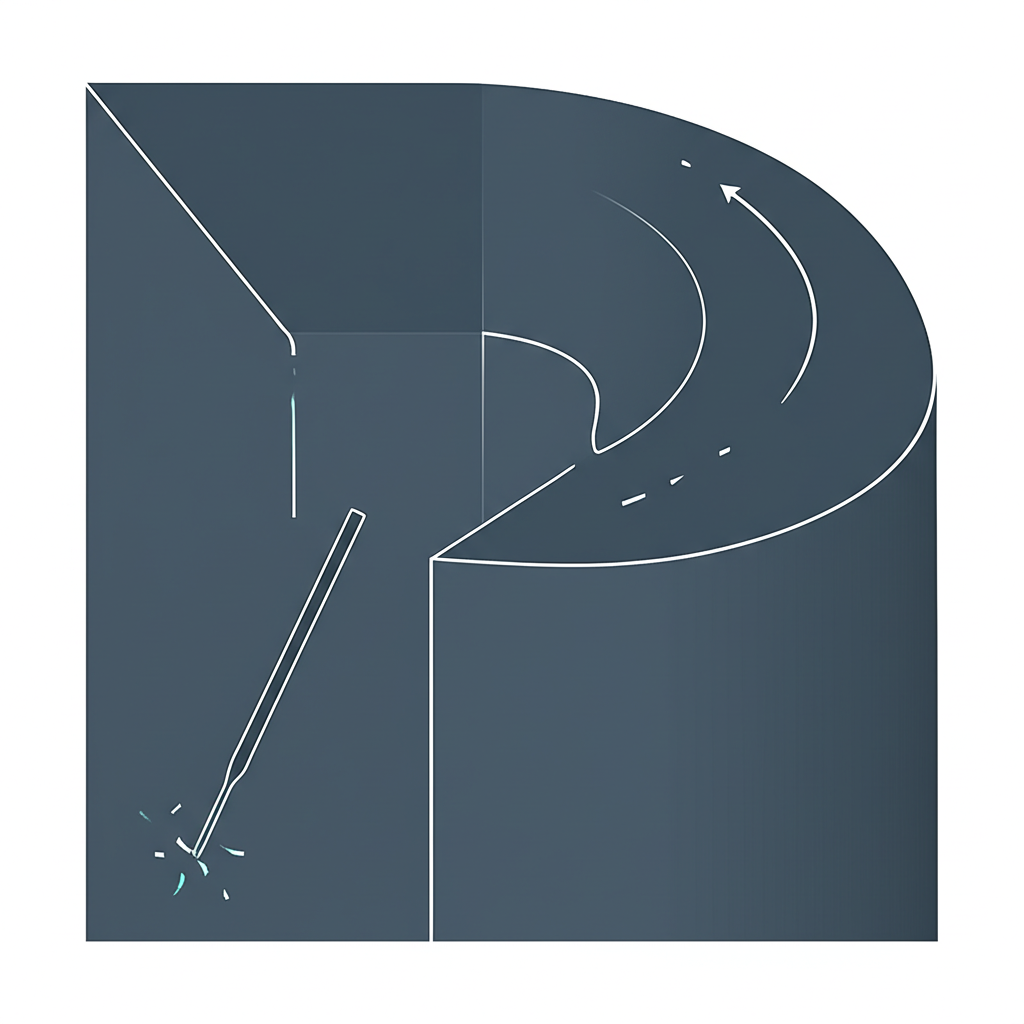

- Ichki burchaklarga "Saxiy radi" qoʻshing. Barcha CNC frezalash asboblari dumaloq, ya'ni ular tabiiy ravishda har qanday ichki burchakda radius qoldiradi. O'tkir yoki juda kichik radiusni yaratishga urinish kichik diametrli vositani talab qiladi, u sekin harakatlanishi va bir nechta o'tishlarni bajarishi kerak, bu esa mashina vaqtini oshiradi. Oddiy qoida shuki, ichki burchak radiuslari chuqurlikning kamida uchdan bir qismiga teng bo'lishi kerak. sifatida Protocase tushuntiradi , imkon qadar katta radiuslardan foydalanish yuzalarni yaxshilaydi va katta va barqaror kesish asboblarini ishlatishga imkon berish orqali xarajatlarni kamaytiradi.

- O'rinlar va cho'ntagining chuqurligini cheklang. Chuqur cho'ntaklarni ishlov berish juda qimmat. Standart kesish asboblari cheklangan kesish uzunligiga ega bo'lib, odatda o'z diametrining taxminan 2-3 baravari chuqurligigacha samarali. Chuqurroq kesish mumkin bo'lsa-da, ular kamroq qattiq bo'lgan maxsus, uzunroq vositalarni talab qiladi va tebranish va buzilishlardan qochish uchun sekinroq tezlikda harakatlanishi kerak. Fiktiv yaxshi yakunlash va arzonroq xarajatlarni ta'minlash uchun oxirgi xayollarda kesish chuqurligini asbobning diametrining besh baravarigacha saqlashni tavsiya qiladi.

- Nozik devorlardan qoching. Metall uchun 0,8 mm dan yoki plastik uchun 1,5 mm dan past devorlar ishlov berish paytida tebranish, buzilish va buzilishlarga moyil. Ushbu xususiyatlarni aniq yaratish uchun mashinist past kesish chuqurligida bir nechta sekin o'tishlardan foydalanish kerak. Agar qismning funktsiyasi uchun mutlaqo zarur bo'lmasa, qalinroq, qattiqroq devorlarni loyihalashtirish qismni yanada barqaror va ishlab chiqarishni sezilarli darajada arzonlashtiradi.

- Xususiyatlarni soddalashtirish va mustahkamlash. Dizaynning murakkabligi narxga bevosita ta'sir qiladi. Simmetrik qismlarni ishlov berish osonroq bo'ladi va noyob xususiyatlarning umumiy sonini kamaytirish vositani o'zgartirishni minimallashtiradi. Agar qismning bir nechta yuzidagi kesish yoki teshiklar kabi murakkab xususiyatlari bo'lsa, dizayni bir nechta sodda qismlarga bo'linishi mumkinligini va ularni osonlikcha ishlov berish va yig'ish mumkinligini ko'rib chiqing. Bu usul ko'pincha 5 o'qli mashina va maxsus jihozlarni talab qiladigan juda murakkab qismni ishlov berishdan ko'ra arzonroq.

Toʻgʻrilik, toʻqimalar va teshiklar uchun aqlli strategiyalar

Katta geometrik xususiyatlar xarajatlarni aniq boshqarsa-da, chidamliliklar, iplar va teshiklar kabi kichik tafsilotlar yakuniy narxga kutilmagan darajada katta ta'sir ko'rsatishi mumkin. Bu xususiyatlar ko'pincha aniqlik, maxsus vositalar yoki qo'shimcha mashinalarni ishlatishni talab qiladi. Ushbu elementlarga aqlli dizayn strategiyalarini qo'llash xarajatlarni samarali ishlab chiqarish uchun qismni optimallashtirishda muhim qadamdir.

Toleranslar ma'lum bir o'lcham uchun qabul qilinadigan og'ish miqdorini belgilaydi. Ba'zan muhim interfeyslar uchun tor toleranslar zarur bo'lsa-da, ularni kamdan-kam hollarda ko'rsatish kerak. Tolerans qancha tor bo'lsa, shuncha ko'proq vaqt, e'tibor va tekshiruv talab qilinadi, bu esa xarajatlarni darajasiga oshiradi. MakerVerse tomonidan tushuntirilganidek, juda tor toleranslar asbob-qirollarning tezroq eskirishiga, tsikl vaqtining uzayishiga va chiqindi miqdorining oshishiga olib kelishi mumkin. Muhim bo'lmagan xususiyatlar uchun standart mashina toleransidan (odatda ±0.125 mm) foydalanish yetarli hamda ancha iqtisodiydir.

Shunday qilib, teshiklar va tishli ulamalarni standartlashtirishni hisobga olib loyihalash kerak. Noaniq diametrni belgilashdan ko'ra, teshiklar uchun standart burgu o'lchamlaridan foydalanish ancha arzon bo'ladi, chunki bunda oxirgi freza sekin-sa-kin teshik yaratishi kerak bo'ladi. Tishli ulamalar to'g'risida aytganda, ularning uzunligi cheklangan bo'lishi kerak. Teshik diametridan 1,5 marta kattaroq bo'lgan tishli ulama qo'shimcha mustahkamlik bermaydi, lekin ancha katta qo'shimcha xarajatlarga olib keladi. Yuqori teshiklar uchun ham pastki qismda tishlarsiz bo'limni loyihalash muhim, bu metchkaga ega bo'lish imkonini beradi va uning sindirilish xavfini kamaytiradi.

Arzon materiallar va yakuniy qoplamalarni tanlash

Materialni tanlash va talab qilinadigan sirt qoplamasini tanlash — ishlash xarajatlarini boshqarishda oxirgi, lekin juda muhim jihatlar hisoblanadi. Bu qarorlar xom ashyoning narxiga ham, detalni ishlash uchun ketadigan vaqtga ham ta'sir qiladi. Sotib olishi arzon, lekin ishlash qiyin bo'lgan material, narxi qimmatroq, lekin ishlash osonroq bo'lgan alternativdan umuman olganda qimmatroq bo'lishi mumkin.

Materialning qayta ishlash qobiliyati uning qanday darajada oson kesilishini tavsiflaydi. Alyuminiy 6061 kabi yumshoq materiallar hamda POM (Delrin) kabi plastiklar ajoyib qayta ishlash qobiliyatiga ega bo'lib, yuqori tezlikdagi kesish va qisqaroq tsikl vaqtiga imkon beradi. Bunga qarama-qarshi ravishda, shlishlangan po'lat yoki titanning kabi qattiqroq materiallarni kesish qiyinroq bo'ladi, sekinroq tezlik talab qiladi va asbobning ko'proq eskirishiga olib keladi, bu esa qayta ishlash vaqtini ikki yoki uch marta oshiradi. Shu sababli, agar yuqori mustahkamlikdagi quymaning maxsus xususiyatlari talab etilmasa, qayta ishlash qobiliyati yaxshiroq bo'lgan materialni tanlash xarajatlarni kamaytirish uchun juda samarali strategiyadir.

Yana bir optimallashtirish sohasi material bo'shlig'ining o'zini ishlab chiqarish jarayonini hisobga olishdir. Forjlash kabi jarayon orqali yaratilgan taxminan to'liq shakldagi bo'shlik, mashina qismlarini ishlash uchun olib tashlanadigan material miqdorini sezilarli darajada kamaytirish, vaqt tejash va chiqindilarni kamaytirish imkonini beradi. Masalan, avtomotot sohasidagi mutaxassislarning ushbu sohadagi imkoniyatlarini o'rganish foydali bo'lishi mumkin. Avtomashinalarning mustahkam va ishonchli komponentlari uchun siz sanoat uchun yuqori sifatli issiq forjlashga ixtisoslashgan shaoyi Metal Technology tomonidan taklif etiladigan moslashtirilgan pichoqlash xizmatlari ni o'rganishingiz mumkin.

Nihoyat, sirtini tozalash talablari e'tibor bilan ko'rib chiqilishi kerak. Standart "sotib olingan holda" tozalash eng arzon variantdir. Siljiyotirilgan sirtlarni olish uchun qo'shimcha soxta o'tishlar yoki dumaloq donalar bilan tozalash yoki polirovka kabi qo'shimcha operatsiyalar talab etiladi, bu esa har biri xarajatlarni oshiradi. Bir xil detalning turli sirtlariga turli xil tozalash usullarini belgilash yanada qimmatga tushadi, chunki bu maskalashni va bir nechta jarayonlarni talab qiladi. Faqat funksional jihatdan kerak bo'lgan joylarga ma'lum bir tozalash usulini qo'llash - xarajatlarni pasaytirishning oddiy, lekin samarali usulidir.

Koʻpincha soʻraladigan savollar

1. CNC ishlash xarajatlarini qanday kamaytirish mumkin?

CNC ishlash xarajatlarini kamaytirish dizaynni optimallashtirish, material tanlovi va jarayonni soddalashtirishni o'z ichiga olgan kombinatsiyani talab qiladi. Asosiy strategiyalarga quyidagilar kiradi:

- Geometriyani soddalashtiring: Murakkab egri chiziqlardan, chuqur cho'ntaklardan va ingichka devorlardan saqlaning.

- Burchak radiuslarini qo'shing: Ichki burchaklarda imkon qadar katta radiuslarni foydalaning, bu tezroq ishlash imkonini beradi.

- Standart elementlardan foydalaning: Maxsus moslamalarni talab qilmagan holda teshiklar va tishlar uchun standart o'lchamlarga amal qiling.

- Chidamli o'zgarishlarni kamaytiring: Faqat funksionalligi unga bog'liq bo'lgan asosiy xususiyatlarda qattiq chidamlilikni belgilang.

- Qayta ishlash uchun mos materiallarni tanlang: Aluminiy 6061 kabi tez kesish mumkin bo'lgan materiallarni tanlang.

- Sozlamalarni minimal darajada qiling: Barcha xususiyatlarga imkon qadar kamroq mashina orientatsiyasida kirish mumkin bo'ladigan qilib tayyorlang.

2. Qayta ishlanadigan detallar loyihasini ishlab chiqishda qanday jihatlarga e'tibor beriladi?

Mexanik ishlov beriladigan detallarning asosiy loyihalash jihatlari ishlab chiqariluvchanlik va xarajatlarni tejashni ta'minlashga qaratilgan. Bunga kesuvchi asboblar uchun soddalik va kirish imkoniyatini ta'minlash maqsadida detalning geometriyasini baholash kiradi. Loyihalashtiruvchilar mukammal o'tkir ichki burchaklarni yaratib bo'lmasligi kabi, mexanik ishlash jarayonining cheklovlari hisobga olinishi kerak. Boshqa muhim jihatlarga funktsional talablarga hamda ishlanuvchanlikka qarab material tanlash, me'yorida to'g'ri chidamlilik qo'llash hamda teshiklar va tishli ulamalar kabi elementlarni standart texnik shartnomaga mos ravishda loyihalash kiradi. Oxirgi navbatda, loyihalashtiruvchilar detalni yakunlash uchun talab qilinadigan mashina sozlamalari sonini minimal darajada saqlashga harakat qilishlari kerak.

Kichik partiyalar, yuqori standartlar. Bizning tez prototip yaratish xizmatimiz tasdiqlashni tez va oddiy qiladi —

Kichik partiyalar, yuqori standartlar. Bizning tez prototip yaratish xizmatimiz tasdiqlashni tez va oddiy qiladi —