Profillarga o'rnatiladigan vintlarning muhim konstruksiyasi

Qisqacha

Ekstruziyaga vintli uzuklar va kanallarni loyihalash yig'ish uchun birlashtirilgan, ishonchli biriktirish nuqtalarini yaratadi. Muvaffaqiyatli dizayn tekis devor qalinligini saqlashga, etarli radiuslarni foydalanishga va vintli uzuklarning matritsani yaratishni soddalashtirish va xarajatlarni kamaytirish uchun 60 gradus ochilishiga ega bo'lishini ta'minlashga bog'liq. Rip va gusset kabi mustahkamlash elementlari bardoshlilikni oshirish va mexanik kuchlanishga chidash uchun ayniqsa muhim.

Ekstruziyalangan profilarda vintli uzuklarning roli va ahamiyati

Alyuminiy asboblar dunyosida vintli g'ildiraklar — ko'pincha vintli portlar yoki kanallar sifatida ataladigan — biriktiruvchi qismlarni o'rnatish uchun maxsus mustahkamlangan joylarni ta'minlaydigan asosiy xususiyatlardir. Ularning asosiy maqsadi alohida komponentlarni mustahkam birlashtirish yoki qo'shimcha qismlarni profilga o'rnatish imkonini berishdir. To'g'ri loyihalangan g'ildiraklar bo'lmasa, ingichka devorli asbobga bevosita vint kiritish natijasida ulanish zaif bo'ladi, chunki material momentni ushlab turish yoki katta yukni o'tkazish uchun etarlicha qalin emas. Threadlar osongina yiqiladi va butun tuzilmani buzadi.

Ushbu xususiyatlarning strukturaviy ahamiyati ortiqcha baholanmaydi. Yaxshi loyihalangan vintli g'ildirak fastenerdan kelib chiqadigan kuchni asbobning kengroq maydoniga tarqatadi va lokal materiallarning ishdan chiqishini oldini oladi. Bu arxitektorlik ramkalari va sanoat mexanizmlaridan tortib, iste'mol elektronikasi korpuslarigacha bo'lgan dasturlarda muhim ahamiyatga ega. Muhokamada aytilishicha, Linkedin , ingichka metallga vint aylantirish momentini yoki yukni ushlab turish uchun samarasiz. O'qlar (bosses) die dizayn bosqichida aniq joylashtiriladi, bu esa sozlanadigan yoki o'z-o'zidan tishli vintlarni ishlatish uchun tayyor mustahkam, qalin devorli silindrlar yoki kanallarni yaratadi.

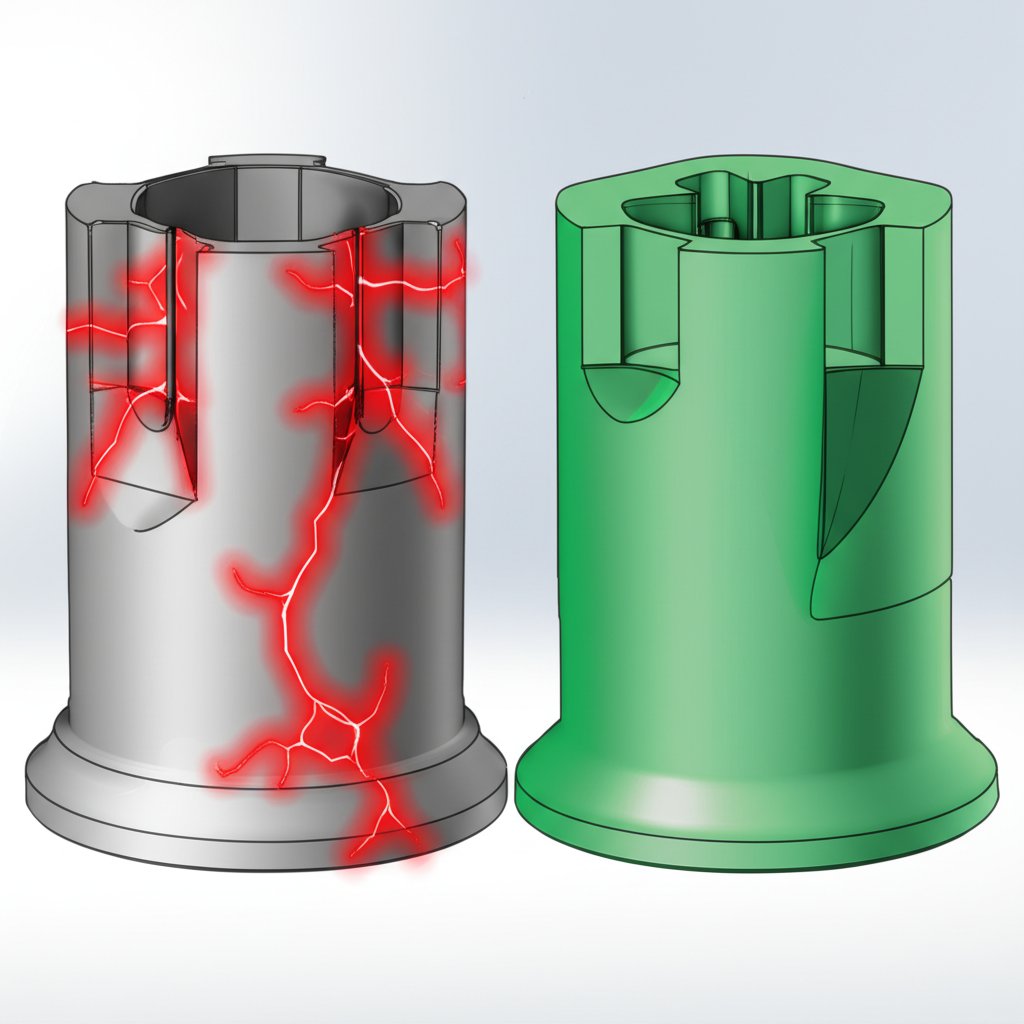

Shuni ham aytish kerakki, vint o'qlari murakkab mahsulotlarni yig'ishni birlashtirish uchun sodda, lekin mustahkam usuldir. Gabrian , yetakchi etkazib beruvchiga ko'ra, vint o'qini ekstruzyon oxiriga qo'shish - profilni oddiy ramkalardan tortib, nozik, ko'p qismlardan iborat tizimlargacha bo'lgan modular dizaynlarning universal qurilish blokiga aylantiruvchi samarali usuldir. Boshqa tomondan, yomon loyihalangan o'qlar ishlab chiqarishda qimmatga tushadigan muammolarga, zaif ulanishlarga va yakunda mahsulotning ishdan chiqishiga olib kelishi mumkin.

Ishlab chiqariluvchanlik va mustahkamlik uchun asosiy dizayn tamoyillari

Samarali va ishlab chiqarish uchun mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos mos Ushbu qoidalar metallning matodan yaxshi o'tishini ta'minlaydi, natijada o'lchamlar aniq va mustahkam profil hosil bo'ladi. Asosiy prinsip - iloji boricha devorning qalinligini bir xil saqlash. koʻrsatilganidek Yaji Alyuminiy tomonidan DFM dizayn qoʻllanmasi , devor qalinligining sezilarli o'zgarishi metallning turli tezlikda oqishiga olib kelishi mumkin, bu esa buzilishga, sirt nuqsonlariga va ichki bo'shliqlarga olib keladi.

Eng muhim va aniq ko'rsatmalardan biri - rahbarning o'z geometriyasiga tegishli. koʻrsatilishicha Taber ekstrudatsiyalari , asosiy maslahat 60 daraja ochilish bilan shrub bossinlar dizayn qilishdir. Agar kanal juda tor yoki yopiq bo'lsa, ichki xususiyatni shakllantirish uchun "torpedo" deb nomlangan murakkab va qimmatbaho matritsiyalangan komponent (tuxum matritsiyadagi mandrelning bir qismi) kerak bo'ladi. Bu nafaqat dastlabki asbob-uskunalar narxini oshiradi, balki matanning ishlash muddatini qisqartiradi. Ushbu 60 daraja qoidalariga rioya qilish xususiyatni qattiq profilning bir qismi sifatida tasniflaydi, bu esa ishlab chiqarishni sodda va iqtisodiy jihatdan osonlashtiradi.

Ushbu asosiy qoidalardan tashqari, mustahkam dizaynga yana bir nechta eng yaxshi amaliyotlar ham yordam beradi. Bosh va asosiy profil devorlari o'rtasidagi silliq, asta-sekin o'tish muhimdir. O'tkir burchaklar stress konsentratsiyasini yaratadi va metall oqimini to'sqinlik qilishi mumkin, bu esa nuqsonlarga olib keladi.

- Dengizatchilik: Varaq boshi atrofidagi devor kerakli ipni ushlab turish va tortilishga chidash uchun etarlicha qalin bo'lishi kerak. Qalinligi qo'shni devorlar bilan imkon qadar bir xil bo'lishi kerak.

- Burchak radiuslari: Boshliqning profildagi boshqa kishilar bilan uchrashadigan joyda saxiy radiuslardan foydalaning. Bu yoriqning oldini olishga yordam beradi va ekstrudatsiya paytida alyuminiyning oqimini yaxshilaydi.

- Yumshoq aralashtirish: Boshliq atrofdagi geometriyaga moslashishini ta'minlang. To'satdan o'zgarishlar zaif tomonlarni va yuzaki kamchiliklarni keltirib chiqarishi mumkin.

- Material tanlang: 6061 yoki 6063 kabi 6xxx seriyasidan bo'lgan, ekstrudatsiya qilish, mustahkamlik va korroziyaga chidamlilikning yaxshi muvozanatini ta'minlaydigan mos alyuminiy qotishmasini tanlang.

Ushbu prinsiplarni loyihalash bosqichida integratsiya qilish orqali muhandislar nafaqat funktsional va mustahkam, balki samarali va arzon ishlab chiqarish uchun optimallashtirilgan profillarni yaratishlari mumkin.

Ilgʻor usullar: Qizilkasini qoʻrgʻoshinlar va qoʻrgʻoshinlar bilan mustahkamlash

Asosiy dizayn tamoyillariga rioya qilish funktsional vint tayanchini yaratadi, lekin ko'plab sohalarda yuqori mexanik kuchlanish, vibratsiya yoki ta'sirga chidash uchun qo'shimcha mustahkamlash talab etiladi. Vint tayanchni ortiqcha massani qo'shmasdan va profilning asosiy tanasiga mahkamot kuchlarini samarali tarqatuvchi tirgaklar va plastinalar bilan mustahkamlash uchun g'altaklar va plastinalardan foydalaniladi. Ushbu elementlar strukturaviy tayanch vazifasini bajaradi.

Ribs (tirgaklar) vint tayanchini profilning boshqa yaqin devorlariga ulovchi ingichka, devorga o'xshash uzunayotgan qismlardir. Tayanchni atrofida joylashgan tuzilishga biriktirish orqali ribs yuk ostida tayanchning egilish yoki uzilib ketishining oldini oladi. Optimal ishlash uchun ribs asosiy profil devorlari bilan bir xil qalinlikda bo'lishi kerak, bu esa metall oqish tezligini muvozanatlashtiradi. Bitta qalin ribsdan ko'ra, ko'p sonli ingichka ribs qo'yish ko'pincha samaraliroqdir. Bu usul qattiklik va barqarorlikni oshiradi va profillash jarayonida sovuq nuqta hosil bo'lib, natijada botiqlar yoki boshqa sirt etishmovchiliklari vujudga kelish ehtimolini kamaytiradi.

Qo'shimcha qo'shilar o'xshash maqsadga ega, lekin odatda asosning tagida unga perpendikulyar devor ulanadigan joylarda uchburchak shaklidagi tayanch sifatida ishlatiladi. Ular asosni profilga egilish yoki uzilish kuchlariga qarshi kuchli mustahkamlovchi ta'minlaydi. Ripslar singari, qo'shimcha qo'shilar ichki keskin burchaklarni oldini olish uchun keng radiuslar bilan asos va devorga silliq o'tib ketishi kerak, chunki bu taranglikni jamlashga olib keladi. Yana ham kuchliroq mustahkamlik talab etiladigan sohalarda asosning yuqori qismiga kontrfor (konterbor) loyihalash mumkin. Kontrfor - bu vint ochig'ini kengaytiruvchi, mahkamlagich boshining sirti bilan darhol yoki sirtidan pastroq joylashishiga imkon beradigan tubi tekis silindrik teshik. Bu xususiyat shuningdek, mahkamlash nuqtasida materialning qalinroq qismini ta'minlab, asosning tortilish yuklariga chidash qobiliyatini yanada oshiradi.

Qo'llanilishi: Biriktirish va montaj uchun Vint Kanallarini Integratsiya Qilish

Yaxshi ishlangan vintli etaklar va kanallarning haqiqiy qiymati montaj paytida namoyon bo'ladi. Bu xususiyatlar alohida siqilgan profilni murakkab, funktsional tuzilmalarga ulash imkonini beradigan asosiy omil hisoblanadi. Material bilan yangi tanishayotgan odamlarning beradigan odatdagi savoli: 'Siz siqilgan aluminiyga vint aylantirishingiz mumkinmi?' degan savol. Javob aniqoq, ha, vintli etaklar buni amalga oshirishning professional usulidir. Ular mashina ramkalari va qoplamalardan tortib, deraza tizimlari hamda modulli mebellerga qadar hamma narsani yaratish uchun zarur bo'lgan material chuqurligi va mustahkamligini ta'minlaydi.

To'rtburchak ramka uchun 90 graduslik burchak uloqtirishning amaliy misolini ko'rib chiqing. Ikki profilni vintlarni o'rnatish uchun kanallar ularning uzunligiga parallel bo'lib ketadigan qilib loyihalash mumkin. Ularni bir-biriga ulash uchun, bir profildan kerakli uzunlikdagi qism kesib olinadi va uning yon devoriga ikkinchi profilning vint kanaliga tushadigan qilib teshiklar kuydiriladi. So'ngra vintlar shu teshiklardan o'tkazilib kanalga mahkamlanadi, natijada ikkita qism zich va mustahkam burchak hosil qilish uchun bir-biriga tortiladi. Bu usul ingichka oxirgi devorga tirnoq o'rnatishga qaratilgan har qanday urinishdan ancha yaxshiroq bo'lib, sezilarli buruv momenti va konstruktiv yuklarga chidasa biladigan uloqqa imkon beradi.

Yana murakkabroq sohalarda bunday integratsiyalangan elementlar ishlab chiqarishni soddalashtiradi va yig'ish vaqtini kamaytiradi. Ayniqsa avtomototsiya sohasidagi kabi yuqori aniqlik va sertifikatlangan sifat talab qilinadigan loyihalarda bunday elementlarning dizayni juda muhim ahamiyatga ega. Aniq muhandislik asosidagi komponentlar talab qilinadigan avtomototsion loyihalar uchun ishonchli hamkor tomonidan taklif etiladigan maxsus aluminiy profilga e'tibor bering. Shaoyi Metal Texnologiya iATF 16949 sertifikatlangan sifat tizimi doirasida tezkor namunaviy ishlab chiqarishdan to'liq masshtabli ishlab chiqarishgacha bo'lgan barcha xizmatlarni taklif etadi, komponentlarning eng yuqori standartlarga javob berishini ta'minlaydi. Integratsiyalangan mahkamlash nuqtalari bilan murakkab, ko'p funksional profillarni loyihalashtirish qobiliyati ikkinchi darajali mexanik ishlash operatsiyalariga bo'lgan ehtiyojni kamaytiradi va yakuniy montaj jarayonini soddalashtiradi, oxir-oqibat xarajatlarni kamaytiradi va mahsulot sifatini oshiradi.

Koʻpincha soʻraladigan savollar

1. Vintli ekstruder qanday loyihalash kerak?

Bu savol ko'pincha chalkashlikka olib keladi. *Sovunma ichiga vint tayoqchasi* loyihalash — biriktirish uchun metall profilga xususiyat qo'shishni anglatadi. *Vintlari sovunuvchi moslamani* loyihalash plastmassa yoki oziq-ovqat ishlab chiqarish kabi jarayonlarda foydalaniladigan butun mashinani muhandislik orqali yaratishni nazarda tutadi. Ushbu mashinaning asosiy komponenti materialni o'tkazish, eritish va bosim ostiga olish uchun katta aylanuvchi vintdan iborat. Uni loyihalash termodinamika, suyuqlik dinamikasi va materialshunoslikning murakkab tamoyillarini talab qiladi va bu NC State University tomonidan berilgan manbada batafsil bayon etilganidek, qadam, kanal chuqurligi va siqish nisbati kabi elementlarga e'tibor qaratiladi nC State University tomonidan berilgan qo'llanma .

2. Sovurilgan aluminiyga vint aylantirish mumkinmi?

Ha, siz aralashtirilgan aluminiyga mutlaqo vint aylantirishingiz mumkin va bu juda keng tarqalgan montaj usulidir. Eng mustahkam va ishonchli ulanish uchun vintlarni maxsus ishlab chiqilgan elementlarga, masalan, vint o'qariga yoki kanallarga aylantirish eng yaxshi amaliyotdir. Bu sohalarda teshiklar etarli darajada qalin bo'lib, oldindan payvandlangan yoki o'z-o'zidan payvandlanadigan vintlar bilan foydalanish uchun tirnagining mustahkam ushlanishi uchun etarli material mavjud. Bu standart ingichka devorga biriktirishda sodir bo'ladigan uzilish va zaiflikni oldini oladi.

3. Aralashtirishning 5 bosqichi nimalardan iborat?

Material (masalan, alyuminiy yoki plastik) ga qarab tafsilotlar farq qilishi mumkin, lekin umumiy ekstruziya jarayoni besh asosiy bosqichdan iborat. Birinchidan, materialning (masalan, alyuminiy) isitilgan billeti tayyorlanadi. Ikkinchidan, billet ekstruder pressiga o'rnatiladi va matritsa tomon suriladi. Uchinchidan, katta bosim qo'llanilib, material matritsadagi ochiqqa orqali surib chiqariladi, bu esa unga kerakli profil shaklini beradi. To'rtinchi bosqichda yangi hosil bo'lgan ekstruziya nazorat ostida sovutiladi yoki sho'lish jarayonidan o'tkaziladi. Nihoyat, uzun profil ichki kuchlanishlarni yo'qotish uchun cho'ziladi va so'ngra kerakli uzunlikdagi bo'laklarga kesiladi.

Kichik partiyalar, yuqori standartlar. Bizning tez prototip yaratish xizmatimiz tasdiqlashni tez va oddiy qiladi —

Kichik partiyalar, yuqori standartlar. Bizning tez prototip yaratish xizmatimiz tasdiqlashni tez va oddiy qiladi —