Ano Ang Ibig Sabihin ng Die Cast: Kahulugan, Proseso, At Kailan Gamitin

Ano Ibig Sabihin ng Die Cast?

Sagot sa Madaling Salita

Ang die cast ay isang bahaging metal na nabubuo sa pamamagitan ng pag-iniksyon ng nagbabagang metal sa isang matibay na mold na bakal sa ilalim ng mataas na presyon, at pagkatapos ay tumitigas ayon sa eksaktong hugis ng mold.

Kapag naririnig mo ang termino die cast , maaari mong magtanong: ano ibig sabihin ng die cast, at paano ito naiiba sa iba pang paraan ng paggawa ng metal na bahagi? Sa pagmamanupaktura, die Casting ay parehong proseso at resulta—ang proseso ng pagpilit sa mainit, likidong metal papasok sa isang tumpak na mold na bakal (tinatawag na "die") at ang solidong, natapos na bahagi na lumalabas. Kung dati nang hawak mo ang matibay na metal na laruan kotse o napansin mo ang makinis, detalyadong metal na takip sa paborito mong gadget, malamang ay hawak mo na ang isang die-cast na bahagi kahit hindi mo alam.

Mga Karaniwang Halimbawa na Kilala Mo

Tila teknikal pa rin? Ito ang isipin: tuwing pinipindot mo ang isang light switch, ginagamit ang kahit anong kitchen appliance, o nagmamaneho ng kotse, malamang ay may interaksiyon ka sa isang bagay na gawa gamit ang die casting. Narito ang ilang kilalang produkto na madalas na die cast:

- Mga metal na laruan kotse at kolektibol na modelo

- Mga housing ng appliance (blender, mixer, coffee maker)

- Mga bahagi ng engine ng sasakyan at mga kahon ng transmission

- Mga fixture ng ilaw sa labas at loob ng bahay

- Mga kahon at konektor ng electronics

- Mga hardware tulad ng door handle at lock

Ang mga bahaging ito ay hinahangaan dahil sa kanilang tibay, detalyadong anyo, at kakayahang gawin nang mas malaki ang dami nang may pare-parehong kalidad. Ang die cast meaning ay tungkol sa pagsasama ng tiyakness, bilis, at pag-uulit na ibinibigay ng prosesong ito.

Die Casting vs Karaniwang Pag-iipon

Kung gayon, ano nga ba ang die casting kumpara sa iba pang paraan ng pag-iipon? Hatiin natin ito:

- Die Casting gumagamit ng mataas na presyon upang ipasok ang nagbabagang metal sa isang bakal na modelo, na nagbubunga ng mga bahagi na may mahigpit na toleransya at makinis na surface.

- Siklab sa balatok ibinubuhos ang nagbabagang metal sa isang buhangin na modelo, na mas hindi eksakto at nag-iiwan ng magaspang na tapusin.

- Ang die casting ay pinakamainam para sa malalaking dami at kumplikadong hugis; ang sand casting ay mas nababaluktot para sa iisa lamang o napakalaking bahagi.

Sa madaling salita, kahulugan ng die casting nakatuon sa paggamit ng muling magagamit na steel dies at mataas na presyon, samantalang ang iba pang pamamaraan tulad ng sand casting ay gumagamit ng disposable molds at gravity. Kung nagtatanong ka ano ang diecast kumpara sa iba pang pag-iipon, ang nakikilala ay ang proseso na nagbibigay ng eksaktong precision [Wikipedia] .

Mga Karaniwang Pagkakamali na Dapat Iwasan

Madaling ikalito ang termino sa pagmamanupaktura na "die cast" sa ekspresyon the die is cast . Ngunit narito ang pagkakaiba:

- Sa pagmamanupaktura, ang "die cast" ay tumutukoy sa proseso at sa resultang metal na bahagi.

- Ang salita kahulugan ng die is cast o nabato na ang taya ay galing sa isang sikat na kasabihan tungkol sa kapalaran o mga desisyong hindi na mapapabalik—walang kinalaman ito sa pagtrato sa metal.

Kaya, sa susunod na marinig mo ang sinasabi ng isang tao na "the die is cast," tandaan: maliban kung pinag-uusapan ninyo ang paggawa ng metal na bahagi, marahil ay ang kapalaran ang pinag-uusapan nila, hindi ang die casting!

Sa maikli, kung naghahanap ka ng ano ang ibig sabihin ng die cast , ito ay tungkol sa paggawa ng eksaktong, matibay na metal na bahagi sa pamamagitan ng pag-iniksyon ng natunaw na metal sa isang bakal na modelo sa ilalim ng mataas na presyon. Ito ang pangunahing bahagi ng proseso ng die casting, at iyon ang dahilan kung bakit maraming pang-araw-araw na produkto ang umaasa dito.

Paano Nagiging Tumpak na Bahagi ang Natunaw na Metal sa Pamamagitan ng Die Casting Process

Mga Pangunahing Hakbang sa Proseso ng Die Casting

Nagtanong ka na ba kung ano talaga ang nangyayari sa loob ng isang die casting machine? Kung inilalarawan mo ang tinunaw na metal na pumasok sa isang bakal na mold at lalabas bilang isang malinaw, natapos na bahagi—tama ka roon. proseso ng die casting mula simula hanggang wakas, upang makita mo kung paano ang hilaw na metal ay naging mga bahagi na ginagamit mo araw-araw.

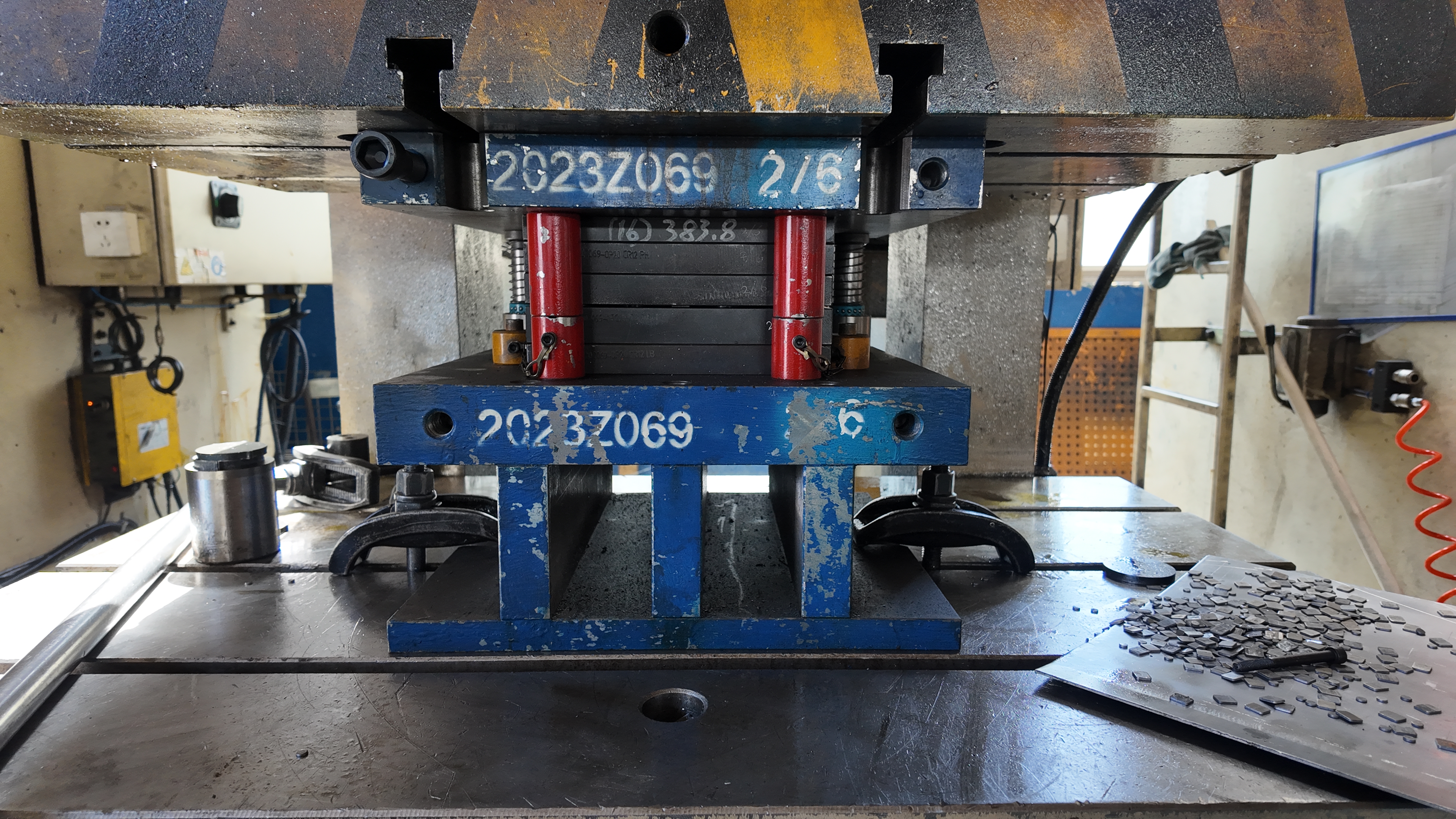

- Paghahanda at Pagkakabit ng Mold: Ang die (isang hardened steel mold) ay nililinis, pinainit, at pinapahiran ng espesyal na lubricant upang matulungan ang pag-alis at kontrol sa temperatura. Ang dalawang kalahati ng die ay isinasara at pinipilit na isaksak nang mahigpit upang maiwasan ang anumang pagtagas.

- Pag-iniksyon: Ang tinunaw na metal—karaniwan ay aluminum o zinc—ay ipinasok sa loob ng die cavity nang may mataas na bilis at presyon. Ito ang puso ng high pressure die casting , kung saan ang presyon ay maaaring umabot sa 100 hanggang 1,800 bars (1,400 hanggang 26,000 psi). Ang matinding puwersa ay tinitiyak na napupunan ng metal ang bawat detalye ng mold.

- Pagpapahinto at Paglamig: Ang metal ay pinapanatiling nasa ilalim ng presyon habang ito'y lumalamig at nagkakabihis, upang manatili ang hugis at detalyadong bahagi ng piraso. Mahalaga ang pare-parehong paglamig upang maiwasan ang mga depekto at matiyak ang mataas na kalidad ng surface.

- Pagbubukas ng Die: Kapag lubusang nabihis, ang dalawang kalahati ng die ay bumubuka, na naglalantad sa bagong nabuong bahagi sa loob.

- Pag-ejection: Ang mga ejector pin na naka-embed sa loob ng die ang humihila nang dahan-dahan at ligtas upang bawasan ang panganib na masira ang bahagi.

- Pagkutsero: Ang anumang sobrang materyales (tulad ng sprues at runners) ay tinatanggal. Ang mga scrap na ito ay madalas i-recycle pabalik sa proseso.

Ulitin nang mabilis ang siklong ito—minsan ay sa loob lamang ng isang minuto—na kaya nga ito ay mainam para sa mataas na produksyon ng magkakatulad at tumpak na mga bahagi.

Mga Bahagi ng Tooling na Nagbibigay-Hugis sa Iyong Piraso

Ano ang gumagawa ng isang matlang para sa die casting kaya epektibo sa paggawa ng mga kumplikadong hugis at makinis na surface? Nasa mga tooling components na nagtutulungan sa loob ng die casting machine ang sagot. Narito ang mga makikita mo sa isang karaniwang die:

- Cavity: Ang butas na hugis ng huling bahagi—dito dumadaloy at nabubuo ang metal.

- Core: Mga insert na bumubuo ng mga butas o panloob na bahagi, na nagbibigay-daan sa mga kumplikadong geometriya.

- Mga Runners at Gate: Mga landas na nagdudulot ng natunaw na metal mula sa punto ng pasukan patungo sa kavidad, upang matiyak ang pare-parehong pagpuno.

- Mga Vent: Maliit na daanan kung saan napapalabas ang nahuhuling hangin at gas, na binabawasan ang porosity at mga depekto sa ibabaw.

- Mga Ejector Pin: Mga mekanismo na itinutulak ang solidong bahagi palabas sa die nang hindi nasusugatan ito.

Ang tiyak na sukat ng mga bahaging ito ay direktang nakakaapekto sa tapusin ng ibabaw, katumpakan ng sukat, at pag-uulit ng bawat bahagi. Ang maayos na disenyo ng kagamitan ay nakatutulong din upang bawasan ang gawaing pangwakas pagkatapos ng pag-iipon.

Bakit Mahalaga ang Presyon at Bilis

Isipin mo ang pagpuno sa bawat sulok ng detalyadong mold gamit ang makapal at mabilis na pumipigil na metal—mukhang mahirap, di ba? Doon papasok ang lakas ng high pressure die casting pumasok. Sa pamamagitan ng pag-iniksyon ng metal sa napakataas na presyon at bilis, ang proseso ay nakakamit:

- Mahusay na pagkakatulad ng mga detalyadong detalye at manipis na pader (na maaaring hanggang 1 mm ang kapalot sa ilang kaso)

- Minimong porosity, na nagreresulta sa mas matibay at mas matibay na mga bahagi

- Mas makinis na surface finish, na madalas hindi na nangangailangan ng pangalawang polishing

- Mataas na pagkakapare-pareho ng sukat sa libu-libo o kahit milyon-milyong bahagi

Karaniwang mga materyales na ginagamit sa die casting ay kinabibilangan ng aluminum —binibigyang-halaga dahil sa magaan nitong lakas at paglaban sa init—at sinko , na mahusay sa pagkuha ng maliliit na detalye at pagkamit ng mahigpit na toleransiya. Ang pagpili ng materyal ay nakadepende sa mga kinakailangan ng bahagi, ngunit pareho ay nakikinabang sa presisyon at kahusayan ng die casting process.

Sa kabuuan, ang pagkakaugnay ng advanced na tooling, mataas na presyong iniksyon, at mabilis na pag-cycling ang nagtatakda sa die casting. Ang bawat hakbang ay idinisenyo upang makagawa ng mga bahagi na maganda ang itsura, maaasahan ang pagganap, at tugma sa mahigpit na pangangailangan ng modernong produksyon. Susunod, tatalakayin natin kung paano ang iba't ibang uri ng die casting machine at pamamaraan—tulad ng hot chamber at cold chamber—ay nakakatulong sa proseso para sa tiyak na metal at aplikasyon.

Paano Nakabubuo ang Iba't Ibang Uri ng Die Casting Machine sa Iyong Mga Bahagi

Mga Hakbang sa Hot-chamber at Karaniwang Mga Materyales

Nagtanong ka na ba kung bakit magkaiba-iba ang itsura ng ilang die casting machine? Ang sagot ay nasa dalawang pangunahing uri ng pressure die casting—hot-chamber at cold-chamber—na bawat isa ay dinisenyo para sa iba't ibang uri ng metal at pangangailangan sa bahagi. Alamin natin kung ano ang nangyayari sa loob ng bawat uri ng casting machine at bakit pipiliin mo ang isang uri kaysa sa iba.

| Hot-chamber die casting | Cold-Chamber Die Casting |

|---|---|

|

Pinakamahusay Para sa: Mga haluang metal na may mababang punto ng pagkatunaw (zinc, magnesium, lead) Kakayahang magkapareho ng haluang metal: Hindi kayang gamitin sa mga metal na may mataas na punto ng pagkatunaw tulad ng aluminum Bilis ng ikot: Mabilis (madalas 15–20 minuto bawat ikot o mas mababa pa) Sukat ng bahagi: Maliit hanggang katamtaman, mga nakapirming hugis Pagpapanatili: Mas mababa ang pagsusuot dahil sa mas mababang temperatura

|

Pinakamahusay Para sa: Mga haluang metal na mataas ang punto ng pagkatunaw (aluminum, tanso, ilang magnesiyo) Kakayahang magkapareho ng haluang metal: Mga Handle aluminum die casting materials at iba pa na maaaring makasira sa isang hot-chamber system Bilis ng ikot: Mas mabagal kaysa sa hot-chamber (nag-iiba-iba ayon sa bahagi at haluang metal) Sukat ng bahagi: Katamtaman hanggang malaking, matibay o istrukturang mga bahagi Pagpapanatili: Mas mataas dahil sa thermal shock at mas mataas na operating temps

|

Mga hakbang sa cold-chamber at karaniwang mga materyales

Sa malamig na silindro pressure die casting, mapapansin mong nagsisimula ang proseso sa paglilipat ng nagbabagang metal mula sa isang panlabas na hurno. Mahalaga ito para sa aluminum die casting materials , dahil ang kanilang mataas na punto ng pagkatunaw ay mabilis na magpapauso sa mga panloob na bahagi ng isang hot-chamber machine. Ang shot sleeve, plunger, at die ay nagtutulungan upang ipasok ang metal nang may mataas na bilis, mahusay na detalye, at tiyak na lakas para sa mga estruktural na bahagi. Karaniwang produkto ay mga automotive engine block, transmission case, at mas malalaking appliance housing.

Pagpili sa pagitan ng mga makina

Kaya, alin machine die ay angkop para sa iyong proyekto? Narito kung paano pipili:

- Hot-chamber die casting ay perpekto para sa mataas na volume ng maliit, detalyadong bahagi gamit ang mga haluang metal na may mababang punto ng pagkatunaw tulad ng sosa. Ang pinagsamang sistema ng pagtunaw at ineksyon ay nagbibigay ng mabilis na cycle at epektibong produksyon.

- Cold-Chamber Die Casting ay kinakailangan para sa mga bahagi na nangangailangan ng aluminum die casting materials o iba pang mga haluang metal na may mataas na punto ng pagkatunaw. Bagaman medyo mas mabagal ang proseso dahil sa dagdag na hakbang ng paglalagyan ng metal, ito ay nagbibigay-daan sa paggawa ng mas malaki at mas matibay na bahagi na kayang tumagal sa mahihirap na kapaligiran.

Kung nagtatanong ka pa rin ano ang ibig sabihin ng die sa casting o kung paano shot die casting angkop sa, tandaan: ang die ay isang precision steel mold, at ang "shot" ay tumutukoy sa bawat kuryente kung saan ipinasok ang nagmumurang metal sa loob ng die. Ang pagpili sa pagitan ng hot at cold chamber ay nakadepende sa uri ng alloy na kailangan mo at sa mga kinakailangan sa pagganap ng iyong huling bahagi.

Ngayon na alam mo na kung paano gumagana ang iba't ibang casting machine, handa ka nang lumusong sa partikular na mga materyales—tulad ng aluminum at zinc—na nagbibigay-buhay sa die cast na mga bahagi at nagdedetermina sa kanilang mga katangian sa tunay na aplikasyon.

Pangkalahatang-ideya ng Materyales para sa Die Cast na Aluminum at Zinc

Kailan Pumili ng Die Cast na Aluminum

Nakahawak ka na ba sa isang magaan ngunit matibay na phone case o napansin mo na ang sleek na frame ng isang laptop? Malaki ang posibilidad na nakatingin ka sa die cast aluminum . Ngunit bakit nga ba ang aluminum ang pangunahing napipili sa die casting? Ang sagot ay nakasalalay sa kakaiba nitong kombinasyon ng mga katangian.

- Ratio ng lakas sa timbang: Ang mga haluang metal ng aluminum ay nagbibigay ng kamangha-manghang lakas nang hindi dinadagdagan ang timbang, kaya mainam ito para sa mga bahagi sa automotive, aerospace, at electronics kung saan mahalaga ang bawat ounce.

- Paggawa ng init at kuryente: Mahusay ang aluminum die casting sa pagkalat ng init, kaya perpekto ito para sa mga bahagi tulad ng heat sinks, katawan, at konektor na kailangang pamahalaan ang temperatura.

- Paglaban sa kaagnasan: Ang aluminum ay natural na bumubuo ng protektibong oxide layer, na nagbibigay sa mga die-cast aluminum na bahagi ng mas mahabang buhay, lalo na sa mapanganib na kapaligiran.

- Mga kumplikadong hugis at detalyadong katangian: Pinapayagan ng proseso ang mga makulay na disenyo at manipis na pader, na binabawasan ang pangangailangan para sa karagdagang machining.

Mula sa mga bahagi ng engine ng sasakyan hanggang sa mga kahon ng electronics at kahit mga frame ng solar panel, aluminium casting karaniwang unang pinipili kapag kailangan mo ng balanse ng magaan, lakas, at tibay. Tandaan lamang, ang mas mataas na melting point ng aluminum ay nangangahulugan na karaniwang ginagawa ito gamit ang cold chamber die casting.

Kailan Pumili ng Zinc Die Casting

Isipin mo na kailangan mo ng bahagi na may matulis na detalye, mahigpit na toleransiya, at mirror-smooth na tapusin—tulad ng dekoratibong hardware, mga gilid, o miniature na bahagi. Doon mismo sumisikat ang zinc die casting zinc die casting.

- Kataasan at detalye: Ang mahusay na daloy ng sisa sa natunaw na anyo ay napupuno ang kahit pinakakomplikadong mga modelo, nahuhuli ang maliliit na detalye at manipis na pader na nahihirapan ng ibang metal.

- Estabilidad sa Dimensyon: Ang mga sasakyan na tinitibag ng sisa ay may mahigpit na toleransya, kaya mainam para sa mga kumplikadong pagkakahugis at gumagalaw na bahagi.

- Lakas sa pag-impact at katatagan: Mas madensidad at mas matibay ang sisa kaysa sa aluminum, kaya zinc die cast mainam ang mga bahagi para sa mga aplikasyon na nangangailangan ng mataas na paglaban sa impact at katatagan.

- Mabilis at epektibong produksyon sa enerhiya: Ang mababang punto ng pagkatunaw ng sisa ay nangangahulugan ng mas mabilis na oras ng siklo at mas mahabang buhay ng kasangkapan, na maaaring bawasan ang gastos para sa mataas na dami ng produksyon.

Kung ang iyong proyekto ay nangangailangan ng hindi pangkaraniwang tapusin sa ibabaw, mahuhusay na detalye, o murang produksyon sa mataas na dami, zinc casting isang matalinong pagpipilian. Tandaan lamang, mas mabigat ang sisa kaysa sa aluminum, kaya hindi ito angkop para sa magaan na disenyo o gamit sa aerospace.

Aluminum vs Zinc: Isang Mabilis na Paghahambing

| Mga ari-arian | Aluminum Die Casting | Zinc die casting |

|---|---|---|

| Katapatan sa detalye | Napakaganda, lalo na para sa manipis na pader | Mahusay—pinakamahusay para sa detalyadong disenyo at maliit na bahagi |

| Timbang | Magaan (humigit-kumulang 2.7 g/cm³) | Mas mabigat (humigit-kumulang 6.6-6.7 g/cm³) |

| Ugali sa Korosiyon | Katauhan na oksihang patong; mataas ang resistensya | Mabuti, ngunit maaaring lumala sa matagal na pagkakalantad |

| Paglilipat ng Init | Mataas—mainam para sa sink ng init at elektronika | Katamtaman—maayos din sa pagkalat ng init |

| Karaniwang Kapal ng Pader | Manipis (2–3 mm ang posibilidad) | Napakalito (mas mababa sa 1 mm ang posibilidad) |

| Mga Tagapagdigma ng Gastos | Mas mataas na gastos para sa alloy at mga kagamitan; mas mababa bawat yunit kapag malaki ang dami | Mas mababa ang pagsusuot ng mga kagamitan; mabilis na mga ikot; mas kaunting paggamit ng enerhiya |

| Mga pagpipilian sa pagtatapos | Malawak na hanay (anodizing, powder coating, plating) | Makinis na ibabaw, angkop para sa plating at pintura |

Tandaan: Die cast steel ay bihirang ginagamit sa mataas na presyong die casting dahil ang melting point ng steel ay mas mataas kaysa kayang hawakan ng mga prosesong ito. Para sa mga bahagi ng steel, mas karaniwan ang ibang pamamaraan tulad ng investment casting o forging.

Mga Opsyon sa Pagtatapos na Nagdaragdag ng Halaga

Kapag natapos nang ma-cast ang iyong bahagi, hindi pa dyan natatapos ang kuwento—maaaring baguhin ng mga surface finish ang hitsura at pagganap. Ang parehong aluminum at zinc die castings ay tumutugon nang maayos sa iba't ibang teknik ng pagtatapos:

- Anodizing (aluminum lamang): Pinapalakas ang likas na oxide layer para sa mas mahusay na paglaban sa korosyon at mga opsyon sa kulay.

- Powder Coating: Nagdaragdag ng matibay, pare-parehong kulay na layer para sa estetika at dagdag na proteksyon.

- E-coating: Ginagamit ang electrostatic painting para sa pare-parehong coverage, karaniwan sa itim o puti.

- Plating (lalo na sink): Nagbibigay ng dekoratibong o panggamit na metalikong tapusin, tulad ng chrome o nickel, para sa paglaban sa korosyon at hitsura.

- Electroless nickel plating: Pare-pareho, nakakalaban sa korosyon na layer para sa mga kumplikadong hugis.

- Alodine (chromate conversion): Pinapassivate ang surface para sa mas mahusay na pandikit ng pintura at conductivity.

- Cerakote at pagpapasok: Mga espesyal na patong para sa pagsusuot, korosyon, o pang-sealing ng mga butas.

Ang mga opsyon sa pagwawakas na ito ay hindi lamang nagpapabuti sa hitsura at pakiramdam ng iyong die-cast na aluminum o sosa casting kundi pinahaba rin ang buhay nito at resistensya sa mga kondisyon ng kapaligiran. Maaari ring isagawa ang mga secondary operation tulad ng machining, drilling, o tapping para sa mahigpit na toleransya o pangangailangan sa pag-assembly.

Kaya, kung ikaw ay nagsusuri aluminum Die Casting para sa isang magaan, bahagi na may laban sa korosyon o zinc die casting para sa masalimuot na detalye at mataas na epekto sa produksyon, ang pag-unawa sa iyong materyales at pagpipilian sa pagwawakas ay susi sa matagumpay na proyekto. Susunod, tatalakayin natin kung paano idisenyo ang iyong die-cast na bahagi para sa madaling paggawa at eksaktong sukat.

Disenyo para sa Madaling Paggawa at Mga Pangunahing GD&T

Tseklis ng DFM para sa Mas Kaunting Depekto

Kapag idinisenyo mo ang isang bahagi para sa die casting, ang mga maliit na desisyon ay maaaring magdulot ng malaking epekto sa gastos ng produksyon, kalidad, at kung gaano kadali maililipat ang disenyo mula sa CAD hanggang sa tunay na mundo mga Bahagi ng Pag-iikot sa Die . Mukhang kumplikado? Hindi naman kailangang ganoon. Sa pamamagitan ng pagsunod sa mga batayang DFM (Design for Manufacturability) na prinsipyo, matutulungan mong mapanatili ang iyong casting die nagpapalabas ng pare-parehong bahagi na walang depekto—maging ikaw man ay gumagawa ng ilang prototipo o nag-iiwan para sa mataas na dami production castings .

- Pare-parehong kapal ng pader: Panatilihing pantay ang mga pader upang mapadali ang maayos na daloy ng metal at maiwasan ang mainit na lugar o pagliit. Ang manipis at pare-parehong pader ay binabawasan din ang paggamit ng materyales at oras ng siklo.

- Sapat na anggulo ng draft: Magdagdag ng bahagyang pagtaper sa lahat ng patayong ibabaw upang matulungan ang bahagi na maluwag mula sa mold at die. Kahit ilang degree lang ay makakaiwas na sa pagkakabit at mga depekto sa itsura.

- Mga fillet sa panloob na sulok: Palitan ang matutulis na sulok ng mas malalaking fillet. Nakakatulong ito sa daloy ng metal, binabawasan ang stress concentration, at pinipigilan ang panganib ng bitak o pagbaluktot.

- Ribs para sa katigasan: Gumamit ng mga rib upang palakasin ang manipis na bahagi nang hindi nagdaragdag ng hindi kinakailangang bigat o pinalapal na pader. Ang maayos na nakatakdang ribs ay sumusuporta rin sa lokasyon ng ejector pin at pinauunlad ang katatagan ng bahagi.

- Cored holes at bulsa: Alisin ang mabibigat na bahagi upang mabawasan ang timbang, mapabilis ang paglamig, at makatipid sa materyal para sa paghuhulma. Nakakatulong din ito sa pagpapanatili ng dimensyonal na katatagan at maiwasan ang mga marka ng pagbaba.

- Maluwag na mga radius sa linya ng paghihiwalay: Ang maayos na transisyon sa linya ng paghihiwalay ay nagpapadali sa paggawa at pagpapanatili ng mold at die, habang binabawasan ang pagsusuot ng kagamitan.

- Tuwid at naa-access na mga linya ng paghihiwalay: Idisenyo ang iyong bahagi upang ang linya ng paghihiwalay ay gaano katuwid at naa-access hangga't maaari. Pinapasimple nito ang konstruksyon ng mold at binabawasan ang panganib ng flash.

- Hakbang-hakbang na transisyon: Iwasan ang biglang pagbabago sa cross-section. Gamitin ang mga fillet at chamfer upang mapadali ang transisyon at maiwasan ang mga depekto dulot ng iba't-ibang paglamig.

Sa pamamagitan ng pagsasama ng mga prinsipyong ito, mas kaunti ang mga depekto at mas maayos ang landas mula disenyo hanggang sa natapos na molde sa pagsusulat ng aluminio o mga bahagi ng sosa.

Mga GD&T Callout na Gumagana para sa Die Casting

Ang Geometric Dimensioning & Tolerancing (GD&T) ay iyong toolkit para maipahayag nang eksakto kung paano dapat gawin at sukatin ang isang bahagi. Ngunit aling mga simbolo ng GD&T ang talagang mahalaga para sa isang materyal na casting tulad ng aluminum o sosa? Narito ang isang mabilis na gabay batay sa mga pamantayan sa industriya tulad ng ASME Y14.5, ISO 8062, at ang NADCA Product Specification Standards [NADCA] :

- Posisyon: Kinokontrol ang eksaktong lokasyon ng mga butas, puwang, o mga katangian—lalo na mahalaga para sa mga cored hole, bosses, o mounting point.

- Profile ng isang surface: Tinutiyak na ang mga kumplikadong kontur o surface ay nasa loob ng takdang tolerance band, angkop para sa mga cosmetic face o functional surface.

- Katumbasan: Tinukoy kung gaano kalaki ang paglihis ng isang surface mula sa perpektong flatness, mahalaga para sa mga mounting face o sealing surface.

- Parallelism at perpendicularity: Ginagamit para sa mga katangian na dapat panatilihin ang tiyak na oryentasyon kaugnay ng isang datum o iba pang katangian.

Maaaring magmukha ang halimbawa ng mga tala sa GD&T para sa isang die casting drawing tulad ng:

- Position ⌀2.0 M A B C (para sa isang cored hole na kaugnay ng tatlong datums)

- Profile ng isang surface 0.5 A (para sa isang contoured face)

- Kapantayan 0.2 (para sa isang mounting boss o pad)

Ang paggamit ng mga ito ay nagbibigay-daan sa parehong designer at foundry na magkasundo kung ano ang mahalaga para sa function at kung ano ang maaaring mas mapagbigay, na maaaring magpababa ng hindi kinakailangang machining at bawasan ang gastos [AMC ATI] .

Ang pagdidisenyo batay sa parting line at kasama ang tamang draft angles ay ang pinaka-epektibong paraan upang mabawasan ang tool wear at mapabuti ang haba ng buhay ng iyong mold at die.

Template ng Pagsusuri ng Sample na Bahagi

Nais nang suriin ang susunod mong die cast design? Narito ang isang simpleng template upang matulungan ka o ang iyong koponan na madiskubre ang karaniwang mga isyu bago ang produksyon:

- Lahat ba ng kapal ng pader ay kasingtapat hangga't maaari para sa casting material?

- May sapat bang draft ang lahat ng vertical na mukha para sa madaling ejection?

- Napalitan ba ang matutulis na sulok ng fillets o radii, lalo na sa parting line?

- Nagdagdag ba ng mga sirang para sa lakas nang hindi nagkakaroon ng makapal na mga bahagi?

- Ang mga mabibigat na bahagi ba ay inalis ang core upang makatipid sa materyal na panghulma at bawasan ang oras ng paglamig?

- Tuwid ba ang linya ng paghihiwalay at madaling ma-access para sa mas madaling paggawa ng hulma?

- Malinaw ba ang mga tawag sa GD&T kung ano ang dapat mahigpit na kontrolin at ano ang maaaring mas maluwag?

- Naipagsiguro na ba ang disenyo laban sa mga pamantayan ng NADCA at ISO 8062 para sa mga hulmahan?

Sa pamamagitan ng paggamit ng checklist na ito at pagbabago ng iyong diskarte sa GD&T para sa die casting, magtataglay ka ng kalagayan para sa tagumpay—nakakatipid sa gastos, binabawasan ang mga depekto, at tiniyak na ang iyong production castings natutugunan ang parehong pagganap at mga kinakailangan sa hitsura.

Sa matibay na disenyo at malinaw na toleransya, ang susunod mong hakbang ay tiyakin ang kalidad sa shop floor—sa pamamagitan ng pag-unawa sa pagsusuri at pagbawas ng mga depekto, na tatalakayin natin sa susunod na seksyon.

Pagsusuri sa Kalidad at Pagbawas ng mga Depekto para sa Die Casting

Karaniwang Mga Depekto at Kung Paano Makilala ang mga Ito

Kapag ikaw ang responsable sa paggawa ng die casting mga bahagi, mabilis mong natutunan na kahit ang pinakamahusay na proseso ay maaaring magdulot ng mga depekto. Ngunit ano ang dapat mong hanapin, at paano mo mahuhuli ang mga isyu bago ito magiging mahal na problema? Iminumulat ang pagsusuri sa isang batch ng die castings —anong mga palatandaan ang nagsasabi sa iyo na may mali? Narito ang isang simple at tuwirang gabay sa mga pinakakaraniwang depekto, ang kanilang mga katangian, at kung paano sila suriin.

| Depekto | Mga Malamang na Pananampalataya | Paraan ng pagsusuri | Korektibong Aksyon |

|---|---|---|---|

| Gas Porosity | Nakulong na hangin/gas habang nagpupuno; mabilis na pag-iniksyon; mahinang bentilasyon | Pananaw (mga bula, butas); radiograpiya (ASTM E155) | Pabutihin ang bentilasyon; i-optimize ang gating; i-adjust ang bilis ng iniksyon |

| Shrinkage Porosity | Hindi pare-parehong paglamig; makapal na bahagi; mahinang pamamahala ng init | Pananaw (mga puwang, bitak); X-ray o UT scan | Baguhin ang disenyo para sa pare-parehong kapal ng pader; i-optimize ang sistema ng paglamig |

| Cold Shut | Mababang temperatura ng metal; mabagal na pagsisidlo; mahinang disenyo ng gating | Biswal (manipis, tuwid na linya sa ibabaw) | Palakihin ang temperatura ng metal/die; mapabuti ang gating; itaas ang bilis ng pagsisidlo |

| Flash | Hindi magkasekto ang die; nasirang die; labis na presyon | Biswal (manipis na fins o flanges sa mga gilid ng bahagi) | I-realign o i-repair ang die; ayusin ang lakas ng clamping; regular na pagpapanatili |

| Soldering/Sticking | Mataas na temperatura; mahinang materyal ng die; hindi tamang ahente ng paglalabas | Biswal (nakadikit na metal sa die o magaspang na bahagi) | I-optimize ang temperatura ng die; i-upgrade ang ahente ng paglalabas; i-polish ang die cavity |

| Nakapupula | Nakulong na hangin; mabilis na paglamig; hindi sapat na bentilasyon | Pansin (mga bula sa ilalim ng surface); pagsusuri gamit ang init | Pabutihin ang bentilasyon; i-adjust ang bilis ng pagpuno/paglamig |

| Mga Bitak | Hanggan ng diwa; mabilis na paglamig; hindi tamang haluang metal | Pansin (hindi regular na mga guhit), tina na penetrante | Gamitin ang tamang haluang metal; i-optimize ang paglamig; magdagdag ng mga gilid na rounded |

| Maling Punong Bahagi/Kulang sa Punong Bahagi | Mababa ang temperatura ng metal; mabagal na pagpuno; mahinang fluidity ng haluang metal | Pansin (hindi kumpleto ang bahagi, nawawalang seksyon) | Pataasin ang bilis ng ineksyon/temperatura; mapabuti ang gating |

Mga Ugat na Sanhi at Pagwawasto ng Aksyon

Tila napakalaki? Kapag hinati-hati mo ito, karamihan sa proseso ng pagbubuhos mga depekto ay nauugnay sa iilang ugat na sanhi—tulad ng mahinang disenyo ng mold, hindi tamang setting ng proseso, o di-optimal na materyal para sa casting na pagpipilian. Halimbawa, ang gas porosity ay madalas sanhi ng nahuling hangin dahil sa hindi sapat na venting o sobrang mabilis na ineksyon. Ang shrinkage porosity ay kadalasang nauugnay sa makapal o hindi pare-parehong mga bahaging pader na lumalamig nang magkaiba-ibang bilis. Sa pamamagitan ng pagsusuri sa iyong proseso at kagamitan, madalas mong matutukoy ang pinagmulan at maisasagawa ang mga tiyak na pagwawasto—tulad ng pagbabago sa disenyo ng gating system, pag-adjust sa temperatura ng natunaw na metal, o pagpino sa geometry ng bahagi.

Upang masimulan ang mga isyu nang maaga, pagsamahin ang mga paraan ng inspeksyon:

- Mga biswal na pagsusuri: Makita ang mga depekto sa ibabaw, flash, at malinaw na mga bitak sa casting parts .

- Mga pagsubok sa pagtagas: Tiyakin ang kahigpit sa presyon para sa mga kahon o bahagi na humahawak ng likido.

- Radiograpiya (ASTM E155): Tuklasin ang panloob na porosity at mga inklusyon.

- Pagsusuri sa sukat (ASME Y14.5): Kumpirmahin ang mga pangunahing toleransya at pagkakabagay.

Epektibo diecasting ang kontrol sa kalidad ay hindi lamang nangangahulugan ng paghahanap ng mga depekto, kundi pati na rin ang dokumentasyon nito at pagtulak sa mga pagpapabuti sa proseso. Para sa aluminyo at sosa na haluang metal die castings , ang mga pamantayan ng sanggunian tulad ng ASTM B85 (aluminyo) at ASTM B86 (sosa) ay tumutulong sa pagtukoy kung ano ang katanggap-tanggap para sa iyong aplikasyon.

Mga Pamantayan na Dapat Sanggunian sa mga Ulat ng QA

Kapag sumusulat ka ng ulat sa QA o buod ng inspeksyon, ang pagbanggit sa mga pamantayan sa industriya ay nagdaragdag ng kaliwanagan at kredibilidad. Narito ang ilan sa mga pinakakilalang pamantayan at gabay para sa die castings :

- ASTM B85 para sa mga die cast na aluminoy na haluang metal

- ASTM B86 para sa mga die cast na sints na haluang metal

- ASTM E155 para sa radiographic na inspeksyon ng mga casting

- NADCA Product Specification Standards para sa mga pangangailangan sa proseso at kalidad

- ASME Y14.5 para sa GD&T at dimensional tolerancing

Kasama ang mga sangguniang ito sa iyong mga ulat upang matiyak na lahat—mula sa shop floor hanggang sa kliyente—ay nakauunawa sa mga pamantayan para sa pagtanggap at mga hakbang na ginawa upang mapamahalaan ang kalidad.

- "Na-inspeksyon ang mga bahagi nang biswal at gamit ang radiograpiya ayon sa ASTM E155; walang natuklasang critical porosity."

- "Sinunod ng sampling plan ang mga gabay ng NADCA; lahat ng sukat ay napatunayan ayon sa ASME Y14.5."

- "Ang mga depekto na natukoy sa paunang batch ay naipanumbalik sa disenyo ng gating; isinagawa ang pampatawag na aksyon at muling pinagsuri."

- "Sertipikadong materyal ng casting ayon sa ASTM B85/B86 na kinakailangan para sa aplikasyon."

Sa pamamagitan ng pagsasama ng sistematikong inspeksyon, pagsusuri sa ugat ng sanhi, at pagsunod sa mga kinikilalang pamantayan, magkakaroon ka ng matibay na proseso ng pagtitiyak ng kalidad para sa anumang diecasting operasyon. Susunod, titingnan natin kung paano balansehin ang mga pangangailangan sa kalidad na ito kasama ang gastos at pagpili ng proseso—upang matulungan kang pumili ng tamang pamamaraan para sa iyong susunod na proyekto.

Mga Driver ng Gastos at Kailan Pumili ng Die Casting

Kailan Ang Tamang Pagpipilian ang Die Casting

Isipin mo na nagplaplano ka para sa isang bagong produkto at kailangan mong magdesisyon: ang die Casting ba ang pinakamainam na landas sa pagmamanupaktura? O mas angkop kaya ang CNC machining, sand casting, o kahit metal injection molding (MIM)? Ang sagot ay nakadepende sa dami ng produksyon, kumplikadong bahagi, at mga layunin sa gastos. Narito ang kailangan mong malaman tungkol sa ano ang casting ng metal at bakit natatanging ang die casting para sa ilang aplikasyon.

Ang die casting ay perpekto kapag kailangan mo ng mga libo—o sampung libo—na magkakaparehong detalyadong metal na bahagi na may mahusay na surface finish at tiyak na sukat. Masigla ang prosesong ito para sa mataas na produksyon kung saan nababayaran ang paunang pamumuhunan sa tooling sa pamamagitan ng mababang gastos bawat yunit at mabilis na cycle time. Kung ang iyong proyekto ay nangangailangan ng kumplikadong geometry, manipis na pader, at pare-parehong sukat sa bawat piraso, alloy die casting o pantulong na permanenteng casting ay madalas na pinakamatalinong pagpipilian.

Mga Driver ng Gastos na Nagpapabago

Bakit iba-iba ang gastos sa pagitan ng casting at mga uri ng casting ? Ang sagot ay nakasalalay sa mga pangunahing driver ng gastos na ito:

- Kumplikado ng tooling at mga kavidad: Ang bakal na dies para sa die casting ay nangangailangan ng malaking paunang pamumuhunan, lalo na para sa multi-cavity tools na nagpapataas ng output. Mas mura ang mas simpleng mold sa sand casting ngunit mas hindi matibay.

- Oras ng siklo: Ang die casting ay nagbibigay ng mabilis na cycles (ilang segundo hanggang minuto), na nagiging epektibo para sa malalaking batch. Mas mabagal ang sand casting at MIM, na nakakaapekto sa throughput at labor costs.

- Presyo ng haluang metal: Ang gastos ng paghuhulma ng metal na aluminum ang mga haluang metal o iba pang metal ay maaaring makaapekto sa kabuuang presyo ng bahagi, lalo na para sa malalaki o mabibigat na komponen.

- Estratehiya sa pag-recycle at pagbawi: Ang die casting ay gumagawa ng mas kaunting kalawang bawat bahagi kumpara sa machining, at ang sobrang materyales ay madalas na nirerecycle. Ang sand casting ay maaaring magkaroon ng mas mataas na basura dahil sa mga mold na isang beses gamitin lang.

- Mga Pangalawang Operasyon: Dagdag na machining, pagpapakinis, o hakbang sa pag-aassemble ay nagdaragdag sa kabuuang gastos, anuman ang proseso.

- Antas ng hindi pagkakasunod: Ang mga depekto, paggawa muli, at mga hakbang sa kontrol ng kalidad ay nakakaapekto sa tunay na gastos ng bawat pamamaraan.

Ang pag-unawa sa mga salik na ito ay nakakatulong upang timbangin ang kabuuang gastos—hindi lang ang presyo ng unang bahagi, kundi ang tunay na gastos sa buong produksyon mo.

Decision Matrix para sa Pagpili ng Proseso

Hindi pa rin sigurado kung aling landas ang dapat tahakin? Ito ay isang talahanayan ng paghahambing na nagpapakita ng mga kalakasan at kalakip na kompromiso ng bawat paraan, upang matulungan kang makita kung paano isinasama ang die casting sa bawat isa casting at mga uri ng casting mga pagpipilian:

| Proseso | Kumplikadong Anyo ng Bahagi | Pinakamainam na Volume | Katapusan ng ibabaw | Toleransiya | Karaniwang Lead Time |

|---|---|---|---|---|---|

| Die Casting | Katamtaman hanggang Mataas | 10,000 pataas | Makinis, detalyadong ibabaw | Mahirap | Katamtaman (matapos ang tooling) |

| Cnc machining | Napakataas (halos walang limitasyon) | 1–1,000 | Mahusay | Napakasikip | Maikli (walang tooling) |

| Siklab sa balatok | Katamtaman hanggang Mataas | 100–10,000 | Mas magaspang, nangangailangan ng pagkumpleto | Maluwag hanggang katamtaman | Mas mahaba (paghahanda ng tooling/mold) |

| MIM (Metal Injection Molding) | Napakataas (maliit, kumplikadong bahagi) | 10,000 pataas | Mahusay, madalas nangangailangan ng sintering | Maganda para sa maliit na detalye | Matagal (tooling, sintering) |

Halimbawa, kung ilulunsad mo ang bagong electronics enclosure at inaasahang aabot sa 50,000 yunit, ang die casting ay nag-aalok ng pinakamahusay na kombinasyon ng bilis, detalye, at gastos. Para sa ilang prototype o lubhang kumplikadong isahan, mas nababaluktot ang CNC machining. Kung malaki ang bahagi at hindi kritikal ang surface finish, mas mababa ang pasukan sa gastos ng sand casting. At para sa napakaliit, napakakomplikadong hugis sa mataas na dami, ang MIM ang nagbibigay ng hindi kayang abutin ng ibang proseso.

Simpleng Worksheet: Pagtataya ng Gastos Bawat Yunit

Handa nang kalkulahin ang mga numero? Gamitin ito hakbang-hakbang na worksheet upang matantya ang iyong gastos bawat yunit para sa anumang metal casting aluminum o iba pang proseso:

- Ilagay ang gastos sa tooling: Magkano ang unang pamumuhunan para sa mga matris o mga bulate?

- Tinatayang inaasahang dami: Ilang bahagi ang plano mong gawing produkto?

- Bilangin ang amortized tooling bawat bahagi: Hatiin ang gastos sa tooling sa kabuuang dami.

- Magdagdag ng gastos sa materyal bawat bahagi: Isama ang presyo ng paghuhulma ng metal na aluminum liga o pinili na metal.

- Magdagdag ng panahon ng paggawa at panahon ng siklo: Factor sa bilis ng produksyon at gastos ng operator.

- Isama ang scrap/pagbawi at pagpapakumpleto: Tantyahin ang basura, pagkumpuni, at anumang pangalawang operasyon.

- Kabuuan para sa kabuuang gastos bawat yunit: Pagsamahin lahat ng nabanggit para sa realistikong presyo ng bahagi.

Sa pamamagitan ng pagpuno sa worksheet na ito, makakakuha ka ng malinaw na larawan tungkol sa ekonomiya sa likod ng bawat casting at mga uri ng casting paraan—at magagawa ang mapagbatayan na desisyon para sa iyong susunod na proyekto.

Habang binibigyang-pansin ang iyong mga opsyon, tandaan: ang die casting ay nagbibigay ng hindi matatawaran na kahusayan para sa mataas na dami at eksaktong mga bahagi, ngunit hindi laging ang sagot para sa bawat proyekto. Sa susunod na bahagi, tatalakayin natin kung paano ihahambing ang die casting sa forging para sa mga aplikasyon na nangangailangan ng pinakamataas na lakas at tibay.

Die Casting o Forging para sa Lakas at Saklaw sa Automotive

Die Casting Versus Forging sa Automotive

Kapag ikaw ay nagdidisenyo ng mga bahagi para sa automotive, ang pagpili sa pagitan ng auto diecasting at ang pag-iit ay hindi lamang tungkol sa gastos. Ito ay tungkol sa pagtupad sa mga hinihingi na kinakailangan para sa pagganap, pagiging maaasahan, at manufacturability. Mukhang kumplikado? I-break ito: ang pag-cast at pag-iitlog ay parehong hugis ng metal, ngunit ginagawa nila ito sa pangunahing iba't ibang mga paraan, na nagreresulta sa magkakaibang mga katangian at pinakamahusay na mga application.

Sa die Casting , ang nabubulok na metal (madalas na aluminyo o magnesium) ay injected sa ilalim ng mataas na presyon sa isang matrix ng bakal, na nakakakuha ng mga pinong detalye at nagbibigay-daan sa manipis na dingding, kumplikadong mga geometry. Ito ang gumagawa nito na mainam para sa mga malaking bahagi tulad ng mga bahay ng transmission, mga takip ng engine, o mga komplikadong bracket kung saan mahalaga ang katumpakan at kosmetiko.

Ang forging naman ay gumagamit ng mga pilit na kompresyon upang baluktutin ang mga pinainit na metal na billet sa pagitan ng mga dies, na nag-aayos sa istruktura ng binhi at lumilikha ng lubhang matibay at matibay na mga bahagi. Ito ang pamantayang ginto para sa mga bahagi ng sasakyan na may mataas na karga at kritikal sa kaligtasan tulad ng mga suspension arm, hubs, o drivetrain yokes—kung saan ang lakas, paglaban sa pagkapagod, at tibay ay pinakamahalaga.

Kung Saan Namumukod-tangi ang Bawat Proseso

| Solusyon/Proseso | Mekanikal na pagganap | Kalayaan sa Disenyong | Oras ng Paggugol | Kakayahang Palawakin |

|---|---|---|---|---|

| Mga Bahaging Nauunat sa Sasakyan (sertipikado sa IATF 16949) | Higit na lakas, paglaban sa pagkapagod, at pagtama dahil sa napapabuting daloy ng binhi at mga de-kalidad na mainit na forging dies | Katamtaman—pinakamainam para sa matibay, mga hugis na may pasan; hindi gaanong angkop para sa lubhang kumplikado o manipis na anyo | Mabilis, na may die design at paggawa sa loob ng planta upang bawasan ang oras ng pagpoproseso | Nasusukat mula sa prototyping hanggang sa mas malaking produksyon; pinagkakatiwalaan ng higit sa 30 pandaigdigang brand ng sasakyan |

| Auto Diecasting (Aluminum o Magnesium) | Magandang lakas at kabigatan; mahusay para sa manipis na pader, magaan, at detalyadong mga bahagi, ngunit mas mababa ang paglaban sa pagod at pag-impact kumpara sa forging | Mataas—nagbibigay-daan sa mga kumplikadong hugis, panloob na daanan, at detalyadong estetikong detalye | Katamtaman—nangangailangan ng paunang pamumuhunan sa die, ngunit mataas ang bilis ng produksyon para sa malalaking gawa | Perpekto para sa mataas na produksyon ng mga kumplikadong hugis |

Ito ang iyong mapapansin: Hindi matatalo ang forging sa mekanikal na pagganap, lalo na sa mga aplikasyon kung saan hindi pwedeng ikompromiso ang kaligtasan at pagdala ng bigat. Ang kontroladong grain flow at kompaksiyon ay nangangahulugan na ang mga forged na bahagi ay mas magaan ngunit mas matibay kumpara sa mga katumbas nitong cast. Samantala, aluminium die casting at nangungunang die casting ang mga pamamaraan ay nagtatamo kapag gumagawa ng mga biswal na kumplikado, manipis ang pader, o mataas na dami ng mga bahagi kung saan ang tumpak at detalye ang pangunahing kailangan.

Paano Pumili para sa Kaligtasan at Pagganap

Nag-aalinlangan pa rin? Itanong mo sa sarili mo ang mga sumusunod:

- Kailangan bang matiis ng aking bahagi ang mataas na bigat, pag-impact, o paulit-ulit na tensyon? Kung oo, mas ligtas ang forging—isipin ang mga suspension arms o drivetrain components.

- Nakakomplikado ba ang geometry, may manipis na pader o kinakailangan sa hitsura? Malaki ang posibilidad na die casting ang solusyon, lalo na para sa mga housing, takip, o bracket kung saan mahalaga ang hitsura at katumpakan.

- Gaano kahalaga ang lead time at flexibility ng supply chain? Ang forging na may in-house die design ay maaaring maghatid ng mga bahagi nang mabilis at maka-angkop sa mga pagbabago, habang ang die casting ay mahusay sa pag-scale up para sa malalaking production run.

- Ano naman ang tungkol sa gastos? Karaniwan ay mas mataas ang paunang gastos sa tooling at bawat bahagi sa forging para sa mga komplikadong hugis, ngunit nagdudulot ito ng halaga sa mekanikal na performance at nababawasan ang basura para sa mga high-strength application. Ang die casting ay nag-aalok ng cost efficiency sa malalaking produksyon para sa mga hindi gaanong demanding na workload.

Ang pagpili sa pagitan ng forging at die casting ay nakadepende sa tungkulin ng iyong bahagi: bigyan ng prayoridad ang forging para sa pinakamataas na lakas at kakayahang lumaban sa pagod, at ang die casting para sa mataas na volume, detalyado, o manipis na pader na automotive parts.

Para sa mga koponan na nagtatasa ng pagpapanday para sa mga bahagi na may mataas na karga at kritikal sa kaligtasan, isaalang-alang ang pakikipagsosyo sa isang IATF 16949 sertipikadong tagapagkaloob tulad ng Shao-Yi Automotive Forging Parts . Ang kanilang end-to-end na produksyon—mula sa mabilisang prototyping hanggang sa mas malaking produksyon—ay tinitiyak na ang iyong mga bahagi ay sumusunod sa pinakamataas na pamantayan ng kalidad sa automotive, na may mabilis na lead time at global shipping upang manatiling nakasunod ang iyong proyekto.

Habang patuloy kang umaasenso, tandaan na ang tamang proseso ay ang tumutugma sa iyong teknikal na pangangailangan, dami ng produksyon, at inaasahang kalidad. Sa huling bahagi, ipapaliwanag namin ang mga pangunahing punto at gabayan ka tungo sa mapanuring pagpili ng proseso para sa iyong susunod na automotive na proyekto.

Ano ang Dapat Hanapin sa Kalidad ng Die-Cast na Laruan

Paano Makilala ang Isang Mahusay na Ginawang Die-Cast na Modelo

Nakakuha ka na ba ng die-cast na laruan at nagtaka kung ito nga ba ay tunay na karapat-dapat kolektahin? Maging ikaw ay baguhan sa diecast & toy vehicles o isang bihasang mahilig, ang pag-alam kung ano ang dapat suriin ay makapagbubukod ng resulta. Ang mga die-cast na laruan—lalo na ang die cast toy cars —ay pinahahalagahan dahil sa kanilang pagkakagawa, detalye, at tibay, ngunit hindi lahat ay magkakapareho ang kalidad. Narito kung paano makikilala ang de-kalidad na produkto nang mabilisan:

- Timbang at Balanse: Dapat pakiramdam na matibay at balanseng-balanseng hawakan ang tunay na die-cast na laruan kotse. Ginagamit ang sosa na gawa sa zinc alloy o metal composite sa tunay na die-cast metal na sasakyan, kaya may kabigatan ito kumpara sa mga plastik na peke.

- Malinis na Parting Lines: Suriin kung saan nagtatagpo ang dalawang bahagi ng mold—dapat maayos at minimal ang mga linya, hindi magaspang o baklad.

- Makinis at Pare-parehong Pinta: Dapat walang butas, tumutulo, o hindi pare-pareho ang kulay. Ang de-kalidad na modelo ay may malinaw at makintab na pintura na sumasakop nang pantay sa lahat ng ibabaw.

- Naka-align na Axles at Gulong: Tiyaking tuwid ang lahat ng gulong, maayos ang pag-ikot, at nakatambad nang patag—ang hindi tamang alignment ng axle ay palatandaan ng mahinang produksyon.

- Malinaw na Tampos o Dekal: Ang mga logo, guhit, at iba pang marka ay dapat matalas, tumpak na nakalagay, at malinis mula sa anumang paninilaw o hindi tamang pagkakaayos.

- Tumpak na Proporsyon Ayon sa Scale: Ang kabuuang hugis at detalye ay dapat magkatugma nang malapit sa tunay na sasakyan, na may realistiko mga katangian tulad ng salamin, grill, at looban.

Tip: Sa ilalim ng matinding liwanag, suriin ang sobrang pintura at subukan ang paggalaw ng gulong—dapat maluwag itong gumulong at malinis ang pintura sa mga gilid.

Importante ang Packaging at Mga Marka

Ang packaging at mga marka ay nagbibigay ng mahahalagang palatandaan tungkol sa kautintikan at kalidad. Bago idagdag ang isang die-cast toy sa iyong koleksyon, hanapin ang mga sumusunod:

- Mga Brand Logo at Paglilisensya: Ang mga tunay na diecast at laruang sasakyan ay nagpapakita ng malilinaw na logo ng brand—kadalasan sa ilalim ng hood o sa base. Ang mga lisensyadong modelo ay maaaring magsama ng mga opisyal na trademark o hologram sticker.

- Mga Label sa Sukat at Serye: Dapat malinaw na nakalagay sa pakete ang sukat ng modelo (tulad ng 1:18, 1:24) at kung minsan ay ang numero ng bahagi o serye.

- Bansa ng Pagmamanupaktura: Karaniwang nakalista sa tunay na mga modelo ang bansa o lugar ng paggawa, maaaring nasa pakete o sa mismong modelo.

- Mga Barcode at Babala sa Kaligtasan: Ang opisyal na pakete ay may mga barcode, babala sa kaligtasan, at kung minsan ay sertipiko ng autentisidad para sa mga limitadong edisyon.

- Kalidad ng Pakete: Hanapin ang malinaw na larawan, tamang baybay, at matibay na materyales. Ang mga larawang mababa ang resolusyon o may maling baybay na pangalan ng tatak ay senyales ng peke. [Toykoo] .

Tandaan, bagaman makatutulong ang pakete at mga marka, tanging ang tagagawa o isang pinagkakatiwalaang eksperto lamang ang makapagtitiyak sa katunayan. Kung may duda, tingnan ang mga forum ng kolektor o mga sangguniang litrato mula sa opisyal na website ng tatak.

Mga Tip sa Pag-aalaga at Pag-iimbak

Gusto mo bang manatiling kumikinang ang iyong koleksyon ng diecast cars sa loob ng maraming taon? Mahalaga ang tamang pag-aalaga at pag-iimbak upang mapanatili ang halaga at ganda ng iyong diecast & toy vehicles [Hearns Hobbies] :

- Iwasan ang Kakahuyan: Imbakin ang mga modelo sa tuyo na kapaligiran upang maiwasan ang oksihenasyon at korosyon sa mga metal na bahagi.

- Protektahan laban sa UV Light: Maaaring mapahina ng liwanag ng araw ang pintura at masira ang goma ng mga gulong—gamit ng display case na may proteksyon laban sa UV.

- Alisin ang Alikabok nang Regular: Gamitin ang malambot na sipilyo o nakapresyong hangin upang mahinang alisin ang alikabok sa mga ibabaw at maliit na detalye.

- Hawakan nang Maingat: Laging iangat ang mga modelo sa kanilang pinakamatibay na bahagi, hindi sa mga salamin, antena, o iba pang delikadong detalye.

- Gumamit ng Tamang Display Cases: Ang mga nakasara na kahon ay nagpoprotekta laban sa alikabok, aksidenteng pagbundol, at mga pagbabago sa kapaligiran.

Para sa mas malalim na paglilinis o pagmemeintina, manatili sa mga espesyalisadong gamit sa paglilinis ng modelo—iwasan ang matitinding household products na maaaring makasira sa pintura o dekala.

Kung gusto mong malaman ang halaga o kakauntuan ng isang die cast metal vehicle , sumali sa mga komunidad ng kolektor o kumuha ng gabay mula sa mapagkakatiwalaang online resources. Ang mga may karanasang hobbyista ay maaaring magbigay ng insight at tumulong sa iyo na patunayan ang katotohanan nito nang hindi umaasa sa hula lamang.

Sa pamamagitan ng pagsunod sa mga tip na ito, masisiguro mong mananatiling pinagmamalaki at nagbibigay saya ang iyong koleksyon ng die-cast na laruan sa loob ng maraming taon. Susunod, ipapakilala namin ang mga pangunahing aral at gabay sa tamang pagpili ng proseso para sa susunod mong proyekto.

Mula sa Kahulugan hanggang sa Mapanuri na Pagpili ng Proseso

Mga pangunahing ideya na maaari mong gawin

- Die Casting ay tungkol sa tumpak na pagganap, paulit-ulit na proseso, at bilis—pinapasok ang nagbabagang metal sa mga bakal na hulma sa ilalim ng mataas na presyon upang makalikha ng mga bahagi na may manipis na pader, detalyadong anyo, at pare-parehong kalidad. Kung ikaw ay naghahanap para sa ano ang die cast na metal o ano ang diecast , tandaan na ito ay isang proseso (at produkto) na nagdudulot ng mataas na dami at lubhang tumpak na metal na sangkap.

- Ang die casting ay pinakamainam para sa mga aplikasyon kung saan mahalaga ang eksaktong sukat, mahusay na surface finish, at mas malaking produksyon—tulad ng mga kahon ng electronics, automotive bracket, lighting fixture, at mga consumer goods.

- Para sa mga bahagi na dapat tumagal sa matitinding bigat, paulit-ulit na tensyon, o kritikal na kalagayan sa kaligtasan—tulad ng suspension arms, axles, o drivetrain yokes— pag-iimbak ay ang pinipiling pamamaraan. Ang forging process ay nagkokompakto at nag-aayos sa istruktura ng grano ng metal, na nagreresulta sa napakahusay na lakas, kakayahang lumaban sa pagod, at maaasahan.

- Ang pagpili sa pagitan ng die casting at forging ay hindi lamang tungkol sa gastos; ito ay tungkol sa pagtutugma ng proseso sa tungkulin ng iyong bahagi. Ang die casting ay mahusay para sa mga kumplikadong hugis at mataas na dami, samantalang ang forging ay hindi matatalo pagdating sa mekanikal na pagganap sa mahigpit na automotive at industriyal na aplikasyon.

- Pag-unawa kahulugan ng diecast at ano ang die-cast tumutulong sa iyo na malinaw na maipahayag ang mensahe sa mga supplier at gumawa ng mas matalino at mas-hemat na desisyon sa produksyon.

Mula Sa Konsepto Hanggang Produksyon

- Suriin ang mga kinakailangan ng iyong bahagi: Kailangan ba nito ng magulong heometriya, manipis na pader, at kaakit-akit na hitsura? O ang pinakamataas na lakas at tibay ang nasa unang prayoridad?

- Konsultahin ang mga may karanasang tagagawa nang maaga—humingi ng puna tungkol sa pagpili ng materyales, proseso, at mga pamantayan sa kalidad upang maiwasan ang mapaminsalang pagbabago sa disenyo sa huli.

- Isama sa pagpapasya ang dami ng produksyon, oras ng paghahatid, at kabuuang gastos sa buong lifecycle—hindi lamang ang presyo ng unang bahagi.

- Kung ang iyong proyekto ay nakatuon sa mga bahagi ng sasakyan na may mataas na karga at kritikal sa kaligtasan, isaalang-alang ang isang forging na solusyon na sumusunod sa pandaigdigang pamantayan ng kalidad at nag-aalok ng masukat na mga opsyon sa pagmamanupaktura.

Kung napagpasyahan mo nang ang forging ang tamang landas para sa iyong mga bahagi ng sasakyan na may mataas na lakas, galugarin ang Mga Parte ng Pagkakalubog para sa Automotibo —na ginawa sa isang pasilidad na sertipikado sa IATF 16949, na may end-to-end na solusyon mula sa prototyping hanggang sa mass production at maaasahang pandaigdigang pagpapadala.

Sa pamamagitan ng pag-unawa sa mga pangunahing pagkakaiba at angkop na aplikasyon ng bawat proseso, matataya mong harapin ang susunod mong proyekto nang may kumpiyansa—tinitiyak na maibibigay nito ang kalidad, pagganap, at gastos. Maging ikaw man ay nagsusuri ng die cast na housing o nagfo-forging ng matitibay na bahagi ng sasakyan, ang mapag-isipang pagpili ng proseso ay ang pinakamahusay mong kasangkapan para sa tagumpay sa pagmamanupaktura.

Mga Karaniwang Tanong Tungkol sa Die Casting

1. Ano ang ibig sabihin ng die cast sa pagmamanupaktura?

Sa pagmamanupaktura, ang die cast ay tumutukoy sa isang proseso kung saan ang naglalagablab na metal ay ipinasok sa ilalim ng mataas na presyon sa isang bakal na mold, na lumilikha ng mga bahagi na tumpak at matibay na may makinis na tapusin. Ang pamamarang ito ay mainam para sa paggawa ng mga hugis na kumplikado sa malalaking dami, na karaniwang ginagamit para sa mga bagay tulad ng mga sangkap ng sasakyan, takip ng appliance, at mga kahon ng electronics.

2. Paano naiiba ang die casting sa sand casting?

Ang die casting ay gumagamit ng muling magagamit na bakal na mga mold at mataas na presyong ineksyon upang makalikha ng mga bahagi na may mahigpit na toleransya at makinis na ibabaw, na angkop para sa mas malaking produksyon. Sa kabila nito, ang sand casting ay kasangkot sa pagbuhos ng naglalagablab na metal sa mga isang-gamit na buhangin na mold, na nagreresulta sa mas magaspang na tapusin at mas mainam para sa mas maliit na dami o mas malalaking bahagi.

3. Anu-ano ang karaniwang materyales na ginagamit sa die casting?

Ang pinakakaraniwang materyales sa die casting ay aluminum at semento. Ang aluminum ay pinipili dahil sa magaan nito, lakas, at paglaban sa init, samantalang ang semento ay mahusay sa pagkuha ng maliliit na detalye at pagkamit ng masikip na toleransya. Hindi karaniwang ginagamit ang bakal sa mataas na presyong die casting dahil sa mataas nitong punto ng pagkatunaw.

4. Gawa ba sa tunay na metal ang die cast na laruan kotse?

Oo, karaniwang gawa sa mga haluang metal tulad ng semento o aluminum ang die cast na laruan kotse gamit ang proseso ng die casting. Ito ang nagbibigay sa kanila ng matibay at mabigat na pakiramdam, at nagbibigay-daan para sa detalyadong disenyo at matibay na konstruksyon, na nagmemerkado sa kanila mula sa mga plastik na laruan.

5. Ano ang ibig sabihin ng pariralang 'the die is cast', at may kaugnayan ba ito sa die casting?

Ang parirala na 'the die is cast' ay nangangahulugang isang desisyon na ginawa na at hindi na mababago, na tumutukoy sa paghagis ng dice sa isang laro ng tsansa. Hindi ito kaugnay sa proseso ng paggawa na die casting, na kung saan kasangkot ang pagbuo ng mga metal na bahagi sa loob ng mga mold.

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —