Steel Laser Cutting Decoded: Thickness Limits, Costs, and Edge Quality Revealed

What Steel Laser Cutting Actually Does to Metal

Ever wondered how manufacturers create those perfectly precise steel components you see in everything from car chassis to industrial machinery? The answer lies in steel laser cutting—a process where a high-density laser beam irradiates the steel surface, melting the material at the beam spot to carve out custom parts with remarkable accuracy.

So, what is laser cutting exactly? At its core, it's a thermal separation process. A focused beam of high-powered laser light—concentrated to just a few millimeters in diameter—travels along a programmed path, melting, burning, or vaporizing the steel in its way. An assist gas then blows away the molten material, leaving behind a clean, precise cut edge. This laser metal cutting method has become the gold standard for metal cutting operations requiring tight tolerances and complex geometries.

How Focused Light Transforms Solid Steel

Imagine concentrating enough energy into a pinpoint beam to slice through solid steel like a hot knife through butter. That's essentially what happens during the cutting process. The laser beam delivers intense thermal energy to a microscopic area, raising the steel's temperature past its melting point almost instantaneously.

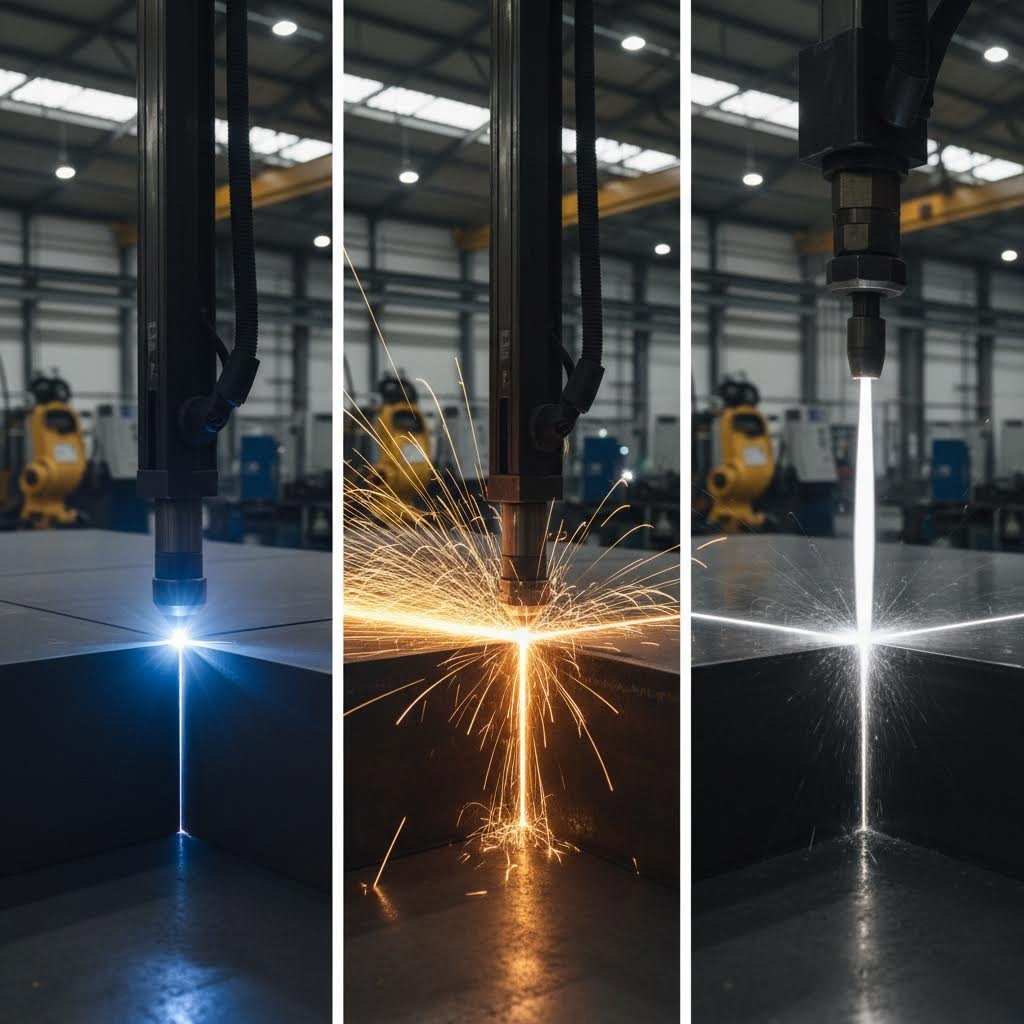

Here's where things get interesting. Unlike generic metal cutting approaches, cutting laser metal requires understanding how steel specifically behaves under extreme heat. The process works through three primary mechanisms:

- Melt cutting: The laser melts the steel while an inert gas (typically nitrogen) blows the molten material away

- Flame cutting: Oxygen assists the laser, creating an exothermic reaction that adds cutting power

- Vaporization cutting: For extremely thin materials, the laser vaporizes the steel directly

The choice between these methods depends on your steel type, thickness, and the edge quality you need—factors we'll explore throughout this guide.

The Science Behind Thermal Separation

Why does steel demand special attention compared to aluminum or copper? It comes down to three critical properties that make this metal uniquely challenging.

First, steel's relatively low thermal conductivity works in your favor. Unlike aluminum, which rapidly disperses heat throughout the material, steel keeps thermal energy localized at the cut zone. This allows for precise cuts with minimal heat-affected zones—particularly beneficial when working with intricate designs or thin sheets.

Steel's dense structure and high carbon content require precise calibration of laser equipment. The localized heating enables clean cuts, but manufacturers must carefully control cutting speeds and cooling methods to prevent warping or distortion in larger pieces.

Second, steel's higher melting point means you need adequate laser power to achieve complete penetration. A 1000W fiber laser can cut through approximately 10mm of carbon steel, but stainless steel of the same thickness demands significantly more power due to its alloying elements.

Third, steel forms oxide layers during oxygen-assisted cutting. When using oxygen as an assist gas for carbon steel, an exothermic reaction occurs that actually aids the cutting process—but it also affects the edge chemistry. Stainless steel, meanwhile, typically requires nitrogen to preserve its corrosion-resistant properties.

Understanding these fundamentals isn't just academic. They directly influence your choice of laser type, power settings, assist gases, and cutting speeds—decisions that ultimately determine whether your steel laser cutting project succeeds or fails.

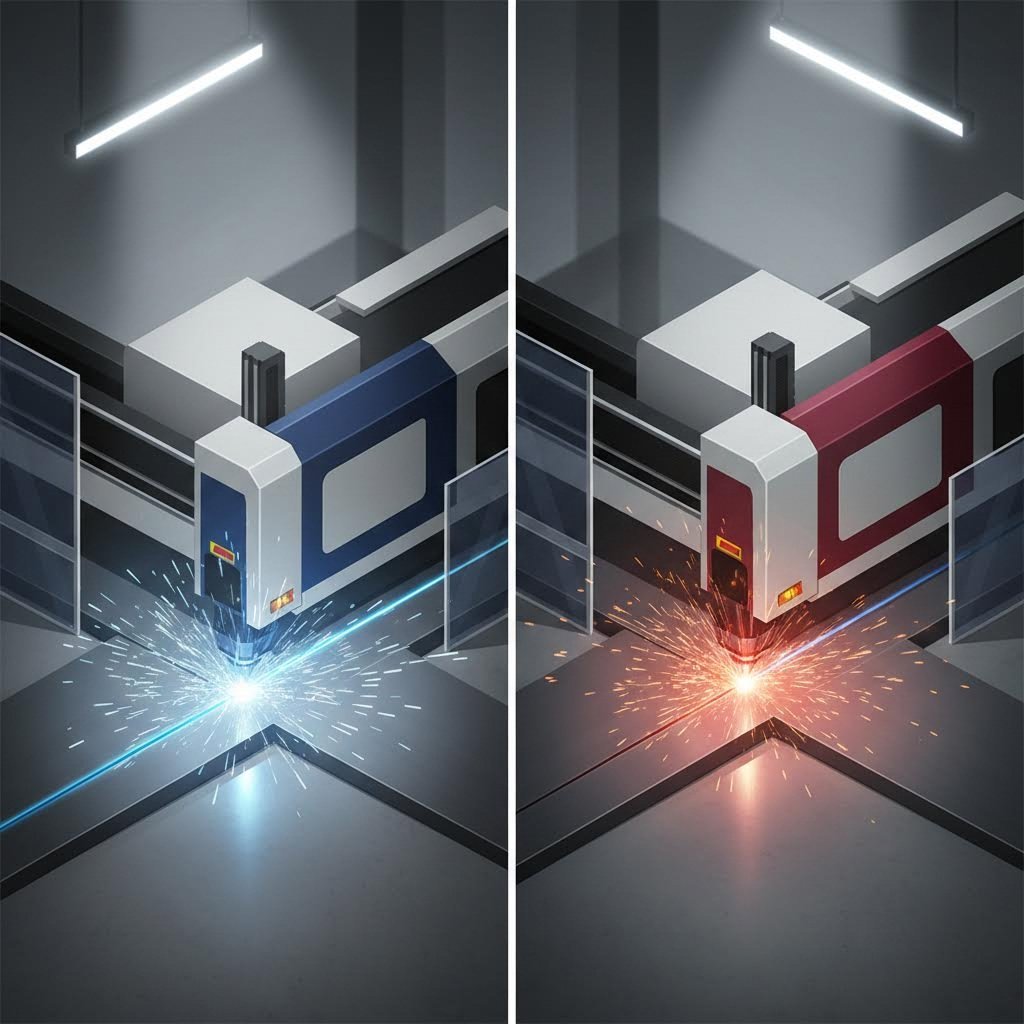

Fiber Laser vs CO2 Laser for Steel Applications

Now that you understand how steel responds to laser energy, the next question becomes: which laser type should you choose? If you've researched any laser cutting machine for metal, you've likely encountered two dominant technologies—fiber lasers and CO2 lasers. Both can cut steel, but they do so in fundamentally different ways that affect your speed, costs, and final results.

Here's the reality: fiber lasers have captured approximately 60% of the metal laser cutting market as of 2025, largely displacing CO2 systems in steel fabrication facilities worldwide. But does that mean CO2 is obsolete? Not quite. Let's break down exactly what makes each technology tick—and when one outperforms the other for your specific steel cutting needs.

Fiber Lasers and Their Steel-Cutting Advantages

Think of fiber lasers as the precision athletes of the metal laser cutter world. These solid-state systems generate light at approximately 1064 nm (1.07 µm) wavelength using optical fibers doped with rare-earth elements like ytterbium. Why does this matter for steel? Because metals absorb this shorter wavelength far more efficiently than the longer CO2 wavelength.

When that 1 µm beam hits carbon steel or stainless steel, the absorption rate dramatically exceeds what you'd see with a CO2 laser. This translates directly into faster cutting speeds—often two to five times faster on thin to medium sheet steel compared to equivalent-power CO2 systems.

The advantages stack up quickly:

- Superior efficiency: Modern fiber lasers achieve 30-50% wall-plug efficiency, meaning they convert electrical input into laser power with minimal waste. A 6 kW fiber system draws roughly 22 kW of electrical power—compared to 65 kW for a 6 kW CO2 machine.

- Minimal maintenance: With no mirrors, sealed gas tubes, or complex optical paths, fiber systems require only $200-400 in annual maintenance versus $1,000-2,000 for CO2 equipment.

- Extended lifespan: Diode pumps in fiber lasers last over 100,000 hours—approximately 10 times longer than CO2 laser components.

- Exceptional beam quality: Near-diffraction-limited beams produce extremely small focal spots, enabling narrower kerfs, tighter tolerances (±0.05 to ±0.20 mm), and cleaner edges.

For fabrication shops processing primarily carbon steel, stainless steel, and aluminum sheets under 20mm thickness, fiber lasers deliver compelling returns. Industry analysis shows typical payback periods of 12-18 months, with total cost of ownership savings exceeding $520,000 over five years compared to CO2 systems.

When CO2 Lasers Still Make Sense for Steel

Does fiber dominance mean your existing CO2 laser cut metal machine belongs in a museum? Not necessarily. CO2 lasers—operating at 10.6 µm wavelength—maintain specific advantages that keep them relevant for certain steel applications.

Consider thick plate processing. While fiber lasers can cut carbon steel up to 100mm with high-power systems, CO2 lasers often deliver superior edge quality on sections exceeding 25mm. The longer wavelength creates different thermal dynamics that some operators prefer for heavy structural steel fabrication.

CO2 systems also shine when your workflow includes non-metallic materials. If you're cutting acrylic, wood, leather, or plastics alongside your steel work, a CO2 laser for cutting machine applications provides versatility that justifies its presence. The 10.6 µm wavelength interacts efficiently with organic materials that fiber lasers struggle to process cleanly.

Additionally, the lower upfront cost of CO2 equipment—sometimes 5 to 10 times less expensive than equivalent fiber systems—makes them accessible for smaller shops or specialized thick-plate applications where cutting speed matters less than edge finish quality.

Complete Technology Comparison for Steel Cutting

Ready to see how these technologies stack up across every metric that matters for steel laser cutting? This comprehensive comparison covers the factors that directly impact your production quality and bottom line:

| Parameter | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1064 nm (1.07 µm) | 10,600 nm (10.6 µm) |

| Steel Absorption Rate | High—metals absorb 1 µm light efficiently | Lower—longer wavelength reflects more from metallic surfaces |

| Cutting Speed (Thin Steel <6mm) | 3-5x faster than equivalent CO2 power | Baseline speed |

| Cutting Speed (Thick Steel >20mm) | Comparable, with speed advantages diminishing | Competitive, often preferred for edge quality |

| Maximum Steel Thickness | Up to 100mm (carbon steel) with high-power systems | 100mm+ with oxygen assist |

| Edge Quality (Thin Materials) | Excellent—narrow kerf, minimal taper | Good—slightly wider kerf |

| Edge Quality (Thick Materials) | Good | Often superior on 25mm+ sections |

| Electrical Efficiency | 30-50% wall-plug efficiency | 10-15% efficiency |

| Power Consumption (6kW Output) | ~22 kW electrical draw | ~65 kW electrical draw |

| Annual Maintenance Cost | $200-400 | $1,000-2,000 |

| Component Lifespan | 100,000+ hours (diode pumps) | ~10,000-25,000 hours |

| Initial Equipment Cost | 5-10x higher than equivalent CO2 | Lower upfront investment |

| Reflective Metal Capability | Excellent—handles aluminum, copper, brass | Challenging—reflection issues with these metals |

| Typical ROI Period | 12-18 months | 24-30 months |

The data tells a clear story for most metal cutting laser machine applications: fiber lasers dominate steel processing under 20mm thickness, delivering faster speeds, lower operating costs, and superior precision. However, the decision isn't always straightforward.

If your projects regularly involve thick structural steel above 25mm where edge quality outweighs speed, or if you process mixed materials including non-metals, CO2 technology retains genuine value. The metal laser cutter market has evolved toward fiber dominance, but smart fabricators match their technology choice to their specific production mix.

Understanding these differences positions you to make informed decisions—but laser type is just one variable. The steel grade you're cutting introduces its own set of challenges and considerations that directly impact your results.

Which Steel Grades Work Best for Laser Cutting

You've selected your laser type—but here's what many fabricators overlook: the steel grade sitting on your cutting table matters just as much as the equipment processing it. Not all steels respond equally to laser energy. Some slice cleanly with minimal parameter adjustments, while others demand specialized techniques or produce frustrating quality issues.

Why does this happen? It comes down to chemistry. Carbon content, alloying elements, and surface conditions all influence how efficiently the laser beam penetrates and separates the material. Research from TWI confirms that material composition has a greater influence on overall laser cut quality than the combined effects of the laser cutting machine and operator—the range in cut quality for different material compositions was twice that found when the same material was processed by different operators on different machines.

Let's break down exactly which grades deliver optimal results and which ones require special handling.

Steel Alloys That Cut Like Butter

If you want predictable, high-quality cuts with minimal fuss, these steel categories should be your first choice. They offer the ideal combination of thermal properties, consistent composition, and surface characteristics that laser systems love.

Mild steel and low-carbon steel represent the gold standard for steel laser cutting. Grades like S275 and S355—commonly used structural steels—feature carbon content typically below 0.25%, which creates a forgiving processing window. Their predictable thermal behavior means you can achieve clean cuts across thickness ranges from 0.5mm up to 30mm with properly configured equipment.

What makes these grades so cooperative? Their relatively uniform composition means fewer surprises during cutting. The iron-carbon matrix absorbs laser energy consistently, creating stable melt pools that clear efficiently with assist gas. You'll notice smooth edge finishes with minimal dross formation when parameters are dialed in correctly.

CR4 (Cold Reduced Grade 4) mild steel deserves special mention for thin-gauge applications. This cold-rolled material features an exceptionally smooth surface finish that enhances cut edge quality—particularly valuable in automotive body panels and visible components where aesthetics matter as much as functionality.

Steel Grade Suitability Guide

Ready to see how different steel types stack up for laser processing? This comprehensive breakdown categorizes common grades by their laser cutting behavior:

| Category | Steel Types | Carbon Content | Laser Cutting Behavior | Recommended Thickness Range |

|---|---|---|---|---|

| Ideal | Mild steel (S275, S355), Low-carbon steel, CR4 | <0.25% | Clean cuts, wide processing window, predictable results | 0.5mm - 30mm |

| Ideal | Laser-grade steels (optimized composition) | 0.09-0.14% | Enhanced edge quality, higher cutting speeds possible | 3mm - 30mm |

| Acceptable | 304 Stainless Steel (austenitic) | <0.08% | Good cuttability, requires nitrogen assist for corrosion resistance | 0.5mm - 30mm |

| Acceptable | 316 Stainless Steel (austenitic) | <0.08% | Similar to 304, molybdenum content slightly affects thermal behavior | 0.5mm - 25mm |

| Acceptable | 430 Stainless Steel (ferritic) | <0.12% | Cuts well but more prone to edge hardening | 0.5mm - 20mm |

| Acceptable | Zintec (zinc-coated cold-rolled) | Low | Good results, zinc coating provides corrosion protection during cutting | 0.7mm - 3mm |

| Acceptable | Galvanized steel | Low | Requires fume extraction, zinc layer affects edge chemistry | 0.7mm - 5mm |

| Problematic | High-silicon steels (>0.4% Si) | Varies | Improved roughness but reduced edge squareness | Requires parameter adjustment |

| Problematic | Heavily coated/painted steels | Varies | Coatings create fumes, contaminate cut edges, reduce quality | Surface prep required |

| Problematic | Shot-blasted surfaces | Varies | Rougher cut edges compared to mill-scale or machined surfaces | Accept quality trade-off or prep surface |

Stainless Steel Laser Cutting: Understanding Grade Differences

Stainless steel laser cutting represents one of the most common—and sometimes most misunderstood—applications in metal fabrication. Yes, you can absolutely laser cut stainless steel with excellent results, but not all grades behave identically.

304 stainless steel (containing approximately 18% chromium and 8% nickel) is the workhorse of stainless laser cutting. Its austenitic structure provides excellent cuttability, and its widespread availability makes it the default choice for food processing equipment, architectural elements, and general fabrication. When you need to laser cut stainless steel for corrosion-resistant applications, 304 typically delivers the best balance of performance and cost.

316 stainless steel adds molybdenum to the mix (typically 2-3%), enhancing corrosion resistance—particularly against chlorides and marine environments. For stainless laser cutting, 316 behaves similarly to 304 but with slightly different thermal characteristics due to its molybdenum content. Expect comparable cut quality when using nitrogen as your assist gas.

The critical factor for laser cutting ss grades? Assist gas selection. Unlike carbon steel (where oxygen can enhance cutting through exothermic reaction), stainless steel typically requires nitrogen to preserve the chromium oxide layer that provides corrosion resistance. Oxygen-assisted cuts leave oxidized edges that compromise the material's protective properties.

Problem Steel Grades and How to Handle Them

Some steels fight back. Understanding why certain grades prove challenging—and what adjustments help—saves you from rejected parts and wasted material.

Silicon content presents a fascinating trade-off. TWI's research identified silicon as the most important element affecting laser cut edge quality. Here's the catch: higher silicon improves surface roughness (smoother cuts) but negatively affects edge squareness. If your steel contains more than 0.4% silicon, expect to adjust your parameters or accept some compromise in dimensional accuracy.

Heavily coated or painted steels create multiple problems. The coating vaporizes during cutting, generating fumes that can contaminate the cut edge and optics. Paint and powder coatings often contain compounds that react unpredictably with laser energy. For clean results, strip coatings from the cut path before processing.

Galvanized and zinc-coated materials require careful handling. While Zintec and galvanized steel can be cut successfully (typically in the 0.7mm to 5mm range), the zinc layer vaporizes at lower temperatures than the steel substrate. This creates zinc fumes requiring proper extraction systems and can affect edge chemistry. The results remain acceptable for most applications, but understand the trade-offs.

What about aluminum laser cutting and other reflective materials? While this guide focuses on steel, it's worth noting that materials like aluminum require different considerations entirely. You can cut aluminum effectively with fiber lasers (which handle reflective metals better than CO2), but the processing parameters differ significantly from steel applications.

Surface Preparation Requirements by Category

Your steel's surface condition directly impacts cut quality—sometimes more than you'd expect. Here's what each category demands:

For Ideal Steel Grades (Mild Steel, Low-Carbon):

- Mill scale can remain in place—research shows machining off the mill scale layer has no significant effect on laser cut quality

- Ensure material is flat and free from significant rust or heavy contamination

- Light surface oxidation is acceptable for oxygen-assisted cutting

- Store materials properly to prevent moisture accumulation and excessive corrosion

For Acceptable Grades (Stainless Steel, Coated Steels):

- Remove protective films before cutting to prevent fumes and edge contamination

- For stainless steel, ensure surfaces are clean and free from oils or lubricants

- Galvanized materials require adequate ventilation and fume extraction

- Verify zinc coating weight on galvanized steel—heavier coatings create more fumes

- Consider edge quality requirements when selecting coated vs. uncoated materials

For Problematic Grades:

- Avoid shot blasting surfaces before laser cutting—TWI research confirms shot blasting produces rougher laser cut edges compared to as-rolled or machined surfaces

- Strip paint, powder coating, and heavy coatings from cut zones

- For high-silicon steels, test cut samples to establish optimal parameters before production runs

- Document successful settings for future reference with challenging materials

Knowing which steel grades cut cleanly—and which ones demand extra attention—positions you for success. But grade selection is only part of the equation. The thickness of your steel introduces another critical variable that directly determines which laser power levels and cutting strategies will work for your project.

Steel Thickness Limits and Laser Power Requirements

You've selected your steel grade and laser type—but here's the question that makes or breaks your project: can your laser actually cut through your material thickness? This isn't just a theoretical concern. Factories regularly discover that the "maximum thickness" in marketing brochures tells only part of the story.

Here's what experienced fabricators know: there are actually three different thickness levels you should understand—the absolute maximum (possible but impractical), the quality maximum (acceptable edge finish), and the production maximum (where you make money with consistent results). Most profitable sheet metal laser cutting operations focus on that third category.

Let's decode exactly what your laser sheet metal cutter can handle—and when you need to consider alternatives.

Maximum Cutting Thickness by Laser Power

How thick can a fiber laser cut? The honest answer depends on laser power, material type, cutting gas, and the quality level you need. But you need concrete numbers to plan your projects. This comprehensive chart breaks down realistic thickness capabilities across power levels for laser cutting of metal sheets:

| Laser Power | Carbon Steel (O₂ Assist) | Stainless Steel (N₂ Assist) | Aluminum (N₂ Assist) | Best Application Focus |

|---|---|---|---|---|

| 1-2 kW | Up to 10mm | Up to 5mm | Up to 4mm | Thin sheet production, high-speed processing |

| 3 kW | Up to 16mm | Up to 8mm | Up to 6mm | First "serious" industrial laser for many shops |

| 6 kW | Up to 22mm | Up to 12mm | Up to 10mm | Best long-term ROI for general fabrication |

| 10-12 kW | Up to 30mm | Up to 20mm | Up to 16mm | Thick plate as core business, not occasional jobs |

| 15-20 kW | Up to 50mm | Up to 30mm | Up to 25mm | Heavy structural steel, specialized thick-plate work |

| 30 kW+ | Up to 100mm | Up to 50mm | Up to 40mm | Ultra-thick specialty applications |

Notice something important? Carbon steel always shows higher thickness capacity than stainless or aluminum at identical power levels. Why? When cutting carbon steel with oxygen assist gas, an exothermic reaction occurs—the oxygen literally helps burn through the material. According to industry analysis, oxygen does approximately 60% of the cutting work on steel, which is why you can push thickness limits significantly further.

Stainless steel and aluminum use nitrogen assist (a shielding gas that prevents oxidation), meaning the laser must do almost all the work alone. That's why identical power levels produce very different maximum thickness results across materials.

How Assist Gas Selection Affects Your Thickness Capabilities

Choosing between oxygen and nitrogen isn't just about edge finish—it directly determines how thick you can cut. Understanding this relationship helps you match your sheet metal laser cutting machine capabilities to your project requirements.

Oxygen-assisted cutting (carbon steel):

- Enables 30-50% thicker maximum cuts compared to nitrogen on the same material

- Creates an exothermic reaction that adds cutting energy

- Produces an oxide layer on cut edges—acceptable for many structural applications

- Gas consumption runs 10-15 times lower than nitrogen, reducing operating costs

- Speed is limited by the burning process, not laser power (a 1500W and 6000W laser cut thin steel at similar speeds with oxygen)

Nitrogen-assisted cutting (stainless steel, aluminum, or premium carbon steel edges):

- Produces oxide-free edges ready for welding or powder coating without secondary operations

- Cutting speed directly correlates with laser power—more watts equals faster processing

- Maximum thickness is reduced compared to oxygen on carbon steel

- Higher gas consumption increases operating costs as thickness increases

- Essential for preserving corrosion resistance on stainless steel cuts

In thin steels, if a laser user can increase their processing speeds and produce more parts with better quality at either the same or slightly greater cost, then nitrogen should be strongly considered as the assist gas.

The practical implication? If you're laser cutting steel sheet up to 6mm and need paint-ready edges, nitrogen makes sense despite higher gas costs. For thick structural carbon steel where appearance matters less than penetration, oxygen extends your maximum capability significantly.

When Your Steel Is Too Thick for Laser

Here's a truth that marketing brochures won't tell you: just because a laser can cut a certain thickness doesn't mean it should. Pushing thickness limits creates real production consequences.

When you approach maximum thickness on any laser cut metal sheets operation, expect these trade-offs:

- Dramatically slower cutting speeds: Thickness always trades speed for stability—production time can increase 5-10x compared to optimal thickness ranges

- Increased edge roughness: Dross formation, striations, and surface irregularities become more pronounced

- Higher gas consumption: Thick plates require higher assist gas pressures and flow rates

- Greater heat-affected zones: More thermal energy input means more potential for warping or metallurgical changes

- Reduced consistency: At maximum limits, small parameter variations cause bigger quality swings

When does laser cutting stop making sense? Consider alternatives when:

- Your carbon steel exceeds 30-35mm and you need production-level throughput

- Edge quality requirements are critical on materials near maximum thickness

- Cutting speed matters more than precision for heavy plate work

- Your laser cutting machine sheet metal capability simply can't reach the required thickness

For these situations, plasma cutting (handles thick plate efficiently), waterjet cutting (no heat-affected zone), or oxy-fuel cutting (cost-effective for very thick carbon steel) may deliver better results. Smart fabricators match the process to the job rather than forcing every project through a single technology.

Practical Implications for Project Planning

Ready to apply these thickness parameters to your actual projects? Here's what the numbers mean for your production decisions:

- For daily production focus on 80% of maximum thickness: If your 6kW laser cuts 22mm carbon steel maximum, plan production around 16-18mm for consistent quality and speed

- Match power to your typical workload: Many factories achieve best ROI in the 3-12mm daily range—buying 20kW capacity for occasional thick plate jobs often delivers poor returns

- Budget assist gas costs realistically: Nitrogen consumption increases significantly with thickness—factor this into per-part pricing

- Plan for secondary operations when pushing limits: Near-maximum thickness cuts may require grinding, deburring, or other finishing before assembly

- Consider outsourcing extreme thickness: Occasionally cutting 30mm+ plate? Outsourcing may cost less than owning equipment sized for it

Understanding these thickness limits positions you to specify realistic requirements and select appropriate equipment. But thickness is just one variable in the cutting equation—how does laser technology compare to plasma, waterjet, and mechanical methods when all factors are considered?

Laser vs Plasma vs Waterjet for Steel Cutting

You've got steel to cut—but laser technology isn't your only option. When searching for plasma cutting near me or evaluating waterjet services, you're facing a decision that affects your project's quality, timeline, and budget. The challenge? Most comparisons gloss over the specific nuances that matter for steel applications.

Here's what experienced fabricators understand: each cutting method excels in different scenarios. A cnc plasma cutter dominates thick structural steel where speed trumps precision. Waterjet preserves material properties when heat damage isn't acceptable. Mechanical methods still make sense for certain applications. And laser cutting? It occupies a sweet spot that often—but not always—delivers the best balance for steel projects.

Let's break down exactly how these technologies perform when cutting steel, so you can match the right method to your specific requirements.

Four Cutting Technologies Face Off on Steel

Sounds complex? It doesn't have to be. Each technology operates on fundamentally different principles that create predictable strengths and limitations for steel cutting.

Laser cutting focuses intense light energy to melt or vaporize steel along a programmed path. As we've explored throughout this guide, this thermal process delivers exceptional precision on thin to medium steel sheets, with cutting speeds that make it economically attractive for production volumes.

Plasma cutting uses an electrical arc and compressed gas to create a superheated plasma jet—reaching temperatures over 30,000°F—that melts through conductive metals. Think of a plasma cutter as a hot knife designed specifically for thick steel plate. Modern CNC plasma table systems combine this raw cutting power with computer control for production-ready results.

Waterjet cutting takes a completely different approach: high-pressure water mixed with abrasive particles slices through material without heat. This cold-cutting process eliminates heat-affected zones entirely—critical when material properties must remain unchanged. Industry projections show the waterjet market reaching over $2.39 billion by 2034, reflecting growing demand for heat-free cutting capabilities.

Mechanical cutting (shearing, sawing, punching) relies on physical force to separate material. While less sophisticated than thermal or abrasive methods, mechanical approaches remain cost-effective for simple cuts, high-volume blanking operations, and situations where edge finish matters less than throughput.

Complete Technology Comparison for Steel Applications

Ready to see how these methods stack up across every factor that matters? This comprehensive comparison focuses specifically on steel cutting performance:

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Cutting |

|---|---|---|---|---|

| Edge Quality | Excellent—smooth edges with minimal post-processing needed | Good—relatively smooth with minimal slag on properly tuned systems | Excellent—smooth finish even on thick materials | Variable—depends on method; shearing creates clean edges, sawing leaves rougher finish |

| Heat-Affected Zone | Minimal—small HAZ due to focused beam and fast cutting | Moderate to large—high temperatures create noticeable HAZ | None—cold cutting process preserves material properties completely | None—no thermal input during cutting |

| Steel Thickness Range | 0.5mm to 50mm+ (power dependent); optimal for thin to medium sheets | 3mm to 150mm+; excels on thick conductive metals | 0.5mm to 300mm+; handles virtually any thickness | Limited by tooling; typically under 25mm for most operations |

| Precision Tolerances | ±0.05 to ±0.20mm—exceptional accuracy for intricate shapes | ±0.5 to ±1.5mm—good for structural work, less precise than laser | ±0.1 to ±0.25mm—high precision comparable to laser | ±0.25 to ±1.0mm—depends on tooling condition and material |

| Cutting Speed (Thin Steel) | Very fast—fiber lasers excel on material under 10mm | Fast—competitive on thin material but slower than optimized laser | Slow—precision comes at the cost of speed | Very fast—shearing and punching are extremely rapid |

| Cutting Speed (Thick Steel) | Moderate—slows significantly as thickness increases | Very fast—3-4x faster than waterjet on 1" steel | Slow—but consistent quality regardless of thickness | Fast—sawing handles thick plate efficiently |

| Complex Shape Capability | Excellent—handles intricate designs, small holes, tight corners | Good—limited on very fine details or small features | Excellent—cuts any shape without tooling changes | Limited—constrained to simple geometries |

| Equipment Cost | High—fiber laser systems represent significant investment | Moderate—approximately $90,000 for complete system | High—approximately $195,000 for comparable system | Low to moderate—varies widely by equipment type |

| Operating Cost per Foot | Low to moderate—efficient electricity usage, gas costs vary | Low—consumables and electricity are economical | Moderate to high—abrasive material adds ongoing expense | Low—minimal consumables for most operations |

| Material Limitations | Metals and some non-metals; reflective metals require fiber lasers | Conductive metals only—cannot cut wood, plastic, or glass | Almost any material—metals, stone, glass, composites | Depends on tooling; primarily metals and some plastics |

When Plasma Makes More Sense Than Laser for Steel

If you're cutting thick structural steel and searching for the most cost-effective approach, a plasma cutting table often delivers better value than laser—despite laser's precision advantages.

Consider the numbers: testing confirms that plasma cutting 1-inch steel runs approximately 3-4 times faster than waterjet, with operating costs roughly half as much per foot. Compared to laser at these thicknesses, plasma maintains speed advantages while reducing equipment investment significantly.

A portable plasma cutter or CNC plasma system makes the most sense when:

- Your steel thickness regularly exceeds 12mm (½ inch)

- Edge tolerances of ±0.5mm or greater are acceptable for your application

- Speed and throughput matter more than precision finishing

- Budget constraints favor lower equipment and operating costs

- You're cutting primarily structural steel, heavy equipment components, or industrial fabrications

Many fabrication shops eventually operate both technologies. Plasma handles the thick plate and structural work efficiently, while laser delivers the precision required for detailed parts, thin sheet metal, and applications where edge quality is critical.

Choosing the Right Method for Your Steel Project

When you step back and evaluate these technologies against your actual project requirements, clear decision patterns emerge. Here's how to match each method to its ideal applications:

Choose laser cutting when:

- Working with steel sheets under 20mm thickness where precision matters

- Your parts require clean edges with minimal or no secondary finishing

- Designs include intricate shapes, small holes, or tight corner radii

- Tolerances of ±0.1mm or tighter are specified

- Production volumes justify the equipment investment through speed and consistency

- You need to cut complex parts from electronics housings to automotive components

Choose plasma cutting when:

- Processing thick conductive metals—steel, aluminum, stainless—over 12mm

- Speed and cost efficiency outweigh ultra-precise edge requirements

- Fabricating structural steel, shipbuilding components, or heavy equipment

- Budget constraints require lower equipment investment

- A cnc plasma cutter's tolerance range (±0.5 to ±1.5mm) meets your specifications

Choose waterjet cutting when:

- Heat-affected zones are absolutely unacceptable—aerospace components, tempered materials

- Material properties must remain completely unchanged after cutting

- Cutting non-metals alongside steel—stone, glass, composites, ceramics

- Precision matters on very thick materials where laser quality degrades

- Working with heat-sensitive alloys or specialty steels

Choose mechanical cutting when:

- Simple straight cuts or basic shapes dominate your work

- High-volume blanking operations require maximum speed

- Material thickness and geometry fit within tooling capabilities

- Edge quality requirements are minimal and finishing will occur anyway

- Cost per cut is the primary decision driver

There's no single "best" cutting technology—each has its place. For many fabrication shops, having access to at least two of these technologies provides the flexibility to handle almost any cutting task effectively and economically.

This comparison helps you evaluate whether laser cutting is the right choice for your steel project—or whether plasma, waterjet, or mechanical methods better match your requirements. But once you've decided on laser cutting, there's another critical factor that determines project success: how you prepare your design files for the cutting process.

Design File Preparation for Steel Laser Cutting

You've selected laser cutting as your method, chosen your steel grade, and confirmed your material thickness works—but here's where many projects silently fail. The design file you submit determines whether your parts cut cleanly on the first run or get rejected before the laser ever fires.

Think about it: a cnc laser cutting system follows your file instructions exactly. Every line, every dimension, every tiny detail gets translated into machine movements. If your CAD file contains errors—features too small for the material, incorrect spacing, improper kerf compensation—the machine will faithfully reproduce those mistakes in steel.

Whether you're running a laser cut cnc machine in-house or submitting files to a laser fabrication service, proper file preparation separates successful projects from expensive failures. Let's walk through exactly what your files need to achieve production-ready results.

Preparing Your CAD Files for Clean Cuts

Your DXF or DWG file is essentially a promise that the finished part will match your design intent. But cnc cutting systems require specific file characteristics to interpret that promise correctly. Here's what your files need:

Essential DXF/DWG Specifications:

- Closed contours with no overlaps: Every cut path must form a complete, closed loop. Open paths or overlapping lines confuse the cutting software and create errors

- Clean geometry: Remove duplicate lines, stray points, and construction geometry before export

- Proper scale: Export at 1:1 scale with correct units specified—confusion between millimeters and inches is surprisingly common

- Layer organization: Separate cut lines, etch/engrave marks, and reference geometry onto distinct layers for clear communication with operators

- No splines or complex curves: Convert splines to polylines or arcs that CNC systems interpret reliably

Minimum Feature Sizes by Steel Thickness:

Laser kerf—the width of material removed by the cutting beam—directly limits how small your features can be. According to fabrication guidelines, features smaller than the kerf width simply disappear during cutting. For steel laser cutting, follow these minimums:

| Steel Thickness | Typical Kerf Width | Minimum Hole Diameter | Minimum Slot Width | Minimum Bridge/Web |

|---|---|---|---|---|

| Under 3mm | 0.15-0.25mm | ≥ material thickness | ≥ 1.5× kerf width | ≥ 1.5× material thickness |

| 3mm - 6mm | 0.20-0.30mm | ≥ material thickness | ≥ material thickness | ≥ 2× material thickness |

| 6mm - 12mm | 0.25-0.40mm | ≥ 50% of thickness minimum | ≥ material thickness | ≥ 2× material thickness |

| Over 12mm | 0.30-0.50mm | ≥ 50% of thickness | ≥ 1.2× material thickness | ≥ 2.5× material thickness |

Kerf Allowance Calculations:

Should you compensate for kerf in your design file, or let the fabricator handle it? This seemingly simple question causes significant confusion. Industry best practice recommends deciding with your shop whether your DXF is nominal (they apply compensation) or pre-offset.

- For holes: Fiber laser kerf on mild steel typically runs 0.15-0.30mm depending on thickness and nozzle setup. Small internal features will effectively "shrink" by this kerf width

- For external dimensions: Large external profiles can "grow" slightly as kerf removes material from the inside of the cut line

- Practical compensation: For an M6 clearance hole (6.6mm), drawing 6.6-6.8mm reduces risk of tight fits after cutting and finishing

- Tab and slot fits: A 3.0mm tab in 3.0mm steel often needs a 3.3-3.6mm slot—tighten or loosen based on your laser and finish requirements

Avoiding Costly File Preparation Mistakes

What actually happens when files aren't properly prepared? The consequences range from annoying to expensive:

Rejected orders: Many cnc fabrication services run automated file checks. Overlapping lines, open contours, or features below minimum sizes trigger immediate rejection—delaying your project before it starts.

Quality failures: Files that pass automated checks can still produce poor results. Features too small for material thickness melt into indistinct shapes. Insufficient spacing between cuts causes parts to warp from heat accumulation. Improper tolerances create parts that don't fit their intended assemblies.

Unexpected costs: Some shops will fix minor file issues—and charge for the engineering time. Others cut exactly what you sent, leaving you with unusable parts and a bill anyway.

Common Mistakes That Kill Projects:

- Insufficient spacing between cuts: Keep holes and slots at least 1.5× material thickness plus inside radius away from bend lines. Clustering small holes near edges increases heat-related distortion

- Features too small for material: As hole size goes below 50% of material thickness, quality and resolution suffer dramatically. Test parts confirm this—tiny features in thick plate simply don't work

- Improper line types: Using different line weights, colors, or styles without clear layer conventions confuses operators about what should be cut versus engraved versus ignored

- Missing specifications: Failing to call out material type, thickness, critical tolerances, and finish requirements forces shops to guess—or stop and ask

- Incorrect docking points: Machine operation guidance warns that incorrect docking point settings can cause the laser head to attempt movements beyond safe limits

- Ignoring bend allowances: If your laser-cut parts will be formed, your flat pattern needs correct bend deductions. Use consistent K-factors (often 0.30-0.50 for steel) that match what the brake operator will apply

Surface Condition Requirements:

Your file might be perfect, but material condition affects results too. Before cutting:

- Rust and scale: Light surface oxidation is acceptable for oxygen-assisted cutting on carbon steel. Heavy rust or scale can interfere with consistent cuts—clean heavily corroded areas

- Mill scale: Research confirms that machining off mill scale has no significant effect on laser cut quality—don't waste time removing it unnecessarily

- Coatings and paint: Remove protective films, paint, and powder coatings from cut zones. These vaporize during cutting, creating fumes that contaminate edges and optics

- Oils and lubricants: Clean stainless steel surfaces to prevent contamination that affects cut quality and edge appearance

- Flatness: Ensure material is flat enough for consistent focal distance across the cutting area—warped sheets produce inconsistent results

Every DXF is a promise that the finished part will match the intent. Tolerances define how close that promise needs to be—and proper file preparation is how you keep that promise.

Taking time to prepare files correctly eliminates the frustrating cycle of rejected orders, quality issues, and surprise charges. But even perfect files produce parts with characteristics you need to understand—particularly regarding edge quality and surface finish expectations that vary based on your cutting parameters and material choices.

Edge Quality and Surface Finish Expectations

Your design files are ready, your steel is on the cutting table—but what will your finished parts actually look like? This question often goes unanswered until parts arrive, leaving fabricators surprised by edges that don't match their expectations.

Here's the reality: laser cut steel edges vary significantly based on cutting parameters, material type, and thickness. Understanding what to expect—and what affects the outcome—helps you specify realistic requirements and plan for any secondary operations your project might need.

What Your Cut Edges Will Actually Look Like

When you laser cut sheet metal, the finished edge tells a story about how the cutting process interacted with your specific material. Several distinct characteristics define what you'll see and feel:

Dross formation: That solidified metal residue clinging to the bottom edge of cuts? That's dross—molten material that didn't get fully ejected by the assist gas. On properly tuned systems, dross is minimal and easily removed. But as you push thickness limits or use suboptimal parameters, dross becomes more pronounced and may require grinding or deburring.

Oxide layers: When cutting carbon steel with oxygen assist gas, an exothermic reaction creates a dark oxide layer on the cut edge. This oxidized surface is perfectly functional for many structural applications—but it affects paint adhesion and welding quality. Nitrogen-assisted cuts produce clean, oxide-free edges ready for coating or joining without additional preparation.

Striations: Look closely at any laser-cut edge and you'll notice fine vertical lines—striations created by the pulsing nature of the cutting process. On thin materials with optimized settings, these are nearly invisible. As thickness increases, striations become more pronounced, creating a rougher surface texture.

Kerf taper: The cut opening is slightly wider at the top (where the beam enters) than at the bottom. High-quality precision laser cutting minimizes this taper, but it's always present to some degree—particularly on thicker materials where the beam diverges more before exiting.

Factors Affecting Edge Quality

Edge quality isn't random—it's the predictable result of specific variables you can control. According to industry guidance, several factors influence the cutting process that directly affect edge quality. Understanding these helps you achieve cleaner, smoother edges:

- Cutting speed: Too fast creates rough edges with excessive dross; too slow causes excess heat buildup, wider kerf, and potential warping. The sweet spot varies by material and thickness

- Assist gas pressure: Low pressure fails to clear molten material efficiently, causing rough edges. Proper pressure improves cooling and debris removal for cleaner cuts

- Focus position: The focal point must be precisely positioned relative to material thickness. Incorrect focus creates inconsistent cut quality and excessive taper

- Material condition: Surface rust, scale, oils, and coatings all affect how consistently the laser interacts with the steel. Clean, flat material produces more predictable results

- Material thickness: Thinner materials generally produce cleaner edges with less post-processing needed. As thickness increases, edge quality naturally degrades

- Steel grade: Carbon content, alloying elements, and surface finish all influence thermal behavior during cutting—some grades simply cut cleaner than others

Heat-Affected Zones and How to Minimize Them

Every thermal cutting process creates a heat-affected zone (HAZ)—the area adjacent to the cut where material properties have changed due to heat exposure. For laser cutting and engraving applications, understanding HAZ matters for both structural integrity and appearance.

The good news? Laser cutting produces relatively small heat-affected zones compared to plasma or oxy-fuel cutting. The focused beam and fast cutting speeds limit heat input to a narrow band along the cut edge. However, HAZ effects still occur:

- Microstructural changes: The steel immediately adjacent to the cut experiences rapid heating and cooling, potentially creating harder, more brittle zones

- Discoloration: Heat causes visible color changes (blues, browns, straw colors) on stainless steel and some carbon steels near the cut edge

- Residual stress: Thermal cycling can create stresses that affect dimensional stability, particularly in thin or intricate parts

Minimizing HAZ impact:

- Use higher cutting speeds within quality limits—less time at temperature means smaller HAZ

- Optimize laser power for your material rather than defaulting to maximum output

- Use nitrogen assist gas when preserving material properties matters more than cutting speed

- Allow adequate spacing between cuts to prevent heat accumulation in clustered features

- Consider pulsed cutting modes for heat-sensitive applications

When Secondary Finishing Is Necessary

Not every laser-cut part leaves the machine ready for use. Knowing when additional operations are required—and when you can skip them—saves time and money:

Edges typically ready for immediate use:

- Thin carbon steel (under 6mm) cut with nitrogen assist—clean, oxide-free edges suitable for welding or powder coating

- Stainless steel cut with nitrogen—preserves corrosion resistance, minimal discoloration

- Parts where edge appearance isn't visible in the final assembly

- Structural components where oxide layers don't affect function

Edges requiring secondary operations:

- Oxygen-assisted carbon steel cuts destined for painting—oxide layer may affect adhesion

- Thick plate cuts with visible striations that don't meet aesthetic requirements

- Parts with dross that interferes with assembly or fit

- Critical surfaces requiring specific roughness values for sealing or bearing applications

- Edges that will be visible in finished products where appearance matters

When Laser Cutting Produces Suboptimal Results

Transparency builds trust—so here's honest guidance on laser cutting's limitations. Consider alternative methods when:

- Material thickness exceeds practical limits: Near maximum thickness, edge quality degrades significantly. Plasma or waterjet may deliver better results on very thick plate

- Zero HAZ is mandatory: Aerospace, tempered materials, or applications where any metallurgical change is unacceptable—waterjet cutting eliminates thermal effects entirely

- Highly reflective alloys: Some copper alloys and specialty materials still challenge even modern fiber lasers

- Cost per part is critical on simple shapes: Shearing or punching may be more economical for basic geometries in high volumes

Edge quality in laser cutting is a blend of science and fine-tuning. By understanding your material, optimizing machine settings, and maintaining equipment, you can achieve cleaner, smoother edges with every cut.

Understanding what your cut edges will look like—and what affects that outcome—positions you to set realistic expectations and plan accordingly. But edge quality is just one factor in your total project cost. What actually determines pricing for steel laser cutting services, and how can you estimate costs before committing?

Cost Factors and Pricing for Steel Laser Cutting

Here's a question that frustrates nearly everyone exploring metal laser cutting services: "What will this actually cost?" Most providers dodge specific pricing discussions, leaving you to submit quotes blindly without understanding what drives the numbers you'll receive.

The truth? Laser cutting charges aren't arbitrary—they follow a predictable formula based on measurable factors you can influence. Understanding this formula transforms you from a passive quote recipient into an informed buyer who can optimize designs for cost efficiency before submitting files.

Let's decode exactly what determines your project costs—and how to use that knowledge strategically.

Understanding Steel Laser Cutting Pricing Factors

Nearly every laser cut services provider—from online platforms to local shops—calculates pricing using the same foundational approach. According to industry pricing analysis, the formula breaks down as:

Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin)

Sounds simple enough. But here's what trips up most buyers: the single most important factor driving your cost isn't the area of material—it's the machine time required to cut your specific design. Two parts from the same steel sheet can have vastly different prices based purely on complexity.

The Six Variables That Determine Your Quote:

- Material thickness: This is the primary cost driver. Fabrication studies confirm that doubling material thickness can more than double cutting time and cost because the laser must move much slower to achieve clean penetration. Thicker materials also require more energy consumption and increase equipment wear

- Steel grade: Different metals have varying base costs and cutting difficulty. Stainless steel typically costs more than mild steel—both for raw material and processing time. Price comparisons show stainless steel cutting ranges $0.15-$1.00 per inch versus $0.10-$0.60 per inch for mild steel

- Cut complexity: Intricate designs with tight curves, sharp corners, and numerous pierce points force the machine to slow down repeatedly. A design with 100 small holes costs more than one large cutout because each pierce adds cumulative time

- Quantity: Fixed setup costs get spread across all parts in an order. Higher volumes dramatically reduce per-part pricing—bulk order discounts can reach 70% compared to single-piece pricing

- Edge quality requirements: Specifying tolerances tighter than functionally necessary increases costs. Precision laser cutting services charge premium rates for tight-tolerance work because machines must run at slower, more controlled speeds

- Turnaround time: Rush orders typically carry 20-50% surcharges—or higher if overtime is required. Standard lead times offer the best value

How Machine Time Really Affects Your Bottom Line

Machine time is the service you're primarily paying for—and it's calculated from several aspects of your design that you control:

- Cut distance: The total linear path the laser travels. Longer paths mean more time and higher costs

- Pierce count: Every time the laser starts a new cut, it must pierce the material first. More holes and cutouts mean more pierces

- Operation type: Cutting through material is slowest and most expensive. Scoring (partial cuts) is faster. Engraving is often priced per square inch rather than linear inch

The typical machine hourly rate ranges from $60 to $120 depending on laser power and capability. A 6kW fiber laser costs more to operate than a 3kW system—but cuts faster, often offsetting the rate difference on suitable materials.

How to Estimate Your Project Costs

You won't get exact numbers without submitting files for a laser cutting quote, but you can develop realistic expectations by understanding relative cost factors:

| Cost Factor | Lower Cost Direction | Higher Cost Direction | Relative Impact |

|---|---|---|---|

| Material Thickness | Thinner gauges (1-3mm) | Thick plate (12mm+) | Very High—exponential increase |

| Steel Grade | Mild steel, low-carbon | Stainless steel, specialty alloys | Moderate—affects both material and processing |

| Design Complexity | Simple shapes, few cutouts | Intricate patterns, many small holes | High—directly increases machine time |

| Order Quantity | Bulk orders (50+ pieces) | Single pieces or small batches | High—setup costs amortization |

| Tolerance Requirements | Standard (±0.2mm) | Tight (±0.05mm) | Moderate—requires slower processing |

| Lead Time | Standard (5-10 days) | Rush (1-2 days) | Moderate—20-50% premium typical |

| Secondary Operations | Cutting only | Deburring, bending, finishing | Additive—each operation adds cost |

Real-World Pricing Context:

While specific prices vary by provider and location, industry benchmarks provide useful reference points:

- Setup and calibration typically runs $6-$30 per job

- Design preparation for complex files: $20-$100+ per hour depending on complexity

- Machine time for straightforward cuts on 2mm mild steel: approximately $1-$3 per linear meter

- Post-processing operations like deburring add $5-$20 per square meter; painting adds $10-$30 per square meter

Interpreting Quotes and Questions to Ask

When you receive a laser cutting quote, you're often looking at a single number without understanding its components. Here's how to evaluate what you're actually paying for:

Questions to Ask Service Providers:

- Is setup fee included or separate? How does it scale with quantity?

- What's the breakdown between material cost and processing cost?

- Are there file preparation charges if corrections are needed?

- What tolerances are included in the quoted price versus premium precision work?

- Is nitrogen or oxygen assist gas included, or priced separately for stainless steel?

- What secondary operations (deburring, edge finishing) are included versus additional?

- How does pricing change at different quantity breakpoints?

Comparing Online Platforms vs. Local Shops:

Your choice of provider affects both pricing and experience:

- Online automated platforms: Deliver instant quotes from CAD files—ideal for rapid prototyping and budget feedback. However, automated systems don't catch costly design errors, and expert DFM feedback often costs extra

- Traditional tube laser cutting services and local fabricators: Provide manual quotes with free Design for Manufacturability guidance that can significantly lower costs. They spot errors, suggest efficient alternatives, and handle customer-supplied materials more flexibly. The trade-off? Quoting takes hours or days instead of seconds

For automotive and precision manufacturing applications, working with manufacturers that offer comprehensive DFM support can optimize your designs before cutting begins. Providers like Shaoyi combine rapid 12-hour quote turnaround with engineering expertise that helps identify cost-saving opportunities in your design—connecting laser cutting preparation to your broader manufacturing workflow.

Design Decisions That Lower Your Costs

You have more control over final pricing than you might realize. These strategies reduce costs without sacrificing function:

- Use the thinnest material possible: This is the single most effective cost reduction. Always verify if a thinner gauge meets your structural requirements

- Simplify geometry: Reduce complex curves, combine multiple small holes into larger slots where functionally acceptable, and minimize total cut distance

- Reduce pierce count: Fewer separate cutouts means fewer time-consuming pierces. Can multiple features connect into continuous paths?

- Clean your files: Remove duplicate lines, hidden objects, and construction geometry. Automated systems will attempt to cut everything—double lines double your cost for that feature

- Order in bulk: Consolidate needs into larger, less frequent orders to spread setup costs

- Choose in-stock materials: Using steel grades your provider already stocks eliminates special order fees and reduces lead times

- Accept standard tolerances: Specify tight tolerances only where functionally necessary—precision laser cutting services charge premiums for ultra-tight specs

The most significant savings are found not in negotiating a quote, but in designing a part that is optimized for efficient manufacturing.

Understanding these cost dynamics positions you to make informed decisions—balancing budget constraints against performance requirements. With pricing factors clear, the final step is selecting the right approach and partner to bring your steel laser cutting project from concept to finished parts.

Selecting the Right Steel Laser Cutting Approach

You've absorbed the technical knowledge—thickness limits, edge quality factors, cost drivers, and technology comparisons. Now comes the practical question: how do you translate all this information into action for your specific project?

Whether you're a maker prototyping a custom bracket or a manufacturing engineer sourcing production components, the decision framework follows the same logic. Match your requirements to the right cutting solution, prepare properly, and select a partner whose capabilities align with your needs.

Let's walk through exactly how to make these decisions systematically.

Matching Your Project to the Right Cutting Solution

Before submitting files or requesting quotes, work through this decision framework to ensure you're choosing the optimal approach:

- Assess your steel type and thickness requirements: What grade are you cutting—mild steel, stainless, or specialty alloy? What thickness does your application demand? Cross-reference these against the thickness capability tables we've covered. If your 25mm carbon steel plate pushes beyond practical laser limits, plasma or waterjet may deliver better results. If you're working with 3mm stainless requiring oxide-free edges, fiber laser with nitrogen assist is your answer.

- Determine edge quality needs: Will cut edges be visible in the finished product? Do they need to accept paint or powder coating without preparation? Must they preserve corrosion resistance? Be honest about what's functionally necessary versus aesthetically preferred. Specifying tighter requirements than needed increases costs without adding value.

- Evaluate quantity and timeline: Single prototypes and production runs of thousands require different approaches. Low quantities favor laser cutting's zero-tooling advantage. High volumes may justify exploring stamping or punching for simple geometries. Rush timelines limit your provider options and increase costs—plan ahead when possible.

- Prepare proper design files: Clean DXF/DWG files with closed contours, appropriate minimum feature sizes, and correct specifications prevent rejected orders and quality failures. Review our file preparation guidelines before submitting. Time spent here saves money and frustration later.

- Select the appropriate service provider: Match provider capabilities to your requirements. Online platforms deliver speed and convenience for straightforward laser cut parts. Local fabricators offer DFM guidance and flexibility for complex projects. For cnc laser cutting services supporting production volumes, evaluate equipment capacity, quality certifications, and turnaround commitments.

From Prototype to Production

One of laser cutting's greatest strengths? The same process that creates your first prototype can scale seamlessly to production volumes. Manufacturing research confirms that 63% of engineering teams reduced prototype development time by 40-60% after adopting laser systems—enabling 5-7 design iterations weekly compared to just 1-2 cycles with traditional methods.

This rapid iteration capability transforms how you approach product development. Instead of committing to expensive tooling based on theoretical designs, you can:

- Produce functional prototypes within hours of finalizing CAD files

- Test multiple design variations quickly and affordably

- Identify and resolve 86% of design problems before investing in production tooling

- Scale from single units to thousands using identical cutting parameters

For DIY Makers and Small-Batch Projects:

When searching for a laser cutting service near me or metal laser cutting near me, prioritize providers who:

- Accept small orders without prohibitive minimum quantities

- Offer instant online quoting for budget feedback during design

- Provide clear guidance on file preparation requirements

- Stock common steel grades to avoid special order delays

- Communicate clearly about tolerances and edge finish expectations

For Professional Manufacturing Applications:

Production contexts demand different priorities. Automotive, aerospace, and industrial applications require partners with:

- Quality certifications appropriate to your industry—IATF 16949 certification matters significantly for automotive chassis, suspension, and structural components

- Capacity to handle your volume requirements consistently

- Rapid prototyping capabilities that transition smoothly to mass production

- Comprehensive DFM support that optimizes designs before cutting begins

- Responsive communication—providers like Shaoyi offer 12-hour quote turnaround and 5-day rapid prototyping specifically for precision metal components

When Steel Laser Cutting Is the Optimal Choice

After everything we've covered, here's the summary: choose laser cutting when your project features:

- Steel thickness under 20-25mm where precision matters

- Complex geometries, intricate patterns, or tight tolerances (±0.1mm achievable)

- Requirements for clean edges with minimal secondary finishing

- Quantities from single prototypes to medium production runs

- Need for rapid design iterations and fast turnaround

- Mixed part sizes that benefit from nesting optimization

When to Consider Alternatives

Laser cutting isn't always the answer. Consider other methods when:

- Thickness exceeds practical limits: Very thick structural steel often cuts better and faster with plasma or oxy-fuel

- Zero heat-affected zone is mandatory: Waterjet cutting eliminates thermal effects entirely for heat-sensitive applications

- Simple shapes dominate at high volumes: Shearing, punching, or stamping may offer lower per-part costs

- Budget is severely constrained: Plasma cutting delivers acceptable results on thick plate at lower equipment and operating costs

The best cutting method is the one that delivers your required quality at the lowest total cost—including secondary operations, scrap rates, and timeline considerations.

Steel laser cutting has earned its dominant position in modern metal fabrication for good reason. When you understand thickness limits, select appropriate steel grades, prepare files correctly, and partner with capable providers, the technology delivers precision, speed, and value that alternative methods struggle to match. Armed with the knowledge from this guide, you're equipped to make confident decisions—whether you're cutting your first prototype or scaling to production volumes.

Frequently Asked Questions About Steel Laser Cutting

1. How thick can a fiber laser cut steel?

Fiber laser cutting capacity depends on laser power and steel type. A 6kW fiber laser can cut up to 22mm carbon steel with oxygen assist and 12mm stainless steel with nitrogen. Higher power systems (15-20kW) handle carbon steel up to 50mm, while 30kW+ lasers can cut up to 100mm. However, optimal production results typically occur at 80% of maximum thickness capability to maintain consistent edge quality and cutting speed.

2. What metals can be laser cut?

Laser cutting works effectively on mild steel, low-carbon steel, stainless steel (304, 316, 430 grades), aluminum, titanium, brass, and copper. Fiber lasers excel with reflective metals like aluminum and copper, while CO2 lasers handle non-metallic materials better. Steel grades with carbon content below 0.25% deliver the cleanest cuts, though heavily coated or high-silicon steels require parameter adjustments or surface preparation.

3. What is the difference between fiber laser and CO2 laser for steel cutting?

Fiber lasers operate at 1064nm wavelength, which steel absorbs efficiently, enabling 2-5x faster cutting on thin materials with 30-50% electrical efficiency. CO2 lasers use 10.6µm wavelength with only 10-15% efficiency but often deliver superior edge quality on steel over 25mm thick. Fiber systems require minimal maintenance ($200-400 annually) compared to CO2 ($1,000-2,000), with component lifespans of 100,000+ hours versus 10,000-25,000 hours.

4. How much does laser cutting steel cost?

Steel laser cutting costs depend on material thickness (the primary driver), steel grade, cut complexity, quantity, and turnaround time. Mild steel typically costs $0.10-$0.60 per inch versus $0.15-$1.00 for stainless steel. Machine hourly rates range $60-$120. Setup fees run $6-$30 per job, while bulk orders can reduce per-part costs by up to 70%. Design simplification and using thinner materials offer the most significant savings.

5. Should I use oxygen or nitrogen assist gas when laser cutting steel?

Oxygen enables 30-50% thicker cuts on carbon steel through exothermic reaction and uses 10-15x less gas, but creates an oxide layer on edges. Nitrogen produces oxide-free edges ready for welding or coating, essential for stainless steel to preserve corrosion resistance. For thin steel under 6mm requiring paint-ready edges, nitrogen justifies higher gas costs. For thick structural carbon steel where appearance matters less, oxygen maximizes cutting capability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —