Stamped Steel Control Arms at ang Paliwanag Tungkol sa Unsprung Weight

TL;DR

Ang mga stamped steel control arms ay isang karaniwang bahagi ng pabrika na matipid sa gastos, ngunit ang kanilang malaking timbang ay nagdaragdag sa unsprung weight ng isang sasakyan. Ang sobrang bigat na ito ay maaaring negatibong makaapekto sa pagmamaneho, na nagiging sanhi ng mas hindi sensitibo ang suspensyon sa mga hindi perpektong bahagi ng kalsada. Ang mas magaang na alternatibo, tulad ng aluminum, tubular, o forged control arms, ay binabawasan ang unsprung weight, na nagdudulot ng makabuluhang pagpapabuti sa kalidad ng biyahe, traksyon, at kabuuang pagganap ng sasakyan.

Pag-unawa sa Unsprung Weight: Bakit Mahalaga Ito para sa Pagganap

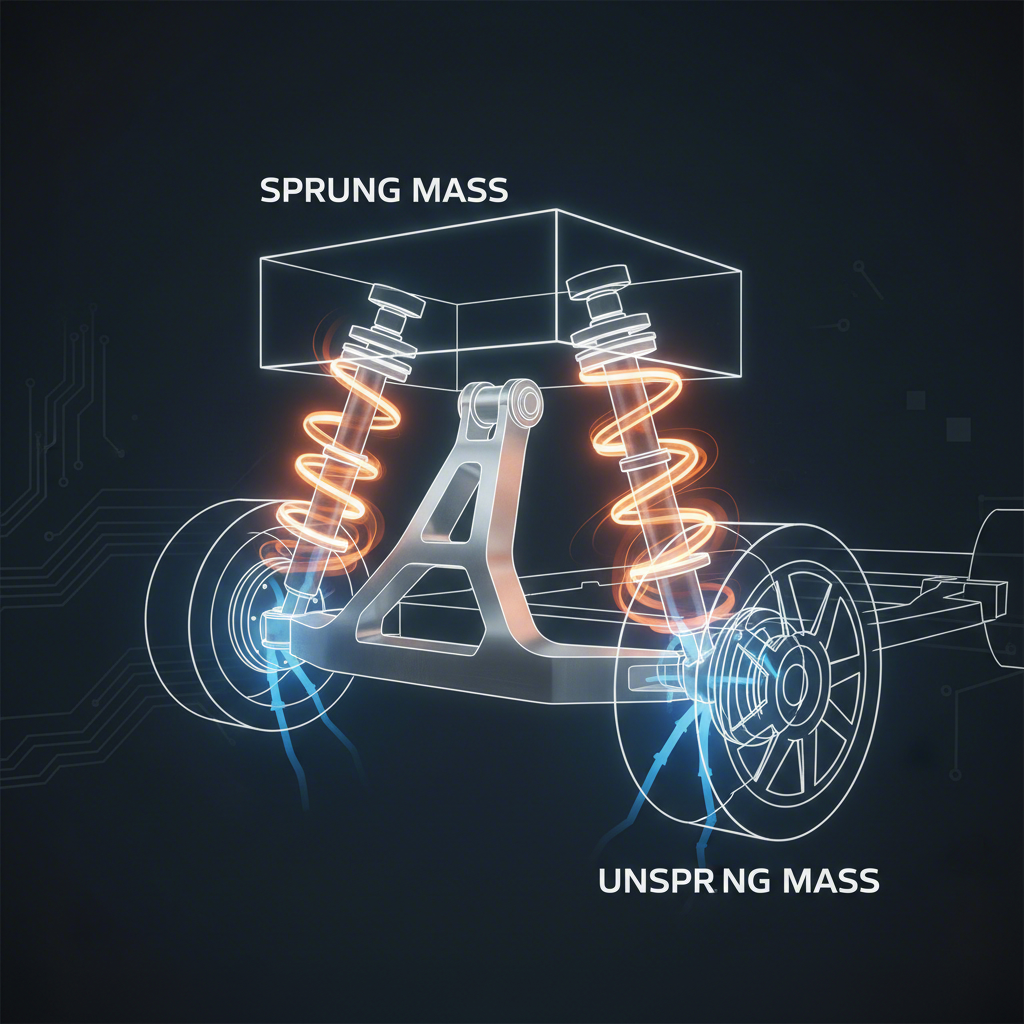

Sa anumang talakayan tungkol sa suspensyon at pagmamaneho ng sasakyan, ang tawag na 'unsprung weight' (o 'unsprung mass') ay napakahalaga. Ito ay tumutukoy sa kabuuang timbang ng lahat ng bahagi na hindi sinusuportahan ng mga spring ng sasakyan. Mahalaga ang pag-unawa sa konseptong ito upang lubos na maunawaan kung bakit mahalaga ang materyal ng isang control arm. Isang simpleng paraan para iisipin ito ay kung ihaharap mo ang chassis ng kotse, ang lahat ng bahagi na nananatili sa lupa ay kasama sa unsprung weight. Ang masa na ito ay dapat gumalaw pataas at pababa sa bawat bump at bitak sa kalsada.

Ang pangunahing prinsipyo ay simple: mas magaan ang mga di-nakaspring na bahagi, mas mainam ang pagganap ng suspensyon. Ang mas mabigat na mga bahagi ay may mas mataas na inersya, kaya mahirap para dito na biglang baguhin ang direksyon. Kapag tumama ang isang mabigat na gulong at suspensyon sa isang bump, kailangan ng mas malaking pwersa ng spring at shock absorber upang kontrolin ang paggalaw nito pataas at ibalik ito pababa upang mapanatili ang kontak sa kalsada. Maaari itong magdulot ng mas matigas na biyahen at nabawasan na traksyon, dahil ang gulong ay maaaring pansamantalang tumalon sa ibabaw. Ayon sa mga eksperto sa suspensyon sa QA1 , napakahalaga ng pagbabawas sa timbang ng di-nakaspring na masa dahil pinapabilis nito ang reaksiyon ng suspensyon sa mga hindi perpektong bahagi ng kalsada, na nagpapabuti sa parehong pagmamaneho at kalidad ng biyahe.

Kasukli, ang mas mababang bigat ng unsprung weight ay nagbibigay-daan sa wheel assembly na mas mabuti na sundin ang hugis ng kalsada. Mas mabilis umaksyon ang suspension, panatilihin ang tire na nakadikit nang mahigpit sa pavement. Ito ay direktang nangangahulugan ng mas mainam na grip, mas sensitibong maniobra, at mapabuting pagbabreno at akselerasyon. Ang epekto ay napakalaki kaya ang mga upgrade na nakatuon sa pagganap ay karaniwang nakatuon sa pagbawas sa partikular na uri ng bigat na ito. Kasama sa karaniwang unsprung components ang:

- Mga gulong at lapis

- Mga brake rotor, caliper, at pad

- Mga gulong hub at bearing

- Mga spindle o steering knuckle

- Kalahati ng bigat ng mga control arm, springs, at shock absorber

Stamped Steel Control Arms: Mga Bentahe at Di-bentahe

Ang mga stamped steel control arms ay pamantayan para sa napakaraming sasakyang produksyon, mula sa mga pampamilyang sedan hanggang sa mga light truck. Ginagawa ang mga ito sa pamamagitan ng pag-stamp ng mga sheet ng bakal sa nais na hugis at pagkatapos ay pagw-welding dito nang magkasama. Ang prosesong ito ay lubhang epektibo at matipid, na nagiging perpektong opsyon para sa mga tagagawa ng sasakyan na gumagawa ng malalaking bilang ng mga sasakyan. Para sa mga negosyo sa sektor ng automotive, mahalaga ang eksaktong pagkakagawa sa prosesong ito. Halimbawa, ang mga espesyalisadong tagagawa tulad ng Shaoyi (Ningbo) Metal Technology Co., Ltd. ay nakatuon sa paghahatid ng de-kalidad, IATF 16949 certified na auto stamping parts, na nagagarantiya na kahit ang mga pangunahing komponente ay sumusunod sa mahigpit na pamantayan para sa tibay at tamang pagkakasya mula sa prototyping hanggang sa mass production.

Ang pangunahing kalamangan ng stamped steel ay ang balanseng sapat na lakas at mababang gastos sa produksyon. Para sa karaniwang drayber sa ilalim ng normal na kondisyon ng kalsada, ang mga control arm na ito ay matagumpay na gumaganap nang maayos sa buong buhay ng sasakyan. Matibay din ang bakal at kayang makatiis ng malalaking pagkakahampas, na madalas umyuko imbes na pumutok, na maaaring isang mahuhulaang paraan ng pagkabigo sa isang aksidente. Gayunpaman, ang pinakamalaking kahinaan nito ay direktang nauugnay sa pagganap: ang timbang nito. Mabigat ang bakal, at nagreresulta ang pamamaraang ito ng konstruksyon sa isang mabigat na bahagi na lubos na nag-aambag sa unsprung mass ng sasakyan.

Ang dagdag na timbang na ito ang pangunahing dahilan kung bakit hinahanap ng mga mahilig sa pagganap na palitan ang mga ito. Tulad ng napag-usapan, ang mas mataas na unsprung weight ay maaaring magdulot ng suspension system na hindi gaanong sensitibo. Isa pang malaking kahinaan ay ang pagiging sensitibo ng bakal sa korosyon. Tulad ng ipinaliwanag sa isang gabay ni PartsAvatar Canada , maliban kung maayos na napapalitan, ang mga kontrol na bisig na bakal ay maaaring magkaroon ng kalawang sa paglipas ng panahon, lalo na sa mga rehiyon na may matinding taglamig kung saan karaniwan ang asin sa kalsada. Ang korosyon na ito ay maaaring paluwagin ang bahagi at sa huli ay magdulot ng pagkabigo.

| Mga Bentahe | Mga Di-Bentahe |

|---|---|

| Mababang gastos sa pagmamanupaktura | Mabigat, nagdaragdag sa unsprung weight |

| Sapat na lakas para sa pang-araw-araw na pagmamaneho | Nakararamdam sa kalawang at korosyon |

| Malawakang available bilang mga bahagi ng OEM | Mas hindi matibay kaysa sa mga naka-forge o tubular na disenyo |

| Matibay at Hindi Madaling Masira | Maaaring negatibong makaapekto sa pagmamaneho at kalidad ng biyahe |

Ang Mga Alternatibo: Aluminum, Forged, at Tubular Control Arms

Para sa mga drayber na nagnanais mapabuti ang pagganap ng kanilang sasakyan sa pamamagitan ng pagbabawas ng bigat na hindi nakasuporta, ilang alternatibo sa mga kontrol na bisig na tinatampang bakal ang available. Bawat isa ay nag-aalok ng natatanging balanse ng timbang, lakas, gastos, at katangian ng pagganap, na naaayon sa iba't ibang aplikasyon mula sa pang-araw-araw na pagmamaneho hanggang sa kompetisyong karera.

Aluminum control arms ay isang sikat na upgrade, kinahuhumalingan dahil sa malaking pagtitipid sa bigat. Bilang Metrix Premium Parts ang aluminoy ay mas magaan kaysa bakal, na direktang nagpapabawas sa bigat ng unsprung weight at nagpapabuti sa pagtugon ng suspensyon. Ang materyal na ito ay likas na nakakalaban sa korosyon. Ang pangunahing kalakdang isinusugal ay karaniwang gastos at, sa ilang kaso, tibay. Bagaman malakas, ang aluminoy ay maaaring mas madaling pumutok o masira sa ilalim ng matinding impact kumpara sa kakayahang lumuwog ng bakal.

Pinagtagpi na mga control arm kumakatawan sa isang hakbang palapit sa higit na lakas. Ang proseso ng forging ay nagsasangkot ng pagbuo ng hugis ng metal sa ilalim ng napakalaking presyon, na nag-uuri sa panloob na estruktura ng grano ng materyal. Ito ay nagreresulta sa isang bahagi na lubhang matibay at lumalaban sa pagod, kadalasang mas malakas kaysa sa mga bahagi na stamped steel at cast aluminum. Nag-aalok ito ng mahusay na kombinasyon ng lakas at makatwirang timbang, bagaman kadalasang mas mahal ito kaysa sa mga opsyon na stamped steel.

Tubular control arms ay isang mataas na pagganap na solusyon na madalas makita sa mga kotse sa rumba at sa pagpapanumbalik ng mga klasikong sasakyan. Gawa ito mula sa matibay na bakal na tubo, na nag-aalok ng mahusay na ugnayan ng lakas at timbang. Mas magaan at mas matibay ang mga ito kumpara sa mga katumbas na gawa sa stamped steel, na nagbibigay ng tumpak na heometriya ng suspensyon at malaki ang pagbawas sa di-nakasakay na timbang. Ang kanilang disenyo ay nagbibigay-daan sa pinakamainam na mga anggulo para sa camber at caster, na lalong pinalalakas ang dinamika ng pagmamaneho.

| Uri ng Control Arm | Pangunahing Beneficio | Pangunahing kahinaan | Karaniwang Gamit | Relatibong Gastos |

|---|---|---|---|---|

| Nakastampang bakal | Mababang gastos | Mabigat / Buhawi | OEM / Pang-araw-araw na Sasakyan | Mababa |

| Aluminum | Magagaan / Lumalaban sa Kalawang | Mas Mataas na Gastos / Maaaring Mabali | Mga Sasakyang May Pagganap at Luho | Katamtaman |

| Nakahugis na Metal (Steel/Alum.) | Superior na Lakas | Mataas na gastos | Malakas / Mataas na Pagganap | Mataas |

| Tubular steel | Mataas na Rasyo ng Lakas-kabataan | Pinakamataas na Gastos / Para sa Rumba | Rumba / Pro-Touring | Napakataas |

Mga madalas itanong

1. Ano ang pagkakaiba sa pagitan ng stamped at forged control arms?

Ang pangunahing pagkakaiba ay nasa kanilang proseso ng pagmamanupaktura at sa resultang lakas. Ang mga stamped na control arm ay ginagawa sa pamamagitan ng pagpindot at pagwelding ng mga sheet ng bakal, na matipid sa gastos ngunit nagreresulta sa mas mabigat at hindi gaanong matibay na bahagi. Ang mga forged na control arm ay ginagawa sa pamamagitan ng pagsikipin ng mainit na piraso ng metal sa isang die, na nag-uuri sa panloob na estruktura ng grano, lumilikha ng mas matibay, mas madensidad, at mas lumalaban sa pagkapagod na sangkap nang walang sobrang timbang ng ilang stamped na disenyo.

2. Mahinahon ba ang mga stamped steel control arms?

Oo, sila nga. Ang bakal ay isang ferrous na metal, na nangangahulugang ito ay may nilalamang bakal at magnetic. Ang isang simpleng paraan upang malaman kung ang isang control arm ay gawa sa bakal o aluminum ay ang paggamit ng isang magnet. Kung mahigpit na humahawak ang magnet sa control arm, ito ay gawa sa cast iron o stamped steel. Kung hindi ito humahawak, malamang na gawa ito sa aluminum.

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —

Maliit na mga batch, mataas na pamantayan. Ang serbisyo sa paggawa ng mabilis na prototyping namin ay gumagawa ng mas mabilis at mas madali ang pagpapatunay —