Sheet Metal Cutting Service Secrets: Match Technology To Your Project

What Sheet Metal Cutting Services Actually Deliver

Ever wondered how a flat metal sheet transforms into the precise bracket in your car's suspension or the sleek enclosure protecting sensitive medical equipment? That transformation begins with a sheet metal cutting service—the critical first step in turning raw materials into functional, precision-engineered components.

At its core, this process involves removing material from metal sheets using specialized cutting methods that apply force, heat, or abrasive streams to achieve exact specifications. Whether you're working with steel plates, metals aluminium, or specialty alloys, the cutting technique you choose directly impacts your project's quality, timeline, and budget.

From Raw Material to Precision Parts

Think of sheet metal fabrication as a journey. It starts with flat stock—typically materials measuring 6mm or less in thickness—and ends with components ready for assembly in everything from aircraft fuselages to corrugated metal roofing systems. The cutting phase is where your design literally takes shape.

Modern metal fabrication capabilities extend far beyond simple straight cuts. Today's technologies can produce intricate patterns, tight tolerances, and complex geometries that would have been impossible just decades ago. According to industry reports, the U.S. metal fabrication sector employs over 400,000 skilled workers and generates more than $21 billion annually—a testament to how essential these services have become.

The Foundation of Modern Metal Fabrication

Why does understanding cutting technologies matter before you contact fabrication shops near me? Because the method you select influences every downstream decision: part tolerances, edge quality, secondary processing requirements, and ultimately, your total project cost.

Here's what makes this knowledge so valuable: each cutting technology excels in specific scenarios. Choosing incorrectly can mean excessive burr removal, heat-affected zones that weaken your material, or simply paying more than necessary for capabilities you don't need.

Industries across the manufacturing spectrum depend on professional cutting services to maintain efficiency and precision:

- Automotive and Transportation: Chassis components, body panels, and structural reinforcements

- Aerospace: Aircraft frames, engine components, and precision brackets requiring tight tolerances

- Medical Equipment: Surgical instruments, diagnostic device enclosures, and hospital bed frames

- Construction: Structural supports, HVAC ductwork, and architectural elements

- Energy: Solar panel mounts, wind turbine housings, and power generation equipment

- Electronics: Enclosures, heat sinks, and mounting brackets

- Agriculture: Machinery components, storage systems, and irrigation equipment

For engineers, procurement specialists, and project managers evaluating their options, the sections ahead break down exactly what you need to know—from comparing laser, waterjet, and plasma technologies to understanding how material selection affects your cutting method choice. You'll gain the practical insights needed to match the right technology to your specific project requirements.

Five Cutting Technologies and When to Use Each

Selecting the wrong cutting method can cost thousands in wasted material, rework, and missed deadlines. Imagine choosing plasma when your thin aluminum panels require precision laser cutting—or specifying waterjet when a simple shear would deliver identical results at half the cost. Understanding what each technology does best helps you avoid these expensive mismatches.

Modern sheet metal cutting services offer five primary methods, each engineered for specific applications. Let's break down how each works and when you should choose one over another.

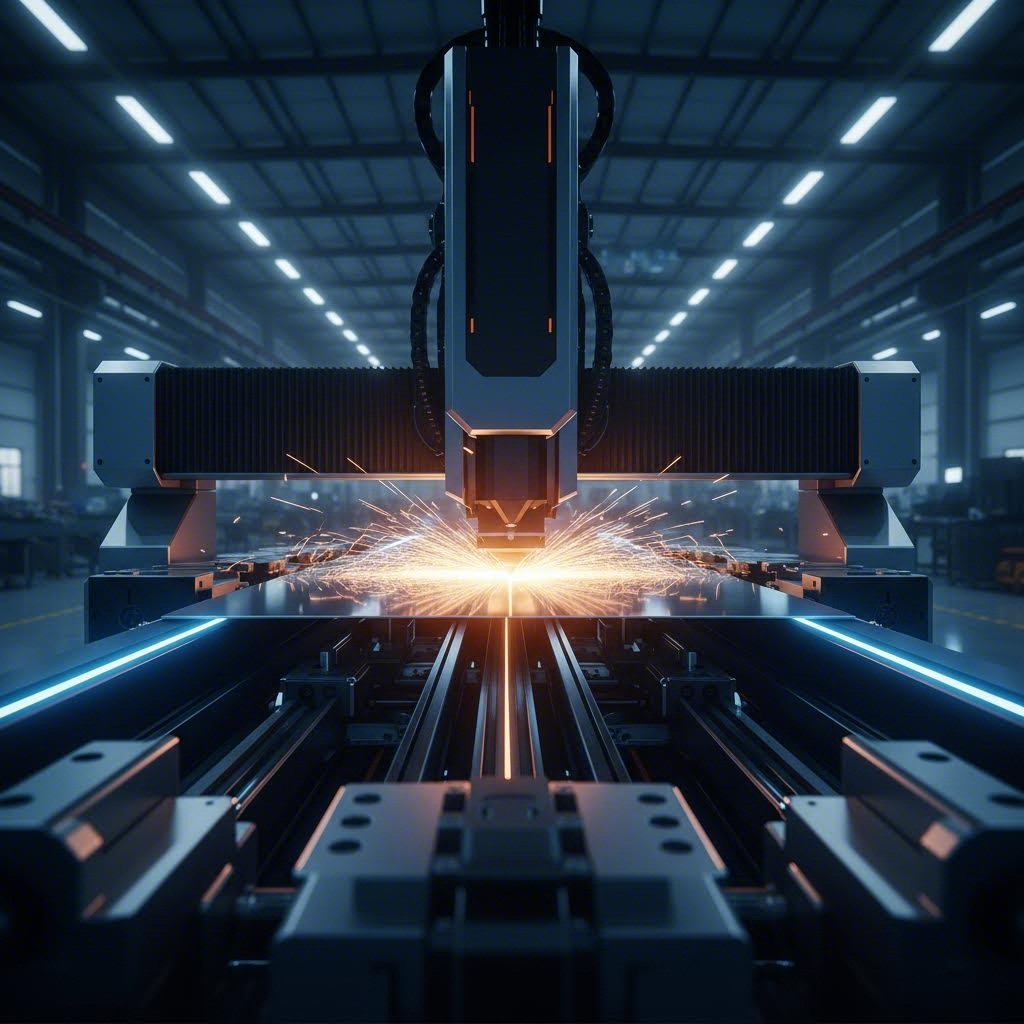

Laser Cutting Technology Explained

A laser cutter focuses intense light energy to melt, burn, or vaporize material along a programmed path. The result? Exceptionally clean cuts with minimal post-processing on thin to medium-thickness materials. When your project demands intricate shapes, small holes, or tight tolerances, precision laser cutting delivers what other methods simply cannot match.

But here's what many engineers don't realize: not all laser cutting is created equal. The two dominant technologies—CO2 and fiber lasers—serve fundamentally different purposes.

CO2 Lasers emit light at 10.6 µm wavelength and excel with non-metallic materials like acrylic, wood, leather, and certain plastics. They also handle thicker metal plates (10-20mm or more) effectively, particularly when paired with oxygen assist for faster processing. However, CO2 systems consume considerably more power—operating at just 5-10% efficiency—which drives up operational costs significantly.

Fiber Lasers operate at 1064 nm wavelength and dominate metal cutting applications. According to Xometry's technical comparison, fiber lasers deliver approximately 3 to 5 times the productivity of similarly capable CO2 machines on appropriate jobs. Their efficiency exceeds 90%, meaning dramatically lower electricity costs. Plus, fiber laser cutting services typically achieve working lives of 25,000 hours—ten times longer than CO2 alternatives.

For reflective metals like aluminum, brass, and stainless steel, fiber laser systems handle these challenging materials without the reflection issues that plague older CO2 technology. The trade-off? Higher upfront equipment costs—sometimes 5 to 10 times more expensive than equivalent CO2 systems.

Waterjet and Plasma Alternatives

When heat becomes the enemy, waterjet cutting steps in. This cold-cutting process uses high-pressure water (often 60,000-90,000 PSI) mixed with abrasive garnet particles to slice through virtually any material without thermal distortion.

Why does this matter? Heat-affected zones can alter material properties, cause warping, and require additional annealing treatments. Waterjet eliminates these concerns entirely. For aerospace titanium brackets, heat-treated tool steels, or materials where microstructure integrity is critical, waterjet becomes the only viable option.

The versatility extends beyond metals. Stone, glass, composites, and food products—waterjet handles them all. Industry projections show the waterjet market reaching over $2.39 billion by 2034, driven by demand for heat-free cutting across diverse industries.

Plasma cutting takes the opposite approach, using an electrical arc and compressed gas to create temperatures exceeding 20,000°C. This makes it the speed champion for thick conductive metals. Cutting 1-inch steel? Plasma processes approximately 3-4 times faster than waterjet, with operating costs roughly half as much per linear foot.

The trade-off is precision. Plasma tolerances range from ±0.5 to ±1.5mm—acceptable for structural fabrication, shipbuilding, and heavy equipment, but insufficient for tight-tolerance assemblies.

Mechanical Shearing for High-Volume Work

Sometimes the simplest solution works best. Mechanical shearing uses opposing blades—like industrial scissors—to make straight cuts through metal sheets. No consumables, no heat, just clean mechanical force.

For high-volume blanking operations where you need thousands of rectangular or square pieces, shearing delivers unmatched speed and cost efficiency. The process handles materials up to approximately 12mm thick while maintaining ±0.1 to ±0.5mm tolerances depending on blade condition and material properties.

The limitation? Geometry. Shearing only produces straight cuts. Complex shapes, curves, or internal features require other methods.

CNC Router CNC Systems round out the options for specific applications. While primarily associated with wood, plastics, and composites, CNC routing handles softer metals like aluminum when equipped with appropriate tooling. These systems excel for larger format pieces and materials where a die cut machine might be overkill.

Tube laser cutting services represent a specialized variation worth noting—these systems rotate tubular stock while the laser head traces complex patterns, enabling features that would be impossible with flat-sheet methods alone.

Comprehensive Method Comparison

How do you translate all this into practical decisions? The following comparison breaks down each metal cutter technology across the factors that matter most for your projects:

| Factor | Laser (Fiber) | Waterjet | Plasma | Shearing | CNC Routing |

|---|---|---|---|---|---|

| Material Compatibility | Most metals, especially reflective types | Any material except tempered glass | Conductive metals only | Sheet metals up to 12mm | Soft metals, plastics, composites |

| Thickness Range | Up to 25mm (precision degrades above 20mm) | Up to 200mm with consistent precision | 100mm+ capability | Up to 12mm | Varies by material hardness |

| Precision Tolerances | ±0.05 to ±0.1mm | ±0.03 to ±0.08mm | ±0.5 to ±1.5mm | ±0.1 to ±0.5mm | ±0.1 to ±0.25mm |

| Edge Quality | Excellent, minimal burr | Excellent, no heat-affected zone | Good, may require cleaning | Good on thin materials | Good, may require deburring |

| Processing Speed | Very fast on thin materials | Slower, especially on thick materials | Fast on thick metals | Very fast for straight cuts | Moderate |

| Equipment Cost | High (~$90K-$500K+) | Very high (~$195K+) | Moderate (~$90K) | Low to moderate | Moderate |

| Operating Cost | Low (high efficiency) | Moderate (abrasive consumption) | Low per foot | Very low | Low |

| Best Application | Precision parts, intricate designs | Heat-sensitive materials, maximum accuracy | Structural steel, thick plates | High-volume blanking | Large format, soft materials |

The decision framework becomes clearer when you focus on your specific constraints. Need fiber laser cutting services for reflective metals under 20mm? Laser is your answer. Require heat-free processing for aerospace alloys? Waterjet delivers. Fabricating structural steel components where speed trumps precision? Plasma makes economic sense.

Understanding these distinctions positions you to have informed conversations with service providers—and more importantly, to avoid paying for capabilities your project doesn't actually require. The next critical decision? Matching your chosen technology to the specific material you're cutting.

Material Selection Guide for Optimal Cutting Results

You've identified the right cutting technology—but here's the challenge: that decision means nothing if you don't account for what you're actually cutting. The same laser settings that produce flawless edges on carbon steel can destroy a stainless steel sheet or create excessive burr on aluminum. Material properties dictate everything from cutting speed to edge quality to whether your parts arrive within tolerance.

Understanding how different metals behave under cutting forces, heat exposure, and abrasive streams helps you specify the right process from the start. Let's examine the major material categories and what makes each one unique.

Steel and Stainless Steel Cutting Considerations

Ferrous metals remain the backbone of metal fabrication projects worldwide. Carbon steel, stainless steel, and specialty alloys like AR500 each present distinct cutting characteristics that influence method selection.

Carbon Steel (Mild Steel) is the most forgiving material for cutting operations. Its moderate tensile strength (typically 400-550 MPa) and thermal conductivity make it compatible with virtually every cutting method. Laser cutting excels here, particularly with oxygen assist gas that accelerates the cutting reaction on thicker steel plate stock. Plasma handles heavy plates efficiently, while shearing works perfectly for high-volume blanking operations.

Stainless Steel introduces complexity. According to Universal Tool's technical analysis, stainless steel produces clean, high-quality edges when using fiber lasers even at higher thicknesses—making it an excellent candidate for precision work. However, the material's lower thermal conductivity compared to carbon steel means heat concentrates at the cut zone, requiring careful parameter adjustment to prevent discoloration and warping.

316 stainless steel deserves special mention. This chromium-nickel-molybdenum alloy offers superior corrosion resistance but cuts approximately 15-20% slower than standard 304 grades due to its higher nickel content. When specifying cutting for marine, chemical processing, or medical applications, factor this speed difference into your timeline expectations.

AR500 Steel represents the challenging end of the spectrum. With Brinell hardness ranging from 470 to 500 HB and tensile strength exceeding 1,380 MPa, this abrasion-resistant alloy demands specialized approaches. According to Metal Zenith's technical documentation, plasma cutting handles AR500 effectively for armor plating, mining equipment, and heavy machinery components. Laser cutting works but requires slower speeds and higher power settings. Waterjet remains the preferred choice when heat-affected zones must be completely eliminated—critical for applications where the steel's hardness cannot be compromised.

Here are the optimal cutting methods for ferrous materials:

- Carbon Steel (up to 25mm): Fiber laser with oxygen assist, plasma for thick plates, shearing for blanks

- Stainless Steel Sheet: Fiber laser with nitrogen assist (prevents oxidation), waterjet for heat-sensitive grades

- AR500 and Hardened Steels: Waterjet (no heat-affected zone), plasma (cost-effective for thick sections)

Aluminum and Soft Metal Challenges

Non-ferrous metals behave fundamentally differently under cutting operations. Their high thermal conductivity, lower melting points, and reflective surfaces create challenges that require adjusted strategies.

Aluminum sheet metal exemplifies these difficulties. The material's thermal conductivity—approximately 205 W/m·K compared to steel's 50 W/m·K—means heat dissipates rapidly from the cut zone. This sounds beneficial but actually requires significantly more energy input to maintain cutting temperature. Too much power causes melting and burr formation; too little creates incomplete cuts.

The reflectivity issue has largely been solved by modern technology. As Universal Tool notes, fiber lasers handle aluminum exceptionally well despite its reflective properties—a capability that older CO2 lasers struggled with. The key is using nitrogen assist gas to prevent oxidation on the cut edge, which would otherwise create a rough, discolored surface unsuitable for visible applications or anodized aluminum finishing.

Copper and Brass present even greater challenges due to their extreme thermal conductivity and reflectivity. Traditional cutting methods often struggled with these materials, but fiber laser technology has changed the equation. When comparing brass vs bronze for your application, remember that brass (copper-zinc alloy) cuts more predictably than bronze (copper-tin alloy) due to its more consistent composition. Both require high-precision fiber lasers operating at specific parameters to achieve clean results.

Optimal cutting methods for non-ferrous materials:

- Aluminum (thin to medium gauge): Fiber laser with nitrogen assist, waterjet for thick sections or heat-sensitive alloys

- Copper: High-power fiber laser with specialized settings, waterjet for thick stock

- Brass: Fiber laser for precision work, waterjet for maintaining surface finish

Specialty Alloys and Exotic Materials

Beyond common metals, certain applications demand specialty alloys where cutting method selection becomes even more critical.

Titanium offers the highest strength-to-weight ratio of common engineering metals but also the highest price point. Its low thermal conductivity concentrates heat at the cut zone, while its reactivity with oxygen at elevated temperatures creates oxidation risks. Laser cutting works with inert gas shielding, but waterjet remains the gold standard for aerospace titanium components where microstructure integrity cannot be compromised.

Nickel Alloys (Inconel, Hastelloy) used in high-temperature and corrosive environments require waterjet or specialized laser cutting. These materials work-harden rapidly, making traditional machining difficult after cutting.

The table below summarizes how key material properties influence cutting parameter decisions:

| Material Property | Impact on Cutting | Adjustment Required |

|---|---|---|

| High Tensile Strength | Increased cutting force/energy needed | Higher power, slower feed rates |

| High Thermal Conductivity | Heat dissipates from cut zone | Increased power input, faster processing |

| Low Melting Point | Risk of melting and burr formation | Reduced power, optimized assist gas |

| High Reflectivity | Laser energy reflection (CO2 systems) | Use fiber laser technology |

| Hardness (above 400 HB) | Accelerated tool/consumable wear | Waterjet preferred, adjust expectations |

Material thickness adds another variable. Most laser systems handle ferrous metals up to 25mm effectively, with precision degrading above 20mm. Aluminum capabilities typically max out around 12-15mm for quality cuts. AR500 and hardened steels may require plasma or waterjet for sections exceeding 10mm where laser would produce excessive heat-affected zones.

When specifying your sheet metal cutting service, communicate both the material grade and thickness clearly. A request for "stainless steel" doesn't tell the fabricator enough—specifying "316 stainless steel, 3mm thickness" enables accurate method selection and pricing. This precision in communication becomes even more important when we examine the tolerance specifications and edge quality standards that define successful cutting outcomes.

Tolerances and Edge Quality Standards Explained

Sounds complex? Here's the reality: your cutting method might produce parts that look perfect but fail to assemble. Why? Because tolerances—the acceptable deviation from specified dimensions—vary dramatically between technologies. Understanding these specifications separates successful projects from costly rework.

When you review a sheet metal gauge chart and specify 14 gauge steel thickness (approximately 1.9mm) for your brackets, you're also inheriting the tolerance capabilities of whatever cutting process you select. Let's decode what these specifications actually mean for your projects.

Understanding Tolerance Specifications

In precision manufacturing, tolerance defines the acceptable amount of variation when processing a part. Think of it as the wiggle room between your design intent and physical reality. Tighter tolerances mean parts fit together more precisely—but they also cost more to achieve.

According to A-Laser's technical specifications, different cutting technologies achieve vastly different precision levels:

| Cutting Technology | Typical Tolerance Range | Best Applications |

|---|---|---|

| UV Laser | ±0.0005" (±0.0127mm) | Micro-precision components, medical devices |

| Fiber Laser | ±0.001" (±0.025mm) | Stainless steel precision parts |

| CO2 Laser | ±0.002" (±0.05mm) | General metal fabrication |

| Waterjet | ±0.005" to ±0.010" (±0.127-0.254mm) | Heat-sensitive materials, thick sections |

| Stamping | ±0.005" to ±0.010" (±0.127-0.254mm) | High-volume production runs |

| Plasma | ±0.020" to ±0.060" (±0.5-1.5mm) | Structural steel, thick plates |

Here's what many designers miss: these numbers represent best-case scenarios on flat features. When your design includes bends, the tolerance picture changes dramatically. As Protolabs explains, crossing each bend introduces additional variation—approximately ±0.030" linear tolerance plus 1° angular tolerance per bend. Four bends between mounting holes? You're now dealing with stacking tolerances that can exceed your original cutting precision by 5-10 times.

What can you do about this? Consider opening mounting holes to accommodate misalignment, or specify floating hardware that self-adjusts during assembly. These design choices effectively trivialize stacking tolerance concerns while maintaining functional performance.

Edge Quality and Surface Finish Expectations

Beyond dimensional accuracy, edge quality determines whether your parts require secondary finishing or proceed directly to assembly. Three critical factors define edge quality: kerf characteristics, thermal effects, and surface contamination.

Kerf refers to the width of material removed during cutting—essentially, the "slot" created by the cutting process. Laser cutting produces narrow kerf widths (typically 0.1-0.3mm for fiber lasers), while plasma creates wider slots (1.5-3mm or more). Why does this matter? Narrow kerf means less material waste and the ability to nest parts more closely together, reducing your per-part costs. For intricate designs with tight feature spacing, kerf width directly limits what's geometrically possible.

When working with 11 gauge steel thickness (approximately 3mm), kerf considerations become especially relevant. Thicker materials require more energy and typically produce wider cuts. Your design should account for this by maintaining adequate spacing between features.

Dross—to define dross simply—is the resolidified metal that adheres to the bottom edge of a cut. Imagine molten material flowing downward during cutting, then cooling and bonding to your part. Excessive dross requires grinding or deburring before assembly, adding time and cost. Laser cutting with optimized parameters produces virtually dross-free cuts on appropriate materials, while plasma typically leaves some residue requiring cleanup.

The heat-affected zone (HAZ) represents the area adjacent to the cut where material properties have been altered by thermal exposure. In this zone, the metal experiences rapid heating and cooling cycles that can change hardness, reduce corrosion resistance, or introduce internal stresses. For hardened steels, a significant HAZ can soften the material exactly where you need strength most. For stainless steel, it can reduce corrosion resistance along the cut edge.

Waterjet cutting eliminates HAZ entirely since it's a cold-cutting process. Laser cutting minimizes HAZ through precise energy control, while plasma creates the largest affected zones due to its extreme temperatures.

Understanding these quality factors helps you specify realistic expectations when requesting quotes. A precision bracket requiring ±0.001" tolerance with zero dross on 316 stainless steel demands fiber laser processing—and commands pricing that reflects those capabilities. Meanwhile, structural components for welded assemblies can often accept wider tolerances and minor cleanup requirements, making plasma or even shearing economically sensible.

With tolerances and edge quality defined, the next consideration becomes what happens after cutting—the secondary operations that transform cut pieces into finished components.

Beyond Cutting to Complete Fabrication Workflows

Your parts just came off the laser table with perfect edges and tight tolerances. Now what? For most projects, cutting represents just the first chapter in a longer manufacturing story. The real value of a comprehensive sheet metal cutting service emerges when you understand how cutting integrates with everything that follows—bending, hardware insertion, welding, and finishing operations that transform flat pieces into functional assemblies.

Imagine ordering cut blanks from one vendor, then shipping them to another for bending, and yet another for powder coating. Each handoff introduces delays, quality risks, and logistical headaches. Smart procurement consolidates these operations with providers who handle the complete workflow in-house.

Secondary Operations After Cutting

Once cutting is complete, your parts typically require additional processing before they're ready for use. These secondary operations add functionality, improve assembly efficiency, and prepare surfaces for finishing. According to Seconn Fabrication's capabilities overview, consolidating these processes with a single provider reduces costs and accelerates turnaround times by eliminating multi-vendor coordination.

Here are the most common secondary operations you'll encounter:

- Bending and Forming: Transforms flat blanks into three-dimensional shapes using press brakes or rolling equipment

- Tapping: Creates internal threads in pre-cut holes for fastener attachment

- Countersinking: Chamfers hole edges to accept flush-mount screws

- Hardware Insertion: Press-fits threaded inserts, standoffs, or captive fasteners into existing holes—a cost-effective alternative to welding

- Welding: Joins multiple cut pieces into unified assemblies through MIG, TIG, or spot welding processes

- Assembly: Combines components with fasteners, adhesives, or mechanical connections into ready-to-install units

- Graining and Polishing: Applies consistent surface textures or mirror finishes to visible surfaces

Hardware insertion deserves special attention. This process utilizes the holes created during cutting to precisely locate fasteners pressed into the metal. Why choose this over welding? It maintains tighter positional accuracy, eliminates heat distortion, and often costs less for high-volume production. When your design requires threaded mounting points, rubber gasket seating surfaces, or captive nuts, discuss insertion options with your fabricator early in the quoting process.

Bending and Forming Integration

Here's something many designers overlook: your cutting tolerances mean nothing if bending introduces unpredictable variation. The relationship between cutting and bending is intimate—hole positions, bend relief cuts, and feature placement all depend on understanding how the material will behave during forming.

Modern fabrication shops use rolling equipment capable of handling various material thicknesses. For example, four-roll plate benders can process materials up to approximately 6mm thick and create cylinders up to 47 inches in diameter. Three-roll systems handle lighter gauge materials—typically up to 11 gauge—for smaller diameter applications. This equipment enables curved enclosures, cylindrical housings, and conical transitions that would be impossible with press brake operations alone.

When specifying parts that require both cutting and bending, consider these integration factors:

- Bend allowance: Material stretches during bending, affecting final dimensions—your cut blank must account for this

- Grain direction: Bending perpendicular to the rolling grain reduces cracking risk

- Minimum flange length: Too-short flanges won't seat properly in the press brake

- Hole proximity to bends: Features too close to bend lines distort during forming

Aluminum welding presents unique challenges when joining bent aluminum components. The material's thermal conductivity and oxide layer require specialized techniques—typically TIG welding with proper filler selection. Discuss these requirements upfront if your assembly includes welded aluminum sections.

Surface Finishing Options

The finish you select protects your parts from corrosion, enhances appearance, and sometimes adds functional properties. Your choice depends on the base material, operating environment, and aesthetic requirements.

Powder Coat finishes dominate metal fabrication for good reason. This electrostatically applied dry powder—typically epoxy, polyester, or hybrid formulations—cures into a durable coating that resists chipping, scratching, and fading. Powder coating services offer hundreds of color options, various textures from smooth gloss to rough matte, and specialized formulations for outdoor exposure, chemical resistance, or antimicrobial properties.

The process works beautifully with steel and aluminum but requires proper surface preparation. Parts must be cleaned, sometimes phosphated or chromated, and completely dry before coating application. Lead times typically add 2-5 days depending on batch sizes and color requirements.

Anodizing serves aluminum components specifically. This electrochemical process creates an integrated oxide layer that becomes part of the base material—not a coating sitting on top. Anodized aluminum resists corrosion, accepts dyes for coloring, and provides excellent wear resistance for high-contact surfaces. Type II anodizing suits decorative applications, while Type III (hardcoat) anodizing creates extremely durable surfaces for aerospace, military, and industrial components.

Other finishing options include:

- Electroplating: Deposits zinc, nickel, or chrome for corrosion protection and appearance

- Passivation: Chemical treatment that enhances stainless steel's natural corrosion resistance

- Painting: Liquid-applied coatings for specialized requirements or small quantities

- Silk Screening: Adds logos, labels, or instructional graphics directly to finished surfaces

When evaluating providers, ask whether they handle finishing in-house or subcontract to third parties. In-house capabilities mean faster turnaround and unified quality control. Subcontracting introduces additional handling, potential damage risks, and longer lead times—factors that compound when you're managing tight production schedules.

Understanding this complete workflow—from cutting through secondary operations to final finishing—positions you to optimize designs for manufacturability and select partners who deliver truly finished products rather than just cut pieces. The next step? Ensuring your design files set the stage for success from the very beginning.

Design Guidelines That Reduce Costs and Errors

You've selected the perfect cutting technology and material for your project. But here's the catch—none of that matters if your design file sets you up for failure. The distance between a hole and an edge, the width of a connecting tab, even how you name your file layers can determine whether your parts arrive perfect or require expensive rework.

Think of design preparation as the foundation supporting everything else. Get it right, and your sheet metal cutting service provider delivers exactly what you envisioned. Get it wrong, and you're facing delays, cost overruns, and parts that don't fit together. Let's break down what separates successful designs from problematic ones.

Design for Manufacturability Essentials

Design for manufacturability (DFM) isn't about limiting creativity—it's about understanding physical realities. According to SendCutSend's Community College series, every cutting process has inherent constraints that dictate minimum feature sizes, spacing requirements, and geometric limitations.

Minimum Feature Sizes exist because cutting tools—whether laser beams, waterjets, or router bits—have physical width. A fiber laser's kerf measures approximately 0.1-0.3mm, meaning internal features smaller than this simply cannot exist. The practical rule? Keep internal cutouts and slots at least 1.5 times material thickness or the kerf width, whichever is larger.

Hole-to-Edge Distance prevents deformation during cutting. When holes sit too close to part edges, heat concentration or mechanical stress creates thin walls that warp, burn through, or tear. A reliable starting point: maintain hole-to-edge distances equal to at least the material thickness. For heat-intensive processes like laser cutting, increase this to 1.5-2 times thickness for safety margins.

Bridge Distance applies when cutting letters or shapes with internal "islands"—think the centers of letters like O, A, or R. Without connecting bridges, these internal pieces fall away during cutting. Bridges should measure at least 50% of material thickness in width, positioned where they'll be least visible after finishing.

When designing for bending operations, the Geomiq sheet metal design guide emphasizes understanding K-factor—the ratio describing where the neutral axis sits within bent material. This value, typically between 0.25 and 0.50, determines how much material stretches during forming and directly affects your flat pattern dimensions. Most CAD programs include K-factor settings, but using manufacturer-specific values from your fabricator ensures accurate results.

Wondering how to cut plexiglass or how do you cut perspex for mixed-material assemblies? The same DFM principles apply—minimum feature sizes, appropriate tool selection, and understanding material behavior under cutting forces. Acrylic requires slower feed rates and specific laser wavelengths to prevent melting or edge frosting.

File Preparation Best Practices

Your design might be perfect, but a poorly prepared file creates confusion, delays, and potential errors. Here's what fabricators need from you:

Accepted File Formats vary by provider, but industry standards include:

- DXF (Drawing Exchange Format): The universal standard for 2D cutting profiles—virtually every service accepts this format

- STEP/STP: Preferred for 3D models requiring bending or complex geometry interpretation

- AI (Adobe Illustrator): Common for decorative or signage work

- PDF: Acceptable for simple profiles, though vector-based PDFs work better than rasterized versions

Critical file preparation steps include converting all text to outlines (fonts don't transfer between systems), removing duplicate overlapping lines that cause double-cutting, and ensuring all geometry forms closed polylines. Open paths or gaps in your cutting profile create ambiguity about what's inside versus outside the part.

Dimensioning and Units cause more errors than you'd expect. Always confirm whether your file uses inches or millimeters—a part designed at 100mm arriving at 100 inches ruins everyone's day. Include key dimensions directly in your file or accompanying documentation, and reference a drill bit size chart or drill size chart when specifying hole sizes to ensure standard tooling compatibility.

Understanding gauge sizes helps communicate material requirements clearly. Rather than assuming your fabricator interprets "16 gauge" the same way you do (steel and aluminum gauge systems differ), specify actual thickness in millimeters or inches alongside gauge references.

Common Mistakes to Avoid

Before submitting your files, run through this design checklist covering the errors that delay projects most frequently:

- Insufficient bend relief: Flanges meeting at corners require relief cuts to prevent cracking—add slots or holes at intersection points

- Features too close to bends: Holes, slots, and tabs distort when positioned within 2-3 times material thickness from bend lines

- Ignoring kerf compensation: Your CAD model shows zero-width lines, but real cuts remove material—adjust critical dimensions accordingly

- Forgetting hardware clearances: Press-fit nuts, standoffs, and rivets need minimum edge distances and flat areas for installation

- Over-specifying tolerances: Requesting ±0.001" precision when ±0.010" suffices dramatically increases costs

- Missing grain direction notes: For visible parts or bending applications, specify whether grain orientation matters

- Incomplete nesting considerations: Parts that nest efficiently reduce material waste—consider how your shapes fit together on standard sheet sizes

Communication with your fabricator prevents most problems before they occur. When submitting complex projects, include a brief description of the application, critical dimensions that must hold tolerance, and any secondary operations required. Ask whether they offer DFM review services—many providers catch issues during quoting that would otherwise surface during production.

The payoff for thorough design preparation? Faster quotes, accurate first-article parts, and production runs that proceed without interruption. With your files optimized, the final consideration becomes selecting the right partner to execute your project—a decision that deserves its own careful evaluation.

How to Evaluate and Select the Right Cutting Partner

Your design files are optimized, your material is specified, and you understand exactly which cutting technology fits your project. Now comes the decision that determines whether all that preparation pays off: choosing the right fabrication partner. The wrong choice means missed deadlines, quality issues, and frustrating communication breakdowns. The right choice? Parts that arrive on-spec, on-time, and within budget.

Finding reliable metal fabrication near me used to mean driving around industrial parks and collecting business cards. Today, you're choosing between traditional job shops with decades of experience and digital-first platforms offering instant quotes from your browser. Both models work—but for different project types. Let's build a framework for making the right match.

Evaluating Provider Capabilities

Before requesting quotes, you need to understand what separates adequate steel fabricators from exceptional partners. According to Thin Metal Parts' evaluation guide, the assessment process should cover technical capabilities, quality systems, and operational factors that affect your project's success.

Technology and Equipment form the foundation. Does the provider operate the cutting technology your project requires? A shop specializing in plasma cutting won't deliver the precision your fiber laser application demands. Ask specifically about equipment manufacturers, age of machinery, and maintenance schedules. Modern equipment with proper upkeep produces consistent results; outdated machines introduce variability.

Material expertise matters equally. Can they handle your specific alloy, thickness range, and surface finish requirements? Some metal fabricators near me specialize in steel fabrication exclusively, while others maintain inventory across dozens of material grades. If your projects span multiple materials, verify they stock—or can source—what you need without extended lead times.

Here are the essential questions to ask potential providers about their capabilities:

- What cutting technologies do you operate, and what are their thickness limitations?

- Can you build a prototype before committing to production quantities?

- What materials do you stock in-house versus source externally?

- What are your typical tolerance capabilities on my material type?

- Do you offer secondary operations like bending, tapping, and hardware insertion?

- How do you ensure repeatability across production runs?

- What's your production capacity, and can you scale with my volume needs?

Prototyping capability deserves special attention. As Thin Metal Parts emphasizes, requesting a prototype—even a virtual one initially—lets you assess quality before committing to production volumes. Providers who resist prototyping or demand full production commitments upfront may lack confidence in their capabilities.

Certifications That Matter for Quality Assurance

Quality certifications tell you whether a provider operates under verified management systems or simply claims to "do quality work." For mission-critical applications, these credentials separate qualified suppliers from risky gambles.

ISO 9001 represents the baseline quality management standard. Certified organizations demonstrate documented processes, customer focus, and continuous improvement commitments. According to industry guidance, always verify ISO certification when your products require consistent quality—which describes virtually every professional application.

IATF 16949 builds on ISO 9001 with automotive-specific requirements. As Xometry's certification overview explains, this framework was developed by the International Automotive Task Force to ensure consistent quality across the automotive supply chain. IATF 16949 certification signals that a manufacturer understands defect prevention, variation reduction, and the rigorous documentation automotive OEMs demand.

Why does this matter for your steel fabrication project? Certification isn't just paperwork—it represents audited systems that catch problems before they reach your dock. Certified providers track corrective actions, maintain calibrated equipment, and train personnel to documented standards. These practices translate directly into fewer quality escapes and more predictable outcomes.

Additional certifications to consider based on your industry:

- ITAR (International Traffic in Arms Regulations): Required for defense-related manufacturing with proper documentation trails

- AS9100: Aerospace quality management extending ISO 9001 with industry-specific controls

- ISO 13485: Medical device quality management for healthcare applications

Online Platforms vs. Traditional Job Shops

The fabrication landscape has split into two distinct service models, each optimized for different project profiles. Understanding this distinction helps you choose the right partner faster.

Online instant-quote platforms like OSH Cut and Send Cut Send have transformed how engineers source cut parts. According to OSH Cut's comparison, these platforms offer in-browser design feedback, automatic nesting previews, and pricing transparency that traditional shops simply cannot match. Upload your DXF, configure options, and receive quotes in minutes rather than days.

The advantages are compelling: OSH Cut maintains over 500 material variations in stock, provides instant manufacturability feedback including bend simulations, and guarantees lead times. Their Design for Manufacturability tools catch issues before ordering—auto-resizing tapped holes, detecting deformation problems, and identifying countersunk holes automatically.

When comparing options, Send Cut Send offers similar instant-quoting capabilities but with some limitations. Maximum part sizes, bending thicknesses, and material selections differ between platforms. OSH Cut quotes parts up to 119" x 59" while competitors may limit instant pricing to smaller formats. For complex bend sequences or thicker materials, verify capabilities before assuming online platforms can handle your requirements.

Traditional job shops excel where online platforms reach their limits. Complex assemblies requiring welding, unusual materials not stocked by digital platforms, and projects needing hands-on engineering consultation often fit better with experienced local steel fabricators. These shops may take longer to quote but offer flexibility that standardized online systems cannot provide.

The decision framework becomes clearer when you match project characteristics to service model strengths:

| Project Characteristic | Best Fit: Online Platform | Best Fit: Traditional Shop |

|---|---|---|

| Volume | Prototypes to medium runs | High-volume production |

| Complexity | Cut + bend + simple finishing | Multi-operation assemblies |

| Materials | Standard metals in stock | Exotic alloys, special orders |

| Timeline | Rapid turnaround critical | Flexible scheduling acceptable |

| Engineering Support | Self-service DFM tools | Consultative design assistance |

| Certifications | Verify per platform | Often ISO/IATF certified |

For rapid prototyping where you need parts in days rather than weeks, online platforms deliver unmatched speed. Their automated systems eliminate quoting delays and production scheduling bottlenecks. But when your project requires IATF 16949-certified production for automotive applications, close collaboration on complex assemblies, or materials outside standard catalogs, traditional metal fabricators near me often provide better solutions.

Before finalizing any partnership, request samples of similar work. As Thin Metal Parts recommends, physical samples reveal quality levels that quotes and capability lists cannot communicate. Examine edge quality, dimensional accuracy, and finishing consistency. These tangible assessments tell you more about what you'll actually receive than any marketing material ever could.

With your evaluation framework established, the next step is understanding how these cutting capabilities translate into real-world applications—from prototype validation through full-scale production.

Industry Applications from Prototyping to Production

You've evaluated providers, optimized your designs, and selected the right cutting technology. But here's where theory meets reality: how do these capabilities translate into actual components for demanding industries? The gap between a well-cut metal plate and a safety-critical automotive bracket isn't just about precision—it's about understanding application requirements and scaling processes that deliver consistent results across thousands of units.

From single prototype validation pieces to production runs of ten thousand steel plates, the journey demands partners who understand your industry's specific demands. Let's examine how sheet metal cutting services support real-world applications, with particular focus on the automotive sector where quality requirements reach their most stringent levels.

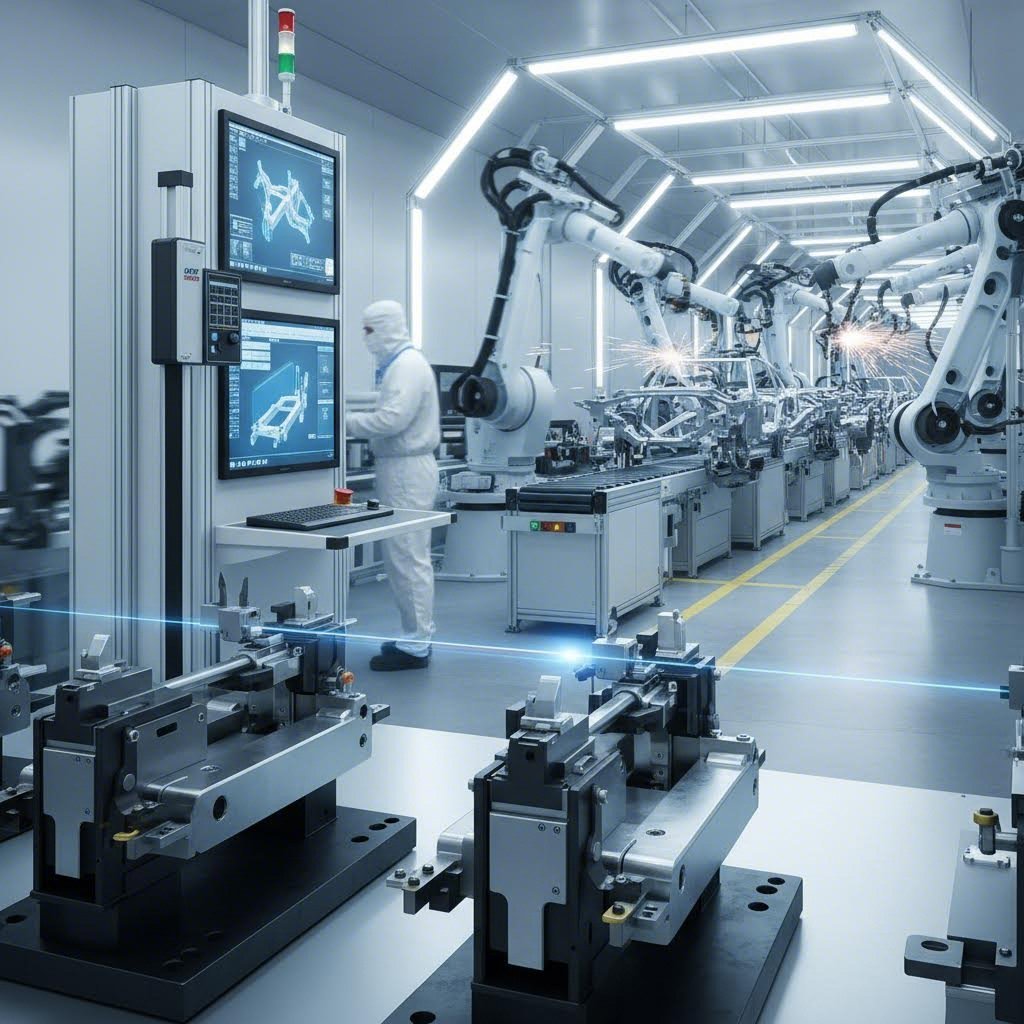

Automotive and Transportation Applications

The automotive industry exemplifies where sheet metal cutting precision matters most. According to Prototek's industry analysis, sheet metal fabrication is essential in making strong, lightweight, and well-designed vehicle parts—affecting everything from safety performance to fuel efficiency and aesthetic appeal.

Consider what's at stake: chassis components absorb crash energy, suspension brackets endure millions of stress cycles, and structural assemblies maintain vehicle integrity under extreme conditions. These aren't decorative pieces—they're safety-critical components where cutting quality directly impacts occupant protection.

Here's how metal fab services support key automotive applications:

- Chassis and Frame Components: Laser-cut stainless steel sheet metal provides the foundation for vehicle structural integrity, requiring precise tolerances where multiple pieces weld together

- Suspension Parts: Brackets, mounting plates, and control arm reinforcements demand both dimensional accuracy and consistent edge quality for reliable fatigue performance

- Body Panels: Doors, hoods, roofs, and fenders—typically cut from aluminum or steel—require smooth edges that accept finishing without additional processing

- Engine Components: Heat shields, brackets, and covers cut from specialty alloys withstand extreme temperatures while maintaining precise clearances

- Interior Structures: Dashboard mounts, seat frames, and safety system supports require accurate hole placement for hardware installation

The exhaust system illustrates multi-material complexity. Pipes, mufflers, and catalytic converter housings require cuts in materials specifically chosen for heat and corrosion resistance. A welding cart loaded with components destined for exhaust assembly might include stainless steel baffles, aluminized steel shells, and specialty alloy flanges—each cut using parameters optimized for that specific material.

What separates automotive-grade manufacturing from general metal fab work? Certification. As Smithers explains, IATF 16949 certification represents an organization's commitment to quality and continuous improvement within the automotive supply chain. This framework extends beyond basic quality management to include defect prevention, variation reduction, and the rigorous traceability automotive OEMs demand.

For chassis, suspension, and structural components where failure isn't an option, IATF 16949-certified manufacturers like Shaoyi (Ningbo) Metal Technology provide the quality assurance automotive applications demand. Their combination of precision cutting capabilities with integrated stamping and assembly operations creates a streamlined path from design to production-ready components.

Modern automotive manufacturing also relies heavily on rivets and mechanical fastening alongside traditional welding. Cut parts often include precisely positioned holes for rivet installation, requiring tolerances that ensure consistent joint strength across high-volume production. The interplay between cutting accuracy and downstream assembly operations makes partner selection critical.

Prototyping to Production Scaling

Here's a reality many engineers discover too late: a prototype that works perfectly at quantity one can become a manufacturing nightmare at quantity ten thousand. According to All Metals Fabrication's scaling guide, small DFM choices invisible in one-off prototypes can multiply cost, increase cycle time, and destabilize production once you go to volume.

The fundamental challenge? Prototypes optimize for speed and form—quick laser cuts, hand-bent flanges, looser tolerances. Production must optimize for repeatability, throughput, and cost per unit. Bridging this gap requires what industry professionals call a "prototype with production intent" mindset.

Typical prototype-to-production mismatch areas include:

- Tolerance Assumptions: Hand-finished prototypes hide variation that automated processes expose

- Material Substitutions: Prototype materials may differ from production specifications

- Process Differences: Prototype cutting methods may not scale economically

- Tooling Requirements: Production volumes may justify dedicated fixtures that prototypes didn't need

Rapid prototyping capabilities serve a critical function beyond simple part production—they enable design validation before committing to production tooling. When you can test form, fit, and function with actual cut parts rather than 3D-printed approximations, you catch problems that would otherwise surface during expensive production runs.

The speed advantage matters enormously. Traditional prototype turnarounds of 2-4 weeks compress design cycles painfully. Modern capabilities—like Shaoyi's 5-day rapid prototyping with 12-hour quote turnaround—accelerate iteration cycles dramatically. Their comprehensive DFM support catches manufacturability issues during quoting rather than after production starts, preventing the costly surprises that derail programs.

What does successful scaling look like in practice? Consider these principles from the All Metals Fabrication guide:

- Design for process capability: Identify the operation that will become your bottleneck and design to its capabilities, not perfection

- Minimize operations: Every extra deburr, welding sub-assembly, or finishing step multiplies cycle time—optimize to reduce or combine operations

- Standardize processes: By reducing special operations, you simplify line balance and reduce variability

- Implement fixture strategy: Modular fixturing converts flexible sheet metal into repeatable, locatable geometry for consistent production

First-article inspection (FAI) represents the critical gate between prototyping and production. This verification process proves that your process and documentation produce parts meeting design intent—including material evidence, process steps, markings, and dimensional data. Treat FAI as a formal event, not a checkbox, and you'll scale metal plate production with fewer surprises.

Revision control becomes equally important as volumes increase. Master part numbers, engineering change order (ECO) templates with impact matrices, and automatic notifications to quality and procurement on revision approval prevent the confusion that derails production schedules. These administrative disciplines seem tedious during prototyping but become essential infrastructure at scale.

The path from concept to volume production doesn't require luck—it requires process. Apply DFM principles from the start, prototype with production intent, select certified partners with scaling experience, and treat the transition as a managed program rather than an afterthought. Do that, and you'll transform steel plates into production-ready assemblies with the predictability your program demands.

Making the Right Choice for Your Metal Cutting Project

You've journeyed through cutting technologies, material science, tolerance specifications, and provider evaluation frameworks. Now comes the moment of decision: translating all that knowledge into action. Whether you're sourcing aluminum sheet for prototype enclosures or metal sheets for production-volume chassis components, the principles remain consistent—match technology to requirements, prepare designs thoughtfully, and partner with capable fabricators.

Matching Technology to Project Requirements

The decision framework you've built throughout this guide distills into three primary variables: material properties, precision demands, and production volume. Get these right, and everything else follows.

The optimal sheet metal cutting method isn't the most advanced or expensive—it's the one that delivers your required precision, on your material, at your volume, within your budget. Laser for precision and speed on thin metals, waterjet for heat-sensitive applications, plasma for thick structural steel, and shearing for high-volume blanking. Match the tool to the task.

When searching for sheet metal near me, remember that geographic proximity matters less than capability alignment. A certified provider across the country who understands your application outperforms a local shop lacking the right equipment or expertise.

Consider how your project fits the technology landscape:

- Prototype validation: Prioritize speed and flexibility—online platforms with instant quoting accelerate iteration cycles

- Production scaling: Emphasize repeatability and certification—IATF 16949 for automotive, AS9100 for aerospace

- Mixed-material assemblies: Seek providers handling both metals and materials like delrin or plastic sheet components under unified quality systems

- Custom metal signs and decorative work: Focus on edge quality and finishing capabilities alongside cutting precision

Taking the Next Step with Confidence

Your path forward involves three concrete actions: finalize design files using the DFM principles covered earlier, request quotes from providers whose capabilities match your requirements, and validate quality through sample parts before committing to production volumes.

Design preparation remains your highest-leverage activity. According to Zintilon's fabrication guidance, the impact of your cutting method extends beyond the immediate cut, influencing subsequent operations like bending, welding, or finishing. A rough-cut edge from plasma cutting might necessitate additional grinding, adding time and cost to the overall process. Prepare files that account for these downstream considerations.

For readers requiring precision metal cutting with integrated stamping and assembly capabilities, manufacturers like Shaoyi (Ningbo) Metal Technology offer comprehensive solutions. Their 12-hour quote turnaround and DFM support help optimize manufacturing projects from initial concept through production—particularly valuable for automotive applications where IATF 16949 certification ensures consistent quality across chassis, suspension, and structural components.

The knowledge you've gained positions you to ask informed questions, evaluate proposals critically, and make decisions that balance quality, cost, and timeline. Request sample cuts for critical applications. Verify certifications match your industry requirements. Confirm secondary operation capabilities before splitting work across multiple vendors.

Sheet metal cutting services form the foundation of modern manufacturing—but only when matched correctly to project demands. Armed with this comprehensive understanding of technologies, materials, tolerances, and provider evaluation criteria, you're prepared to source components that meet specifications, arrive on schedule, and fit your budget. The next move is yours.

Frequently Asked Questions About Sheet Metal Cutting Services

1. How much does metal cutting cost?

Sheet metal cutting costs typically range from $0.50 to $2 per linear inch depending on material type, thickness, and cutting method. Hourly rates generally fall between $20-$30, while full fabrication projects cost $4-$48 per square foot based on customization complexity. Laser cutting commands premium pricing for precision work, while plasma offers cost-effective solutions for thick structural steel. Online platforms provide instant quotes, while traditional shops may require consultation for complex projects.

2. How to cut large pieces of sheet metal?

For large sheet metal pieces, professional services use industrial laser cutters, plasma cutting systems, or waterjet machines depending on material and precision requirements. Fiber lasers handle sheets up to 119" x 59" with tight tolerances, while plasma excels for thick plates over 25mm. For DIY applications, angle grinders, nibblers, and circular saws with metal-cutting blades work for smaller projects, though professional services ensure cleaner edges and tighter dimensional accuracy for critical applications.

3. How much does sheet metal work cost?

Complete sheet metal fabrication ranges from $4 to $48 per square foot, influenced by material selection, cutting complexity, secondary operations like bending and hardware insertion, and finishing requirements such as powder coating or anodizing. Prototype quantities cost more per unit than production volumes due to setup requirements. IATF 16949-certified manufacturers for automotive applications may command higher rates but deliver superior quality assurance for safety-critical components.

4. What is the difference between laser cutting and waterjet cutting for sheet metal?

Laser cutting uses focused light energy to achieve tolerances of ±0.05-0.1mm with excellent edge quality, processing thin to medium materials at high speeds. Waterjet cutting uses high-pressure water with abrasives for cold-cutting that eliminates heat-affected zones, achieving ±0.03-0.08mm tolerances on virtually any material up to 200mm thick. Choose laser for speed and precision on standard metals; select waterjet when thermal distortion must be avoided or when cutting heat-sensitive aerospace alloys.

5. What certifications should I look for in a sheet metal cutting service provider?

ISO 9001 certification establishes baseline quality management standards for consistent results. For automotive applications, IATF 16949 certification is essential, demonstrating defect prevention and traceability requirements demanded by automotive OEMs. Aerospace projects require AS9100 certification, while medical device manufacturing needs ISO 13485 compliance. Defense-related work requires ITAR registration. Always verify certifications directly rather than relying on claims, as certified providers maintain audited systems that catch quality issues before parts ship.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —