Tajne laserskog rezanja metalnih listova: od sirovog čelika do preciznih dijelova

Što zapravo znači lasersko rezanje metalnih listova

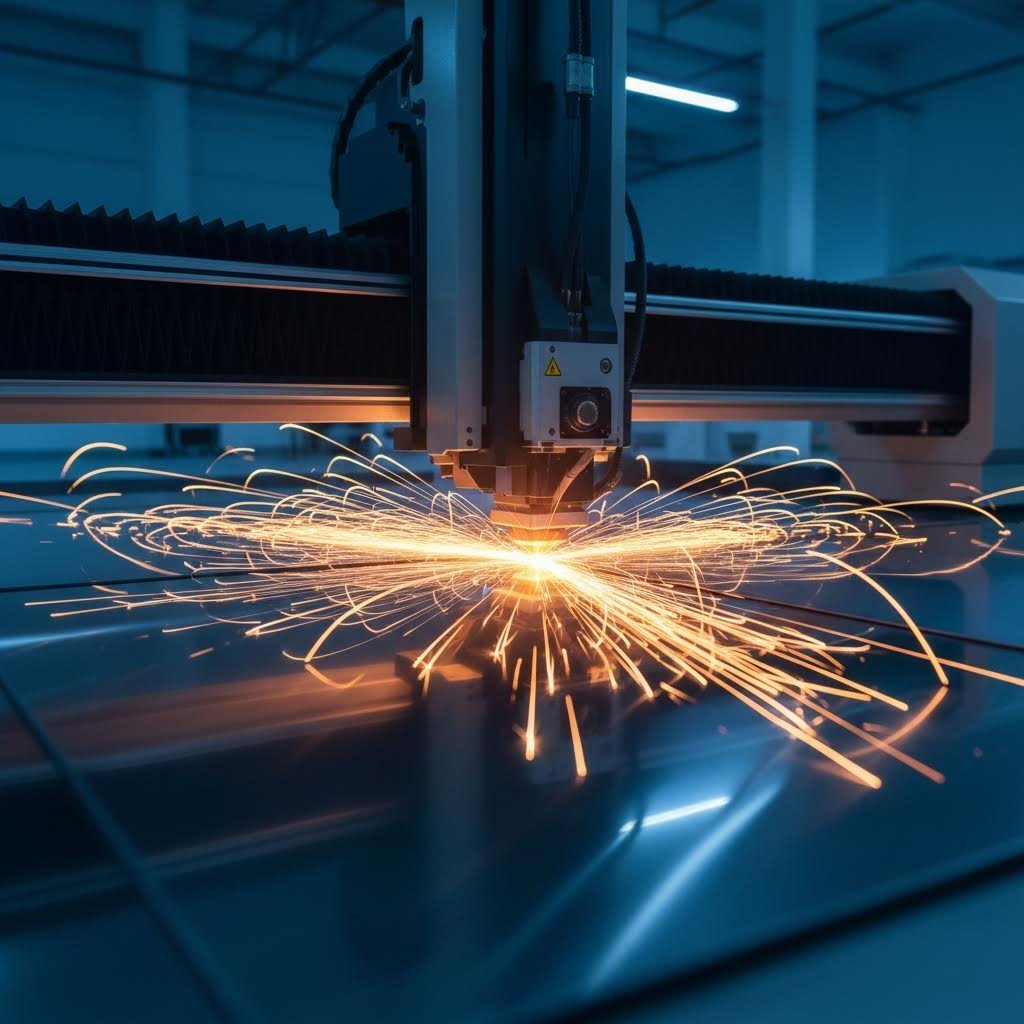

Što je lasersko rezanje i zašto je to promijenilo način na koji oblikujemo metal? Zamislite usmjeravanje nevjerojatno usredotočenog zraka svjetlosti na čelični list i promatranje kako ga probija s kirurškom preciznošću. To se u osnovi događa tijekom operacija laserskog rezanja metalnih listova - Što? Ova tehnologija koristi koncentriranu svjetlosnu energiju da topi, spali ili isparava materijal duž programirane staze, stvarajući rezove tako precizne da se mjere u djelićima milimetra.

Za razliku od tradicionalnih mehaničkih metoda rezanja koji se oslanjaju na fizički kontakt i oštrice, lasersko rezanje metala pretvara svjetlost u moćan proizvodni alat. Što je bilo s time? Čiste ivice, složeni dizajn i minimalni otpad materijala. Bilo da proizvodite automobilske komponente, arhitektonske ploče ili prilagođene znakove, ovaj proces pruža dosljednost koju ručne metode jednostavno ne mogu usporediti.

Znanost koja stoji iza preciznog rezanja metala

Čarolija počinje s laserskim izvorom, obično ili CO2 ili vlakneni laser generator. Ovaj uređaj stvara intenzivno koncentrirani zrak s određenim talasnim dužinama optimiziranim za rezanje metala. Ali evo ključa: sirova laserska svjetlost sama ne može učinkovito rezati. Treba se usredotočiti.

Smatraj to kao da koristiš povećalo da koncentrišeš sunčevu svjetlost. Laserski zrak prolazi kroz specijaliziranu optičku tehnologiju za fokusiranje, obično plan-konveksnu sočivo, koje približava svjetlost do izuzetno male fokalne točke. Prema specifikacije industrije , ta fokusirana točka može postići četverostruko efikasnu snagu u usporedbi s nefokusiranim zraku s istom izlaznom energijom.

Nekoliko komponenti djeluje zajedno kako bi se to dogodilo:

- Izvor lasera: Stvara visokonervno svjetlosno zrako

- Svaka vrsta svjetla mora biti u skladu s ovom Uredbom. Usmjeri laser na rezanje glave

- Smerna sočiva: Koncentrira zrak do maksimalnog intenziteta

- Smanjenje glave s mlaznicom: Isporučuje pomoćni plin i pozicionira zraku

- Sistemi za XY-prikloplje: Premeštaju rezanje glavu precizno preko materijala

Od svjetlosti do čistog roba

Kada fokusirani laser dodirne metalnu površinu, temperature dramatično skoče. Materijal se ne samo zagrijava, već se brzo topi ili isparava točno tamo gdje se zrake dodiruju. U međuvremenu, pomoćni plin, poput kisika ili dušika, puha kroz šofu kako bi se uklonili rastopljeni ostaci i zaštitili područje rezanja.

Rezanje laserom slijedi precizan redoslijed. Prvo, zraka probija metal u početnoj točki. Zatim, pomoću pokreta koje upravlja kompjuter, glava za rezanje prati programirani put. XY sistem portala osigurava da laser slijedi čak i složene krivulje i kutove s iznimnom točkinjom.

Ono što čini metalno lasersko sečenje zaista izvanrednim je njegova ponovljivost. Kada se parametri odaberu, mašina proizvodi identične dijelove bez obzira na to da li pravite jedan ili tisuću. Tipična tolerancija za lasersko sečenje metalnih listova iznosi između plus ili minus 0,005 inča za tanke materijale, što ga čini idealnim za primjene koje zahtijevaju preciznost.

Ova tehnologija postala je industrijski standard za preciznu proizvodnju metala jer nudi ono što druge metode ne mogu pružiti: brzinu bez žrtvovanja točnosti, složenost bez prekomjernih troškova i svestranost u različitim vrstama i debljinama metala. Kao što ćete otkriti kroz ovaj vodič, razumijevanje ovih temelja otvara vrata za učinkovito korištenje ovog moćnog proizvodnog procesa.

Objasnjeno je što je CO2 u odnosu na lasersku tehnologiju vlakana

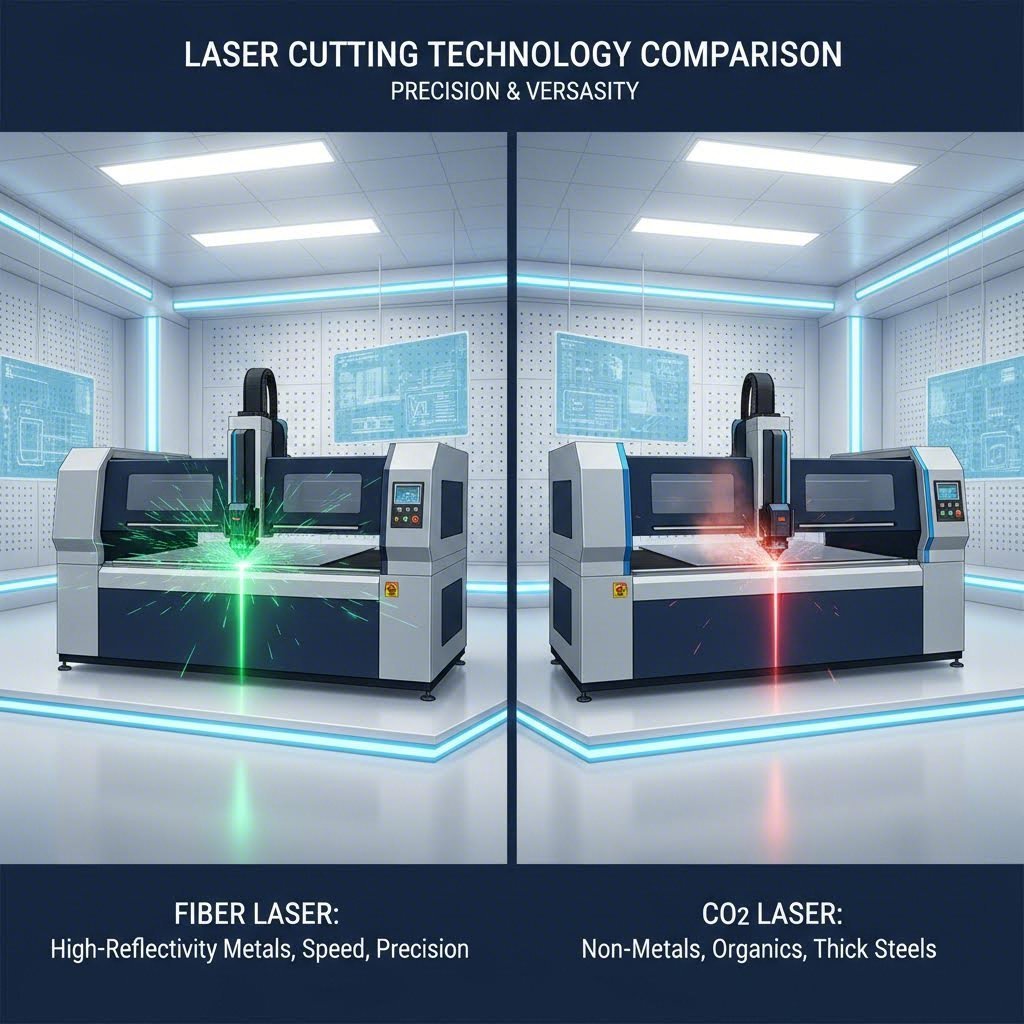

Sada kad znate kako radi lasersko rezanje, evo sljedeće pitanje: koja vrsta lasera bi trebala stvarno raditi rezanje? Dvije tehnologije dominiraju laserskim rezom metalnih listova , a izbor između njih značajno utječe na rezultate, troškove i opcije materijala. Razmotrićemo prave razlike između CO2 i laserskih sustava, kako biste mogli donijeti informiranu odluku.

Obje tehnologije stvaraju snažne svjetlosne zrake, ali to rade na temeljno različite načine. CO2 laser koristi mješavinu plina (uglavnom ugljični dioksid) uzbuđen električnom strujom za proizvodnju svjetlosti. S druge strane, mašina za rezanje laserskih vlakana koristi tehnologiju čvrstog stanja gdje svjetlost iz dioda pumpe putuje kroz optička vlakna dopirana rijetkim zemljama kao što je iterbijum. Ova razlika može zvučati čisto tehnički, ali stvara dramatične razlike u tome kako svaki sustav radi na vašem radnom podu.

Prednosti lasera od vlakana za rad na metalu

Ključna razlika između tih tehnologija se svodi na valnu dužinu. CO2 laser proizvodi svjetlost na 10,6 mikrometara, dok vlakneni laserski rezač radi na približno 1,06 mikrometara, točno deset puta kraće. Zašto je to važno za vaše projekte rezanja metala?

Razmislite o tome kako metali međusobno utječu na svjetlost. Njihove površine sadrže slobodno kretanje elektrona koji brzo reflektuju duže valove. CO2 laser je 10,6 mikrometar duljine valova odbija odbijajući metala kao što su bakar, mesing i aluminij, gubljenje značajne energije prije nego što se rezanje čak i počinje. Međutim, kraća talasna dužina lasera s vlaknima mnogo je učinkovitija u prodiranju kroz elektronsku barijeru, povezujući svoju energiju izravno s materijalom.

Ova superiorna apsorpcija se prevodi u stvarne prednosti:

- Dramatično brže brzine rezanja: CNC vlakna laserski rezač može rezati tanke metale dva do pet puta brže od ekvivalentnih CO2 sustava

- Povećana energetska učinkovitost: Laseri vlakana pretvaraju 30-50% električne ulazne energije u lasersku snagu, u usporedbi s samo 10-15% za CO2 sustave

- Najveća veličina fokusa: Viša kvaliteta zraka stvara uske rezove i mogućnosti finih detalja

- Smanjeno održavanje: Nema ogledala za poravnanje, nema plin cijevi za zamjenu, i minimalni potrošni materijal

- Sposobnost reflektiranja metala: Aluminij, bakar i mesing su čistije rezani bez oštećenja od reflektora

Za tvrtke koje se usredotočuju na proizvodnju metalnih ploča, dijelove automobila ili industrijske komponente, mašine za rezanje vlakana lasera postale su jasni voditelji produktivnosti. Prema analiza sektora , laserski vlakni snage 4 kW mogu rezati kroz 1 mm nehrđajućeg čelika brzinom većom od 30 m/min, dok sličan CO2 laser može postići samo 10-12 m/min na istom zadatku.

Izbor između sustava CO2 i vlakana

Znači li to da su CO2 laseri zastarjeli? -Ne baš. -Da. Dok sustav CNC lasera s vlaknima dominira rezanjem metala, tehnologija CO2 još uvijek se ističe u specifičnim primjenama. Duža talasna dužina koja se bori s reflektornim metalima lako se apsorbira organskim materijalima. Drvo, akril, koža, tekstil i određene plastike lijepo seče CO2 laserima, ali ne reagiraju na valne dužine vlakana.

Za vrlo debele čelikove ploče (preko 20 mm), neki proizvođači još uvijek preferiraju CO2 lasere zbog glatke završetke rubova, iako su moderni visokokvalitetni vlakni sistemi u velikoj mjeri zatvorili ovu jaz. Odluka u konačnici ovisi o vašim primarnim materijalima i proizvodnim prioritetima.

| Radionica | Vlaknasti laser | CO2 laser |

|---|---|---|

| Brzina rezanja (tan metal) | 2-5 puta brže. | Bazna linija |

| Kompatibilnost s metalom | Odličan za sve metale, uključujući reflektorne vrste | Dobro za čelik; bori se s bakrom, mesingom, aluminijem |

| Ne-metalni kompatibilnost | Vrlo ograničeno | Odlično za drvo, akril, plastiku, tekstil |

| Energetska učinkovitost | u slučaju da se ne primjenjuje, to se može učiniti na temelju sljedećih uvjeta: | 10 do 15% učinkovitosti |

| Zahtjevi za održavanje | U slučaju da se ne primijenjuje, potrebno je upisati sljedeće: | Redovito poravnanje zrcala, punjenje plina, čišćenje optike |

| Cijene eksploatacije | Smanjenje potrošnje električne energije i potrošnih materijala | U skladu s člankom 3. stavkom 2. |

| Početni ulog | Viši inicijalni trošak | Donja ulazna točka |

| Tipične primjene | Proizvodnja ploča od metala, automotive, zrakoplovstvo, elektronička oprema | S druge strane, za proizvodnju proizvoda iz kategorije 95.08. |

Evo praktičnog uputstva za odabir: pregledajte svoj spisak narudžbi prije nego što pogledate specifikacije stroja. Ako više od 80% vašeg rada uključuje metalne ploče, laserski vlakni pružaju bolju dugoročnu vrijednost unatoč većim početnim troškovima. Samo ušteda energije može biti značajna, jer vlakneni sustavi koriste otprilike jednu trećinu do jednu petinu električne energije CO2 lasera za jednaku snagu. Za radionice koje služe različitim tržištima s potrebama drveta, akrila i metala, možda ima više smisla održavati obje tehnologije ili odabrati CO2 zbog njegove svestranosti materijala.

Računarski laserski sustavi s vlaknima također su ovu tehnologiju učinili dostupnom manjim operacijama i tvornicama prototipa, iako tvrtke usmjerene na proizvodnju obično ulažu u industrijsku opremu u punom obimu. Razumijevanje koje materijale ćete najčešće rezati ukazuje direktno na pravi izbor tehnologije, a ista svjesnost materijala postaje još kritičnija kada proučavamo kompatibilnost specifičnih metala u sljedećem dijelu.

U skladu s člankom 3. stavkom 2.

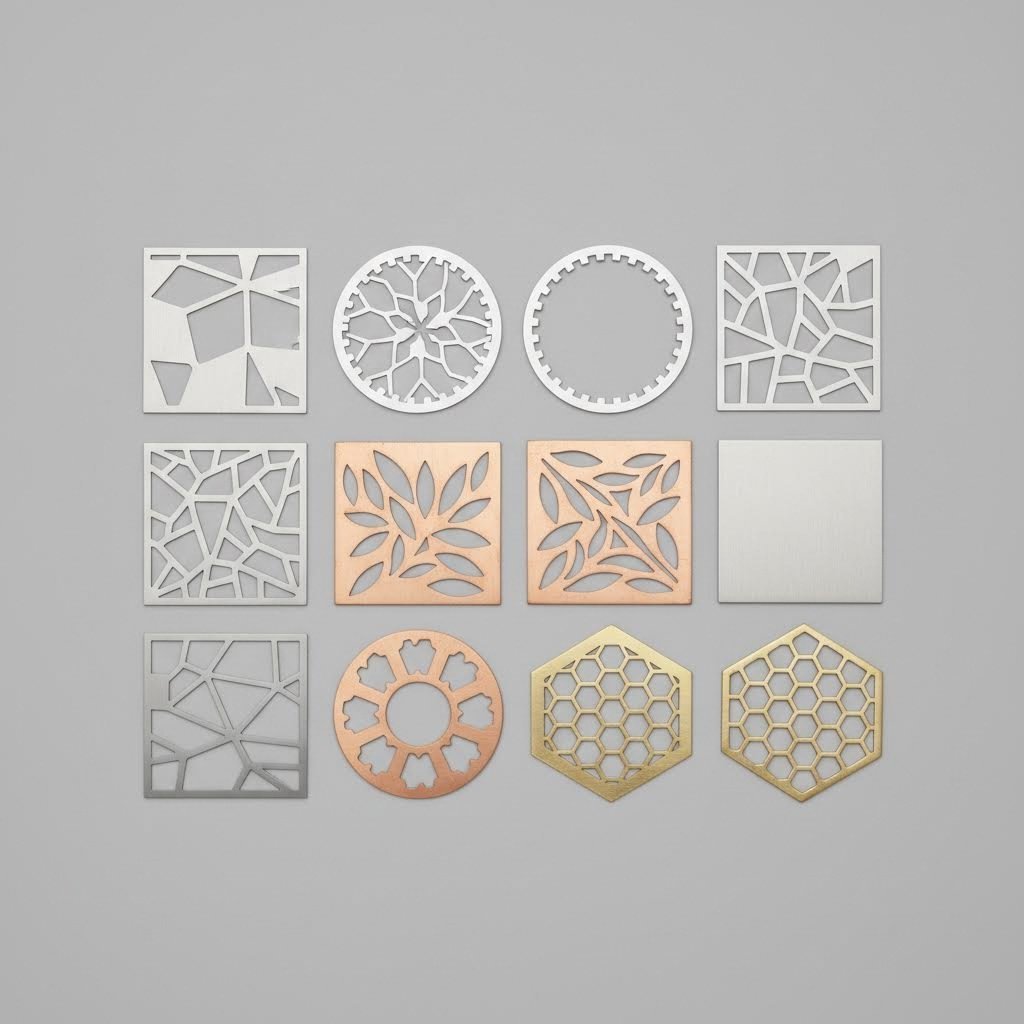

Jeste li se ikad zapitali zašto neki metali klizaju kroz laserski zrak kao maslac dok se drugi bore? Odgovor leži u tri temeljna svojstva: toplinski provodljivost, reflektivnost i tačka topljenja. Razumijevanje kako ti faktori međusobno djeluju s laserskim rezanjem metalnih ploča vas preobražava iz nekoga tko jednostavno šalje datoteke u nekoga tko dizajnira dijelove optimizirane za proizvodnju uspjeha .

Ne reagiraju svi metali jednako na lasersku energiju. Neki od njih učinkovito apsorbiraju toplinu i bez ikakvog napora proizvode netaknute i čiste i čiste rubove. Drugi reflektuju lasersku svjetlost, odvajaju toplinu iz područja rezanja ili se nepredvidljivo ponašaju pod toplinskim stresom. Ispitamo što se točno događa kada obični metali susreću fokusiranu svjetlost, i što je još važnije, kako iskoristiti ovo znanje za bolje rezultate.

Karakteristike rezanja čelika i nehrđajućeg čelika

Ugljični čelik ostaje najčešći materijal za laserski rezni rad na ploči. Njegova umjerena toplinska provodljivost omogućuje toplini da se učinkovito koncentrira u zoni rezanja, dok njegova relativno niska reflektivnost znači da vlakna i CO2 laseri učinkovito spajaju energiju u materijal. Za proizvođače, to znači brze brzine rezanja, čiste ivice i oprostive parametre.

Pri rezanju blage čelika, kisik pomaže gas stvara egzotermnu reakciju koja zapravo dodaje energiju rezu. To znači da lasersko rezanje s kisikom snage 3 kW može postići rezultate slične onima s 6 kW lasera koji koristi dušik. -Kakva je razmjena? Kisik ostavi tanak sloj oksida na rezanih rubova koji se možda mora ukloniti prije varenja ili bojenja.

Lasersko sečenje od nehrđajućeg čelika predstavlja nešto drugačiji izazov. Prema Sklopi od aluminija , nehrđajući čelik je iznimna otpornost na koroziju i izdržljivost čine ga jednim od primarnih metala obrađenih laserskim rezanjem. Materijal zadržava svoj strukturni integritet čak i nakon termičke obrade, osiguravajući čiste rubove bez ugrožavanja svojstava.

U slučaju da se proizvod proizvodi od nehrđajućeg čelika, to znači da se proizvod proizvodi od nehrđajućeg čelika koji se koristi za proizvodnju čelika. Ovaj sastav stvara odličnu otpornost na koroziju, ali i veću toplinsku provodljivost od ugljikovog čelika. Trebat će vam otprilike 1,5 puta više energije da biste seče od nehrđajućeg čelika na jednake brzine. U slučaju nerđajućeg materijala zona koja je pogođena toplinom (HAZ) obično je nešto veća, iako je minimalna u usporedbi s rezom plazmom ili oksigorijevom gorivom.

U slučaju da se ne primjenjuje, potrebno je utvrditi:

- Ugljikov nafta: Najbrže brzine rezanja; pomoć kisika za maksimalnu brzinu, dušik za rubove bez oksida

- T304 nerđajuća: U slučaju da se ne može koristiti nitrogeni plin, potrebno je upotrijebiti i nitrogeni plin.

- T316: nehrđajuća: U skladu s člankom 3. stavkom 1.

- S druge vrijednosti: U slučaju da se ne primijenjuje primjena ovog standarda, potrebno je utvrditi:

Rad s metalnim reflektorima

Možeš li laserom rezati aluminijum? Apsolutno, iako to zahtijeva razumijevanje zašto se ovaj metal ponaša drugačije od čelika. Visoka reflektivnost aluminija u početku odražava značajan dio laserske energije, posebno iz CO2 lasera. Njegova izuzetna toplinska provodljivost, otprilike četiri puta veća od željeza, brzo odvaja toplinu iz zone rezanja. Niska tačka topljenja znači da se prijelaz od čvrste na tekuću tvar događa brzo kada se dovoljno energije nakuplja.

Za uspješno rezanje aluminijuma laserski, laseri od vlakana su postali jasan izbor. Njihova kraća valna dužina prodire kroz reflektornu barijeru aluminijuma mnogo učinkovitije od CO2 sustava. Moderni laseri s vlaknima s tehnologijom protiv odražavanja mogu čistoto rezati aluminij do debljine 25 mm, iako većina aplikacija za ploče uključuje materijal ispod 10 mm.

Aluminijski laserski rez proizvodi različite karakteristike ivica od čelika. Niska tačka topljenja stvara glatke, gotovo polirane ivice na tankim listovima, ali može uzrokovati lagano nakupljanje otpada na debljim dijelovima. Upotreba dušik-pomoćnog plina pri većem pritisku pomaže da se rastopljeni materijal odvaži prije nego što se ponovno zagrli na donjoj ivici.

Bakar i bakr predstavljaju još veće izazove u pogledu reflektivnosti. Prema Longxin Laser je metal rezanje vodič , laseri s vlaknima učinkovito obrađuju reflektirajuće metale poput bakra i mesinga zahvaljujući njihovoj valnoj dužini i učinkovitosti energije. Međutim, za ove materijale potrebne su više postavke snage, obično 50-100% više od čelika jednake debljine, kako bi se prevazišli početni gubitak odražavanja.

U slučaju da se ne primjenjuje, to se može dogoditi u slučaju da se ne primjenjuje.

- Ugljikov nafta: HAZ obično 0,1-0,3 mm; minimalne promjene tvrdoće

- Nerustingajući čelik: HAZ 0,15-0,4 mm; moguće je blago obaranje karbida u vrstama sklonim senzibilizaciji

- Aluminij: HAZ 0,2-0,5 mm; u legurama koje se mogu toplinski tretirati može se pojaviti omekšavanje u blizini ruba reza

- Bakar: HAZ 0,3-0,6 mm; odlična toplinska provodljivost ograničava širenje toplote unatoč većoj ulaznoj snazi

- Brass: HAZ 0,2-0,4 mm; sadržaj cinka utječe na izgled rubova i može proizvesti pare koje zahtijevaju ventilaciju

| Vrsta materijala | Preporučeni laser | Maksimalni raspon debljine | Kvaliteta ruba | Posebna razmatranja |

|---|---|---|---|---|

| Ugljični ocel | Uređaji za proizvodnju električnih goriva | U slučaju da je proizvodnja materijala u skladu s člankom 6. stavkom 1. točkom (a) ili (b) ovog članka, u skladu s člankom 6. stavkom 2. točkom (a) ovog članka, ne smije se upotrebljavati. | Odlična; minimalna otpada | Kisik pomaže povećati brzinu; dušik za čiste rubove |

| Sredstva za proizvodnju i proizvodnju proizvoda | Preporučljivo vlakno | Do 20mm | Vrlo dobro; moguće je blago promjenjivanje boje HAZ-a | Sklopna površina |

| Aluminij | Potrebna vlakna | S druge površine | Dobro; može imati blage krhotine na debelim dijelovima | U slučaju da se radi o uređaju koji se koristi za proizvodnju proizvoda, potrebno je provjeriti da li je u skladu s ovom Uredbom. |

| Bakar | Potrebna vlakna (3kW+) | S masenim udjelom od: | Srednja; zahtijeva optimizirane parametre | Najveća reflektivnost; potreba za značajnim pogonom |

| Mjed | Preporučljivo vlakno | S masenim udjelom od: | Dobro; sadržaj cinka utječe na izgled | Potrebna je odgovarajuća ventilacija; na rubovima može biti blage žutila |

| Nikelove legure | Uređaji za proizvodnju električnih goriva | S masenim udjelom od: | Odlično, minimalno HAZ | U zrakoplovstvu i svemiru potrebne su certificirane parametre; obično se koriste u kemijskoj obradi |

| Titan | Preporučljivo vlakno | Do 10 mm | Vrlo dobro sa inertnim gasom štitnjače | Argon-asistent sprečava oksidaciju; reaktivna na visokim temperaturama |

Razumijevanje ponašanja specifičnih materijala pomaže vam odabrati odgovarajuće metale za vašu primjenu i učinkovito komunicirati s pružateljima usluga laserskog rezanja. Dizajn koji dobro funkcionira u ugljičnom čeliku može zahtijevati izmjene za aluminij ili bakar zbog različitih termalnih dinamika i očekivanja kvalitete ivice.

Ali izbor materijala je samo pola jednadžbe. Kada odaberete pravi metal, postavljanje ispravnih parametara rezanja određuje da li ćete dobiti precizne dijelove ili otpad. Sljedeći dio otkriva točno kako postavke snage, brzine rezanja i izbor plina pomažu zajedno da se dobiju dosljedni, visokokvalitetni rezultati.

Parametri rezanja koji određuju kvalitete rezultata

Izabrali ste pravi tip lasera i razumjeli ponašanje vašeg materijala. Sada dolazi kritično pitanje: kako odabrati postavke koje proizvode dosljedno izvrsne dijelove laserskim rezom? Odnos između snage, brzine i pomoćnog plina određuje jesu li vaši gotovi dijelovi čisti ili zahtijevaju opsežnu naknadnu obradu. Razmotrićemo parametre koji razdvajaju precizne laserske rezače od prosječnih rezultata.

Smatraj to kao stolicu na tri noge. Prilagodi jedan parametar bez razmatranja ostalih, a kvaliteta pati. Ovladajte njihovom interakcijom, i postići ćete preciznost laserskog rezanja koja ispunjava čak i zahtjevne specifikacije tolerancije.

Osnove optimizacije snage i brzine

Laserska snaga i brzina rezanja dijele inverzni odnos koji izravno utječe na kvalitetu ivice. Prema HARSLE-ov vodič za optimizaciju , postavljanje snage previše visok dovodi do prekomjernog topljenja, grube ivice, ili materijal deformacije. Nedovoljna snaga rezultira nepotpunim rezovima ili lošom kvalitetom ivica. Cilj je pronaći slatko mjesto gdje zraka isporučuje točno dovoljno energije da čisti materijal.

Brzina rezanja radi kao protivteža. Brže brzine povećavaju produktivnost, ali mogu žrtvovati kvalitet krajeva kada se greda ne zadrži dovoljno dugo da bi dovršila rez. Sporije brzine poboljšavaju kvalitetu rezanja, ali negativno utječu na propusnost. Kada laserskim rezanjem čelika, proizvođači obično počinju s preporučenim parametrima i postupno se prilagođavaju sve dok se ne postignu optimalni rezultati.

Evo što se događa u različitim kombinacijama snage i brzine:

- Visoka snaga, spora brzina: Prekomjerna ulazna toplina uzrokuje široki raskrt, velike HAZ, potencijalno zakrivljenje i nakupljanje droge

- S niskom snagom, brzom brzinom: Nepotpuno prodiranje, gruba donja oboda, moguće ponovno zavarivanje rezanih materijala

- Izbalansirana postavka: Čista prolazna reznica, minimalna HAZ, glatke ivice, dosljedna širina reza

Laserska frekvencija ili brzina pulsa, dodaje još jednu dimenziju optimizaciji laserskog rezanja čelika. Visoke frekvencije obično stvaraju glatke ivice, ali stvaraju više toplote, što zahtijeva precizne mjere hlađenja. Niže frekvencije smanjuju nakupljanje toplote, ali mogu proizvesti grublje rubove. Za nehrđajući čelik, frekvencije u rasponu od 2.000 do 5.000 Hz često daju izvrsne rezultate, iako su testiranje i dalje bitno za određenu opremu i kombinacije materijala.

Pomoć pri odabiru plina za kvalitetu rubova

Pomoćni plin koji izaberete dramatično utječe na brzinu rezanja i izgled krajeva. U operacijama s metalnim listovima dominiraju dvije primarne opcije: kisik i dušik. Svaka služi različitim svrhama na temelju vaših zahtjeva za materijalom i kvalitetom.

Kiseonik podržava reakciju sagorevanja tijekom laserskog rezanja i obrade čelika. Ovaj egzotermni proces dodaje energiju rezalu, značajno povećavajući brzinu rezanja željeznih metala. Prema Sharpe proizvodi , kisik je posebno povoljna pri radu s debljim materijalima gdje dodatna rezanja energije ubrzava proizvodnju. Međutim, ova reakcija ostavlja sloj oksida na reznim rubovima koji se može morati ukloniti prije varenja ili premaza.

Dušik nudi suprotan pristup. Njegova inertna svojstva u potpunosti sprečavaju reakcije sagorevanja i oksidaciju. Što je bilo s time? Čistije rezane ivice koje zahtijevaju minimalnu naknadnu obradu. Azot odgovara širem spektru materijala, uključujući nehrđajući čelik, aluminij i druge neželjezne metale gdje bi oksidacija ugrozila izgled ili otpornost na koroziju.

U slučaju da se ne može koristiti pomoćni plin, potrebno je uzeti u obzir sljedeće čimbenike:

- S druge konstrukcije od čelika od čelika U slučaju da se planira uklanjanje oksida, kisik za brzinu; dušik za aplikacije izravno na boju

- Nerustingajući čelik: U slučaju da se ne koristi nitrogena, u slučaju da se ne koristi nitrogena, ne smije se koristiti nitrogena.

- S druge vrijednosti: U slučaju da je proizvod izravno proizveden, mora se upotrebljavati samo jedan od sljedećih proizvoda:

- U slučaju da je to potrebno, u slučaju da je potrebno, u skladu s člankom 4. stavkom 1. U skladu s člankom 3. stavkom 2.

Indikatori kvalitete i rješavanje problema

Kako znaš kad su parametri ispravno optimizirani? Za potrebe provedbe ovog postupka, korisnici moraju imati dovoljno iskustva u provedbi sustava za upravljanje kvalitetom.

- Izravno: Pravilno rezane ivice izgledaju jednako bez pruga ili gruboće vidljive golim okom

- Sastavljanje prašine: U slučaju da se ne primijenjuje primjena ovog standarda, u slučaju da se ne primjenjuje, to znači da se ne primjenjuje.

- U slučaju da je to potrebno, mora se upotrebljavati sljedeća metoda: Jednokratna širina rezanja diljem dijela potvrđuje stabilnu usredotočenost i snaga

- Dimenziona točnost: Čestice koje mjere unutar specifikacije (obično plus ili minus 0,1 mm za tanke listove) potvrđuju pravilnu kompenzaciju za obaranje

Kada se na rezanim rubovima formiraju grede, to obično signalizira pogrešnu lasersku snagu ili brzinu rezanja. Obično je čistiji rezultat ako se snaga malo poveća ili smanji brzina rezanja. U slučaju da je uobičajeno da se u ovom slučaju ne koristi žarište, to znači da se ne može koristiti žarište. Rafiniranje fokalne točke i eksperimentiranje s višim frekvencijama često poboljšava glatkoću rubova.

Izkrivljanje ili pretjerano oštećenje toplinom zahtijevaju drugačiji pristup. Pokušajte povećati brzinu rezanja, smanjiti lasersku snagu ili optimizirati sustave hlađenja kako bi se toplota bolje raspršila. Tanki listovi posebno su podložni deformaciji, pa je potrebno pravilno postaviti i upravljati toplinom.

Automatski fokusiranje visine prati tehnologija rješava jednu od najčešćih kvalitete varijabli. Ovaj sustav koristi kapacitativne senzore kako bi održao dosljednu udaljenost između rezne mlaznice i površine materijala, automatski kompenzirajući promjene ploče, blago savijanje ili nesavršenosti površine. Zamislite krstarenje za glavu za rezanje: sustav neprekidno prilagođava visinu kako bi se fokusna točka točno pozicionirala, osiguravajući dosljednu kvalitetu rezanja na cijelom listu.

U slučaju preciznog laserskog rezanja, specifikacije tolerancije obično se kreću od plus ili minus 0,05 mm na tankim materijalima do plus ili minus 0,2 mm na debljim sekcijama. Za postizanje tih specifikacija potrebno je ne samo ispravne parametre, nego i redovito kalibriranje stroja. HARSLE preporučuje da se laserski rezali strojevi ponovno kalibriraju svakih 300 do 500 radnih sati kako bi se održala njihova točnost i dosljednost.

Kad savladaš ove parametre rezanja, sljedeći izazov prelazi na pripremu dizajna koji će u potpunosti iskoristiti mogućnosti laserskog rezanja. Pravilna priprema datoteke sprečava uobičajene pogreške koje mogu narušiti čak i savršeno optimizirane postavke stroja.

Priprema za uspješno lasersko sečenje

Ovladao si parametrom stroja i razumio ponašanje materijala. Ali stvarnost je: čak i najsofisticiraniji laserski CNC stroj ne može spasiti loše pripremljenu dizajnersku datoteku. Prije nego što vaš projekt stigne do rezanja, odluke koje se donesu tijekom faze projektiranja određuju uspjeh ili neuspjeh. -Dobre vijesti? Nekoliko jednostavnih načela razdvajaju dosjee koji se savršeno režu od onih koji zahtijevaju skupe revizije.

Razmislite o pripremi dizajna kao stvaranju karte za laser. Svaka crta, krivulja i karakteristika u vašem datoteku postaje direktna instrukcija. Nejasne puteve zbunjuju sustav. Prepliće geometrije gubljenje rezanje vrijeme. Karakteristike su premali za vaš debljina materijala jednostavno neće preživjeti proces. Razmotri kako napraviti datoteke koje će vam pretvoriti viziju u precizne dijelove.

Najbolje prakse pripreme dosjea

Laserski rezači govore posebnim jezikom: vektori. Za razliku od fotografija ili raster slika koje se sastoje od piksela, vektorske datoteke definiraju točne matematičke puteve koje slijedi rezna glava. Prema Sculpteo vodiču za pripremu datoteke, trebat ćete vektorsku datoteku za svaku operaciju laserskog rezanja ili graviranja. Razumijevanje koji formati rade osigurava da se vaš dizajn precizno prevodi u gotove dijelove.

Tri formata datoteka dominiraju radnim tokovima prilagođenih laserskih rezanja:

- DXF (format razmjene crteža): Univerzalni standard za laserske CNC operacije; podržan gotovo svim softverima za rezanje i održava preciznu geometriju

- Slika za obradu podataka AutoCAD format s izvrsnom preciznošću; može zahtijevati pretvaranje ovisno o softveru za rezanje

- AI (Adobe Illustrator): Prednost za dizajne koji potječu iz kreativnog softvera; osigurati da su svi objekti prije izvoza pretvoreni u obrise

Prije izvoza datoteke provjerite sljedeće ključne elemente:

- Konvertirati sve tekst u oblike: Fontovi koji nisu dostupni na rezanju sustava će zamijeniti ili nestati u potpunosti

- Pridruži se otvorenim stazama: Nepojavljeni segmenti linija stvaraju nepotpune rezove ili neregularno ponašanje stroja

- Ukloniti duplične redove: Preplićući se putevi uzrokuju da laser presječe isto područje dva puta, trošeći vrijeme i potencijalno oštećujući materijal

- Postavite ispravne jedinice: Potvrdi da datoteka koristi inčeve ili milimetre dosljedno kako bi se izbjegle greške u skali.

Odšteta za Kerf zaslužuje posebnu pažnju. Laserski zrak ima fizičku širinu, obično od 0,1 do 0,3 mm ovisno o materijalu i postavkama. To znači da se od odrezanja uklanja mali trakač materijala. Za dijelove koji zahtijevaju precizne dimenzije ili tesno priključene sastave, pomaknite rezne linije za pola širine reza. Većina rezanja softvera primjenjuje ovu kompenzaciju automatski, ali potvrditi postavke odgovara vašim specifičnim zahtjevima.

Prilikom projektiranja dijelova koji se međusobno zaključavaju, kao što su šifre i otvorovi za konstrukciju kutija, uzeti u obzir debljinu materijala u svojim dimenzijama. Za vezanje treba napraviti otvor koji je dizajniran točno na debljini materijala; dodavanje razmak od 0,1 do 0,2 mm osigurava pravilno uklanjanje. Ovaj se princip jednako primjenjuje i ako radite s metalnim listovima ili istražujete opcije za servisiranje laserski rezanih drveta za izradu prototipa.

Karakteristike dizajna koje utječu na uspjeh rezanja

Zvuči složeno? Ne mora biti. Većina neuspjeha u dizajnu proizlazi iz nekoliko predvidljivih grešaka. Prema Citat: Cut Ship analiza , ove se česte pogreške pojavljuju u stotinama dostavljenih dosjea svaki tjedan. Izbjegavanje ih stavlja vas ispred većine dizajnera prvi put.

Česte pogreške u projektiranju koje treba izbjegavati:

- Neadekvatno razmak između rezova: Previše blizu jedni drugima postavljene linije uzrokuju preopterećenje ili strukturnu slabost. Udržavanje najmanje 0,25 mm (0,010 inča) između kritičnih puteva, i povećati ovaj razmak za deblje materijale

- Oštri unutarnji kutovi: Laserski zrak ima minimalni radijus koji može postići. U slučaju da su unutarnji uglovi savršeno kvadratni, rezultat će biti blago zaokruživanje ili koncentracija napetosti. Dodajte male kutne polupremine (minimalno 0,5 mm) kako bi poboljšali kvalitetu rezanja i čvrstoću dijela

- Problemi s veličinom teksta: U nekim slučajevima, detalji u tekstu nestaju ili postaju nečitljivi ispod određenih granica. U slučaju čitljivog urezanog teksta, visine slova moraju biti veće od 2 mm, a širine rukci ne manje od 0,3 mm.

- Nedostaju kartice za zadržavanje dijelova: U slučaju da se proizvod ne može upotrijebiti za proizvodnju, potrebno je upotrijebiti i proizvodnju za proizvodnju. Dizajniranje malih kartica koje povezuju dijelove na okolni materijal, a zatim ih ručno ukloniti nakon rezanja

- S obzirom na debljinu materijala: Funkcije koje izgledaju savršeno u 2D softveru propadaju kada Z-dimenzija uđe u jednadžbu. Tanki prsti ili uski mostovi možda neće imati dovoljno snage u materijalu koji ste odabrali

Razmatranja ugla radijusa protežu se izvan unutarnjih značajki. Vanjski uglovi su točno odrezani kako su dizajnirani, ali unutarnji uglovi predstavljaju izazove. Kada vam je iz funkcionalnih razloga potreban kvadratni unutarnji kut, razmislite o dodavanju reliefa: male kružne rupe na uglovskim presjekovima koje omogućuju da se dijelovi za spajanje pravilno smeste bez smetnje prirodnog radijusa lasera.

Vaš izbor dizajna direktno utječe na smanjenje vremena i troškova. Svaka točka probijanja, gdje laser u početku prodire u materijal, dodaje sekunde ciklusu. Složeni dizajn s stotinama malih rupa zahtijeva znatno više vremena od jednostavnijih geometrija s jednakim dužinom rezanja. Učinkovito ugnežđivanje dijelova unutar ploče smanjuje otpad materijala, dok organiziranje sekvenci rezanja kako bi se minimiziralo kretanje glave poboljšava produktivnost.

Za dizajnere koji prelaze s prilagođenih projekata za laserno rezanje drva na rad na metalu, sjetite se da toplinska provodljivost metala mijenja pravila. Karakteristike koje lako opstaju u skraćenoj drveni drveni mogu se iskriviti u tankom aluminiju. Povećajte veličinu i razmjer kada prelazite na metalne materijale.

Ako se odvojite vremena za optimizaciju dizajna prije nego što ga pošaljete, to će vam donijeti bolje rezultate, brže isporuke, niže troškove i dijelove koji odgovaraju vašim očekivanjima. Sa ispravno pripremljenim datotekama u ruci, spremni ste procijeniti da li lasersko rezanje nudi najbolje rješenje za vaš specifičan projekt, ili da li vam alternativne tehnologije mogu bolje služiti.

Lasersko sečenje u usporedbi s vodenicom i plazmom

Je li lasersko rezanje uvijek pravi izbor? Dok operacije laserskog rezanja metalnih ploča izvrsne su u mnogim scenarijima, alternativne tehnologije ponekad nude jasne prednosti ovisno o vašem materijalu, debljini i zahtjevima za kvalitetom. Razumijevanje kada odabrati laser rezanje metala nasuprot vodeni mlazni ili plazma metode vam pomaže odabrati optimalan proces za svaki projekt, a ne podrazumijevaju poznate tehnologije.

Svaki način rezanja radi na temeljno različitim načelima. Lasersko sečenje koristi fokusiranu svjetlosnu energiju. Plasma rezanje koristi pregrevan ionizirani plin koji doseže temperature do 45.000 ° F. Rezanje vodnim mlazom temelji se isključivo na mehaničkoj eroziji iz vode pod vrlo visokim pritiskom pomiješane s abrazivnim česticama. Ove razlike stvaraju jedinstvene karakteristike performansi koje svaku tehnologiju čine idealnom za određene primjene.

Kada lasersko sečenje nadmašuje druge

Lasersko rezanje i graviranje sjaje najjače kada je preciznost najvažnija. Prema Univerzalni alat i inženjering , lasersko sečenje može dosljedno postići tolerancije od plus ili minus 0,001 inča ili bolje zbog precizne kontrole zraka i minimalne širine reza. To nadmašuje plazmu i često odgovara ili premašuje vodeni mlazak u većini aplikacija za ploče.

Za tanke do srednje metalne ploče, obično ispod 10 mm debljine, laserska tehnologija pruža optimalan balans brzine, preciznosti i kvalitete rubova. Fokusirani zrak stvara minimalne zone koje su pogođene toplinom u usporedbi s plazmom, čime se čuvaju svojstva materijala blizu ivica reza. Moderni laseri od vlakana obrađuju reflektirajuće metale poput aluminija i bakra bez problema s povratnim odrazom koji su mučili ranije CO2 sustave.

Brzina se dramatično povećava na tankim materijalima. Stroj za rezanje metala koji koristi lasersku tehnologiju vlakana može rezati 1 mm nehrđajućeg čelika brzinom većom od 30 metara u minuti. Ni plazma ni vodeni mlaznici ne dolaze blizu ovoj razini produktivnosti na tankim listovima. Za proizvodnju preciznih dijelova u velikim količinama, lasersko sečenje ostaje neprikosnovano.

Međutim, laserska tehnologija ima ograničenja. Kako se debljina materijala povećava iznad 20-25 mm, brzina sečenja značajno opada dok se zahtjevi za snagom povećavaju. Zona koja je pogođena toplinom, iako je manja od plazme, još uvijek postoji i može utjecati na toplinski osjetljive aplikacije. To je mjesto gdje alternativne tehnologije zaslužuju svoje mjesto.

Odabir prave tehnologije rezanja

Plasma rezanje izvrsno gdje sirova brzina na debelom čeliku je važnija od tesnih tolerancija. Prema Analiza StarLab CNC , visoko snažni plazma sustav može rezati pola inča blage čelika pri brzinama koje prelaze 100 inča u minuti, što ga čini najbržom opcijom za srednje do debele metalne ploče. Iz tog razloga se proizvodnja konstrukcijske čelika, proizvodnja teške opreme i brodogradnja u velikoj mjeri oslanjaju na plazmu.

-Kakva je razmjena? Plazma proizvodi grublje ivice i šire zone pogođene toplinom. Većina dijelova s plasmom zahtijeva sekundarnu obrada kako bi se postigle čiste ivice pogodne za zavarivanje ili vidljive primjene. Tehnologija radi samo na električno provodnim materijalima, eliminišući opcije za trgovine mješovitim materijalima. Ipak, za strojeve za sečenje čelika debljine većoj od jedan inč, plazma često pruža najbolju ekonomičnost u troškovima po inču.

U skladu s člankom 3. stavkom 1. točkom (a) ovog članka, "sredstva za proizvodnju" uključuju: Rad na pritiscima do 90.000 psi, vodeni tok pomiješan s abrazivnim granatom erodira materijal bez stvaranja značajne toplote. To stvara nuli zone na bilo kojem materijalu, čuvajući originalne osobine do ivice reznice.

Ova toplinska neutralnost čini vodeni mlaž idealnim za toplinski osjetljive materijale i primjene gdje se ne može tolerirati tvrđanje ili distorzija. Stroj za sečenje metala koji koristi tehnologiju vodenih zraka može obrađivati materijale koji su nemogući i za laser i za plazmu: kamen, kompozitne materijale, ugljična vlakna, staklo i slojeviti materijali. Za posebne primjene koje zahtijevaju maksimalnu svestranost materijala, vodeni mlaznici ostaju rješenje.

Nedostatak vodenih mlaznika uključuje brzinu i troškove. Brzina rezanja obično se kreće od 5 do 20 inča u minuti ovisno o materijalu, dramatično sporija od lasera ili plazme. U skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br.

| Radionica | Laserskog rezanja | Rezanje plazmom | Rezanje vodenim jetom |

|---|---|---|---|

| Tolerancija točnosti | svaka vrsta vozila mora biti u skladu s ovom Uredbom. | svaka vrsta vozila mora biti u skladu s ovom Uredbom. | svaka vrsta vozila mora biti u skladu s ovom Uredbom. |

| Raspon debljine materijala | S druge konstrukcije | smanjenje i smanjenje emisije | Smanjenje i smanjenje |

| Kvaliteta ruba | Odlično, potrebno je samo malo završetka | Uzrok: | Dobro; moguće je blago koniciranje na debljim rezovima |

| Brzina rezanja (tan metal) | Najbrža | Umerena | Najsporije |

| Brzina rezanja (debeli metal) | Umerena | Najbrža | Najsporije |

| Zona utjecaja topline | Najmanji (0,1-0,4 mm) | Veliki (može utjecati na svojstva) | Nijedan |

| Operativni troškovi po inču | Niska do umjerena | Najniža | Najviša |

| Materijalna svestranost | Metali, neke plastike | S druge vrste | Bilo koji materijal |

| Najbolje primjene | Proizvodnja ploče, precizni dijelovi, automobilska industrija | Izravno je da je to bio jedan od najvažnijih razloga za to. | Sastavljeni materijali, kamen, toplinski osjetljivi metali, debeli materijali |

Koju tehnologiju rezanja metala biste trebali odabrati? Razmotrimo sljedeće čimbenike koji utječu na odluku:

- Izbor laserskog rezanja kada: Za rad s listom ispod 20 mm, potrebna su preciznost, čiste ivice bez završetka ili proizvodni volumen zahtijeva visok prolaz

- Za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određivanje vrijednosti za određ Obrada čeličnih ploča debljine iznad 12 mm, prioriteta brzina iznad preciznosti, ograničenja proračuna favoriziraju niže operativne troškove ili će dijelovi dobiti sekundarnu završnu obradu bez obzira

- U slučaju da se ne koristi vodeni mlazni rez, potrebno je: U slučaju da se ne može primijeniti HAZ, ne može se koristiti za proizvodnju materijala koji se upotrebljavaju za proizvodnju električne energije.

Mnoge tvornice održavaju više tehnologija rezanja upravo zato što nijedna metoda ne optimizira svaki posao. Projekt ploče zahtijeva stroge tolerancije putova do lasera. Rad na strukturnim pločama ide u plazmu. Titanijumska komponenta s kritičnim svojstvima materijala ide u vodeni mlažnjak. Razumijevanje prednosti svake tehnologije omogućuje vam da donosite pametne odluke o usmjeravanju koje uravnotežavaju kvalitetu, brzinu i cijenu.

Nakon što je odabir tehnologije razjasnjen, sljedeće pitanje postaje jednako praktično: koliko će to zapravo koštati? Razumijevanje čimbenika koji utječu na cijene laserskih rezača pomaže vam da precizno proračunate i procijenite ponude pružatelja usluga.

Objasnjeno je što je troškovi i cijene

Dizajnirali ste svoj dio, odabrali pravi materijal, i identificirali lasersko rezanje kao svoj proces. Sada dolazi pitanje koje određuje održivost projekta: koliko će to zapravo koštati? Za razliku od kupnje robe s fiksnim cijenama, cijene laserskog rezanja značajno se razlikuju na temelju faktora koje mnogi kupci nikada ne uzimaju u obzir. Razumijevanje što pokreće te troškove pretvara vas iz nekoga tko jednostavno prihvaća citat u nekoga tko može optimizirati dizajne, inteligentno pregovarati i precizno proračunati.

Razlika u transparentnosti cijena u ovoj industriji često dovodi do zbunjenosti kupaca. Možda ćete dobiti tri ponuda za iste dijelove s cijenama koje se razlikuju za 50% ili više. -Zašto? -Zašto? Zato što svaka trgovina razlikuje u mjerenju troškova, a samo se malo njih trudi objasniti što ih je motiviralo. Raščistimo ekonomiju iza metalnih laserskih rezačkih usluga kako biste mogli donositi informirane odluke.

Razumijevanje faktora cijena po dijelovima

Svaki laser rezanje navod odražava izračun uravnotežavanje vrijeme stroja, potrošnju materijala, i radne snage zahtjeva. Prema analizi cijena Komacuta, glavni faktori koji utječu na troškove uključuju vrstu materijala, debljinu, složenost dizajna, vrijeme rezanja, troškove rada i procese završetka. Svaki element doprinosi drugačije ovisno o vašem konkretnom projektu.

Evo glavnih čimbenika troškova, po tipičnom učinku:

- Vrsta i debljina materijala: Deblji materijali zahtijevaju više energije i sporije brzine rezanja. U slučaju 10 mm nehrđajućeg čelika, rezanje traje znatno duže od 2 mm blage čelika, što direktno povećava vrijeme rada i potrošnju energije. Prema Sklopi od aluminija , brzina sečenja utječe na vrijeme potrebno za prodiranje laserskog zraka u materijal, a tvrđi i deblji materijali traju duže i skuplje.

- Složenost dizajna: Broj probijanja, ukupna dužina rezova i složene karakteristike sve to produžava vrijeme rezanja. Svaka tačka gdje laser počinje rez dodati sekunde ciklusu. Za složene konstrukcije s brojnim malim rupama ili detaljnim uzorcima potrebna je veća preciznost, što povećava vrijeme rada i troškove programiranja.

- Ukupna dužina reznice: Usluge laserskog rezanja obično se naplaćuju na temelju vremena rada stroja, što se izravno povezuje s udaljenostima koje se kreću glavom rezanja. U slučaju da je proizvod na tržištu u skladu s člankom 6. stavkom 2. točkom (a) ovog članka, u skladu s člankom 6. stavkom 2. točkom (a) ovog članka, proizvod se može koristiti za proizvodnju proizvoda koji se upotrebljavaju u proizvodnji proizvoda.

- Naručena količina: Troškovi postavljanja, uključujući programiranje i kalibraciju stroja, raspoređeni su na sve dijelove. Naručivanje deset komada znači da svaki apsorbira jednu desetinu troškova postavljanja, dok naručivanje stotinu dramatično smanjuje troškove po jedinici.

- Zahtjevi za završnom obradom: Drugi procesi kao što su odbrana, šampiranje, navoj ili površinski tretmani dodaju radnu snagu i vrijeme specijalizirane opreme. Dijeli koji zahtijevaju čiste, spremne rubove skuplji su od onih koji su prihvatljivi s manjim otpadom.

Troškovi materijala su u znatnoj mjeri različiti. Cijene sirovina za nehrđajući čelik su veće od cijena ugljikovog čelika, dok posebne metale poput bakra ili titana imaju visoke cijene. Učinkovito ugradnja, koja maksimalno povećava upotrebu materijala tako što dijelove smješta blizu jedni drugima, smanjuje otpad i smanjuje troškove. Napredni softver za ugradnju gnijezda može optimizirati raspored kako bi se smanjio otpad, ponekad se od svakog lista oporavlja 10-15% više upotrebljivog materijala.

Smanjenje količine i ekonomija proizvodnje

Koliko vrijedi mašina za rezanje lasera ako razmišljate o ulaganju u opremu? Cijena laserskih strojeva za rezanje vlakana kreće se od 30.000 dolara za početne sustave do preko 500.000 dolara za industrijsku opremu velike snage. Cijena laserskih rezača na profesionalnom nivou obično pada između 100.000 i 300.000 dolara za sposobne vlaknene sustave. U skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br. 1303/2013 Komisija je odlučila da se odredi da se u skladu s člankom 3. stavkom 1.

U skladu s člankom 3. stavkom 1.

- Proizvodnja: Troškovi postavljanja i programiranja dominiraju, često premašujući stvarne troškove vremena rezanja. U skladu s člankom 3. stavkom 2. stavkom 3.

- Smanjena količina (10-100 komada): Troškovi postavljanja raspoređuju se povoljnije, a učinkovitost nabavke materijala se poboljšava. Cijene po jedinici obično padaju za 20-40% u usporedbi s cijenama prototipa.

- Srednja količina (100-1000 komada): Proizvodnja efikasnosti dobiva spojeno. Operatori optimiziraju parametre, gnijezdo dostiže maksimalnu učinkovitost, a primjenjuju se popusti za raspršeni materijal. Očekuju se troškovi po jedinici 40-60% ispod cijena prototipa.

- Visoka količina (1.000+ komada): Na ovoj razini, alternative poput pečatiranja mogu postati ekonomičnije za jednostavne geometrije. Međutim, složeni dijelovi često ostaju jeftiniji putem laserskog sečenja zbog nulte investicije u alat.

Ponavljajuće narudžbe obično nose niže troškove postavljanja jer je programski rad već završen. Prema Datum Alloys-u, ponavljajući se radovi zahtijevaju minimalnu pripremu jer su radovi na projektiranju i kalibraciji završeni tijekom početne narudžbe. Održavanje dobrih odnosa s uslugama za lasersko rezanje metala često automatski otključava te uštede.

U slučaju da se projekt ne završi u skladu s člankom 3. stavkom 1. točkom (a) ovog članka, u skladu s člankom 3. točkom (a) ovog članka, podnositelj zahtjeva može zatražiti da se u skladu s člankom 3. točkom (a) ovog članka, u skladu s člankom 3. točkom (a) ovog članka, od Možda ćete otkriti da naručivanje 50 komada košta samo marginalno više od 25, što čini veću seriju ekonomski razumnom čak i ako vam odmah nisu potrebne sve dijelove. Slično tome, konsolidacija više dizajna dijelova u pojedinačne narudžbe maksimizira učinkovitost gnijezda i raspršuje troškove postavljanja na više dijelova.

Razumijevanje tih faktora troškova pomaže vam optimizirati dizajne prije nego što ih pošaljete za ponudu. Smanjenje mjesta probijanja, pojednostavljenje geometrije gdje je to moguće i odabir odgovarajuće debljine materijala sve to pridonosi smanjenju troškova bez ugrožavanja funkcionalnosti. Sa jasnim osnovama cijena, spremni ste istražiti kako se ti troškovi primjenjuju u stvarnim industrijskim aplikacijama gdje precizno lasersko rezanje pruža mjerljivu vrijednost.

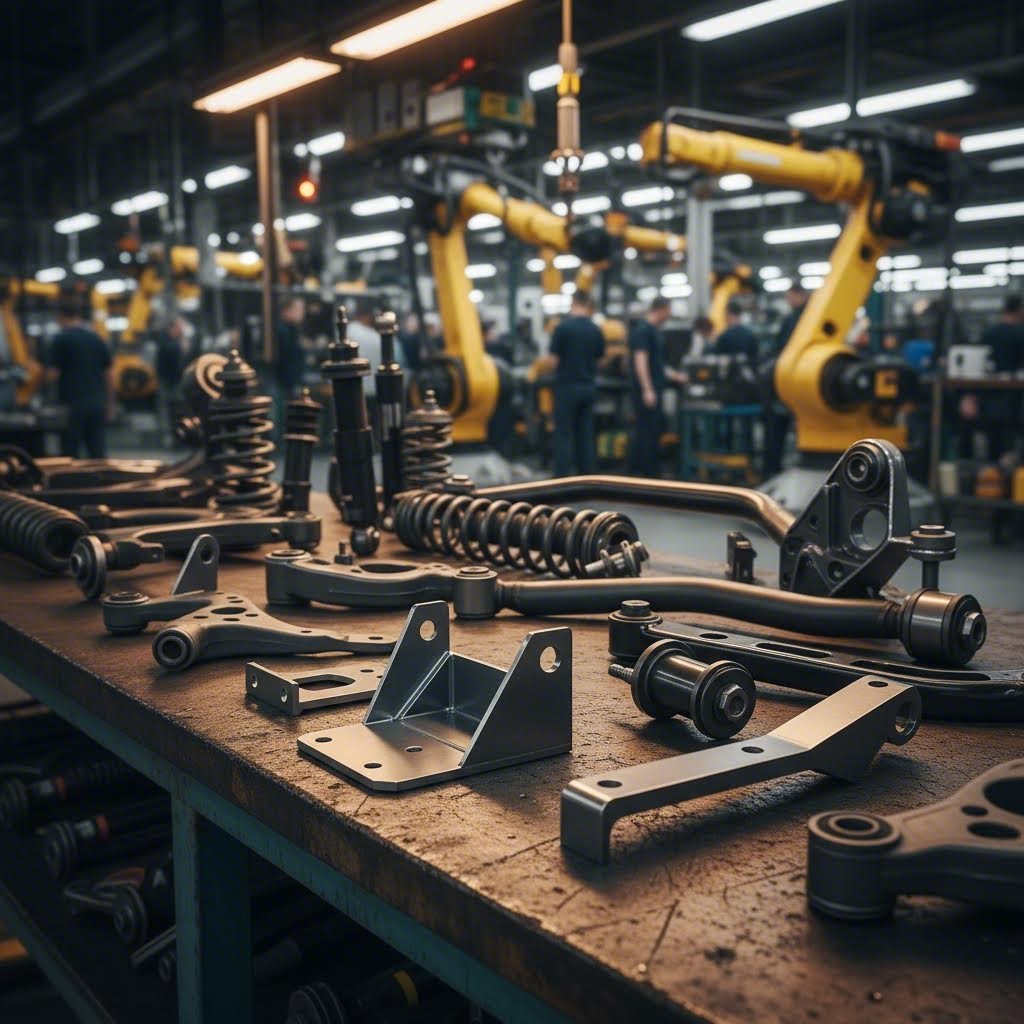

Industrijske primjene i proizvodnja automobila

Gdje tehnologija laserskog rezanja metalnih listova pruža najveću vrijednost? Prođite kroz bilo koji moderni proizvodni pogon, i naći ćete precizno rezane komponente posvuda: šasiju ispod vašeg automobila, kućište koje štiti vaš pametni telefon, konstrukcijske grede koje podupiru zgrade. Industrijsko lasersko sečenje postalo je okosnica bezbrojnih lanaca snabdijevanja upravo zato što prekida jaz između prototipa i masovne proizvodnje.

Razumijevanje načina na koji se u različitim industrijama koristi ta tehnologija otkriva zašto se za određene primjene lasersko sečenje više koristi nego za druge. Još važnije, pokazuje proizvodne razmatranja koja odvajaju projekte na nivou hobija od certificirane industrijske proizvodnje.

Automobilske i zrakoplovne primjene

U skladu s člankom 3. stavkom 1. Prema analizi industrije Xometry-a, laserski rezači se koriste u različitim primjenama u automobilskoj industriji, uključujući rezanje plastičnih dijelova, proizvodnju metalnih komponenti te označavanje i graviranje dijelova za identifikaciju i brendiranje. To čini automobilsku industriju učinkovitijom i troškovno učinkovitijom.

Razmislite o tome što se nalazi u modernom vozilu. Komponente šasije zahtijevaju točno tolerancije kako bi se osigurao strukturni integritet tijekom sudara. U slučaju vozila s brzinom od 300 km/h, vozila s brzinom od 300 km/h moraju biti opremljena: Strukturna pojačanja trebaju dosljedne dimenzije preko tisuća jedinica. Metalni laserski rezač daje upravo tu ponovljivost.

Specifične automotive primjene u kojima se tehnologija laserskih strojeva za rezanje metala iznimno dobro koristi:

- Komponente šasije i okvira: S druge strane, u slučaju da se ne upotrebljava, to znači da se ne upotrebljava niti se ne upotrebljava.

- Sklopna vrata: U slučaju da je to potrebno, za postavljanje na podnožje mora se upotrijebiti samo jedan od sljedećih elemenata:

- Svaka od sljedećih opcija: Ulazne ploče, krovne konstrukcije i podne ploče često se obrađuju laserski prije oblikovanja

- Sistemi zračnih jastuka: Prema Xometryju, laserski rezači su posebno idealni za rezanje i zapečaćivanje zračnih jastuka zbog njihovog beskontaktnog rada i preciznosti

Avio-svemirska industrija zahtijeva još strože specifikacije. Prema Uvodnik za primjenu ACCURL-a , preciznost je obilježje zrakoplovnih komponenti, a lasersko sečenje, s svojom visokom preciznošću i sposobnošću rukovanja širokim spektrom materijala, savršeno je prikladno za ovaj zadatak. Proces osigurava održavanje strukturalnog integriteta materijala, što je od iznimne važnosti u zrakoplovstvu.

U zrakoplovstvu se često koriste specijalne legure poput titana, Inconela i aluminija i litijuma. Laser mašina za sečenje metala s odgovarajućim parametrima upravlja ovim zahtjevnim materijalima, a zadržava njihova inženjerska svojstva. Ušteda težine, mjerena u gramovima, rezultira povećanjem učinkovitosti goriva tijekom životnog vijeka zrakoplova, što čini precizno sečenje nužnim, a ne opcijskim.

Od prototipa do masovne proizvodnje

Put od koncepta do proizvodne komponente ističe jedinstvenu fleksibilnost laserskog sečenja. Za razliku od pečatiranja ili rezanja na stampu, za koje je potrebno skupo oruđe prije proizvodnje prvog dijela, industrijski laserski rezač proizvodi se isključivo pomoću digitalnih datoteka. To dramatično smanjuje vremenske linije razvoja.

Moderni lanci snabdijevanja automobilskim proizvodima zahtijevaju brze mogućnosti odgovora. Promjena dizajna koja je nekada zahtijevala tjedne modifikacija alata sada zahtijeva satima ažuriranja programa. Prema Xometryju, laserski sečevi se precizno kreću kako bi se rezali oblici koji su programirani u stroj za rezanje jer su njihove glave za rezanje CNC-kontrolisane. To omogućuje dosljednu proizvodnju složenih komponenti uz minimalnu ručnu intervenciju.

Proizvodnja se širi u predvidljivom postupku:

- Sljedeći članak: U skladu s člankom 4. stavkom 2.

- Proizvodnja mostova (10-500 komada): U slučaju da se proizvodnja ne provodi u skladu s člankom 6. stavkom 1. točkom (a) ovog članka, proizvodnja se može provesti u skladu s člankom 6. stavkom 1. točkom (a) ovog članka.

- Sredstva za proizvodnju: U skladu s člankom 3. stavkom 2.

- Podrška za velike količine: Lasersko sečenje ostaje troškovno učinkovito za složene geometrije čak i u automobilskoj proizvodnji

Sertifikat kvalitete razdvaja industrijske dobavljače od općih tvornica. IATF 16949 certifikat, međunarodni standard upravljanja kvalitetom za proizvodnju automobila, pokazuje sustavnu kontrolu procesa koja je nužna za integraciju lanca opskrbe. Za ovakav certifikat potrebne su dokumentirane procedure za planiranje proizvodnje, statističku kontrolu procesa i stalno poboljšavanje.

Za proizvođače koji nabavljaju šasije, ovlaštenja i strukturne komponente, suradnja s dobavljačima s IATF 16949 sertifikatom eliminira glavobolje kvalifikacija. U skladu s člankom 1. stavkom 2. stavkom 3. točkom (a) Uredbe (EU) br. Njihova odjel za otpadne proizvode pruža IATF 16949-certificiranu kvalitetu od brzog prototipiranja u trajanju od 5 dana do automatizirane masovne proizvodnje, s 12-satnim okretnim časom i DFM podrškom koja optimizira dizajne u procesima laserskog rezanja i žigosanja.

Elektronska i arhitektonska primjena

Osim u automobilskoj industriji, industrijsko lasersko sečenje transformiše proizvodnju elektronike i arhitektonsko metalno djelo. Elektronski kućišta zahtijevaju precizne rezove za konektore, uzorke ventilacije i montiranje. Prema ACCURL-u, elektronička industrija stalno pomjera granice kako mali, ali učinkoviti uređaji mogu biti, oslanjajući se na precizne mogućnosti rezanja laserske tehnologije gdje djelić milimetara može napraviti značajnu razliku.

Uzmimo za primjer kućište koje štiti mrežni prekidač ili server. Desetine precizno postavljenih izrezaka smješta napajanje, ventilatore, upravljanje kablovima i korisničke sučelje. Industrijski laserski stroj za rezanje proizvodi ove karakteristike s dimenzionalnom točnostom koja osigurava pravilno uklapavanje tijekom montaže.

Arhitektonski metal prikazuje umjetnički potencijal laserskoga rezanja uz njegovu industrijsku preciznost. Dekorativni paneli, elementi fasade i strukturni detalji pretvaraju vanjske površine zgrade u vizualne izjave. Prema ACCURL-u, korištenje laserskoga rezanja u proizvodnji čeličnih okvira i detaljnih arhitektonskih elemenata donijelo je novu razinu kreativnosti i preciznosti u području gradnje.

Industrijsko lasersko sečenje služi dodatnim sektorima s specijaliziranim zahtjevima:

- Medicinski uređaji: Za kirurške instrumente i implantate koji zahtijevaju iznimnu točnost i biokompatibilnost materijala

- Energetski sektor: Sljedeći članci:

- Aplikacije u obrambenoj industriji: U skladu s člankom 3. stavkom 1.

- Sljedeći članci: U skladu s člankom 3. stavkom 1.

Ono što razlikuje uspješne industrijske primjene od neuspješnih projekata često se svodi na izbor dobavljača. Sama tehnologija daje dosljedne rezultate kada se pravilno primjenjuje. Izazov leži u pronalaženju partnera koji razumiju vaše specifične zahtjeve industrije, održavaju odgovarajuće sertifikacije i nude sveobuhvatnu podršku od optimizacije dizajna do razmnožavanja proizvodnje.

Bilo da razvijate automobilske komponente koje zahtijevaju usklađenost s IATF 16949 ili arhitektonske elemente koji zahtijevaju kreativnu preciznost, pravi proizvodni partner kombinuje tehnologiju rezanja s stručnim procesima. To nas dovodi do praktičnog pitanja kako procijeniti ima li ulaganje u opremu ili partnerstvo s pružateljima usluga smisla za vašu specifičnu situaciju.

Izbor između ulaganja u opremu i pružatelja usluga

Da li da kupim laserski rez ili da iznajmim posao? Ova odluka utječe na vaš proračun, fleksibilnost proizvodnje i operativnu složenost za godine koje dolaze. Mnogi proizvođači se bore s tim izborom, tražeći uslugu laserskog rezanja u mojoj blizini dok istodobno istražuju cijene opreme. Odgovor ovisi o čimbenicima koji su jedinstveni za vašu situaciju: količini proizvodnje, raspoloživom kapitalu, tehničkoj stručnosti i dugoročnoj proizvodnoj strategiji.

Nijedna od opcija ne funkcionira univerzalno. Neke tvrtke prosperiraju s vlastitom opremom koja donosi prihod 24 sata dnevno. Drugi se izuzetno dobro osjećaju jer prepuste da specijalizirani stručnjaci rade na strojevima, održavanju i stručnim radovima. Ispitamo stvarne faktore koji određuju koji put ima smisla za vaše posebne okolnosti.

Ulozi u ulaganje u unutarnje opreme

Donijeti lasersku rezanje mogućnosti u kući zvuči privlačno. Potpuna kontrola nad rasporedom, kvalitetom i vremenom isporuke. Bez troškova dostave. Odmah reagirati na promjene u dizajnu. No financijska stvarnost zahtijeva pažljivu analizu prije potpisivanja ugovora o kupnji opreme.

Prema McHone Industries-u, industrijska oprema za lasersko rezanje košta između 200.000 i 500.000 dolara. I ta unaprijed ulaganja predstavlja samo početak. U skladu s člankom 3. stavkom 1.

- Zahtjevi za objekat: Odgovarajući električni kapacitet, ventilacijski sustavi i podni prostor za siguran rad

- Potrošni materijal: Pomoćni plinovi, sočiva, mlaznice i drugi dijelovi koji se redovito zamjenjuju

- Ugovori o održavanju: Zaštita od preventivnog održavanja i hitnih popravaka koja štiti vašu investiciju

- Obuka operatera: Strogo osposobljeni tehničari imaju visoke plaće, a razvijanje internih stručnih znanja zahtijeva vrijeme

- Licencija za softver: CAD/CAM paketi i softver za ugradnju često zahtijevaju stalnu naknadu za pretplatu

U skladu s člankom 3. stavkom 2. Amortizacija strojeva, potrošnja električne energije, potrošnja plina, rezerve za održavanje, plaće operatera i troškovi rada na postrojenju sve su u pitanju. U skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br. 1303/2013 Komisija je odlučila da se odluka o uvođenju mjera odredi u skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br. 1303/2013.

Kada je u kući oprema financijski smisleno? Općenito, operacije s dosljednim velikim obimom rada opravdavaju ulaganje. Ako vaša mašina radi produktivno dvije ili više smjena dnevno, amortizacija kapitalnih troškova postaje upravljiva. Poduzeća koja zahtijevaju strogu kontrolu kvalitete na složenim dijelovima kritičnim za toleranciju također imaju koristi od izravnog nadzora. Prema McHone Industries, dijelovi koji zahtijevaju složen rezanje i tesne tolerancije možda vrijedi dovesti u kuću kako bi se održao najviši nivo kontrole kvalitete.

Međutim, radnje s povremenom potražnjom ili vrlo promjenjivim sastavom dijelova često nalaze opremu neaktivnu, stvarajući troškove bez odgovarajućih prihoda. Račun razbrisa se dramatično mijenja na temelju stope korištenja.

Ocenjivanje pružatelja usluga laserskog rezanja

Outsourcing eliminiše ulaganja kapitala, a pruža pristup tehnologiji koju se inače ne bi mogao priuštiti. No, nisu svi pružatelji usluga pružaju jednaku vrijednost. Kada tražite uslugu laserskog rezanja u mojoj blizini ili usluge rezanja metala laserskim rezanjem u mojoj blizini, znati što treba procijeniti odvaja odlične partnere od razočaravajućih iskustava.

Prema Izrezanje željezničkim putem laserskim rezom , većina proizvođača nema sredstava ili resursa za kupnju i održavanje naprednih laserskih rezačkih strojeva u kući, zbog čega partnerstvo s pouzdanom tvrtkom za rezanje pojednostavljuje proizvodni proces. Ključ je u odabiru pravog partnera kroz sustavnu evaluaciju.

Počnite potvrđivanjem tehničkih mogućnosti koje odgovaraju vašim zahtjevima. Svaki renomirani proizvođač objavljuje specifikacije koje obuhvaćaju kompatibilnost materijala i granice debljine. Steelway napominje da većina pružatelja usluga laserskog rezanja metala lako može proizvesti uobičajene materijale poput nehrđajućeg čelika, ali njihova oprema možda ne stvara kvalitetne dijelove iz izazovnijih materijala poput visoko reflektativnog aluminija. Provjerite njihove sposobnosti prije nego što se obvežete.

Vreme obrade je izuzetno važno. Pitaj se konkretno koliko vremena projekt traje od podnošenja dokumenta do isporuke. Neki pružatelji nude ubrzane usluge za hitne poslove, iako obično po višestrukoj cijeni. Razumijevanje standardnih vremena za isporuku pomaže vam da realistično planirate proizvodne rasporede.

Iskustvo i ugled zaslužuju istragu. Tražite svjedočanstva drugih klijenata, osobito onih iz sličnih industrija. Prema Steelway-u, optimalni pružatelji će imati desetljeća iskustva zajedno s najmodernijom tehnologijom dostupnom u najsavremenijim objektima osmišljenim za rješavanje projekata svih vrsta.

Transparentnost cijena razdvaja pouzdane partnere od onih koji će vas vjerojatno iznenaditi skrivenim troškovima. Budite oprezni s ponuditeljima koji nude trenutne cijene bez razumijevanja vaših specifičnih potreba. Sveobuhvatne cifre trebaju uključivati materijal, vrijeme rezanja, završetak i isporuku. Potvrdi sve troškove prije formalizacije partnerstva.

Kada primate uzorke dijelova ili prve narudžbe, sustavno procjenjujte kvalitetu pomoću sljedećih pokazatelja:

- Konzistencija rubova: U skladu s člankom 3. stavkom 2. točkom (a) ovog Pravilnika, proizvođač mora imati pravo na sve informacije koje je potrebno za utvrđivanje vrijednosti proizvoda.

- Dimenziona točnost: Čestice koje se izmjeravaju unutar određenih tolerancija kada se provjeravaju prema crtežima pomoću kalibriranih instrumenata

- Površinska obrada: Odgovarajuća tekstura bez prekomjerne toplinske promjene boje, tragova prskalica ili kontaminacije

- U slučaju da se ne primjenjuje, mora se upotrijebiti: U slučaju da se ne primjenjuje, ispitivanje se provodi u skladu s člankom 6. stavkom 2.

- Kvalitet pakiranja: U slučaju da se u slučaju izbijanja vozila u prometnom prometu ne primjenjuje relevantna pravila o zaštiti, to znači da se ne primjenjuje propusnica o zaštiti.

Industrijski i proizvođački perspektivi

Kriteriji za ocjenu se mijenjaju na temelju razmjera zahtjeva. Industrijski proizvođači daju prioritet sertifikacijama, kapacitetu i integraciji lanca opskrbe. Proizvođači i ljubitelji se fokusiraju na pristupačnost, minimalnu fleksibilnost narudžbe i podršku dizajna.

U slučaju automobila koji zahtijevaju usklađenost s IATF 16949 standardom, sertifikacija postaje nepredstavljiva. U skladu s člankom 3. stavkom 1. To je mjesto gdje integrirani proizvođači nude jasne prednosti. Tvrtke kao što su Shaoyi (Ningbo) Metal Technology u skladu s člankom 3. stavkom 1. stavkom 2. Njihova 5-dnevna brza obrta prototipa i 12-satni odgovor na ponudu pojednostavljuju proces ocjenjivanja dobavljača za proizvođače koji nabavljaju šasiju, oslanjanje i strukturne komponente.

U slučaju da se radi o proizvodnji proizvoda za proizvodnju proizvoda, potrebno je osigurati da su proizvodi u skladu s člankom 3. stavkom 1.

- Svaka vrsta vozila može se upotrebljavati za proizvodnju vozila s brzinom od 300 km/h do 300 km/h. Inženjerski ulaz koji poboljšava kvalitetu dijela istovremeno smanjujući troškove

- Brze mogućnosti izrade prototipova: U slučaju da se proizvodnja ne završi, potrebno je osigurati da se proizvodnja ne završi.

- Skalabilnost: Sposobnost povećanja od količine prototipa do proizvodnje velikih količina

- Potvrde kvalitete: U skladu s člankom 3. stavkom 2.

- Sekundarna obrada: Plošeno premazovanje, zavarivanje, montaža i druge usluge s dodanom vrijednošću koje smanjuju broj vaših dobavljača

Proizvođači i proizvođači malih serija suočavaju se s različitim čimbenicima odlučivanja. Traženje laserskog rezanja u mojoj blizini često otkriva lokalne makerspaces, radnje i online usluge koje se odnose na manje količine. Minimalni zahtjevi za narudžbu, fleksibilnost formata datoteka i volja za rad s početnicima u dizajnu važniji su od certifikata u ovoj razini.

Online platforme su demokratizirale pristup uslugama laserskog rezanja, omogućavajući dizajnerima da učitaju datoteke i primaju ponudu u roku od nekoliko minuta. U skladu s člankom 3. stavkom 1. točkom (a) Uredbe (EU) br. 600/2014 Komisija je odlučila o uvođenju mjera za utvrđivanje cijene za te usluge. Izmjena uključuje manje personalizirane usluge i potencijalno duže vrijeme isporuke tijekom najgorih razdoblja.

Donošenje odluke

U slučaju da se ne uspije osigurati da se osiguraju usluge, potrebno je osigurati da se ne dovode u pitanje sljedeća pitanja:

- Koja je vaša realistična godišnja količina rezanja u satima rada stroja?

- Imate li kvalificirane operatore ili proračun za obuku i plaće?

- Koliko je hitno rješenje ključno za iteracije dizajna?

- U skladu s člankom 3. stavkom 2.

- Hoće li vaš sastavni dio koristiti sve mogućnosti opreme?

Ako iskreni odgovori ukazuju na korištenje ispod 60-70%, vanjski poduzeća vjerojatno donose bolju ekonomiju. Prema McHone Industries-u, proizvođači koji razmišljaju o uvođenju laserskog rezanja u tvrtku trebali bi otvoreno razgovarati s proizvođačima koji razumiju proces i faktore troškova. To je najbolja polazna točka, bilo da na kraju ulažete u opremu ili formalizirate partnerstva u uslugama.

Za one koji se naklone vanjskim tvrtkama, McHone predlaže da pošalju nekoliko malih projekata kako bi usporedili troškove i kvalitetu s unutarnjim procjenama. Rezultati iz stvarnog svijeta otkrivaju da li cijene i performanse pružatelja usluga ispunjavaju vaša očekivanja bolje od teorijskih izračuna.

Laserskim rezom metalnih listova nudi se više puteva za precizne dijelove. Bez obzira na to ulažete li u opremu ili pružatelje usluga za podizanje poluge, razumijevanje tih čimbenika za donošenje odluka osigurava da vaš izbor odgovara poslovnim ciljevima, a ne pretpostavkama. Svaki od tih načina, ako se dobro provede, pruža preciznost, ponovljivost i učinkovitost koja čine lasersko sečenje proizvodnim standardom.

Često postavljana pitanja o laserskom sečenju metalnih listova

1. za Može li se metalni list laserski rezati?

Da, listovi metala jedan su od primarnih materijala koji se obrađuju pomoću laserske tehnologije rezanja. Moderni laseri od vlakana učinkovito seče čelik, nehrđajući čelik, aluminij, bakar, mesing i posebne metale s iznimnom preciznošću. Fokusirani laserski zrak topi ili ispariva materijal duž programiranih puteva, postižući tolerancije unutar plus ili minus 0,005 inča za tanke materijale. Ova tehnologija postala je industrijski standard za preciznu proizvodnju metala zbog svoje brzine, točnosti i sposobnosti rukovanja složenim geometrijama bez fizičkog alata.

2. - Što? Koji je najbolji laser za rezanje ploče?

Laseri s vlaknima su općenito najbolji izbor za sečenje ploče metala, posebno za reflektirajuće metale poput aluminija, bakra i mesinga. Njihova valna dužina od 1,06 mikrometara prodire na metalne površine učinkovitije od CO2 lasera, pružajući 2-5 puta brže brzine rezanja tankih materijala. Laseri od vlakana također nude učinkovitost od 30-50% u odnosu na 10-15% za sustave CO2, što rezultira nižim operativnim troškovima. Međutim, CO2 laseri ostaju održiv za deblje čelikove ploče i trgovine mješovitim materijalima koje zahtijevaju mogućnosti rezanja nemetala.

3. Slijedi sljedeće: Koliko debljina može laser rezati metalni list?

Laseri od vlakana mogu rezati čelik i nerđajući čelik do debljine 25 mm, aluminij do debljine 25 mm, bakar do debljine 12 mm i mesing do debljine 15 mm. Maksimalna debljina ovisi o snazi lasera, vrsti materijala i potrebnom kvalitetu ruba. U slučaju da je proizvodnja proizvoda u skladu s člankom 3. stavkom 1. točkom (a) ovog članka, proizvodnja proizvoda u skladu s člankom 3. točkom (a) ovog članka može se upotrebljavati samo za proizvodnju proizvoda koji se upotrebljavaju u skladu s člankom 3. točkom (a) ovog članka. Za materijale koji premašuju te debljine, rezanje vodnim mlazom ili plazmom može biti ekonomičnija alternativa, iako lasersko rezanje pruža višu preciznost i kvalitetu ivica u svom operativnom rasponu.

4. - Što? Koliko košta lasersko rezanje ploče?

Troškovi laserskog rezanja variraju ovisno o vrsti materijala, debljini, složenosti dizajna, količini i zahtjevima za završetkom. Glavni faktori troškova uključuju vrijeme rada stroja (koji utječu na ukupnu dužinu reznice i točke probijanja), potrošnju materijala i naknade za postavljanje. Protihodni proizvodi obično imaju veće troškove po jedinici zbog raspodjele instalacije, dok količine od 100+ komada mogu smanjiti troškove za 40-60%. Proizvođači s IATF 16949 sertifikatom kao što je Shaoyi nude 12-satnu obratu cijena kako bi vam pomogli precizno proračunati za automobilske i industrijske aplikacije.

- Pet. Da li da kupim laserski rez ili da koristim uslugu rezanja?

Odluka ovisi o obimu proizvodnje, raspoloživosti kapitala i tehničkoj stručnosti. Ugrađena oprema ima ekonomski smisao kada strojevi rade produktivno dvije ili više smjena dnevno uz dosljedan rad velikog obima. Industrijski laserski rezači iznose između 200.000 i 500.000 dolara plus troškovi održavanja, potrošnih materijala i operatora. U slučaju intermitentne potražnje ili miješanja varijabilnih dijelova, outsourcing certificiranim pružateljima usluga eliminiše ulaganja kapitala, a pruža pristup naprednoj tehnologiji. U skladu s člankom 3. stavkom 2.

Male količine, visoki standardi. Naša usluga brzog prototipiranja čini potvrdu bržom i lakošću —

Male količine, visoki standardi. Naša usluga brzog prototipiranja čini potvrdu bržom i lakošću —