Toplo i hladno komorni postupak lijevanja pod pritiskom za auto dijelove

KRATKO

Kalupljenje pod tlakom s toplim i hladnim komorama razlikuje se po tome gdje se metal topi. Kod kalupljenja pod tlakom s toplim komorom, metal se topi unutar stroja, što omogućuje brze proizvodne cikluse, idealan za legure s niskom temperaturom taljenja poput cinka, kositra i olova. Suprotno tome, kod kalupljenja pod tlakom s hladnim komorom koristi se odvojena peć, postupak koji je neophodan za legure s visokom temperaturom taljenja poput aluminija, čime se proizvode jači i izdržljiviji dijelovi koji su ključni za mnoge primjene u automobilskoj industriji.

Ključna razlika: proces i mehanizam

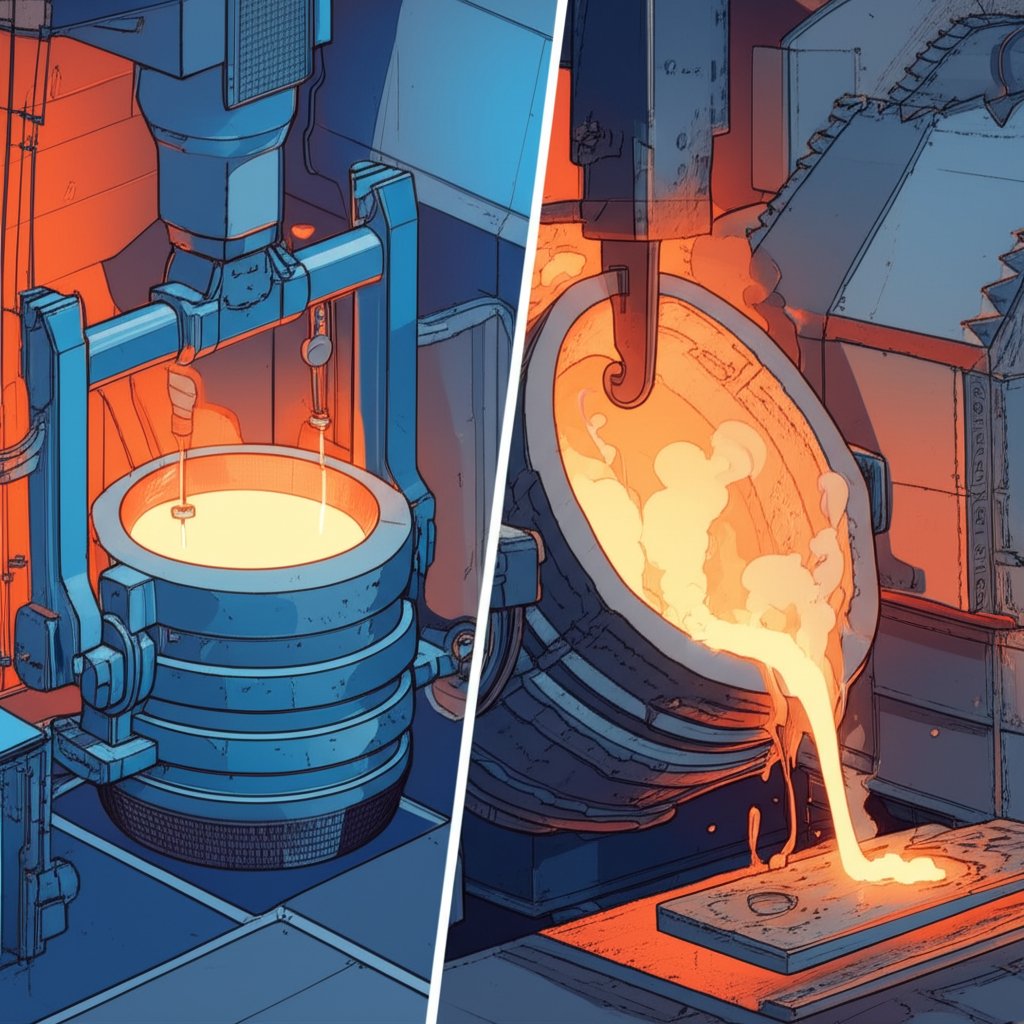

Razumijevanje osnovne razlike između die castinga u vrućoj i hladnoj komori počinje s dizajnom stroja i lokacijom peći. Taj jedan faktor određuje brzinu procesa, kompatibilnost materijala i konačno vrste komponenti koje svaka metoda može proizvesti. Osnovna razlika je u integraciji tiglja za taljenje: strojevi za vruću komoru imaju unutarnju, ugrađenu peć, dok se strojevi za hladnu komoru oslanjaju na vanjsku.

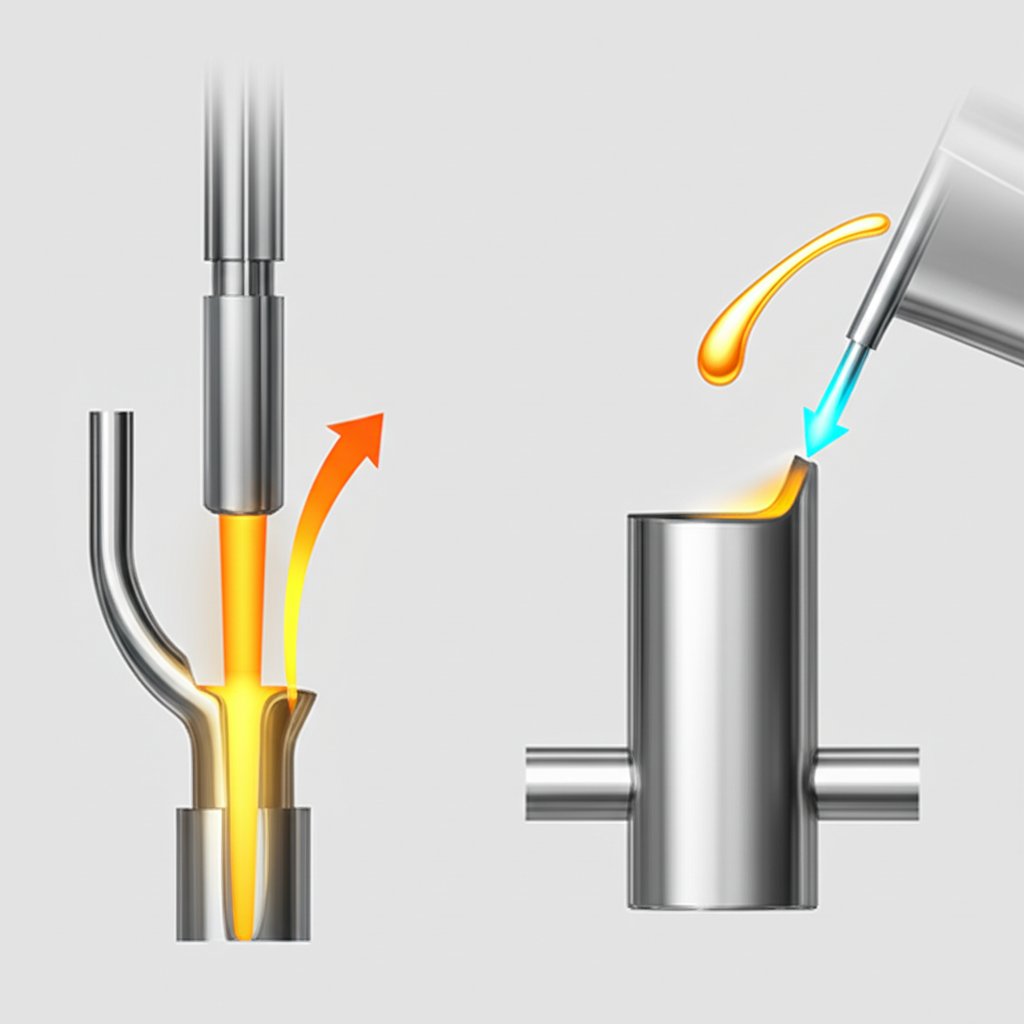

U odlijevanju na vrućoj komori, mehanizam za ubrizgavanje, često nazvan "grizlica", direktno se potopava u bazen rastopljenog metala smješten unutar stroja. Kad se ciklus započne, pišton pritiska ovaj tekući metal kroz vrat i u šupljinu. Budući da je metal snabdijevanje je unutar i stalno topljenje, proces je nevjerojatno brzo i učinkovito. U skladu s nekim analizama industrije, strojevi za vruće komore mogu postići proizvodne stope od 400900 ciklusa na sat. Ovaj integrirani sustav smanjuje izloženost metala atmosferi, smanjuje oksidaciju i otpad materijala.

U slučaju da se proizvod ne koristi za proizvodnju električne energije, proizvodnja se može provesti u skladu s postupkom iz članka 4. stavka 1. točke (a) Uredbe (EZ) br. 1225/2009. Metal se topi u posebnoj vanjskoj pećnici i zatim se ručno ili pomoću automatizirane štapke prenosi u "streljni rukav" stroja. Odatle visokotlakni hidraulički strijelnik ubrizgava topljeni metal u maticu. Ovaj dodatni korak prijenosa metala prirodno usporava proizvodni ciklus, s tipičnim brzinama između 50 i 90 ciklusa na sat. Iako je sporija, ova separacija ključna je jer sprečava oštećenje dijelova za ubrizgavanje stroja zbog visokih temperatura i korozivne prirode određenih legura.

Kompatibilnost materijala: Odabir prave legure

Izbor između toplog i hladnog lijanja na lijevom izduvanju prvenstveno je određena legura određena za automobilski dio. Temperatura rada i dizajn svakog procesa stvaraju stroge ograničenja u kojima se metali mogu koristiti. Odliv u toploj komori isključivo se koristi za legure s niskim tačkama topljenja, dok je odliv u hladnoj komori neophodan izbor za legure s visokim tačkama topline koje nude superiornu čvrstoću i toplinsku otpornost.

Strojevi s vrućom komorom idealni su za nemetalne legure poput cinka, magnezija, kositra i olova. Ovi materijali imaju relativno niske temperature taljenja (obično ispod 450°C), koje može izdržati ugrađeni sustav za ubrizgavanje stroja bez značajnog oštećenja. Legure cinka posebno su popularne zbog izvrsne tečivosti, što omogućuje izradu dijelova s kompleksnim detaljima i glatkim površinama. Međutim, korištenje legure s visokom temperaturom taljenja poput aluminija u stroju s vrućom komorom nije izvedivo. Visoka temperatura i korozivna svojstva rastopljenog aluminija brzo bi oštetili ili uništile uronjeni sustav gusjeg vrata i klip.

Upravo ta ograničenja su razlog za postojanje postupka pod tlačnim lijevanjem u hladnoj komori. Taloženjem metala u odvojenoj peći, ovaj postupak može sigurno obraditi legure s visokom točkom taljenja poput aluminija, bakra i mesinga. Aluminij je dominirajući materijal u automobilskoj industriji zbog izvrsnog omjera čvrstoće i težine, što ga čini savršenim za strukturne komponente. Postupak u hladnoj komori omogućuje proizvodnju čvrstih, laganih dijelova koji su ključni za performanse vozila, sigurnost i učinkovitost potrošnje goriva.

| Proces | Kompatibilni legurni materijali | Primarne karakteristike |

|---|---|---|

| Lijeđenje u toplu štoperu | Cink, Kalaj, Olovo | Niska točka taljenja, izvrsna tečnost, pogodan za detaljne dijelove. |

| Die casting s hladnom komorom | Aluminij, Magnezij, Bakar, Mesing | Visoka točka taljenja, visoka čvrstoća, idealan za strukturne komponente. |

Primjena u automobilskoj industriji: Od blokova motora do emblema

U automobilskoj industriji i vruće i hladno komorni postupak tlačnog lijevanja imaju ključnu ulogu, ali koriste se za potpuno različite vrste komponenti ovisno o njihovim svojstvima materijala i mogućnostima proizvodnje. Odluka o korištenju jednog od postupaka temelji se na tome treba li dio biti strukturni i visoke čvrstoće ili manji, detaljniji i proizveden u vrlo velikim serijama.

Hladno komorno tlačno lijevanje je radna sila za velike, kritične i strukturne dijelove vozila. Mogućnost korištenja aluminijevih legura visoke čvrstoće čini ga nezamjenjivim za proizvodnju komponenata koje osiguravaju integritet i sigurnost vozila. Posebne primjene uključuju:

- Blokovi motora i glave cilindara

- Kućišta mjenjača i transmisija

- Komponente ovjesa poput nosača upravljača i zglobova

- Strukturne dijelove šasije i podramanja

- Kućišta za baterije i motore električnih vozila (EV)

Za ove dijelove potrebna su izvrsna mehanička svojstva i izdržljivost koja je karakteristična za aluminij i legure dobivene hladnim komornim postupkom tlačnog lijevanja.

Lijevanje pod tlakom u vrućoj komori, zbog visoke brzine i preciznosti, izvrsno je za proizvodnju manjih, nestrukturnih i često dekorativnih komponenti u velikim količinama. Ovi dijelovi zahtijevaju fine detalje i visokokvalitetnu površinsku obradu, koju cinkove legure mogu pouzdano osigurati. Uobičajene primjene u automobilskoj industriji za lijevanje pod tlakom u vrućoj komori uključuju:

- Unutarnje uređenje i dekorativne trake

- Grbovi, logotipi i natpisne pločice

- Kućišta senzora i malih elektroničkih modula

- Mehanizmi bravica na vratima i pribor za prozore

- Mali nosači i spojni elementi

Iako lijevanje pod tlakom izvrsno odgovara složenim oblicima, važno je napomenuti da su drugi procesi, poput kovanja, ključni za komponente koji zahtijevaju maksimalnu čvrstoću i otpornost na zamor. Na primjer, mnogi kritični dijelovi pogonskog sustava i ovjesa izrađuju se kovanjem, procesom kojeg nude stručnjaci poput Shaoyi (Ningbo) Metal Technology , koji pružaju precizijski projektirana rješenja za primjene s visokim opterećenjem.

Detaljna analiza performansi: Usporedba jedan na jedan

Kod odabira postupka lijevanja pod tlakom za automobilsku primjenu, inženjeri i menadžeri projekata moraju procijeniti niz kompromisa koji uključuju brzinu proizvodnje, kvalitetu komponente i ukupne troškove. Lijevanje u vrućoj komori nudi brzinu i učinkovitost za ograničen raspon materijala, dok lijevanje u hladnoj komori pruža veću prilagodljivost i čvrstoću, ali sporijim tempom. Izravna usporedba ističe jasne prednosti i nedostatke koji vode konačnoj odluci.

Najznačajnija razlika u radu je brzina proizvodnje. Zahvaljujući integriranom pećnicima, postupak s vrućim komorama znatno je brži, što ga čini iznimno isplativim za serije visokog volumena proizvodnje kompatibilnih dijelova. Nasuprot tome, postupak s hladnom komorom zahtijeva dotjecanje metala za svaki ciklus, zbog čega je po prirodi sporiji. Međutim, taj gubitak u brzini nadoknađuje se boljom kvalitetom dijelova. Lijevanje u hladnoj komori proizvodi gušće i jače dijelove s boljim mehaničkim svojstvima, zbog čega je to jedina mogućnost za sigurnosno kritične i strukturne komponente.

Cijena je još jedan ključni faktor. Strojevi s vrućom komorom često imaju niže operativne troškove za velike serije zbog bržih ciklusa i duljeg vijeka trajanja kalupa, budući da slitine na nižoj temperaturi uzrokuju manji termički napon u kalupima. Strojevi s hladnom komorom zahtijevaju veća početna ulaganja, a kalupi su izloženi većem termičkom udaru, što može skratiti njihov vijek trajanja. Međutim, za dijelove koji zahtijevaju aluminij ili druge slitine visoke čvrstoće, ne postoji alternativa, a trošak se opravdava zahtjevima za performansama. Konačni izbor ovisi o ravnoteži između potrebnih svojstava materijala, željenog obujma proizvodnje i predviđenog proračuna.

| Značajka | Lijeđenje u toplu štoperu | Die casting s hladnom komorom |

|---|---|---|

| Mehanizam procesa | Integrirana peć, sustav za podmorsko ubrizgavanje ('labodova vrata') | Odvojena vanjska peć, talina se prelijeva u 'cijev za ubrizgavanje' |

| Primjenjivi metali | Slitine s niskom točkom taljenja (cink, kosit, olovo) | Slitine s visokom točkom taljenja (aluminij, magnezij, bakar, mjed) |

| Brzina proizvodnje / Vrijeme ciklusa | Vrlo brzo (npr. 400-900 ciklusa/sat) | Sporije (npr. 50-90 ciklusa/sat) |

| Veličina komponente | Najbolje za male do srednje velike dijelove | Pogodno za velike, strukturne dijelove |

| Mehanička svojstva | Dobra obrada površine, niža čvrstoća | Izvrsna čvrstoća i gustoća, idealno za strukturnu uporabu |

| Alati i vijek trajanja kalupa | Duži zbog nižeg toplinskog naprezanja | Kraći zbog visokih temperatura i termičkog udara |

| Tipični troškovni profil | Niži operativni troškovi za velike količine | Veća početna ulaganja i ciklusni troškovi |

Često postavljana pitanja

1. Koje su mane die castinga u vrućoj komori?

Glavne mane die castinga u vrućoj komori su ograničenja materijala i zahtjevi za tlakom. Pogodan je samo za legure s niskom točkom taljenja, poput cinka i kositra, budući da bi visokotemperaturni metali poput aluminija korodirali dijelove za ubrizgavanje stroja. Osim toga, proces možda nije ekonomičan za serije proizvodnje malih količina, a složenost dijelova može biti ograničena fluidnošću specifičnih korištenih legura.

2. Za što se koristi die casting u hladnoj komori?

Litje u hladnoj komori koristi se za proizvodnju visokokvalitetnih, izdržljivih metalnih dijelova od slitina s visokom točkom taljenja, poput aluminija, mesinga i bakra. U automobilskoj industriji ključno je za proizvodnju velikih strukturnih i sigurnosno kritičnih komponenti poput blokova motora, kućišta mjenjača, dijelova ovjesa i kućišta baterija za električna vozila (EV). Njegova sposobnost stvaranja čvrstih, gusto strukturiranih dijelova čini ga nezamjenjivim za primjene koje zahtijevaju visoke mehaničke performanse.

3. Koje strojeve za die casting obično imaju veću stopu proizvodnje, strojeve za hladnu ili toplu komoru?

Strojevi za die casting s toplom komorom imaju znatno veću brzinu proizvodnje. Budući da se rastaljeni metal čuva unutar stroja i izravno ubrizgava, ciklusi su mnogo brži, što često omogućuje stotine ciklusa po satu. Strojevi s hladnom komorom su sporiji jer zahtijevaju dodatni korak prijenosa rastaljenog metala iz vanjske peći u stroj za svaki ubrizgavanje.

Male količine, visoki standardi. Naša usluga brzog prototipiranja čini potvrdu bržom i lakošću —

Male količine, visoki standardi. Naša usluga brzog prototipiranja čini potvrdu bržom i lakošću —