Προβλήματα Ελεγκτικού Μοχλού Από Σφυρηλατημένο Χάλυβα Που Δεν Μπορείτε Να Αγνοήσετε

TL·DR

Οι σφυρηλατημένοι χαλύβδινοι κάτω μοχλοί ελέγχου, οι οποίοι συνήθως εμφανίζονται σε οχήματα όπως το Chevrolet Silverado και το GMC Sierra, παρουσιάζουν αρκετά γνωστά προβλήματα. Οι κύριες ανησυχίες αφορούν την ευαισθησία τους στη σκουριά και τη διάβρωση, κάτι που μπορεί να μειώσει τη διάρκεια ζωής τους, καθώς και ένα σχεδιασμό που μπορεί να οδηγήσει σε πρόωρη βλάβη της σφαιρικής άρθρωσης. Σε σύγκριση με εναλλακτικές λύσεις όπως ο χυτοσίδηρος ή ο σφυρήλατος χάλυβας, θεωρούνται γενικά λιγότερο ανθεκτικοί, ειδικά για βαριά χρήση ή σε δύσκολα κλιματικά συνθήκη.

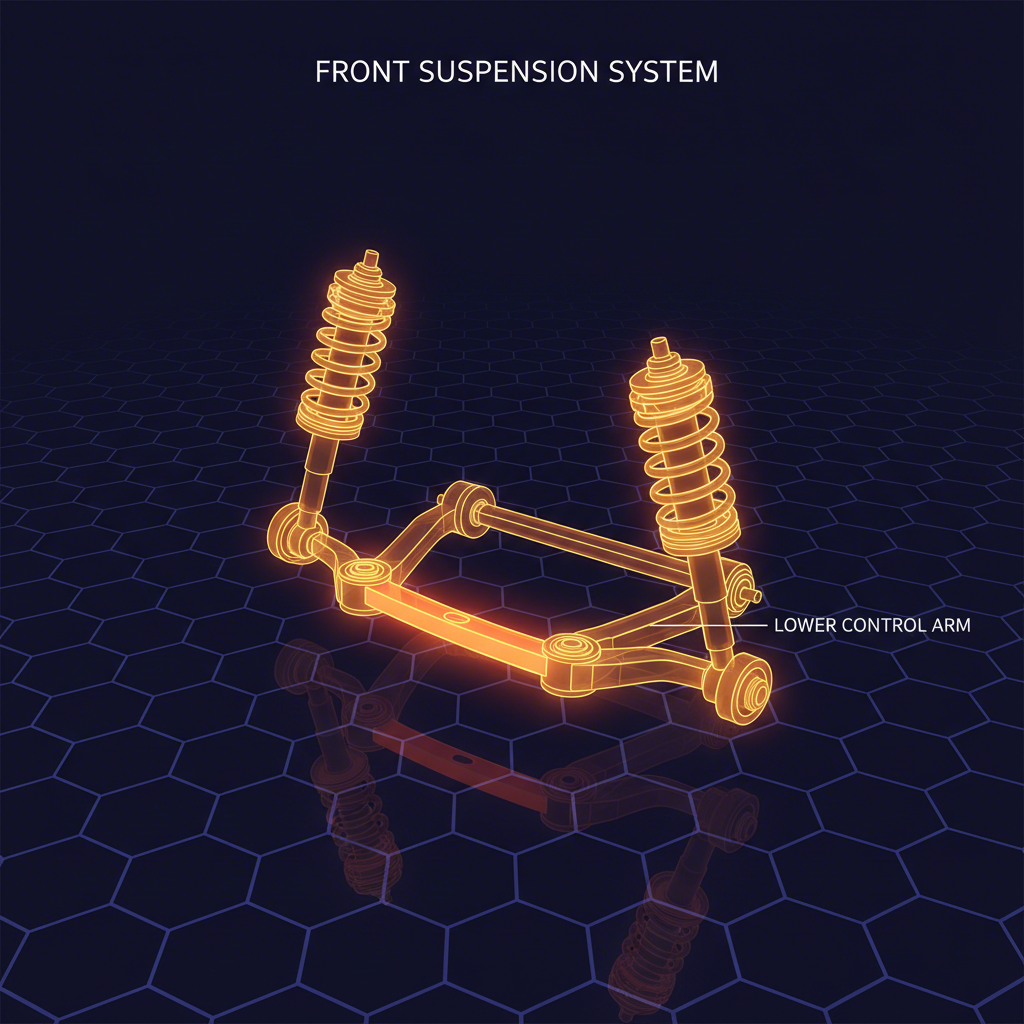

Αναγνώριση Των Μοχλών Ελέγχου Σας: Σφυρηλατημένος Χάλυβας Έναντι Εναλλακτικών

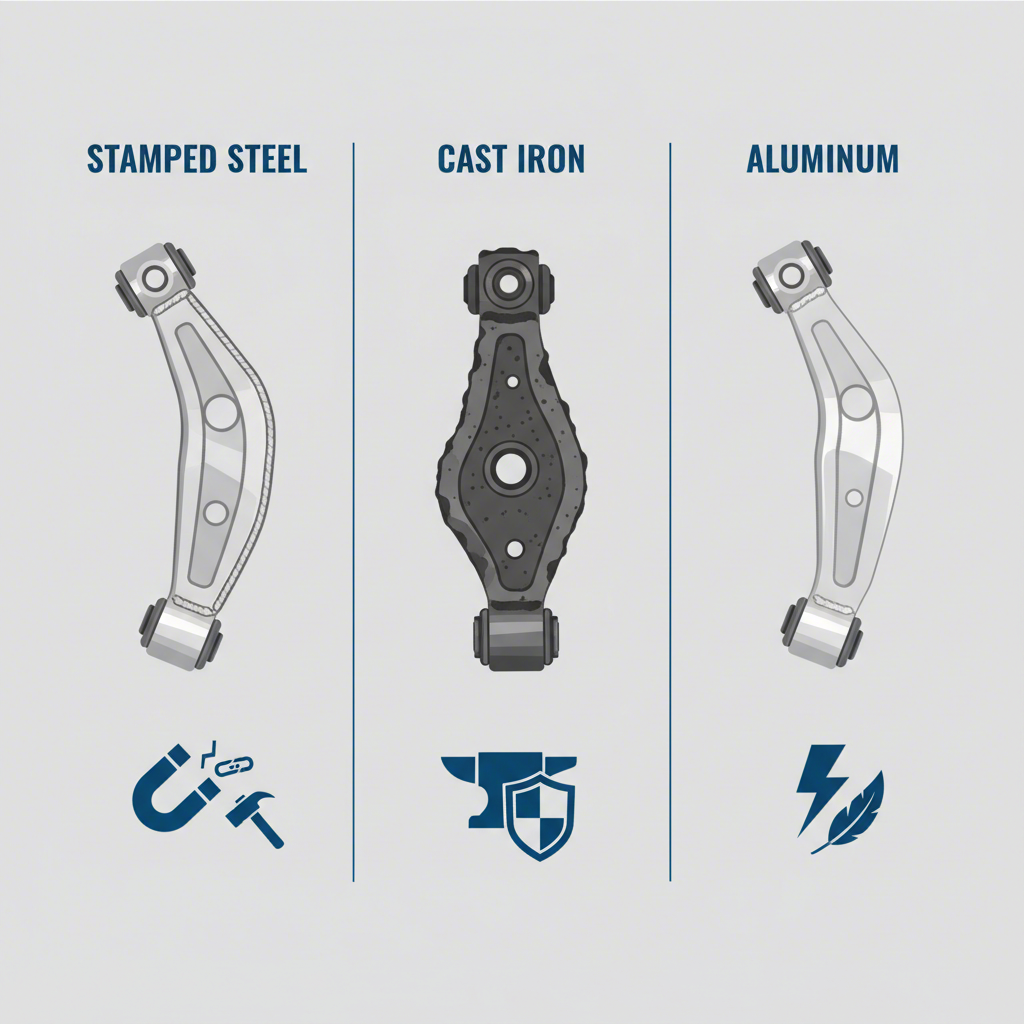

Πριν μπορέσετε να διαγνώσετε οποιαδήποτε προβλήματα, είναι απαραίτητο να γνωρίζετε το είδος των βραχιόνων ελέγχου που έχει το όχημά σας. Τα τρία πιο συνηθισμένα υλικά είναι χαλύβδινα ελάσματα, χυτοσίδηρος και αλουμίνιο, τα οποία έχουν διαφορετικά χαρακτηριστικά. Οι βραχίονες από χαλύβδινα έλασμα κατασκευάζονται με σφυρηλάτηση και συγκόλληση ελασμάτων χάλυβα, εμφανίζοντας συχνά δύο σχήματος C κομμάτια ενωμένα στις ραφές. Οι βραχίονες από χυτοσίδηρο κατασκευάζονται από υγρό σίδηρο που χύνεται σε καλούπι, δίνοντας ένα ενιαίο, στερεό κομμάτι με τραχύτερη επιφάνεια. Οι βραχίονες από αλουμίνιο μπορεί να είναι είτε χυτοί είτε σφυρήλατοι, αλλά είναι εμφανώς ελαφρύτεροι.

Η προσδιορισμός του υλικού στο όχημά σας είναι μια απλή διαδικασία που μπορείτε να κάνετε στο σπίτι. Σύμφωνα με τεχνική εγκύκλιο από κατασκευαστή αυτοκινητικών εξαρτημάτων MOOG , μερικοί απλοί έλεγχοι μπορούν να δώσουν μια οριστική απάντηση. Ξεκινήστε καθαρίζοντας πλήρως το βραχίονα ελέγχου για να αφαιρέσετε οποιαδήποτε βρωμιά ή λάσπη που θα μπορούσε να κρύψει τα χαρακτηριστικά του.

Ακολουθήστε αυτά τα βήματα για να προσδιορίσετε το υλικό του βραχίονα ελέγχου σας:

- Η δοκιμή μαγνητικού: Πάρτε ένα μαγνήτη και τοποθετήστε τον πάνω στο μοχλό ελέγχου. Αν ο μαγνήτης δεν προσκολλάται, ο μοχλός είναι φτιαγμένος από αλουμίνιο. Αν προσκολλάται, τότε πρόκειται είτε για χάλυβα είτε για χυτοσίδηρο.

- Ο Έλεγχος με Σφυρί: Αν ο μαγνήτης προσκολλάται, το επόμενο βήμα είναι να χτυπήσετε ελαφρά το μοχλό ελέγχου με ένα μικρό σφυρί. Ένας μοχλός από χάλυβα θα παράγει έναν κοίλο, ηχητικό ήχο, παρόμοιο με το χτύπημα σε λαμαρίνα. Ένας στερεός μοχλός από χυτοσίδηρο θα παράγει έναν βαρύ, αμβλύ ήχο χωρίς ηχώ.

Η απλή αυτή διαγνωστική διαδικασία σας βοηθά να προσδιορίσετε με ακρίβεια τα εξαρτήματά σας, το οποίο αποτελεί το κρίσιμο πρώτο βήμα πριν εξετάσετε επισκευές ή αντικαταστάσεις. Η γνώση του τύπου υλικού διασφαλίζει ότι θα παραγγείλετε τα σωστά εξαρτήματα και θα κατανοήσετε τις πιθανές ευπάθειες που σχετίζονται με αυτό.

Συνηθισμένα σημεία βλάβης μοχλών ελέγχου από χάλυβα

Ενώ είναι λειτουργικά για πολλές εφαρμογές, τα σφραγισμένα χάλυβα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνητα χειροκίνη Τα θέματα αυτά συζητούνται συχνά στα φόρουμ των ιδιοκτητών και είναι γνωστή ανησυχία για τους μηχανικούς, ιδιαίτερα σε σκληρά εργαζόμενα φορτηγά και SUV που εκτίθενται σε σκληρές συνθήκες.

Μια από τις πιο σημαντικές ανησυχίες είναι η πρόωρη αποτυχία των σφαιρικών αρθρώσεων. Σε ορισμένα σχέδια, ιδιαίτερα τα άνω χέρια ελέγχου σε ορισμένα φορτηγά της GM, η κατασκευή από χαλύβδινο στύλο προσφέρει ελάχιστη ή καθόλου υποστήριξη για να διατηρήσει τη σφαιρική άρθρωση εάν αποτύχει. Αυτό μπορεί να οδηγήσει σε καταστροφικό διαχωρισμό της ανάρτησης, προκαλώντας την κατάρρευση του τροχού. Ενώ τα κάτω χέρια μπορεί να έχουν διαφορετικό σχεδιασμό, η συνολική πίεση στις ολοκληρωμένες σφαιρικές αρθρώσεις σε ένα σφραγισμένο σύνολο χάλυβα παραμένει ένα σημείο αδυναμίας.

Η σκουριά και η διάβρωση αποτελούν ένα άλλο σημαντικό πρόβλημα. Οι συγκολλημένες ραφές ενός βραχίονα από χαλυβδόφυλλο δημιουργούν περιοχές όπου μπορεί να συγκεντρωθεί υγρασία και αλάτι του δρόμου, επιταχύνοντας τη διαδικασία σκουριάς. Σε αντίθεση με το συμπαγές χυτοσίδηρο ή το ανθεκτικό στη διάβρωση αλουμίνιο, το χαλυβδόφυλλο μπορεί να σκουριάζει από το εσωτερικό προς τα έξω, ενδεχομένως να υπονομεύει τη δομική του ακεραιότητα χωρίς προφανή εξωτερικά σημάδια, μέχρι ότου η ζημιά γίνει σοβαρή. Αυτό είναι ιδιαίτερα προβληματικό σε περιοχές με έντονες χιονοπτώσεις και δρόμους που αλατώνονται.

Τέλος, υπάρχει ο κίνδυνος κάμψης ή αδυναμίας υπό ακραίες φορτίσεις. Επειδή κατασκευάζονται από συγκολλημένα ελάσματα αντί να είναι ένα συμπαγές κομμάτι, οι βραχίονες από χαλυβδόφυλλο είναι πιο ευάλωτοι σε κάμψη ή παραμόρφωση υπό μεγάλα φορτία ή απότομες κραδασμούς. Οι ιδιοκτήτες σε φόρουμ συχνά αναφέρουν ανησυχίες για την αντοχή τους μετά την εγκατάσταση κιτ εξισορρόπησης, τα οποία μπορούν να αλλάξουν τις γωνίες της ανάρτησης και να αυξήσουν την πίεση στα εξαρτήματα.

Να είστε σε εγρήγορση για αυτά τα συνηθισμένα συμπτώματα ενός βραχίονα ελέγχου που αποτυγχάνει:

- Κρότοι ή κλικ στα αναρτησιακά, ειδικά όταν περνάτε πάνω από τρύπες ή στρίβετε.

- Δονήσεις ή αίσθηση χαλαρότητας στο τιμόνι.

- Μη ομοιόμορφη ή πρόωρη φθορά των ελαστικών.

- Το όχημα τραβάει προς τη μία πλευρά κατά την οδήγηση.

Σύγκριση Υλικών: Χαλύβδινο Στάμπωμα έναντι Χυτοσίδηρου, Forged και Αλουμινίου

Η επιλογή υλικού για έναν βραχίονα ελέγχου επηρεάζει σημαντικά την αντοχή, το βάρος, το κόστος και τη συνολική απόδοση. Ο χαλύβδινος στάμπωμας χρησιμοποιείται συχνά από τους κατασκευαστές ως λύση με χαμηλό κόστος, αλλά η κατανόηση των συμβιβασμών σε σύγκριση με άλλα υλικά είναι κρίσιμη για ενημερωμένες αποφάσεις επισκευής ή αναβάθμισης. Η ίδια η διαδικασία παραγωγής καθορίζει πολλές από αυτές τις ιδιότητες· για παράδειγμα, το στάμπωμα μετάλλου απαιτεί ακριβή μηχανική μελέτη και εξοπλισμό για τη δημιουργία εξαρτημάτων από φύλλο μετάλλου. Για κατασκευαστές αυτοκινήτων που αναζητούν αξιόπιστες λύσεις, εταιρείες όπως Shaoyi (Ningbo) Metal Technology Co., Ltd. εξειδικεύονται στην παραγωγή υψηλού όγκου τέτοιων πολύπλοκων εξαρτημάτων με στάμπωμα.

Κάθε υλικό προσφέρει διαφορετική ισορροπία πλεονεκτημάτων. Το χυτοσίδηρο είναι γνωστό για την τεράστια αντοχή και ανθεκτικότητά του, κάνοντάς το συνηθισμένη επιλογή για βαρέα φορτηγά και SUV. Το σφυρηλατημένο χάλυβας και το σφυρηλατημένο αλουμίνιο προσφέρουν το υψηλότερο επίπεδο αντοχής λόγω μιας διαδικασίας παραγωγής που συμπιέζει το μέταλλο, ευθυγραμμίζοντας τη δομή του κόκκου και εξαλείφοντας τους εσωτερικούς κενούς χώρους. Αυτό καθιστά τα σφυρηλατημένα εξαρτήματα ιδιαίτερα ανθεκτικά στις κρούσεις και την κόπωση.

Παρακάτω αναλύεται η σύγκριση των διαφορετικών υλικών:

| Τύπος Υλικού | Πλεονεκτήματα | Μειονεκτήματα | Χρησιμοποιείται συχνά σε |

|---|---|---|---|

| Διαμορφωμένος Χάλυβας | Χαμηλό κόστος παραγωγής, ελαφρύ σε σύγκριση με το χυτοσίδηρο. | Ευάλωτο σε σκουριά και διάβρωση, λιγότερο άκαμπτο, πιθανότητα αστοχίας της μπαλακρίδας. | Πολλά επιβατικά αυτοκίνητα και ορισμένα ελαφρά φορτηγά. |

| Χυτοσίδηρο | Πολύ ισχυρό και ανθεκτικό, κατάλληλο για βαριές φορτία. | Βαρύ, μπορεί να είναι εύθραυστο υπό ακραίες κρούσεις. | Βαρέα φορτηγά, SUVs και παλαιότερα οχήματα. |

| Κατεσταλμένο χάλκινο χάλυβα | Ανώτερη αντοχή και αντίσταση στην κόπωση, πολύ ανθεκτικό. | Υψηλότερο κόστος, βαρύτερο από το αλουμίνιο. | Οχήματα απόδοσης και εφαρμογές βαρέων καθηκόντων. |

| Αλουμίνιο (Χυτό/Μαχηρωτό) | Ελαφρύ (μειώνει την ακάλυπτη μάζα), ανθεκτικό στη διάβρωση. | Πιο ακριβό, μπορεί να σπάσει αντί να λυγίσει σε ατύχημα. | Σύγχρονα επιβατικά αυτοκίνητα, οχήματα υψηλών επιδόσεων και κάποια φορτηγά. |

Για τις περισσότερες καθημερινές χρήσεις οδήγησης, τα εργοστασιακά εξοπλισμένα στηρίγματα από σφυρηλατημένο χάλυβα είναι ικανοποιητικά. Ωστόσο, για οχήματα που υπόκεινται σε μεγάλα φορτία, χρήση εκτός δρόμου ή σκληρές καιρικές συνθήκες, η αναβάθμιση σε πιο ανθεκτικό υλικό, όπως χυτοσίδηρος ή μαχηρωτός χάλυβας, θεωρείται συχνά μια σκόπιμη επένδυση για μακροπρόθεσμη αντοχή και ασφάλεια.

Συχνές Ερωτήσεις

1. Ποια είναι η διαφορά μεταξύ των ελεγκτών βραχιόνων από χυτοσίδηρο και από εμφανισμένο χάλυβα;

Η βασική διαφορά έγκειται στην κατασκευή και τις ιδιότητές τους. Τα στηρίγματα από σφυρηλατημένο χάλυβα κατασκευάζονται από ελάσματα χάλυβα που πιέζονται σε σχήμα και συγκολλώνται μαζί, γεγονός που τα καθιστά σχετικά ελαφριά και φθηνά. Τα στηρίγματα από χυτοσίδηρο κατασκευάζονται με τη ρίψη τήγματος σιδήρου σε καλούπι, δημιουργώντας ένα ενιαίο, στερεό κομμάτι που είναι πολύ πιο ισχυρό, βαρύτερο και ανθεκτικότερο στο λύγισμα, κάνοντάς το ιδανικό για οχήματα βαρέος τύπου.

2. Πώς να καταλάβετε αν έχετε διαγώνιους βραχίονες από χαλυβδέλασμα;

Μπορείτε να πραγματοποιήσετε δύο απλές δοκιμές. Πρώτον, δείτε αν ένας μαγνήτης προσκολλάται στο μοχλό ελέγχου· αν ναι, τότε είναι από χάλυβα ή σίδηρο. Αν όχι, είναι από αλουμίνιο. Δεύτερον, αν ο μαγνήτης προσκολλάται, χτυπήστε το μοχλό με ένα σφυρί. Ένας κούφιος, ηχητικός ήχος υποδεικνύει χαλυβδένιο ελασμένο μέρος, ενώ ένας βαρύς, αμβλύς ήχος υποδηλώνει συμπαγές χυτοσίδηρο.

3. Ποια είναι η διαφορά μεταξύ εμφυτευόμενων και σφυρηλατημένων βραχιόνων ελέγχου;

Οι ελασμένοι μοχλοί ελέγχου δημιουργούνται από πιεσμένα και συγκολλημένα φύλλα μετάλλου, μια οικονομική διαδικασία. Οι σφυρηλατημένοι μοχλοί ελέγχου δημιουργούνται με τη θέρμανση ενός συμπαγούς κομματιού μετάλλου και τη συμπίεσή του υπό ακραία πίεση μέσα σε καλούπι. Αυτή η διαδικασία σφυρηλάτησης ευθυγραμμίζει την εσωτερική δομή του μετάλλου, καθιστώντας το τελικό εξάρτημα σημαντικά πιο ανθεκτικό και ανθεκτικότερο στην κόπωση και τις κρούσεις σε σύγκριση με ένα ελασμένο εξάρτημα.

Μικρές παραγωγικές σειρές, υψηλοί πρότυποι. Η υπηρεσία γρήγορης δημιουργίας πρωτότυπων μας κάνει την επαλήθευση ταχύτερη και ευκολότερη —

Μικρές παραγωγικές σειρές, υψηλοί πρότυποι. Η υπηρεσία γρήγορης δημιουργίας πρωτότυπων μας κάνει την επαλήθευση ταχύτερη και ευκολότερη —