Metal Laser Cutting Costs Exposed: Plasma And Waterjet Can't Compete

Understanding Metal Laser Cutting Technology

What exactly happens when a beam of light slices through solid steel like butter? Metal laser cutting represents one of the most transformative advances in modern manufacturing, combining raw power with surgical precision. This technology has revolutionized how industries approach fabrication, from crafting intricate aerospace components to producing automotive chassis parts at scale.

So, what is laser cutting? At its core, it's a process that uses a high-power laser directed through optics and computer numerical control (CNC) to cut through various materials, including metal. The focused laser beam burns, melts, or vaporizes the material while a jet of gas blows away debris, leaving behind a high-quality surface finished edge. Think of it as concentrating sunlight through a magnifying glass—except exponentially more powerful and precisely controlled.

How Focused Light Transforms Metal Fabrication

Imagine focusing enormous energy into a spot smaller than a pencil tip. That's precisely what a laser for cutting machine accomplishes. The laser beam is created by stimulating lasing materials through electrical discharges inside a closed container. This material is amplified by internal reflection via a partial mirror until its energy escapes as a stream of coherent, monochromatic light.

Here's where it gets impressive: at its narrowest point, a laser beam is typically under 0.32 mm (0.0125 inches) in diameter. However, kerf widths as small as 0.10 mm (0.004 inches) are achievable depending on material thickness. This incredible precision enables manufacturers to create complex geometries that traditional cutting methods simply cannot match.

The Science Behind Precision Metal Cutting

When you need to start cutting somewhere other than the edge, a piercing process kicks in. A high-power pulsed laser punches through the material—taking approximately 5-15 seconds to burn through a 13 mm (0.5-inch) thick stainless steel sheet. From there, the laser metal cutter follows programmed CNC paths with remarkable accuracy.

Precision laser cutting delivers tolerances as tight as ±0.005 inches (±0.13 mm), making it indispensable for industries where microns matter—from medical device manufacturing to aerospace structural components.

Why has this technology become essential across manufacturing sectors? The answer lies in its unique combination of benefits: unmatched precision, minimal material waste, and the ability to handle complex designs without tooling changes. Automotive manufacturers rely on it for consistent chassis components. Aerospace engineers trust it for structural parts where tolerances are non-negotiable. Medical device companies depend on it for intricate instruments requiring absolute accuracy.

The technology continues evolving, with fiber lasers now producing narrower beams that deliver approximately four times the effective power for the same energy output. This advancement has made precision laser cutting faster, more efficient, and capable of handling reflective metals that previously posed significant challenges.

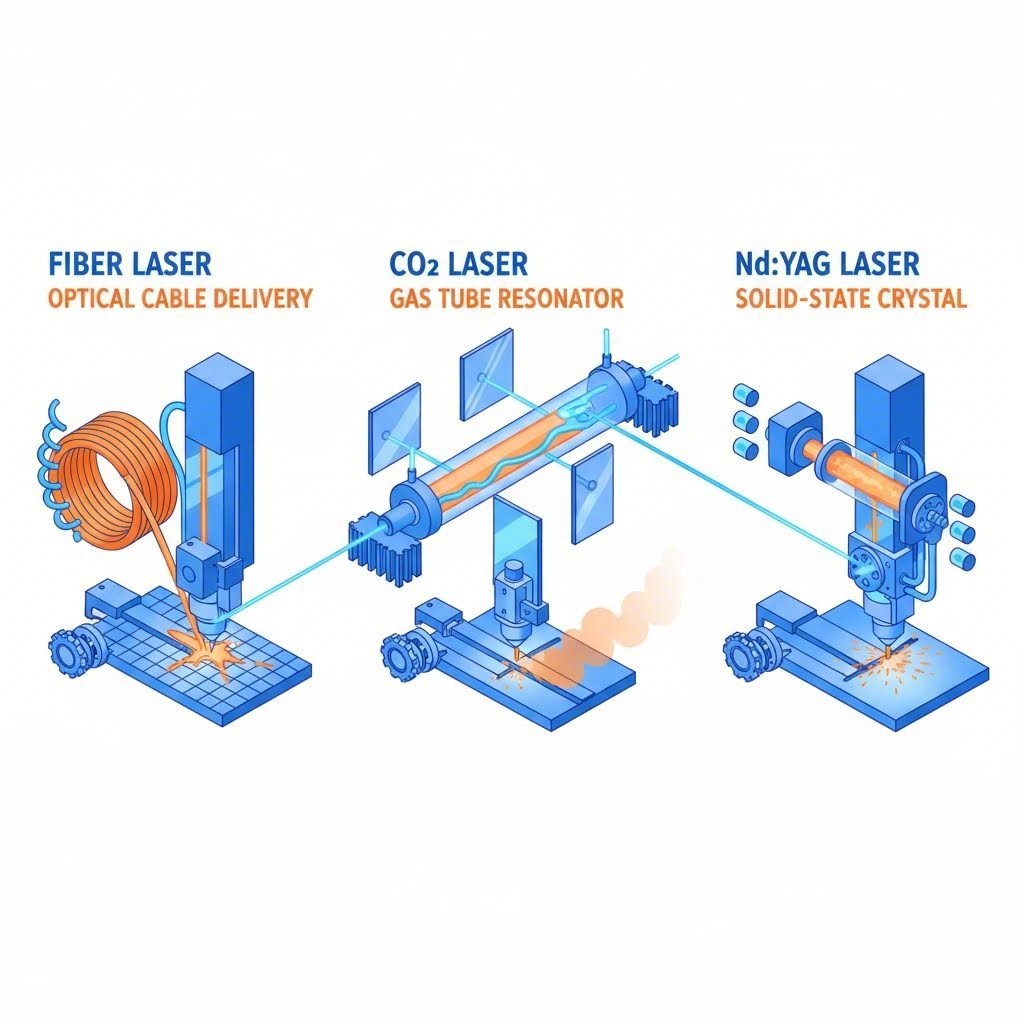

Fiber Laser Versus CO2 and Nd YAG Systems

Ever wondered why your metal fabricator recommends one laser type over another? The answer lies in fundamental physics—and understanding these differences can save you thousands in production costs. Three primary technologies dominate metal laser cutting: CO2, fiber, and Nd:YAG lasers. Each brings distinct advantages depending on your materials, thickness requirements, and production volumes.

Fiber Laser Technology Explained

Fiber lasers have transformed the metal cutting landscape, capturing 60% of the market while delivering speeds that leave older technologies behind. But what makes a fiber laser cutting machine so effective?

The technology works by generating laser light through fiber optic cables doped with rare-earth elements like ytterbium. This solid-state approach creates a wavelength of approximately 1 micron (1,064 nm)—significantly shorter than CO2 lasers. Here's why that matters: metals absorb this shorter wavelength far more efficiently, meaning more cutting power reaches the material rather than bouncing away.

A cnc fiber laser cutting machine offers several compelling advantages:

- Exceptional efficiency: Modern fiber systems achieve up to 50% wall-plug efficiency compared to just 10-15% for CO2 systems

- Superior reflective metal handling: Aluminum, copper, and brass cut cleanly without back-reflection damage

- Minimal maintenance: No mirrors to align, no gas tubes to replace—just solid-state reliability

- Compact footprint: Fiber delivery eliminates complex beam path requirements

The fiber laser cnc approach has become dominant for sheet metal applications because it delivers throughput rates that transform production economics. Facilities report processing up to 277 parts per hour compared to 64 parts per hour with equivalent CO2 systems.

CO2 Versus Fiber Performance Differences

While fiber lasers dominate metal cutting, CO2 systems haven't disappeared—they've found their niche. Understanding when each technology excels helps you make smarter equipment and service decisions.

CO2 lasers generate their beam using a gas mixture primarily composed of carbon dioxide, producing a 10,600 nm wavelength. This longer wavelength interacts differently with materials. Non-metals like wood, acrylic, leather, and textiles absorb it readily, making CO2 the preferred choice for these applications. However, metals reflect this wavelength more readily, reducing cutting efficiency.

The fibre laser cutter advantages become stark when examining operating costs. Energy costs run approximately $12.73 per hour for CO2 versus $3.50-4.00 for comparable fiber systems. Annual maintenance costs tell a similar story: $200-400 for fiber versus $1,000-2,000 for CO2 equipment.

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers occupy a specialized position. These solid-state systems deliver high peak power for applications requiring deep penetration—think welding, deep engraving, and cutting through thick materials. However, their lower efficiency and higher maintenance requirements limit widespread adoption for general metal cutting.

| Specification | Fiber Laser | CO2 Laser | Nd:YAG Laser |

|---|---|---|---|

| Wavelength | 1,064 nm | 10,600 nm | 1,064 nm |

| Power Efficiency | 30-50% | 10-15% | 3-10% |

| Metal Compatibility | Excellent (all metals including reflective) | Good (non-reflective metals) | Good (thick metals) |

| Cutting Speed (thin metal) | 3-5x faster than CO2 | Baseline | Slower than fiber |

| Operating Cost/Hour | $3.50-4.00 | $12.73 | $15-20+ |

| Annual Maintenance | $200-400 | $1,000-2,000 | $2,000+ |

| Best Applications | Sheet metal, reflective metals, high-volume production | Non-metals, thick plate over 25mm | Deep engraving, welding, thick plate specialty |

Why have fiber lasers become the dominant choice for metal cutting? The numbers tell the story. Total cost of ownership over five years shows CO2 systems costing $1,175,000 compared to $655,000 for fiber systems—a $520,000 difference that goes straight to your bottom line. Factor in 95-98% uptime versus 85-90% for CO2, and the productivity advantages compound dramatically.

However, CO2 lasers still excel when cutting materials exceeding 25mm thickness where edge quality takes precedence over speed. They also remain unmatched for mixed-material shops processing wood, plastics, and textiles alongside occasional metal work. The 15-25mm thickness range represents a transition zone where your specific quality requirements and production volumes should drive the decision.

With this foundation in laser technologies, you're ready to explore which metals work best with each system—and that's where material compatibility becomes your next critical consideration.

Metal Types and Thickness Capabilities

Which metals can you actually cut—and how thick can you go? This question determines whether your project succeeds or stalls. Understanding material compatibility isn't just technical knowledge; it's the foundation for accurate quotes, realistic timelines, and finished parts that meet your specifications.

The laser cutting of metal sheets varies dramatically based on material properties. Carbon steel behaves entirely differently from aluminum, and copper presents challenges that mild steel never does. Let's break down what you need to know for each major metal category.

Steel and Stainless Steel Cutting Capabilities

When it comes to laser cutting steel, you're working with the most forgiving material category. Carbon steel absorbs laser energy efficiently, producing clean cuts with minimal fuss. A 3kW fiber laser handles up to 16mm carbon steel, while stepping up to 6kW extends your range to 22mm with excellent edge quality.

Stainless steel laser cutting requires slightly more power due to the material's thermal properties. The chromium content that makes stainless corrosion-resistant also affects how it responds to concentrated heat. You'll typically need about 20% more power compared to equivalent carbon steel thicknesses. However, the results justify the extra energy—laser cut stainless steel delivers smooth, oxide-free edges when using nitrogen assist gas.

Here's what thickness capabilities look like across common laser power levels:

- 1.5kW systems: Carbon steel up to 10mm, stainless up to 6mm

- 3kW systems: Carbon steel up to 16mm, stainless up to 10mm

- 6kW systems: Carbon steel up to 22mm, stainless up to 16mm

- 12kW+ systems: Carbon steel up to 40mm, stainless up to 30mm

Tolerance specifications for laser cutting ss typically achieve ±0.1mm for thicknesses under 6mm, expanding to ±0.2mm for heavier plates. These tolerances satisfy most industrial applications, from structural components to precision enclosures.

Aluminum and Reflective Metal Considerations

Aluminum laser cutting introduces a challenge that trips up many newcomers: reflectivity. Aluminum's shiny surface bounces laser energy back toward the source rather than absorbing it for cutting. This isn't just an efficiency problem—reflected laser energy can damage optical components if equipment isn't properly configured.

Why do reflective metals behave this way? The physics comes down to resistivity and surface structure. The lower a material's resistivity, the more it reflects laser light. Copper and aluminum rank among the best electrical conductors—which unfortunately makes them challenging to cut.

However, fiber lasers have largely solved this problem. Their 1.07 µm wavelength is significantly shorter than CO2 lasers (10.6 µm), making it easier for metals to absorb rather than reflect. Modern cutting heads with anti-reflection coatings provide additional protection, allowing facilities to process aluminium laser cutting jobs confidently.

Not all aluminum grades cut equally. Series 7 and 8 aluminum alloys exhibit lower reflectivity than pure aluminum, making them easier to process. Common alloys like 5052, 6061, and 6063 fall in between—manageable with proper parameters but requiring attention to settings.

For laser cut aluminum applications, expect these thickness capabilities:

- 3kW fiber laser: Up to 10mm aluminum

- 6kW fiber laser: Up to 16mm aluminum

- 12kW+ fiber laser: Up to 25mm+ aluminum

Copper and brass demand even more respect. These highly reflective metals require fiber lasers with sufficient power to overcome initial reflectivity and rapidly heat material to melting point. For copper thicker than 2mm, oxygen assist gas becomes necessary to achieve clean cuts through oxidation assistance.

| Material | Recommended Laser Type | Typical Max Thickness | Tolerance Range | Special Considerations |

|---|---|---|---|---|

| Carbon Steel | Fiber or CO2 | 40mm (12kW+) | ±0.1 to ±0.2mm | Most forgiving; oxygen assist improves speed |

| Stainless Steel | Fiber (preferred) or CO2 | 30mm (12kW+) | ±0.1 to ±0.2mm | Nitrogen assist for oxide-free edges |

| Aluminum | Fiber only | 25mm (12kW+) | ±0.1 to ±0.25mm | High reflectivity; requires anti-reflection optics |

| Copper | Fiber only (3kW+ recommended) | 12mm (6kW+) | ±0.15 to ±0.3mm | Extremely reflective; oxygen assist above 2mm |

| Brass | Fiber only | 10mm (6kW+) | ±0.15 to ±0.3mm | Similar to copper; nitrogen produces cleaner edges |

When selecting materials for your project, using standard thicknesses significantly reduces costs and lead times. Laser cutters are calibrated for common gauges, making these materials more readily available and less expensive to process. Custom thicknesses often require minimum order quantities and extended timelines that inflate project budgets.

Understanding these material capabilities positions you to specify parts correctly—but knowing what you can cut only tells half the story. The real value emerges when you see how different industries leverage these capabilities for specific applications.

Industrial Applications and Use Cases

Where does metal laser cutting actually make a difference? The technology's versatility shines brightest when you examine real-world applications across industries. From life-saving medical devices to towering architectural installations, laser fabrication has become the backbone of precision manufacturing worldwide.

Understanding these applications helps you identify where this technology fits your projects. Whether you're sourcing laser cut parts for a prototype or planning high-volume production, knowing how different industries leverage these capabilities informs better decisions.

Automotive and Aerospace Component Manufacturing

The automotive industry relies heavily on metal laser cutting for components where precision and consistency are non-negotiable. Chassis components, body panels, and structural reinforcements all benefit from the technology's ability to produce identical parts at scale. When you're manufacturing thousands of components that must fit together perfectly, tolerances of ±0.1mm become essential rather than optional.

What makes laser cutting ideal for automotive applications? Speed and repeatability. An industrial laser cutting machine can process complex contours that would require multiple operations with traditional tooling. This translates to faster production cycles and lower per-part costs as volumes increase.

Aerospace takes precision requirements even further. The need for lightweight, high-strength materials in this sector cannot be overstated. Aircraft components demand materials like titanium alloys and high-grade aluminum—metals that respond exceptionally well to fiber laser processing. Structural integrity cannot be compromised, making the clean, heat-controlled cuts from laser technology indispensable.

Key automotive and aerospace applications include:

- Chassis and frame components: Precision-cut steel and aluminum structural elements

- Body panels and brackets: Complex contours with consistent edge quality

- Engine components: Heat shields, mounting brackets, and gasket materials

- Aircraft structural parts: Titanium and aluminum alloy components meeting strict tolerances

- Interior fittings: Lightweight aluminum panels and decorative elements

Precision laser cutting services have transformed how these industries approach prototyping and production. The ability to move from digital design to finished part without tooling changes accelerates development cycles dramatically.

Medical Device Manufacturing

When precision becomes a matter of patient safety, metal laser cutting delivers. Laser cutting technology enables the production of medical devices with unparalleled precision and accuracy—whether creating intricate surgical instruments or custom-fit implants designed to match individual patient anatomy.

The medical device industry presents unique challenges that laser cutting addresses directly:

- Surgical instruments: Scalpels, forceps, and specialized tools requiring razor-sharp edges

- Implantable devices: Custom prosthetics and orthopedic implants tailored to patient specifications

- Stents and catheters: Ultra-thin components for minimally invasive procedures

- Diagnostic equipment: Precision housings and internal components

Laser cutting ensures the processing of sterile and biocompatible materials essential for medical applications. Whether working with surgical-grade stainless steel or titanium implants, the technology maintains material integrity while achieving the tight tolerances these applications demand. The non-contact cutting process minimizes contamination risks—critical for components that enter the human body.

The ability to rapidly prototype and iterate designs has accelerated medical device development significantly. Designers and engineers can rapidly iterate on designs, test prototypes, and refine products before final production, bringing life-saving innovations to market faster.

Architectural and Decorative Metal Applications

Walk into any contemporary building lobby, and you'll likely encounter laser cut metal sheets transformed into stunning visual elements. Architectural metalwork represents one of the most visible applications of this technology—and one where aesthetics matter as much as precision.

Consider this real-world example: a decorative stainless steel screen wall measuring 30 feet high and 10 feet wide, weighing approximately 20,000 lbs. This architectural installation required tolerances of ±0.010 inches across 6,000 square feet of intricate patterns—specifications that only laser cutting could achieve consistently.

Architectural applications leverage the technology's unique capabilities:

- Decorative screens and partitions: Intricate pattern work in stainless steel and aluminum

- Facade panels: Weather-resistant cladding with complex geometries

- Railings and balustrades: Custom designs combining aesthetics with structural requirements

- Signage and wayfinding: Dimensional letters and detailed graphics

- Art installations: Large-scale sculptural elements in various metals

Laser cutting's ability to cut through thick steel plates and produce precise cuts makes it invaluable in construction. The technology delivers a combination of structural strength and aesthetic appeal that modern architecture increasingly demands.

Electronics and Industrial Equipment

The electronics industry pushes laser cutting capabilities in a different direction—toward miniaturization. The industry constantly pushes the boundaries of how small yet efficient devices can be, relying on an industrial laser cutter's ability to produce components where fractions of a millimeter determine functionality.

Industrial equipment manufacturing demands versatility across material types and thicknesses:

- Enclosures and housings: Precision sheet metal work with consistent dimensions

- Control panels: Accurate cutouts for displays, switches, and connectors

- Heat sinks and thermal management: Complex fin patterns in aluminum and copper

- Machine guards and covers: Safety components meeting regulatory requirements

What ties all these applications together? The decision points remain consistent regardless of industry. You're evaluating precision requirements, material compatibility, production volumes, and cost considerations. An automotive chassis component and a medical implant may serve entirely different purposes, but both require the same fundamental approach: matching project specifications to appropriate cutting capabilities.

Understanding these industry applications positions you to communicate effectively with service providers—but how do costs compare across different cutting technologies? That's where the numbers tell a compelling story.

Cost Comparison With Plasma and Waterjet Cutting

How much does metal laser cutting actually cost compared to alternatives? This question drives countless fabrication decisions—and the honest answer reveals why laser technology dominates despite higher upfront investments. Understanding the true cost picture requires looking beyond equipment price tags to examine operating expenses, precision capabilities, and production throughput.

When you're requesting a laser cutting quote, you're not just comparing dollars per inch of cut. You're evaluating total project economics: How much post-processing will you need? What's your scrap rate? Can you meet tolerance specifications without secondary operations? These factors determine whether metal cutting services deliver value or drain budgets.

Laser Cutting Cost Factors Explained

Let's break down what actually drives laser cutting charges. The hourly operating cost for fiber laser systems runs approximately $3.50-4.00 per hour for electricity and consumables—dramatically lower than you might expect. Compare this to plasma cutting near me services that advertise lower rates but often require extensive finishing work.

Several key factors determine your final project cost:

- Material thickness: Thin sheets (under 6mm) process rapidly; thicker plates slow cutting speeds and increase cost per part

- Design complexity: Intricate patterns require more cutting time but don't add tooling costs

- Edge quality requirements: Nitrogen assist gas produces oxide-free edges but costs more than oxygen cutting

- Volume: Setup costs distribute across larger runs, reducing per-part pricing significantly

- Material type: Reflective metals like copper require more power and slower speeds

For custom metal cutting projects, laser technology offers a hidden advantage: minimal post-processing. Laser cutting produces tolerances of ±0.005 inches with smooth edge finishes, often eliminating deburring and secondary finishing entirely. When steel cutting services quote lower cutting rates but require extensive grinding afterward, your total cost rises substantially.

Technology Comparison: Laser, Plasma, and Waterjet

Each cutting technology excels in specific scenarios. Understanding these differences helps you match your project requirements to the optimal process—and avoid overpaying for capabilities you don't need.

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Precision Level | ±0.005 inches (highest) | ±0.020 inches (moderate) | ±0.010 inches (high) |

| Material Thickness Range | 0.5mm to 40mm (optimal under 25mm) | 0.5mm to 50mm+ (optimal 6-50mm) | Any thickness up to 200mm+ |

| Cutting Speed (12mm steel) | Fast (40-60 inches/min) | Fastest (100+ inches/min) | Slowest (5-15 inches/min) |

| Operating Cost/Hour | $3.50-4.00 | $2.50-3.50 | $15-25 (abrasive costs) |

| Equipment Investment | $150,000-500,000+ | $50,000-150,000 | $100,000-400,000 |

| Heat-Affected Zone | Minimal (0.1-0.3mm) | Significant (1-3mm) | None (cold cutting) |

| Material Versatility | Metals only (conductive and non-conductive) | Conductive metals only | Any material (metals, stone, glass, composites) |

| Best Applications | Precision parts, thin-medium sheet metal, complex designs | Thick plate, high-volume structural steel, speed-critical projects | Heat-sensitive materials, thick plates, mixed-material shops |

When Alternative Cutting Methods Make Sense

Here's what competitors won't tell you: laser cutting isn't always the right choice. Being honest about limitations helps you make smarter decisions.

Plasma cutting wins when:

- You're processing steel plates from 12mm to 50mm thick where speed matters more than edge perfection

- Budget constraints make the lower equipment investment decisive

- Structural applications tolerate wider tolerances and minor finishing work

- High-volume production of simple shapes justifies the trade-offs

Waterjet cutting wins when:

- Heat-affected zones absolutely cannot exist—think aerospace titanium or hardened tool steels

- You're cutting extremely thick materials (50mm+) where lasers lose efficiency

- Non-metallic materials like stone, glass, or composites enter your product mix

- Material properties cannot change during cutting (no thermal stress)

The heat-affected zone (HAZ) deserves specific attention. The area between the melted part and unaffected base metal undergoes chemical and structural modifications—oxidation, localized hardening, and in some cases, corrosion susceptibility. Laser cutting produces the smallest HAZ among thermal processes (0.1-0.3mm), but waterjet eliminates it entirely by cutting cold.

For downstream forming operations, HAZ matters significantly. During forming, the HAZ can make it difficult to manage bending angles because it becomes impossible to foresee how metal will behave after heat-intensive cutting. If your parts require precise bends after cutting, factor this into your process selection.

ROI Framework for Equipment vs. Services

Should you invest in equipment or outsource to metal cutting services? The answer depends on your production reality:

Consider in-house equipment when:

- Annual cutting volume exceeds $150,000-200,000 in outsourced costs

- Lead time control provides competitive advantage

- Proprietary designs require confidentiality

- You have skilled operators or can invest in training

Outsource to services when:

- Volume doesn't justify capital equipment investment

- You need access to multiple technologies without owning each

- Capacity requirements fluctuate significantly

- Specialized materials require equipment you'd rarely use otherwise

The total cost calculation extends beyond cutting alone. Non-shearing methods can achieve high nesting efficiency, minimizing material waste, especially for complex parts. When material costs represent 40-60% of total project expense, the difference between 75% and 90% material utilization translates directly to profitability.

Understanding these cost dynamics positions you to negotiate effectively with service providers and make informed equipment decisions. But before committing resources, you'll want to understand the safety infrastructure that professional operations require—an often-overlooked factor that separates reliable providers from risky alternatives.

Safety Protocols and Operational Requirements

What happens when a laser powerful enough to slice through steel operates without proper safeguards? The consequences range from permanent eye damage to workplace fires—risks that reputable industrial laser cutting facilities invest heavily to prevent. Understanding these safety requirements helps you evaluate service providers and protects anyone working near this technology.

Most facilities operate Class-4 lasers for metal cutting—the highest hazard classification. These lasers are powerful enough to cause eye injuries if viewed directly or indirectly, and can potentially cause skin damage or fire. However, proper engineering controls and protocols transform these powerful tools into safely contained systems.

Essential Safety Equipment and Protocols

When evaluating a commercial laser cutter operation or considering in-house equipment, specific safety infrastructure separates professional facilities from dangerous shortcuts.

Critical safety requirements include:

- Eye protection: Laser safety goggles matched to the specific wavelength and optical density (OD) adequate for the energy involved are mandatory for anyone in the cutting area

- Safety interlocks: The laser will not fire when the lid is open—bypassing these interlocks exposes operators to dangerous Class-3B or Class-4 laser radiation

- Fire extinguishers: CO2 extinguishers must be clearly mounted within immediate reach of the laser cutter, with unobstructed access at all times

- Non-flammable mounting surfaces: Equipment must sit on concrete or steel decks—never wooden surfaces that could spread fires

- Operator training: Comprehensive instruction covering general hazards, specific machine procedures, and emergency response protocols

- Operating logs: Documentation tracking materials processed, operating hours, and maintenance schedules

An operator should never leave a laser cutter unattended while it is running due to the risk of ignition. Fire can occur at any moment during operation—quick response puts out flames before they spread.

Ventilation and Fume Extraction Requirements

The invisible hazard of laser and CNC cutting operations often causes more long-term harm than the visible risks. When lasers vaporize metal, they create airborne contaminants that demand serious attention.

Exposure to laser fumes can lead to various health issues, from mild respiratory problems to severe chronic conditions such as bronchitis, asthma, and chronic respiratory issues. Beyond respiratory effects, workers may experience skin irritation, eye irritation, nausea, and dizziness without proper extraction systems.

Effective fume extraction systems include:

- Extraction hoods: Positioned directly above work areas with high CFM ratings to capture fumes at the source

- HEPA filtration: Capturing harmful particles with 99.97% efficiency

- Activated carbon filters: Removing over 90% of specific volatile organic compounds (VOCs)

- Proper airflow velocity: Maintaining 100 to 150 feet per minute at the extraction hood face

- Regular maintenance: Pre-filters serviced monthly; HEPA and carbon filters replaced every several months to one year depending on usage

Regulatory compliance matters significantly. Adequate ventilation shall be installed to reduce noxious or potentially hazardous fumes and vapors to levels below OSHA's permissible exposure limits. Facilities cutting certain materials face additional restrictions—PVC plastic, for example, releases hydrogen chloride gas that forms hydrochloric acid when it contacts moisture in eyes or lungs.

Why do reputable laser cnc service providers invest substantially in safety infrastructure? Beyond protecting workers, proper safety systems ensure consistent uptime, regulatory compliance, and the professional operation that quality-conscious customers expect. When evaluating providers, ask about their extraction systems, operator training programs, and maintenance protocols—these details reveal whether a facility prioritizes long-term quality over short-term cost cutting.

With safety fundamentals understood, you're ready to make informed decisions about whether to invest in equipment or partner with service providers—a choice that depends heavily on your specific production requirements and volume projections.

Choosing Between Equipment and Services

Should you invest $200,000 to $1,500,000 in laser cutting equipment—or partner with specialists who've already made that commitment? This decision shapes your manufacturing strategy for years to come. The answer isn't universal; it depends entirely on your production reality, quality requirements, and long-term business objectives.

Many manufacturers assume owning equipment always makes sense. The truth? If most of your projects do not require the fine accuracy of laser cutting, then outsourcing your work would likely serve you better. But if speed, versatility, and extreme precision drive your competitive advantage, in-house capabilities become a strategic asset rather than just a capital expense.

Evaluating Your Production Volume Requirements

How much cutting do you actually need? This question determines whether equipment investment makes financial sense. A thorough cost-benefit analysis reveals the break-even point where ownership outperforms outsourcing.

When conducting this evaluation, consider these key decision factors:

- Annual cutting volume: If outsourced costs exceed $150,000-200,000 annually, equipment investment deserves serious consideration

- Production consistency: Steady, predictable demand justifies capital equipment; sporadic needs favor flexible service relationships

- Part complexity: Tight-tolerance components requiring extensive quality control benefit from in-house oversight

- Turnaround requirements: When lead time control provides competitive advantage, owning equipment eliminates external scheduling dependencies

- Budget constraints: Beyond equipment cost, factor in operator training, maintenance, facility modifications, and consumables

Shops that fabricate tight-tolerance components or perform work that requires complex cutting may find that purchasing a laser cutter is well worth it. Having equipment on-site allows better quality control and eliminates a frequently overlooked cost—fixing mistakes made by external providers who don't understand your specifications as intimately as your own team.

Consider the hidden costs of outsourcing: shipping time, communication delays, and the inability to make rapid adjustments when designs evolve mid-project. Conversely, equipment ownership introduces labor costs, maintenance schedules, and the responsibility for repairs. These costs are related to time, such as hours that your technicians spend repairing and maintaining the equipment—hours that could otherwise generate revenue.

The automation advantage deserves attention here. Many laser cutting systems require surprisingly little manpower. While an experienced machine operator still plays a role in the final quality and speed of cutting, there is little need for manual labor, resulting in lower labor costs than traditional fabrication methods.

Service Provider Selection Criteria

When outsourcing makes sense, choosing the right partner becomes critical. Not all laser cutting services near me deliver equivalent results—the difference between providers can mean the difference between successful projects and costly failures.

Before forming a partnership, evaluate these essential criteria:

- Material capabilities: Can they handle your specific materials and thicknesses? Most metal laser cutting service providers can easily fabricate common sheet metal like stainless steel, but their laser cutter may not be able to create parts from more difficult materials like highly reflective aluminum

- Equipment technology: What laser types do they operate? Fiber lasers excel for metals; understanding their capabilities prevents mismatched expectations

- Turnaround times: Ask specifically how long projects take from design receipt to shipping—reliable providers give clear timelines upfront

- Certifications and quality systems: ISO certifications, industry-specific qualifications (like IATF 16949 for automotive), and documented quality procedures indicate professional operations

- Experience and testimonials: Ask for testimonials from other clients, as well as about the metal laser cutting capabilities and technology that powers your provider's services

- Additional services: Can they handle secondary operations like powder coating, metal bending, or laser engraving? Consolidated services streamline your supply chain

When searching for a laser cutter service near me, transparency about pricing matters significantly. Be wary of providers that offer incentives like a low instant price but are hazy on the exact cost for your distinct projects. Prices vary based on material type, unit quantity, and design complexity—reputable providers account for all variables before committing to final quotes.

The technology question deserves deeper investigation. Different processes—fiber laser, CO2 laser, plasma, waterjet—produce different results at different price points. It's imperative to ask your metal cutting provider what laser cutter they use for their clients, as well as any other technology, tools, or resources that ensure an exceptional final product.

Material Selection Guidance Framework

Matching project requirements to appropriate approaches requires understanding how material choices affect both process selection and provider capabilities.

Start by answering these questions:

- What material will you cut? Standard materials like mild steel and stainless steel work with virtually any metal laser cutting services provider; specialty alloys or highly reflective metals narrow your options

- What thickness range? Confirm your provider's equipment handles your requirements—especially for thick plates or ultra-thin materials

- What tolerances matter? Precision requirements determine whether fiber laser (tightest tolerances) or plasma (acceptable for structural work) fits best

- What edge quality do you need? Aesthetic applications require nitrogen-assisted cutting for oxide-free edges; structural components tolerate oxygen-cut surfaces

- What's your production timeline? cnc laser cutting services with automation capabilities deliver faster turnaround for high-volume orders

Using standard material thicknesses significantly reduces costs and lead times. Providers stock common gauges; custom thicknesses often require minimum order quantities and extended procurement. When possible, design around standard specifications rather than forcing providers to source specialty materials.

Whether you choose equipment investment or service partnerships, success depends on matching capabilities to requirements. The next step? Optimizing your projects to extract maximum value from whichever approach you select.

Optimizing Your Metal Cutting Projects

You've selected your technology, identified capable service providers, and understand the cost dynamics—now what? The difference between good results and exceptional outcomes lies in project optimization. Small adjustments to design files, material specifications, and communication protocols compound into significant quality improvements and cost reductions.

Think of laser metal cutting optimization as a system rather than individual tweaks. Each decision—from initial CAD preparation to final inspection criteria—affects downstream outcomes. When you approach projects systematically, you eliminate the rework cycles and surprise costs that plague poorly planned fabrication.

Design Optimization for Laser Cutting Success

Your design file determines roughly 70% of project success before cutting even begins. Following established Design for Manufacturing (DFM) principles transforms complex geometries into efficiently producible parts. Here's the systematic approach that consistently delivers results:

- Prepare design files correctly: Export clean vector files (DXF or DWG format) with all geometry on a single layer. Remove duplicate lines, overlapping paths, and construction geometry that could confuse CNC systems. Use smooth, continuous lines instead of sharp angles or complex curves to facilitate easier and faster cutting.

- Account for kerf width in dimensions: The laser beam removes material as it cuts—typically 0.1mm to 0.3mm depending on thickness and laser type. Adjust your design dimensions to compensate, especially for parts requiring press-fit assembly or tight tolerances.

- Optimize feature spacing: Design parts with adequate spacing between cut lines to manage heat buildup and prevent warping or distortion. Minimum spacing typically equals 1.5x material thickness for steel, increasing to 2x for aluminum due to its higher thermal conductivity.

- Select standard material thicknesses: Using standard material thicknesses is one of the easiest ways to optimize the laser-cutting process. Laser cutters are calibrated for common gauges, making these materials more cost-effective and readily available. Custom thicknesses often require minimum order quantities and extended lead times that inflate budgets significantly.

- Define realistic tolerances: Specify tolerances that match actual requirements—not tighter than necessary. Define tolerances that are achievable with laser cutting technology, typically within ±0.1mm for most applications. Over-specifying precision adds cost without functional benefit.

- Design for efficient nesting: Arrange parts in a way that minimizes material waste and reduces cutting time. Rectangular outer profiles nest more efficiently than irregular shapes. Consider shared cut lines between adjacent parts to reduce cutting length.

- Include holding features for small parts: Include holding features like tabs or small bridges that keep parts in place during cutting, especially for components under 25mm or lightweight pieces that could shift during processing.

For custom metal laser cutting projects involving tubes or structural profiles, additional considerations apply. Tube laser cutting services require specific file formats that define both 2D unwrapped geometry and 3D positioning. If your project involves cylindrical or rectangular tube profiles, confirm your provider's file requirements before investing design time in incompatible formats.

Working Effectively With Manufacturing Partners

Even perfect design files require effective communication to translate into quality parts. How you interact with your laser cutting machine for metal service provider directly impacts outcomes—from initial quoting through final delivery.

- Provide complete project specifications upfront: Include material grade (not just type), finish requirements, quantity, tolerance callouts, and any secondary operations needed. Incomplete information forces providers to assume—and assumptions rarely favor your budget or timeline.

- Request DFM feedback before production: Quality providers review designs for manufacturability issues before cutting begins. This feedback loop catches problems that would otherwise become expensive rework. Manufacturers with comprehensive DFM support—like Shaoyi, which offers 12-hour quote turnaround and detailed design feedback for automotive applications—accelerate this optimization process significantly.

- Establish clear inspection criteria: Define which dimensions require verification, acceptable surface finish standards, and any special handling requirements. Written acceptance criteria prevent disputes over subjective quality judgments.

- Plan for prototyping phases: Designers and engineers can rapidly iterate on designs, test prototypes, and refine products before final production. Build prototype runs into your timeline—the cost of a small validation batch pales compared to scrapping a full production run. Rapid prototyping capabilities (some providers offer 5-day turnaround) enable this iterative refinement without derailing schedules.

- Communicate timeline flexibility honestly: If your deadline has flexibility, share that information. Rush charges for artificial urgency waste money; conversely, if timing truly matters, early communication prevents missed deliveries.

- Consolidate secondary operations when possible: If your metal laser cutter provider offers bending, welding, powder coating, or custom laser etching services, bundling operations reduces handling, shipping, and coordination overhead.

Quality Verification and Continuous Improvement

Optimization doesn't end when parts ship. Establishing feedback loops between your quality requirements and manufacturing outcomes drives continuous improvement across projects.

Key verification practices include:

- First-article inspection: Verify critical dimensions before approving full production runs

- Document recurring issues: Track defect patterns to address root causes rather than symptoms

- Share feedback with providers: Constructive communication about quality gaps enables targeted improvements

- Review nesting efficiency: For repeat orders, evaluate whether material utilization can improve

The laser metal cutting machine technology continues advancing rapidly. Staying informed about capability improvements—higher power systems, faster processing speeds, enhanced reflective metal handling—positions you to leverage new opportunities as they emerge. What required compromise three years ago may now be standard capability.

Successful metal laser cutting projects result from systematic optimization across design, material selection, and manufacturing partnerships. By applying these principles consistently, you'll extract maximum value from this precision technology while minimizing the costs and delays that plague unoptimized approaches. The investment in upfront planning pays dividends throughout production—and across every subsequent project that benefits from lessons learned.

Frequently Asked Questions About Metal Laser Cutting

1. How much does metal laser cutting cost?

Metal laser cutting costs typically range from $13-$20 per hour for steel cutting operations. The final price depends on several factors including material type, thickness, design complexity, and edge quality requirements. Fiber laser systems operate at approximately $3.50-4.00 per hour for electricity and consumables, significantly lower than plasma or waterjet alternatives. For high-volume automotive applications, manufacturers like Shaoyi offer 12-hour quote turnarounds to help you accurately budget your precision metal cutting projects.

2. What kind of laser do you need to cut metal?

Fiber lasers are the preferred choice for metal cutting, capturing 60% of the market due to their 1,064 nm wavelength that metals absorb efficiently. They excel at cutting steel, stainless steel, aluminum, copper, and brass with tolerances as tight as ±0.005 inches. CO2 lasers work for non-reflective metals but are less efficient, while Nd:YAG lasers serve specialized thick-plate applications. For reflective metals like copper and aluminum, fiber lasers with anti-reflection optics are essential to prevent equipment damage.

3. What cannot be cut with a laser cutter?

Laser cutters cannot safely process certain hazardous materials including PVC (releases toxic hydrogen chloride gas), leather containing chromium (VI), carbon fibers, and materials that produce dangerous fumes when heated. Additionally, extremely thick metals beyond equipment capacity limits pose challenges—standard fiber lasers handle steel up to 40mm and aluminum up to 25mm. Materials requiring zero heat-affected zones may need waterjet cutting instead, as laser cutting does create minimal thermal impact on surrounding material.

4. What is the maximum thickness for laser cutting metal?

Maximum cutting thickness depends on laser power and material type. A 12kW+ fiber laser can cut carbon steel up to 40mm, stainless steel up to 30mm, and aluminum up to 25mm. For thinner materials under 6mm, tolerances reach ±0.1mm. Copper and brass typically max out around 10-12mm due to their reflective properties. When your project exceeds these thicknesses, plasma cutting (up to 50mm+) or waterjet (200mm+) become more suitable alternatives.

5. Should I buy laser cutting equipment or outsource to a service provider?

Consider purchasing equipment when annual outsourcing costs exceed $150,000-200,000, you need tight lead time control, or proprietary designs require confidentiality. Outsourcing makes sense for fluctuating capacity needs, access to multiple technologies, or specialized materials you'd rarely process. Evaluate providers based on material capabilities, equipment technology, certifications like IATF 16949, and turnaround times. For automotive applications requiring rapid prototyping and IATF-certified quality, partnering with specialized manufacturers like Shaoyi provides DFM support without capital investment.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —