Διατοιχίσεις Συμπλέκτη Σφυρηλατημένες έναντι Διαμορφωμένων: Γιατί Η Αντοχή Έχει Σημασία Εκτός Δρόμου

TL·DR

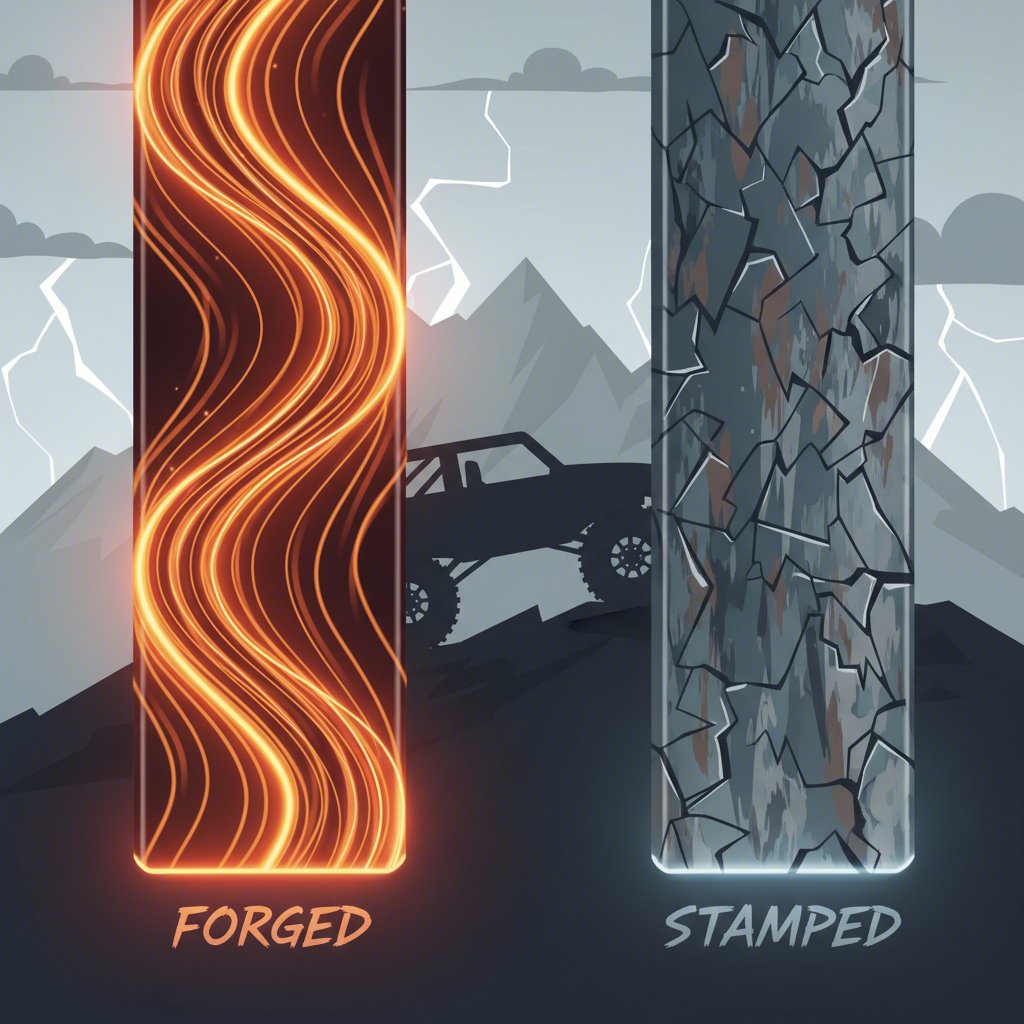

Για εφαρμογές εκτός δρόμου, οι ελεγχόμενοι βραχίονες εξαρτύσεως από σφυρηλάτηση είναι σημαντικά ισχυρότεροι και ανθεκτικότεροι από τους αντίστοιχους εμφανίζοντες. Η διαδικασία σφυρηλάτησης συμπιέζει ένα μονό κομμάτι μετάλλου, ευθυγραμμίζοντας την εσωτερική δομή του κόκκου για ανώτερη αντοχή στη λυγισμό και σπάσιμο. Οι ελεγχόμενοι βραχίονες εξαρτύσεως που εμφανίζονται, οι οποίοι είναι τυπικοί στα περισσότερα στοκ όχηματα, κατασκευάζονται από λυγισμένα φύλλα χάλυβα που συγκολλώνται μαζί. Ενώ είναι λιγότερο ακριβείς, είναι πολύ πιο ευάλωτοι σε αποτυχία υπό την ακραία τάση της οδήγησης εκτός δρόμου.

Βαθιά Ανάλυση Κατασκευής: Πώς Κατασκευάζονται οι Βραχίονες Εξαρτύσεως με Σφυρηλάτηση και Εμφάνιση

Η κατανόηση της θεμελιώδους διαφοράς μεταξύ των βραχιόνων εξαρτύσεως με σφυρηλάτηση και εμφάνιση ξεκινά από τη διαδικασία κατασκευής τους. Αυτή η βασική διαφορά ευθύνεται για κάθε πλεονέκτημα και μειονέκτημα απόδοσης, ειδικά σε περιβάλλοντα υψηλής τάσης. Κάθε μέθοδος παράγει ένα εξάρτημα με εντελώς διαφορετική εσωτερική δομή και, συνεπώς, διαφορετικά επίπεδα αντοχής και αξιοπιστίας.

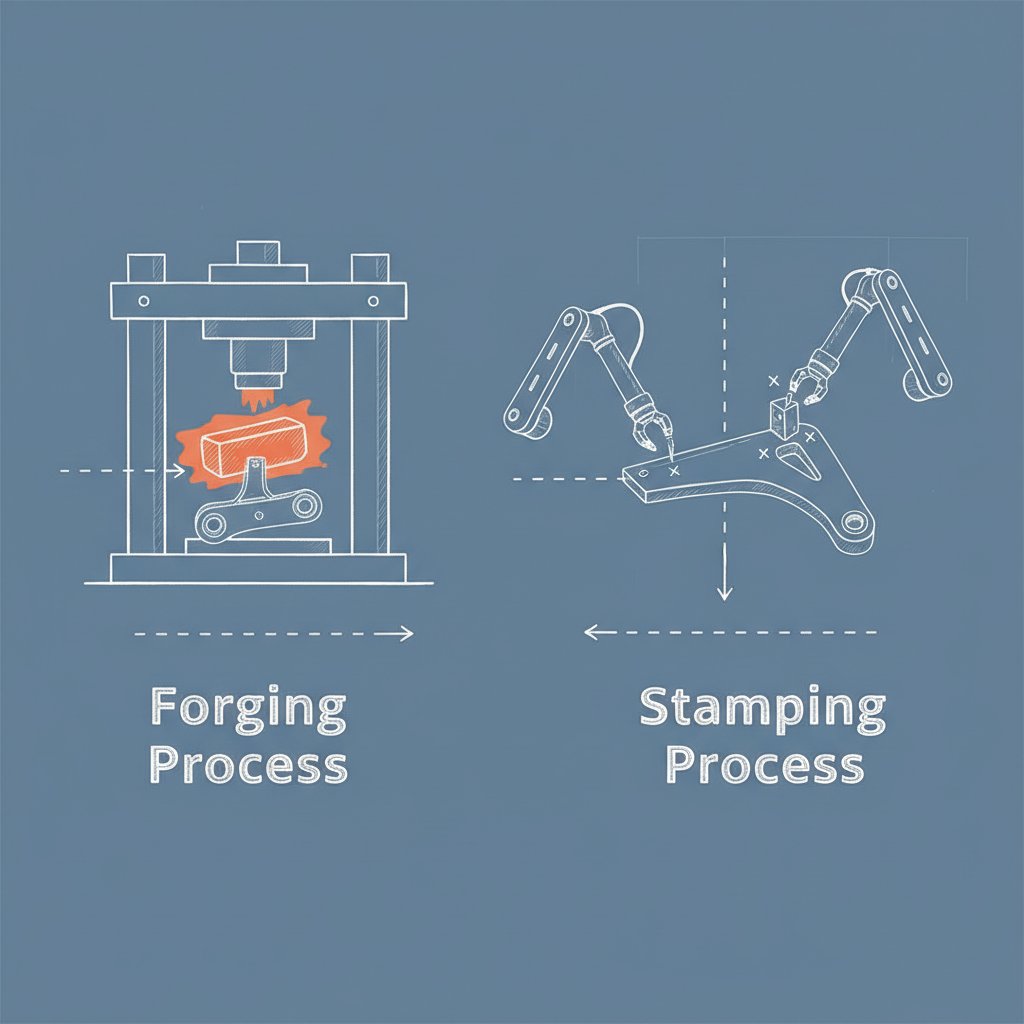

Ένας ελασματουργημένος βραχίονας ελέγχου δημιουργείται με τη θέρμανση ενός συμπαγούς αμαξωματίου μετάλλου (συνήθως χάλυβα ή κράμα αλουμινίου) και τη χρήση τεράστιας πίεσης για να εισχωρήσει σε καλούπι. Αυτή η διαδικασία, όπως αναλύεται σε οδηγούς όπως ο Γλωσσάρι SH Auto Parts , δεν απλώς διαμορφώνει το μέταλλο· το αλλάζει ουσιωδώς. Η έντονη συμπίεση αναγκάζει την εσωτερική δομή του μετάλλου να ευθυγραμμιστεί με το σχήμα του βραχίονα. Αυτή η συνεχής, ευθυγραμμισμένη ροή δομής είναι σαν τις ίνες σε ένα κομμάτι ξύλου, προσδίδοντας στο εξάρτημα απίστευτη εφελκυστική αντοχή και αντίσταση σε κόπωση και ρωγμές. Δεν υπάρχουν ραφές ή συγκολλήσεις που να δημιουργούν αδύναμα σημεία.

Αντίθετα, ένας εμφυτευόμενος βραχίονας ελέγχου κατασκευάζεται από φύλλα χάλυβα. Η διαδικασία περιλαμβάνει την κοπή επίπεδων προτύπων από τον χάλυβα, τη διαμόρφωσή τους στο απαιτούμενο σχήμα και στη συνέχεια τη συγκόλληση των κομματιών για να σχηματιστεί ο τελικός βραχίονας. Αυτή η μέθοδος είναι γρήγορη, οικονομική και κατάλληλη για μαζική παραγωγή, γι' αυτόν τον λόγο οι εμφυτευόμενοι βραχίονες είναι η προεπιλεγμένη επιλογή για τα περισσότερα εργοστασιακά οχήματα. Ωστόσο, οι συγκολλήσεις εισάγουν πιθανά σημεία αποτυχίας, ενώ η μη ευθυγραμμισμένη δομή κόκκων του πλακιδίου χάλυβα δεν έχει την εν γένει αντοχή ενός εξαρτήματος από σφυρηλατημένο υλικό.

Για τους κατασκευαστές αυτοκινήτων που επικεντρώνονται στην ακρίβεια και την αξιοπιστία σε αυτόν τον τομέα, το ειδικευμένο επίπεδο γνώσεων είναι κρίσιμο. Εταιρείες όπως Shaoyi (Ningbo) Metal Technology Co., Ltd. παρέχουν ολοκληρωμένες λύσεις εμφύτευσης μετάλλου, δείχνοντας πώς η προηγμένη αυτοματοποίηση και η μηχανική μπορούν να παράγουν εξαρτήματα υψηλής ποιότητας για διάφορες εφαρμογές αυτοκινήτων. Ακόμη και με προηγμένες τεχνικές, η θεμελιώδης διαφορά στη δομική ακεραιότητα παραμένει.

Σύγκριση Μεθόδου Κατασκευής

| Χαρακτηριστικό | Σφυρηλατημένος Βραχίονας Ελέγχου | Εμφυτευόμενος Βραχίονας Ελέγχου |

|---|---|---|

| Υλικό εισόδου | Συμπαγές μεταλλικό αγών (κράμα χάλυβα ή αλουμινίου) | Επίπεδες πλάκες χάλυβα |

| Διαδικασία | Θερμαίνονται και συμπιέζονται σε καλούπι υψηλής πίεσης | Κόβονται, διαμορφώνονται και συγκολλούνται μαζί |

| Βασικό χαρακτηριστικό | Ευθυγραμμισμένη εσωτερική ροή κόκκων | Συγκολλημένες ραφές και συνδέσεις |

| Προκύπτουσα δομή | Μονολιθικό εξάρτημα με υψηλή εφελκυστική αντοχή | Κατασκευασμένο εξάρτημα με πιθανά αδύναμα σημεία |

Αγώνας Απόδοσης Εκτός Δρόμου: Δύναμη, Ανθεκτικότητα και Ευελιξία

Όταν το οδόστρωμα τελειώνει, οι θεωρητικές διαφορές στην παραγωγή μετατρέπονται σε κρίσιμα κενά απόδοσης στην πραγματική χρήση. Για οποιαδήποτε σοβαρή οδήγηση εκτός δρόμου — από διαδρομές έως αναρρίχηση βράχων — η ανωτέρα δύναμη ενός τεμαχισμένου βραχίονα ελέγχου αποτελεί σημαντικό πλεονέκτημα. Ο βασικός σκοπός ενός βραχίονα ελέγχου είναι να διατηρεί τη σωστή γεωμετρία της ανάρτησης, και υπό τις έντονες, επαναλαμβανόμενες πληγές της οδήγησης εκτός δρόμου, οι αδυναμίες ενός εμφυτευμένου βραχίονα γίνονται φανερές.

Οι τεμαχισμένοι βραχίονες ξεχωρίζουν σε δύναμη και ανθεκτικότητα. Επειδή αποτελούν ένα ενιαίο, συμπαγές κομμάτι με ευθυγραμμισμένη δομή κόκκων, αντιστέκονται στη λυγισμένη και στην καταστροφική αποτυχία. Μια ειδικευμένη σύγκριση από Shock Surplus σημειώνει ότι οι βραχίονες από σφυρήλατο χάλυβα, όπως αυτοί του κατασκευαστή SPC, είναι «εξαιρετικά ανθεκτικοί» και «σχεδόν ακαταστρόφωτοι». Αυτό το επίπεδο αντοχής διασφαλίζει ότι η ευθυγράμμιση των τροχών σας παραμένει σταθερή ακόμα και όταν κινείστε σε δύσβατο έδαφος, αποτρέποντας την ανομοιόμορφη φθορά των ελαστικών και διατηρώντας προβλέψιμο χειρισμό. Έχουν σχεδιαστεί για να αντέχουν τις δυνάμεις που θα παραμορφώσουν εύκολα ένα λιγότερο ανθεκτικό εξάρτημα.

Οι εμφιαλωμένοι βραχίονες, αντίθετα, τείνουν να κάμπτονται υπό μεγάλα φορτία. Αυτή η κάμψη μπορεί προσωρινά να αλλάξει τη στοίχιση του οχήματός σας, οδηγώντας σε ασαφή κατεύθυνση και απρόβλεπτη συμπεριφορά στο μονοπάτι. Πιο σοβαρά, οι κοχλιώσεις αποτελούν το αχίλλειο πτέρνα του εξαρτήματος. Επαναλαμβανόμενοι κύκλοι έντασης από πλήγματα μπορούν να προκαλέσουν ρωγμές στις κοχλιώσεις και τελικά να αποτύχουν, γεγονός που μπορεί να σας αφήσει ακινητοποιημένους με μη λειτουργικό όχημα. Αν και επαρκείς για καθημερινή οδήγηση σε στεγασμένους δρόμους, απλώς δεν έχουν σχεδιαστεί για τις απαιτήσεις σοβαρής χρήσης εκτός δρόμου.

Πλεονεκτήματα και Μειονεκτήματα για Off-Road

| Τύπος βραχίονα ελέγχου | Πλεονεκτήματα | Μειονεκτήματα |

|---|---|---|

| Καταχαλκωμένο |

|

|

| Χτυπημένα |

|

|

Πώς να αναγνωρίσετε τους μοχλούς ελέγχου σας: Ένας οπτικός οδηγός

Πριν παραγγείλετε ανταλλακτικά ή σχεδιάσετε αναβάθμιση, πρέπει να γνωρίζετε τι έχετε ήδη στο όχημά σας. Ευτυχώς, οι μοχλοί ελέγχου από σφυρηλάτηση και οι εμφανιζόμενοι μοχλοί έχουν ξεκάθαρα οπτικά χαρακτηριστικά που τους καθιστούν εύκολα αναγνωρίσιμους με μια γρήγορη επιθεώρηση. Το να ξέρετε πώς να τους διακρίνετε μπορεί να σώσει χρόνο και να αποτρέψει λανθασμένες παραγγελίες.

Ένας σφυρήλατος μοχλός ελέγχου φαίνεται γενικά ως ένα ενιαίο, στερεό κομμάτι μετάλλου. Η επιφάνειά του μπορεί να είναι λίγο τραχιά, και ένα βασικό χαρακτηριστικό αναγνώρισης είναι μια λεπτή «γραμμή διαχωρισμού» ή γραμμή φλας. Πρόκειται για μια μικρή εξογκωματική γραμμή που απομένει από το σημείο όπου συναντήθηκαν τα δύο μισά του καλουπιού σφυρηλάτησης. Συχνά έχει πιο πολύπλοκο και ισχυρό σχήμα σε σύγκριση με έναν εμφανιζόμενο μοχλό.

Ένα εμφανιζόμενο χέρι ελέγχου, από την άλλη πλευρά, φαίνεται ξεκάθαρα ότι κατασκευάζεται από πολλά κομμάτια μετάλλου. Το πιο προφανές στοιχείο είναι η ύπαρξη συγκολλήσεων. Ψάξτε για γραμμές όπου τα πάνω και κάτω ή πλευρικά ελάσματα έχουν ενωθεί μαζί. Το χέρι μπορεί επίσης να φαίνεται κούφιο ή να έχει πιο κουτιστή, κατασκευασμένη εμφάνιση. Αυτά τα ράμματα είναι το καθοριστικό σημάδι μιας κατασκευής με εμφάνιση.

Ακολουθήστε αυτά τα απλά βήματα για να ελέγξετε τα χέρια ελέγχου σας:

- Πρόσβαση στην ανάρτηση με ασφάλεια: Σταθμεύστε το όχημά σας σε επίπεδη επιφάνεια και ενεργοποιήστε το χειρόφρενο. Εάν χρειαστεί, χρησιμοποιήστε γρύλο και στηρίγματα για να ανυψώσετε με ασφάλεια το μπροστινό μέρος του οχήματος και να έχετε καλύτερη θέα.

- Καθαρίστε το Μοχλό Ελέγχου: Τα χέρια συχνά είναι καλυμμένα με βρωμιά και λάσπη. Χρησιμοποιήστε σύρματο βούρτσας και πανί για να καθαρίσετε την επιφάνεια, ώστε να δείτε ξεκάθαρα τα χαρακτηριστικά της.

- Ψάξτε για βασικά χαρακτηριστικά: Εξετάστε προσεκτικά το χέρι. Υπάρχουν ορατές συγκολλήσεις κατά μήκος του μήκους του; Αν ναι, είναι ένα εμφανιζόμενο χέρι. Φαίνεται σαν ένα ενιαίο κομμάτι με μια αδιόρατη γραμμή διαχωρισμού; Αν ναι, είναι ένα σφυρήλατο χέρι.

- Σύγκριση με Εικονικά Παραδείγματα: Αν εξακολουθείτε να αμφιβάλλετε, αναζητήστε εικόνες ελεγκτικών βραχιόνων χυτεύσεως και σφυρηλατήσεως για το συγκεκριμένο μοντέλο οχήματός σας, ώστε να τις χρησιμοποιήσετε ως οπτική σύγκριση.

Κόστος έναντι Επένδυσης: Αξίζει για εσάς η αναβάθμιση σε χυτευμένο;

Ένας από τους πιο σημαντικούς παράγοντες σε κάθε τροποποίηση οχήματος είναι το κόστος. Οι χυτευμένοι ελεγκτικοί βραχίονες είναι αμφίβολα πιο ακριβοί από τους σφυρηλατημένους, αλλά για έναν ερασιτέχνη off-road, είναι πιο ακριβές να θεωρείται η διαφορά τιμής ως επένδυση στην αξιοπιστία και την ασφάλεια παρά απλώς ως έξοδο. Η απόφαση τελικά εξαρτάται από το πώς χρησιμοποιείτε το όχημά σας.

Η διαφορά στην τιμή δεν είναι πάντα τόσο μεγάλη όσο ίσως νομίζετε. Για παράδειγμα, ένα σετ τυποποιημένων άνω ελαστικών βραχιόνων μπορεί να κοστίζει περίπου 550 δολάρια, ενώ ένα ανώτερο σετ ελαστικών βραχιόνων από υλικό εξαρτημάτων μπορεί να έχει τιμή περίπου 629 δολάρια. Αν και πρόκειται για μια αύξηση στην αρχική δαπάνη, είναι σημαντικό να ληφθεί υπόψη το Συνολικό Κόστος Ιδιοκτησίας. Το πραγματικό κόστος μιας αποτυχημένης τυποποιημένης διάταξης σε μια απομακρυσμένη διαδρομή περιλαμβάνει όχι μόνο το ανταλλακτικό, αλλά επίσης πιθανά τέλη ρυμούλκησης, εργασία επισκευής και μια κατεστραμμένη εκδρομή—δαπάνες που μπορούν γρήγορα να ξεπεράσουν την αρχική εξοικονόμηση.

Η επένδυση σε βραχίονες από υλικό είναι προληπτικό μέτρο κατά της αποτυχίας εξαρτημάτων. Πρόκειται για ψυχική ησυχία και τη διασφάλιση ότι το όχημά σας μπορεί να ανταποκριθεί στο έδαφος που προτίθεστε να κατακτήσετε. Για ένα όχημα που σπάνια αφήνει τον ασφαλτόδρομο, οι τυποποιημένοι βραχίονες είναι εντελώς επαρκείς. Αλλά για ένα όχημα που έχει φτιαχτεί για περιπέτειες, η αντοχή των εξαρτημάτων από υλικό αποτελεί κρίσιμο κομμάτι του παζλ.

Έλεγχος Λήψης Αποφάσεων

Χρησιμοποιήστε αυτή την απλή λίστα ελέγχου για να καθορίσετε ποιος τύπος βραχιόνα ελέγχου αποτελεί τη σωστή επένδυση για τις ανάγκες σας:

- Θα πρέπει να επενδύσετε σε σφυρηλατημένα μέρη αν: Οδηγείτε συχνά εκτός δρόμου, αντιμετωπίζετε δύσκολα εδάφη όπως βράχια ή πρόχωμα, έχετε ανυψωμένη ανάρτηση ή προτιμάτε τη μέγιστη ανθεκτικότητα και αξιοπιστία πάνω απ' όλα.

- Τα τυπωμένα μέρη είναι πιθανόν αρκετά αν: Το όχημά σας χρησιμοποιείται κυρίως για καθημερινή οδήγηση, αν χρησιμοποιείτε μόνο ελαφριές παραλλαγές σε διατηρούμενους χωματόδρομους, αν έχετε περιορισμένο προϋπολογισμό για αντικατάσταση προϊόντος stock ή αν το όχημά σας δεν είναι ανυψωμένο.

Συχνές Ερωτήσεις

1. Είναι καλά τα σφυρηλατημένα επάνω πλευρικά ελατήρια αλουμινίου;

Ναι, οι επάνω αγκυρώσεις ελέγχου από σφυρήλατο αλουμίνιο αποτελούν εξαιρετική επιλογή, ιδιαίτερα για εφαρμογές που επιδιώκουν υψηλές επιδόσεις. Προσφέρουν σημαντική μείωση του βάρους σε σύγκριση με τις αντίστοιχες από χάλυβα, μειώνοντας έτσι την αναρτημένη μάζα και βελτιώνοντας την ανταπόκριση της ανάρτησης και την οδική συμπεριφορά. Η διαδικασία σφυρηλάτησης εξασφαλίζει ότι είναι πολύ πιο ανθεκτικές σε σύγκριση με τις χυτές ή εμφανιζόμενες από αλουμίνιο. Αν και ο κράματος χάλυβας είναι συνήθως το ισχυρότερο υλικό για ακραίες χρήσεις όπως το rock crawling, το σφυρήλατο αλουμίνιο προσφέρει εξαιρετική ισορροπία μεταξύ υψηλής αντοχής και χαμηλού βάρους, καθιστώντας το ιδανικό για overlanding, χρήση στην έρημο και γενικές εκτός δρόμου εφαρμογές.

2. Ποιο είναι το καλύτερο υλικό για τους βραχίονες ελέγχου;

Το καλύτερο υλικό εξαρτάται από την προβλεπόμενη χρήση του οχήματος και τον προϋπολογισμό. Για μέγιστη αντοχή και αντίσταση σε κρούσεις σε εφαρμογές βαρέως τύπου εκτός δρόμου, το κατεργασμένο κράμα χάλυβα (όπως το 4140 Chromoly) είναι συχνά η κορυφαία επιλογή λόγω της ανθεκτικότητας και διάρκειας ζωής του. Για εφαρμογές απόδοσης όπου το βάρος είναι ο κύριος παράγοντας, τα κατεργασμένα κράματα αλουμινίου (όπως το 6061-T6) είναι ιδανικά καθώς παρέχουν εξαιρετικό λόγο αντοχής προς βάρος. Για τυπικά επιβατικά αυτοκίνητα και ελαφρά φορτηγά που χρησιμοποιούνται επί του δρόμου, ο στάμπαρις χάλυβας είναι το πιο συνηθισμένο υλικό, καθώς πληροί τις απαιτήσεις του εργοστασίου με το χαμηλότερο κόστος.

Μικρές παραγωγικές σειρές, υψηλοί πρότυποι. Η υπηρεσία γρήγορης δημιουργίας πρωτότυπων μας κάνει την επαλήθευση ταχύτερη και ευκολότερη —

Μικρές παραγωγικές σειρές, υψηλοί πρότυποι. Η υπηρεσία γρήγορης δημιουργίας πρωτότυπων μας κάνει την επαλήθευση ταχύτερη και ευκολότερη —