লেজার কাটিং মেটাল ডেমিস্টিফাইড: কাঁচা শীট থেকে নির্ভুল অংশ পর্যন্ত

লেজার কাটিং মেটাল প্রযুক্তি বোঝা

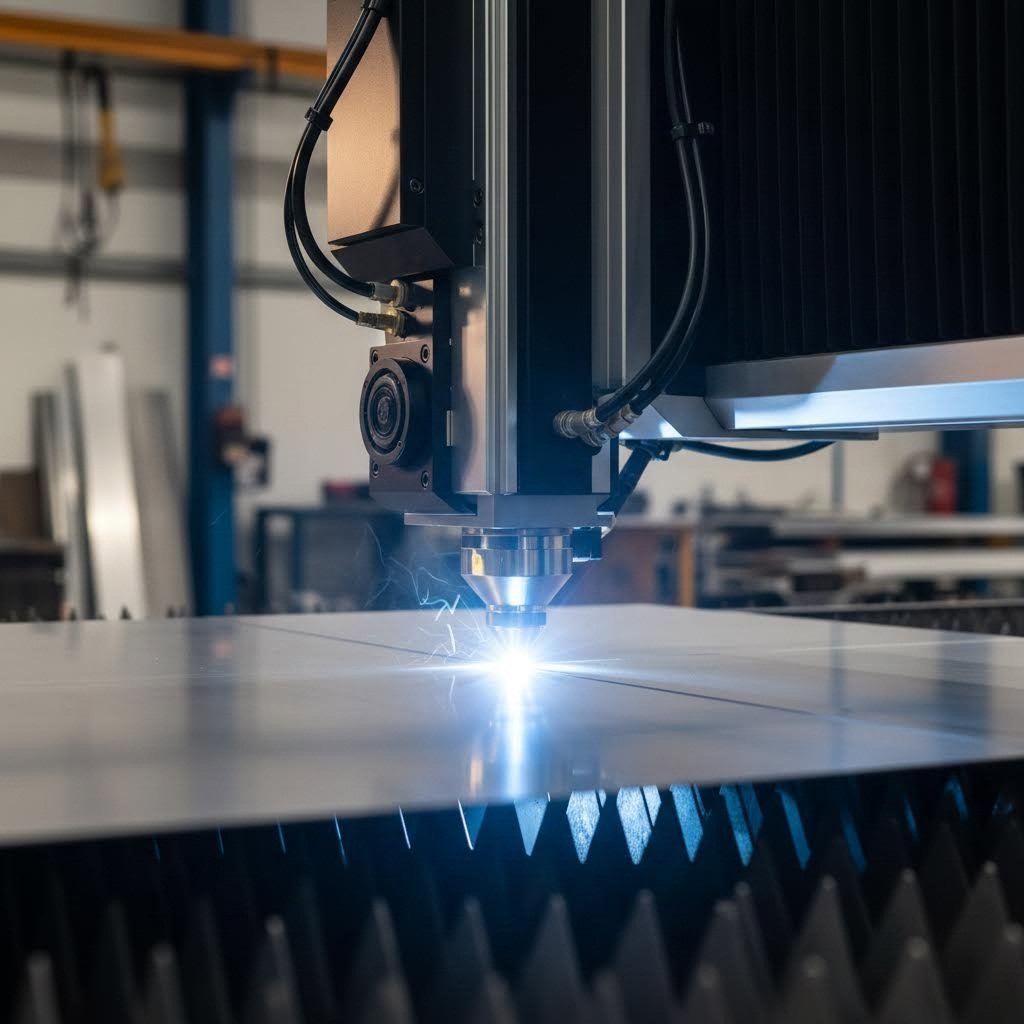

শতাংশের মধ্যে মাইক্রোমিটার পরিমাপ করা সহনশীলতা সহ একটি সমতল ইস্পাতের পাতকে একটি নির্ভুল অটোমোটিভ উপাদানে রূপান্তরিত করার কথা কল্পনা করুন। এটি হল লেজার কাটিং মেটাল যা বিশ্বব্যাপী উত্পাদন সুবিধাগুলিতে প্রতিদিন সম্ভব করে তোলে। এই নির্ভুল তাপীয় প্রক্রিয়াটি বিভিন্ন ধরনের ধাতু গলিত করে, বাষ্পীভূত করে এবং অসাধারণ নির্ভুলতার সাথে কাটার জন্য অত্যন্ত ফোকাসড আলোক রশ্মি ব্যবহার করে।

আসলে, লেজার মেটাল কাটিং কাঁচামালগুলি আকৃতি দেওয়ার আমাদের পদ্ধতিতে একটি মৌলিক পরিবর্তন প্রতিনিধিত্ব করে। যান্ত্রিক কাটিংয়ের বিপরীতে যা শারীরিক বলের উপর নির্ভর করে, এই প্রযুক্তি পরিষ্কার, বার-মুক্ত প্রান্তগুলি তৈরি করতে ঘনীভূত আলোক শক্তির কাজে লাগায়। আধুনিক সিএনসি লেজার কাটিং সরঞ্জাম ±0.003 মিমি পর্যন্ত সহনশীলতা অর্জন করতে পারে, যা সেই শিল্পগুলির জন্য অপরিহার্য করে তোলে যেখানে নির্ভুলতা ঐচ্ছিক নয়—এটি বাধ্যতামূলক।

লেজার মেটাল কাটিংয়ের পিছনের বিজ্ঞান

আলোর একটি রশ্মি কীভাবে ঘন ধাতুকে কাটতে পারে? যখন একটি লেজার মাধ্যম, যেমন CO2 গ্যাস বা ফাইবার অপটিক্সের মধ্যে থাকা পরমাণুগুলিকে বৈদ্যুতিক উৎস উদ্দীপিত করে, তখন এই প্রক্রিয়া শুরু হয়। এটি একটি অত্যন্ত ঘনীভূত রশ্মি উৎপন্ন করে যা আয়নার মাধ্যমে প্রতিফলিত হয়ে কাটার এলাকার দিকে পাঠানো হয়। এরপর ফোকাসিং লেন্সগুলি আলোকে একটি অত্যন্ত উত্তপ্ত বিন্দুতে কেন্দ্রীভূত করে, কাটার নোজেলের মধ্য দিয়ে যাওয়ার সময় শক্তির ঘনত্ব ব্যাপকভাবে বৃদ্ধি করে।

এই ফোকাসড রশ্মি যখন ধাতব পৃষ্ঠের সংস্পর্শে আসে, তখন এটি দ্রুত স্থানীয় উত্তাপনের কারণ হয় যা প্রোগ্রাম করা পথ ধরে উপাদানটিকে গলিয়ে বা বাষ্পে পরিণত করে। একটি গ্যাস স্রোত একই সঙ্গে গলিত আবর্জনা সরিয়ে ফেলে, ফলে সূক্ষ্ম কাট থেকে যায়। যেহেতু এটি একটি নন-কনটাক্ট প্রক্রিয়া, তাই উপাদানের বিকৃতির সর্বনিম্ন ঝুঁকি থাকে—বিশেষত পাতলা প্লেট বা সূক্ষ্ম উপাদান নিয়ে কাজ করার সময় এটি খুবই গুরুত্বপূর্ণ।

মেটাল লেজার কাটারটি কম্পিউটার নিউমেরিকাল কন্ট্রোল (সিএনসি) এর অধীনে কাজ করে, যা হাতে করা কাজের অসঙ্গতিগুলি দূর করে। এই স্বয়ংক্রিয়করণের ফলে জটিল আকৃতির কাটিং ঘটে যায় পুনরাবৃত্তিমূলক নির্ভুলতার সাথে, চাই আপনি একটি প্রোটোটাইপ তৈরি করুন অথবা হাজারগুলি অভিন্ন অংশ উৎপাদন করুন।

উৎপাদকদের ঐতিহ্যবাহী পদ্ধতির চেয়ে লেজার কেন বেছে নেওয়া

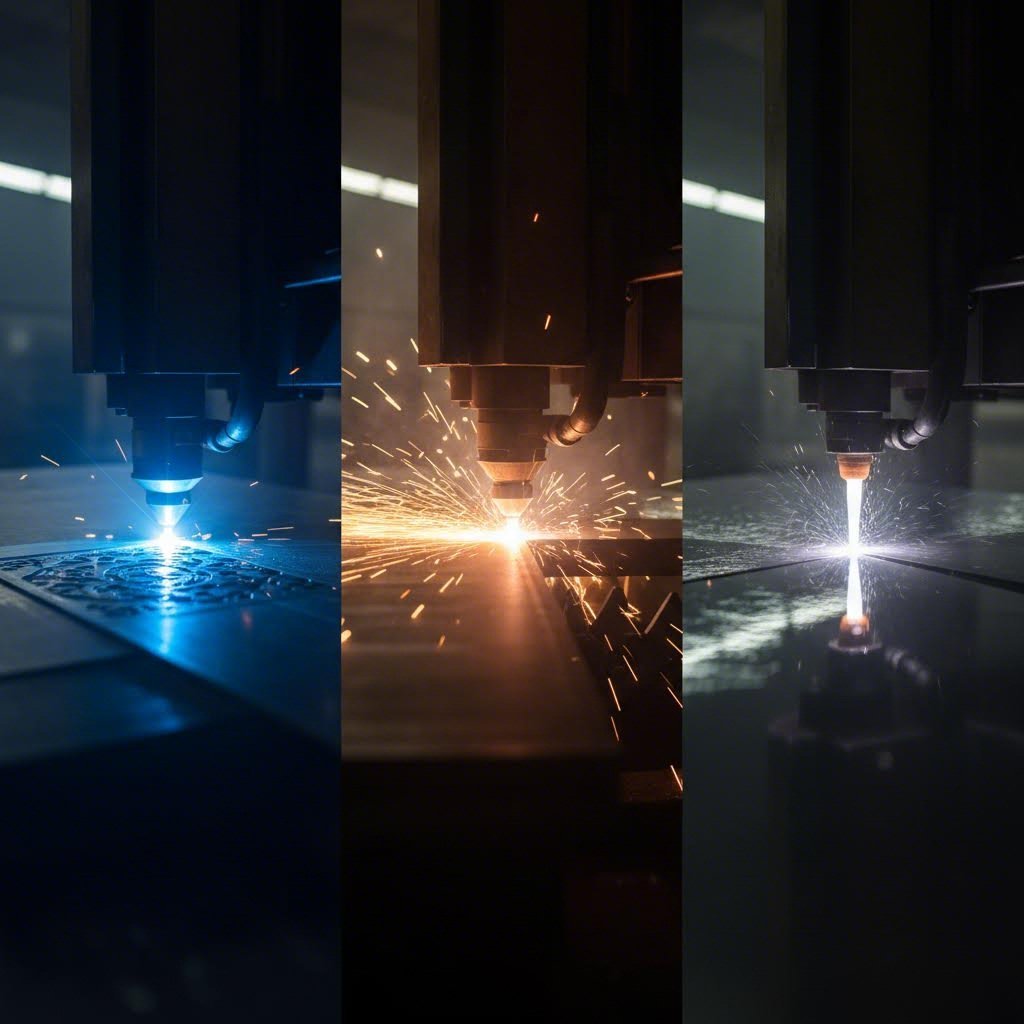

ধাতু কাটার প্রযুক্তি তুলনা করার সময়, লেজার সিস্টেমের সুবিধাগুলি খুব দ্রুত স্পষ্ট হয়ে ওঠে। প্লাজমা কাটিং, যান্ত্রিক শিয়ারিং এবং করাত দিয়ে কাটা এর মতো ঐতিহ্যবাহী পদ্ধতিগুলির প্রত্যেকটির নিজস্ব জায়গা আছে, কিন্তু ফোকাস করা আলোক রশ্মি যা দেয় তার সমতুল্য দেওয়া এদের পক্ষে কঠিন হয়।

লেজার কাটিং ±0.030 মিমি পর্যন্ত সহনশীলতা অর্জন করে এবং ঝিলমিল ছাড়া পরিষ্কার কিনারা দেয়—যা প্লাজমা এবং যান্ত্রিক পদ্ধতির সাধারণত প্রয়োজন হয় এমন দ্বিতীয় প্রক্রিয়াকরণের পদক্ষেপগুলি দূর করে।

প্রান্তের গুণমানের পার্থক্য বিবেচনা করুন। প্লাজমা কাটিংয়ের ফলে ছাই ও খাড়া প্রান্ত থাকে, যার পরে গ্রাইন্ডিং বা বিড ব্লাস্টিং-এর প্রয়োজন হয়। অন্যদিকে, লেজার কাটিং এমন মসৃণ পৃষ্ঠ তৈরি করে যা পরবর্তী উৎপাদন পর্যায়ের জন্য প্রস্তুত থাকে। এয়ারোস্পেস এবং মেডিকেল ডিভাইসের মতো শিল্পগুলিতে, এটি শুধু সুবিধাজনক নয়—এটি কঠোর গুণমানের মান পূরণের জন্য অপরিহার্য।

গতিও গুরুত্বপূর্ণ। 1.25 মিমি-এর কম পুরুত্বের উপকরণের ক্ষেত্রে, লেজার কাটিং প্লাজমা কাটিংয়ের তুলনায় প্রায় দ্বিগুণ দ্রুত হয়। এই প্রযুক্তি প্লাজমা তৈরি করার চেয়ে কম শক্তি খরচ করে, যা দীর্ঘমেয়াদে অপারেশনকে আরও খরচ-কার্যকর করে তোলে।

বহুমুখিতা ধাতুর বাইরেও প্রসারিত। যেখানে প্লাজমা কাটিং কেবল পরিবাহী উপকরণের জন্য কাজ করে, সেখানে লেজার সিস্টেমগুলি ইস্পাত, অ্যালুমিনিয়াম, তামা, এক্রাইলিক এবং কাঠ—সমস্ত কিছুই একই মেশিন দিয়ে পরিচালনা করতে পারে। এই নমনীয়তা কারখানার লজিস্টিক্সকে সরল করে এবং একক উৎপাদন চক্রে যা সম্ভব তা প্রসারিত করে।

এই গাইডটি জুড়ে, আপনি আজকের প্রাপ্য মূল লেজার প্রযুক্তিগুলি সম্পর্কে জানতে পারবেন, বিভিন্ন অ্যাপ্লিকেশনের জন্য কোন ধাতুগুলি সবচেয়ে ভালো কাজ করে তা শিখবেন, প্রকল্পের মূল্য নির্ধারণকে প্রভাবিত করে এমন খরচের কারণগুলি বুঝতে পারবেন এবং অটোমোটিভ থেকে এয়ারোস্পেস পর্যন্ত বাস্তব ব্যবহারের ক্ষেত্রগুলি অন্বেষণ করতে পারবেন। যদি আপনি সরঞ্জাম ক্রয় মূল্যায়ন করছেন, আউটসোর্সিং বিকল্পগুলি বিবেচনা করছেন বা কেবল এই রূপান্তরকারী প্রযুক্তি সম্পর্কে আরও ভালোভাবে বুঝতে চান, তাহলে আপনি সামনে ব্যবহারিক অন্তর্দৃষ্টি পাবেন।

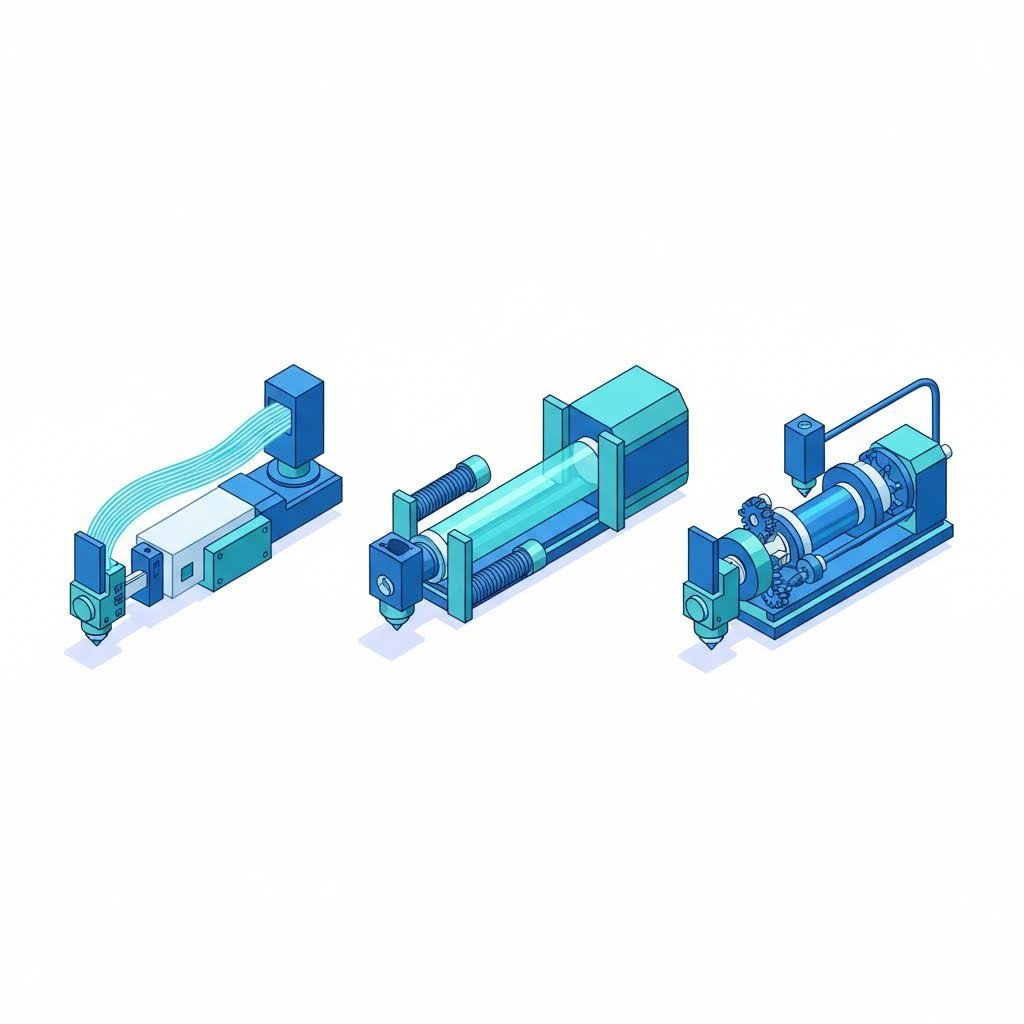

ফাইবার লেজার বনাম CO2 লেজার বনাম Nd YAG সিস্টেম

আপনার ধাতব কাটার প্রকল্পের জন্য সঠিক লেজার প্রযুক্তি নির্বাচন শুধুমাত্র একটি প্রযুক্তিগত সিদ্ধান্ত নয়—এটি আপনার উৎপাদনের গতি, পরিচালন খরচ এবং চূড়ান্ত অংশের গুণমানকে সরাসরি প্রভাবিত করে। আজ শিল্প ক্ষেত্রে তিনটি প্রধান প্রযুক্তি প্রভাব বিস্তার করে: ফাইবার লেজার, CO2 লেজার এবং Nd:YAG লেজার। প্রতিটি তার লেজার বিম আলাদাভাবে উৎপাদন এবং সরবরাহ করে, যা নির্দিষ্ট অ্যাপ্লিকেশনের জন্য স্পষ্ট সুবিধা তৈরি করে।

এই পার্থক্যগুলি বোঝা আপনাকে আপনার উপাদান এবং প্রকল্পের প্রয়োজনীয়তার সাথে সঠিক সরঞ্জাম মেলাতে সাহায্য করে। প্রতিটি সিস্টেম কীভাবে কাজ করে এবং কোথায় এটি শ্রেষ্ঠ তা আসুন বিশদে দেখি।

ফাইবার লেজার প্রযুক্তি ব্যাখ্যা করা হল

গত দশকে ফাইবার লেজার ধাতব কাটার প্রযুক্তি শিল্পে বিপ্লব এনেছে, এবং ভালো কারণে। এই সলিড-স্টেট প্রযুক্তি আলটারবিয়ামের মতো বিরল পৃথিবীর মৌলিক উপাদান দিয়ে দূষিত অপটিক্যাল ফাইবার ব্যবহার করে লেজার আলো তৈরি ও প্রবর্ধন করে। কাটার মাথায় পৌঁছানোর জন্য রশ্মি একটি ফাইবার অপটিক কেবলের মধ্য দিয়ে যাত্রা করে—কোনও আয়না বা গ্যাস টিউবের প্রয়োজন হয় না।

ফাইবার লেজার কাটারগুলিকে কী করে এত আকর্ষক করে তোলে? দক্ষতা দিয়ে শুরু করুন। অনুযায়ী শিল্প তুলনা , ফাইবার লেজারগুলি CO2 সিস্টেমগুলির তুলনায় প্রায় 35% দক্ষতায় বৈদ্যুতিক শক্তিকে লেজার আলোতে রূপান্তরিত করে, যা মাত্র 10-20%। এর ফলে সরাসরি বৈদ্যুতিক বিল কমে যায় এবং শীতল করার প্রয়োজনীয়তা হ্রাস পায়।

কার্যকারিতার সুবিধাগুলি শুধু শক্তি সাশ্রয়ের চেয়ে বেশি:

- পাতলা উপকরণে শ্রেষ্ঠ গতি: একটি সিএনসি ফাইবার লেজার কাটিং মেশিন 20 মিটার প্রতি মিনিট গতি অর্জন করতে পারে পাতলা স্টেইনলেস স্টিলের শীটে—আনুমানিক তুলনামূলক কাজের জন্য CO2 লেজারের চেয়ে তিন গুণ বেশি।

- প্রতিফলিত ধাতব ক্ষমতা: ফাইবার লেজারগুলি অ্যালুমিনিয়াম, তামা এবং পিতল কাটতে দুর্দান্ত কারণ তাদের 1.064-মাইক্রোমিটার তরঙ্গদৈর্ঘ্য প্রতিফলিত পৃষ্ঠগুলি পরিচালনা করে অন্যান্য প্রযুক্তির মতো পিছনের প্রতিফলনের ক্ষতি ছাড়াই।

- ন্যূনতম রক্ষণাবেক্ষণ: গ্যাস-পূর্ণ টিউব বা অপটিক্যাল দর্পণ প্রতিস্থাপনের প্রয়োজন নেই, ফাইবার লেজার ধাতু কাটার জন্য আয়ু প্রায় 100,000 ঘন্টা পর্যন্ত—ডাউনটাইম এবং খরচ খুব কমিয়ে দেয়।

- কম্প্যাক্ট ফুটপ্রিন্ট: সলিড-স্টেট ডিজাইন বাল্কি গ্যাস ডেলিভারি সিস্টেমগুলি অপসারণ করে, এমনকি একটি ডেস্কটপ ফাইবার লেজারও ছোট দোকানগুলির জন্য একটি বাস্তব বিকল্প হিসাবে তৈরি করে।

যাইহোক, ফাইবার লেজার কাটারের কিছু সীমাবদ্ধতা রয়েছে। ঘন উপকরণগুলির কিনারার গুণমান CO₂ সিস্টেম যা দেয় তা মেটাতে পারে না, এবং প্রাথমিক সরঞ্জাম বিনিয়োগ সাধারণত বেশি হয়। তবে পাতলা ধাতব শীট প্রক্রিয়াকরণে মূলত ফোকাস করা অপারেশনের ক্ষেত্রে, ফাইবার প্রযুক্তি দীর্ঘমেয়াদী সমাধান হিসাবে সবচেয়ে খরচ-কার্যকর বিকল্প প্রদান করে।

যখন CO₂ লেজার ফাইবার সিস্টেমকে ছাড়িয়ে যায়

CO₂ লেজার ধাতু কাটাকে এখনও উপেক্ষা করবেন না। এই প্রতিষ্ঠিত প্রযুক্তিতে 10.6-মাইক্রোমিটার তরঙ্গদৈর্ঘ্যে লেজার আলো উৎপন্ন করতে কার্বন ডাই-অক্সাইডযুক্ত গ্যাস দিয়ে পূর্ণ একটি টিউব ব্যবহার করা হয়। তারপর অপটিক্যাল আয়না বিতরণ ব্যবস্থার মাধ্যমে কাটিং হেডে বীম পাঠায়।

CO₂ লেজার দিয়ে ইস্পাত কাটা এখনও অত্যন্ত কার্যকর, বিশেষ করে যখন আপনি ঘন উপকরণ নিয়ে কাজ করছেন। দীর্ঘতর তরঙ্গদৈর্ঘ্য তাপকে আরও সমানভাবে ছড়িয়ে দেয়, 20 মিমি পুরুত্বের বেশি প্লেটগুলির কাটা কিনারাকে আরও মসৃণ করে তোলে। যেসব অ্যাপ্লিকেশনে কাঁচা গতির চেয়ে কিনারার গুণমান বেশি গুরুত্বপূর্ণ, সেখানে এই বৈশিষ্ট্য অপরিহার্য।

যেখানে CO2 লেজারগুলি সত্যিই উজ্জ্বল হয় সেটি হল বহুমুখিতা। কেবলমাত্র ধাতুর জন্য অপটিমাইজ করা ফাইবার সিস্টেমের বিপরীতে, CO2 লেজারগুলি কাঠ, এক্রাইলিক, কাপড় এবং প্লাস্টিকসহ অ-ধাতব উপকরণগুলি দক্ষতার সাথে কাটতে পারে। আপনার দোকানে যদি মিশ্র উপকরণের উৎপাদন চলে, তবে একটি একক CO2 মেশিন একাধিক বিশেষায়িত কাটিং সিস্টেমের প্রয়োজন দূর করতে পারে।

এর বিনিময়ে গ্যাস খরচের কারণে উচ্চতর পরিচালন খরচ এবং আরও ঘন ঘন রক্ষণাবেক্ষণ অন্তর্ভুক্ত। গ্যাস-পূর্ণ টিউব এবং অপটিক্যাল আয়নাগুলি নিয়মিত মনোযোগ প্রয়োজন, এবং দক্ষতা হ্রাসের অর্থ সমতুল্য আউটপুটের জন্য বিদ্যুৎ খরচ বেশি হয়। তবুও, মোটা প্লেট কাজ এবং বৈচিত্র্যময় উপকরণের প্রয়োজনীয়তার জন্য, CO2 প্রযুক্তি এখনও একটি শক্তিশালী প্রতিযোগী হিসাবে রয়ে গেছে।

নির্ভুল অ্যাপ্লিকেশনের জন্য Nd:YAG লেজার

Nd:YAG (নিওডিমিয়াম-ডোপড ইট্রিয়াম অ্যালুমিনিয়াম গার্নেট) লেজারগুলি ধাতব প্রক্রিয়াকরণে একটি বিশেষায়িত নিচে দখল করে। এই সলিড-স্টেট সিস্টেমগুলি ফ্ল্যাশল্যাম্প বা লেজার ডায়োড দ্বারা পাম্প করা একটি ক্রিস্টাল গেইন মাধ্যম ব্যবহার করে 1064-ন্যানোমিটার তরঙ্গদৈর্ঘ্যে আলো উৎপন্ন করে, যা ফাইবার লেজারের মতো একই।

অনুযায়ী লেজার মার্কিং প্রযুক্তি , Nd:YAG সিস্টেমগুলি সংক্ষিপ্ত পালসে উচ্চ শীর্ষ ক্ষমতা প্রয়োজনীয় নির্ভুল কাজে শ্রেষ্ঠ। Q-সুইচ ক্ষমতা শক্তি জমা হতে এবং তীব্র ঝলকে মুক্তি দেওয়ার অনুমতি দেয়, যা এই লেজারগুলিকে বিশেষভাবে কার্যকর করে তোলে:

- নির্ভুল ওয়েল্ডিং: অটোমোটিভ, ইলেকট্রনিক্স এবং মেডিকেল ডিভাইস উত্পাদন Nd:YAG-এর উপর নির্ভর করে কম তাপীয় বিকৃতির সাথে ছোট উপাদানগুলি যুক্ত করতে।

- প্রতিফলনশীল ধাতু কাটিং: ফাইবার লেজারের মতোই, Nd:YAG সিস্টেমগুলি তামা এবং অ্যালুমিনিয়াম কার্যকরভাবে পরিচালনা করে।

- গভীর খোদাই: উচ্চ শীর্ষ ক্ষমতা কঠোর পরিবেশের সম্মুখীন শিল্প উপাদানগুলিতে স্থায়ী মার্কিং তৈরি করে।

- মেডিকেল এবং এয়ারোস্পেস অ্যাপ্লিকেশন: স্টেন্ট এবং কাঠামোগত উপাদানগুলির জন্য টাইটানিয়াম এবং নিকেল খাদগুলির নির্ভুল কাটিং।

যদিও সাধারণ ধাতব কাটার অ্যাপ্লিকেশনের জন্য Nd:YAG প্রযুক্তি ফাইবার লেজার দ্বারা প্রায়শই প্রতিস্থাপিত হয়েছে, তবুও এটি বিশেষ নির্ভুলতার কাজের ক্ষেত্রে পছন্দের বিকল্প হিসাবে রয়ে গেছে যেখানে এর অনন্য পালসিং বৈশিষ্ট্যগুলি সুস্পষ্ট সুবিধা প্রদান করে।

এক নজরে প্রযুক্তির তুলনা

এই তিনটি লেজার প্রকারের মধ্যে থেকে নির্বাচন করতে আপনার নির্দিষ্ট উৎপাদনের প্রয়োজনীয়তার বিরুদ্ধে একাধিক ফ্যাক্টর মূল্যায়ন করা প্রয়োজন। নিম্নলিখিত তুলনাটি প্রধান পার্থক্যগুলি তুলে ধরে:

| গুণনীয়ক | ফাইবার লেজার | Co2 লেজার | Nd:YAG লেজার |

|---|---|---|---|

| উপযুক্ত ধাতব প্রকার | প্রতিফলিতকারী (অ্যালুমিনিয়াম, তামা, পিতল) সহ সমস্ত ধাতু | ইস্পাত, স্টেইনলেস স্টীল; প্রতিফলিত ধাতুগুলিতে সমস্যা হয় | প্রতিফলিত ধাতুসহ সমস্ত ধাতু; নির্ভুল কাজের জন্য সেরা |

| সাধারণ পুরুত্ব পরিসর | সর্বোচ্চ 25 মিমি (পাতলা থেকে মাঝারির জন্য আদর্শ) | সর্বোচ্চ 40 মিমি+ (মোটা উপকরণে চমৎকার) | সাধারণত 10 মিমি-এর নিচে (নির্ভুলতার উপর ফোকাস) |

| শক্তি দক্ষতা | ~35% (সর্বোচ্চ) | ১০-২০% (সর্বনিম্ন) | মাঝারি (পাম্প উৎসের ওপর নির্ভর করে পরিবর্তিত হয়) |

| রক্ষণাবেক্ষণের প্রয়োজনীয়তা | ন্যূনতম; ১০০,০০০ ঘণ্টা পর্যন্ত আয়ু | উচ্চতর; গ্যাস টিউব এবং আয়না নিয়মিত প্রতিস্থাপন করা প্রয়োজন | মাঝারি; ক্রিস্টাল এবং পাম্প উৎসের পরিষেবা প্রয়োজন |

| কাটিং গতি (পাতলা উপকরণ) | ঘণ্টায় ২০ মিটার পর্যন্ত (সবচেয়ে দ্রুততম) | ফাইবারের তুলনায় ২-৩ গুণ ধীরগতির | মাঝারি; গতির চেয়ে নির্ভুলতার জন্য অপ্টিমাইজ করা হয় |

| কিনারার গুণমান (মোটা উপকরণ) | ভালো; খুব মোটা প্লেটের ক্ষেত্রে সমাপ্তকরণের প্রয়োজন হতে পারে | চমৎকার; মোটা অংশগুলিতে সবচেয়ে মসৃণ কিনারা | নির্ভুলতার জন্য আদর্শ |

| সর্বোত্তম ব্যবহারের ক্ষেত্রসমূহ | উচ্চ-পরিমাণ পাতলা ধাতু উৎপাদন; অটোমোটিভ; ইলেকট্রনিক্স | মোটা প্লেট কাটিং; মিশ্র উপকরণ; সাইনেজ | নির্ভুল ওয়েল্ডিং; মেডিকেল ডিভাইস; এয়ারোস্পেস উপাদান |

আজকের দিনে অধিকাংশ ধাতু নির্মাণ দোকানের জন্য, সাধারণ কাটিং অ্যাপ্লিকেশনের জন্য ফাইবার লেজার হল ডিফল্ট পছন্দ। গতি, দক্ষতা এবং কম রক্ষণাবেক্ষণের এই সমন্বয় সাধারণ উৎপাদন কাজের জন্য সেরা রিটার্ন অফ ইনভেস্টমেন্ট প্রদান করে। তবে, যদি আপনার প্রকল্পগুলি নিয়মিতভাবে মোটা প্লেট প্রক্রিয়াকরণ, মিশ্র উপকরণ বা বিশেষ নির্ভুলতার প্রয়োজনীয়তা জড়িত থাকে, তবে CO2 বা Nd:YAG সিস্টেমগুলি আরও উপযুক্ত প্রমাণিত হতে পারে।

আপনি যে প্রযুক্তি নির্বাচন করবেন তা আপনি কোন ধাতু প্রক্রিয়া করতে পারবেন এবং কতটা মোটা কাটতে পারবেন তার উপরও প্রভাব ফেলে। আপনি যখন আপনার বিকল্পগুলি মূল্যায়ন করবেন, তখন এই উপাদান-নির্দিষ্ট বিবেচনাগুলি বোঝা অপরিহার্য হয়ে ওঠে।

ধাতুর প্রকার এবং উপাদান সামঞ্জস্যতা গাইড

তাহলে আপনি আপনার লেজার প্রযুক্তি নির্বাচন করেছেন—এখন আপনি আসলে কোন ধাতুগুলি কাটতে পারবেন? ফোকাসড আলোক শক্তির প্রতি সমস্ত উপকরণ একইভাবে সাড়া দেয় না। কিছু কাটা হয় মাখনের মতো সহজে, অন্যদিকে কিছু নির্দিষ্ট সরঞ্জাম কনফিগারেশন এবং সতর্ক প্যারামিটার সমন্বয় এর প্রয়োজন হয়। এই উপকরণ-নির্দিষ্ট আচরণগুলি বোঝা আপনাকে পরিষ্কার কাট অর্জন করতে, অপচয় কমাতে এবং দামি সরঞ্জামের ক্ষতি এড়াতে সাহায্য করে।

ভালো খবরটি হলো? আধুনিক ফাইবার লেজার প্রযুক্তি যা সম্ভব তা আকাশছোঁয়াভাবে বাড়িয়ে দিয়েছে। এমন ধাতু যা একসময় অপারেটরদের জন্য মাথাব্যথা ছিল, এখন সঠিক লেজার প্রকার উপযুক্ত উপকরণের সাথে মিলিয়ে নেওয়া হলে নির্ভরযোগ্যভাবে কাটা যায়।

সাধারণত লেজার-কাট ধাতু এবং তাদের বৈশিষ্ট্য

প্রতিটি ধাতু কাটার টেবিলে নিজস্ব অনন্য বৈশিষ্ট্য নিয়ে আসে। যে উপকরণগুলি সবচেয়ে বেশি প্রক্রিয়া করা হয় তাদের সম্পর্কে আপনার যা জানা দরকার:

- মাইল্ড স্টিল (নিম্ন কার্বন স্টিল): লেজার কাটিংয়ের জন্য সবচেয়ে সহজ ধাতু। এর কম প্রতিফলন এবং পূর্বানুমেয় তাপীয় আচরণ সব ধরনের দক্ষতা সম্পন্ন অপারেটরদের জন্য উপযোগী করে তোলে। মাইল্ড স্টিল কম পোস্ট-প্রসেসিংয়ের সাথে পরিষ্কার কিনারা তৈরি করে এবং ফাইবার ও CO2 উভয় লেজারের সাথেই ভালোভাবে কাজ করে। ক্ষয়রোধ ক্ষমতার চেয়ে সাশ্রয়ী মূল্য এবং স্থায়িত্ব যখন গুরুত্বপূর্ণ, এটি হয়ে ওঠে প্রাথমিক পছন্দ।

- রুটিলেস স্টিল: ক্ষয়রোধী ক্ষমতা প্রয়োজন এমন নির্ভুলতার অ্যাপ্লিকেশনের জন্য চমৎকার। ফাইবার লেজার বেশি পুরুত্বেও পরিষ্কার, উচ্চ মানের কিনারা তৈরি করে। অনুসারে সার্বিক টুল , বিভিন্ন উপাদানের পুরুত্বেও কিনারার মান স্থির থাকার কারণে লেজার কাটিংয়ের জন্য স্টেইনলেস স্টিল সেরা ধাতুগুলির মধ্যে একটি।

- অ্যালুমিনিয়াম: হালকা, শক্তিশালী এবং পুনর্ব্যবহারযোগ্য—কিন্তু কাজ করা একটু জটিল। উচ্চ তাপ পরিবাহিতা দ্রুত তাপ বিস্তার ঘটায়, কাটার গতি এবং কিনারার মানের মধ্যে ভারসাম্য রাখতে সতর্ক শক্তি ব্যবস্থাপনার প্রয়োজন হয়। এর কম গলনাঙ্কের কারণে অতিরিক্ত তাপ প্রবেশ বিকৃতি এবং রঙ পরিবর্তনের দিকে নিয়ে যায়।

- তামা: উচ্চ প্রতিফলনশীল এবং তাপ-পরিবাহী, যা পুরানো লেজার প্রযুক্তির জন্য চ্যালেঞ্জ তৈরি করে। তবে, ফাইবার লেজার প্যারামিটারগুলি সঠিকভাবে টিউন করা হলে তামা কাটার ক্ষেত্রে কার্যকর হয়। সাধারণ অ্যাপ্লিকেশনগুলির মধ্যে রয়েছে বৈদ্যুতিক উপাদান এবং তাপ বিনিময়ক।

- তামার সীসা: একটি তামার খাদ যা অনুরূপ প্রতিফলনের চ্যালেঞ্জ ভাগ করে নেয়। ফাইবার লেজার প্রযুক্তি সূক্ষ্ম কাটার অ্যাপ্লিকেশনের জন্য পিতলকে অনেক বেশি সহজলভ্য করে তুলেছে, বিশেষ করে সজ্জা এবং স্থাপত্য কাজে।

- টাইটানিয়াম: ওজনের তুলনায় সর্বোচ্চ শক্তি প্রদান করে কিন্তু উচ্চ মূল্য নির্ধারণ করা হয়। এর ক্ষয় প্রতিরোধ এবং জৈব-সামঞ্জস্যতা এটিকে বিমান এবং চিকিৎসা অ্যাপ্লিকেশনের জন্য অপরিহার্য করে তোলে। টাইটানিয়াম থেকে লেজার-কাট শীট ধাতু স্ট্যাম্পড বা যান্ত্রিকভাবে কাটা বিকল্পগুলির তুলনায় উৎপাদন করা অনেক সহজ।

প্রতিফলনশীল ধাতু সফলভাবে কাটা

এখানেই উপাদান নির্বাচন আকর্ষক হয়ে ওঠে। আগে অ্যালুমিনিয়াম লেজার কাটিং এবং তামা প্রক্রিয়াকরণ অপারেটরদের জন্য দুঃস্বপ্ন ছিল। কেন? কারণ এই উচ্চ-প্রতিফলনশীল ধাতুগুলি লেজার শক্তিকে মেশিনের দিকে ফিরিয়ে দিতে পারে, যা সংবেদনশীল অপটিক্যাল উপাদানগুলির ক্ষতি করতে পারে।

সমস্যাটি তরঙ্গদৈর্ঘ্যের শোষণ থেকে উদ্ভূত। CO2 লেজার 10.6 মাইক্রোমিটার তরঙ্গদৈর্ঘ্যে আলো নির্গত করে—যা প্রতিফলনশীল ধাতুগুলি শোষণ করতে বিপুল কষ্ট পায়। আলোক রশ্মি ভেদ না করে প্রতিফলিত হয়, যা পরিষ্কার কাট করা প্রায় অসম্ভব করে তোলে এবং সরঞ্জামের ক্ষতির ঝুঁকি বাড়ায়।

ফাইবার লেজার সবকিছু পালটে দিয়েছে। তাদের 1.064-মাইক্রোমিটার তরঙ্গদৈর্ঘ্য CO2 সিস্টেমগুলিকে প্রভাবিত করে এমন প্রতিফলনের সমস্যা ছাড়াই প্রতিফলনশীল পৃষ্ঠের সাথে কাজ করতে পারে। ইউনিভার্সাল টুলের শিল্প বিশেষজ্ঞদের মতে, "আজকের ফাইবার লেজার কাটিং মেশিনগুলির সাথে, প্রতিফলন আর কোনো সমস্যা নয়।"

কিন্তু প্রতিফলনই একমাত্র চ্যালেঞ্জ নয়। লেজারের ধরন নির্বিশেষে তাপ পরিবাহিতা এখনও একটি উপাদান। অ্যালুমিনিয়াম কাটার সময় তাপ ব্যবস্থাপনা খুব গুরুত্বপূর্ণ কারণ উপাদানটি দ্রুত শক্তি ছড়িয়ে দেয়। আপনাকে কাটার গতির বিরুদ্ধে শক্তি প্রবেশ করানোর ভারসাম্য রাখতে হবে যাতে এগুলি রোধ করা যায়:

- অতিরিক্ত তাপ জমা হওয়ার কারণে বিকৃতি

- কাটার কিনারার চারপাশে রঙ পরিবর্তন

- অসম্পূর্ণ কাটা, যখন তাপ জমা হওয়ার চেয়ে দ্রুত ছড়িয়ে যায়

- অসঙ্গত গলনের কারণে খারাপ কিনারার গুণমান

সমাধান কী? এই তাপীয় গতিবিদ্যা বোঝেন এমন অভিজ্ঞ অপারেটরদের সাথে কাজ করুন, অথবা প্রতিফলিত উপকরণের জন্য বিশেষভাবে অনুকূলিত আধুনিক ফাইবার সরঞ্জাম ব্যবহার করে এমন নির্মাতাদের সাথে অংশীদারিত্ব করুন।

ধাতুর ধরন এবং লেজার শক্তি অনুযায়ী পুরুত্বের সীমা

আপনি কতটা পুরু কাটতে পারবেন? উত্তরটি তিনটি পরস্পর সম্পর্কযুক্ত বিষয়ের উপর নির্ভর করে: আপনার লেজারের শক্তি আউটপুট, আপনি যে নির্দিষ্ট ধাতু প্রক্রিয়া করছেন এবং আপনার যে কিনারার গুণমান প্রয়োজন।

উচ্চতর ওয়াটেজ মানে বৃহত্তর কাটিং ক্ষমতা, কিন্তু সমস্ত উপকরণের জন্য এই সম্পর্কটি রৈখিক নয়। সমতুল্য পুরুত্বে কার্বন স্টিল স্টেইনলেস স্টিলের চেয়ে সহজে কাটা যায়, অন্যদিকে অ্যালুমিনিয়াম এবং তামা তাদের তাপীয় বৈশিষ্ট্যের কারণে আরও বেশি শক্তি প্রয়োজন করে।

ভিত্তি করে HGTECH-এর স্পেসিফিকেশন , এখানে সাধারণ পাওয়ার লেভেলগুলির জন্য সর্বোচ্চ কাটিং পুরুত্ব দেওয়া হল:

| লেজার শক্তি | কার্বন স্টিল | স্টেইনলেস স্টীল | আলুমিনিয়াম প্লেট | তামা প্লেট |

|---|---|---|---|---|

| ৫০০ ওয়াট | ৬মিমি | 3 মিমি | 2মিমি | 2মিমি |

| ১০০০ওয়াট | 10 মিমি | 5mm | 3 মিমি | 3 মিমি |

| ২০০০W | 16 মিমি | 8মিমি | 5mm | 5mm |

| ৩০০০W | 20মিমি | 10 মিমি | 8মিমি | 8মিমি |

| ৪০০০W | 22মিমি+ | 16 মিমি | 10 মিমি | 10 মিমি |

| 10000W+ | 30মিমি+ | 50 মিমি | 40মিমি | 20মিমি+ |

এখানে গুরুত্বপূর্ণ পার্থক্যটি রয়েছে যা অধিকাংশ ক্রেতাই উপেক্ষা করে: সর্বোচ্চ কাটিং পুরুত্ব এবং গুণগত কাটিং পুরুত্ব এক জিনিস নয় । একটি 3000W লেজার তাত্ত্বিকভাবে 20মিমি কার্বন স্টিল কাটতে পারে, কিন্তু ধ্রুব্য মসৃণ, উজ্জ্বল পৃষ্ঠের কাটিংয়ের জন্য, আপনাকে ঐ সংখ্যাগুলি প্রায় 40% কমাতে হবে। মেশিনের সর্বোচ্চ ক্ষমতায় ধাতব শীটগুলি কাটলে প্রায়শই খসখসে কিনারা তৈরি হয় যার পরবর্তী ফিনিশিংয়ের প্রয়োজন হয়।

চাহিদা মতো সৌন্দর্যের জন্য ইস্পাত লেজার কাটিংয়ের ক্ষেত্রে, আপনার সাধারণ বেধের চাহিদার চেয়ে বেশি ক্ষমতাসম্পন্ন সরঞ্জাম বেছে নিন। 3000W সিস্টেমটি 12 মিমি পর্যন্ত প্লেটগুলিতে নির্ভরযোগ্য মানের কাটিং প্রদান করে, যদিও এর চেয়ে বেশি বেধের ক্ষেত্রে ফিনিশিং কাজের প্রয়োজন হতে পারে।

অর্থনীতিও গুরুত্বপূর্ণ। HGTECH-এর তথ্য অনুসারে, 6kW সিস্টেমে 8 মিমি স্টেইনলেস স্টিল কাটার গতি 3kW মেশিনের তুলনায় প্রায় 400% বেশি। উচ্চ পরিমাণে অ্যালুমিনিয়াম লেজার কাটিং বা উৎপাদন কাজের ক্ষেত্রে, উচ্চ ওয়াটেজে বিনিয়োগ করা প্রায়শই বৃহত্তর আউটপুটের মাধ্যমে নিজেকে প্রতিদান দেয়।

উপাদান নির্বাচন এবং বেধের সীমাবদ্ধতা বোঝার পর, পরবর্তী বিষয়টি হল আপনার নির্দিষ্ট প্রকল্পের প্রয়োজনীয়তার সাথে লেজার পাওয়ার মিলিত করা—সেইসাথে সহায়ক গ্যাসগুলি যা কাটিংয়ের মান এবং প্রক্রিয়াকরণের গতি উভয়কেই প্রভাবিত করে।

পাওয়ার প্রয়োজনীয়তা এবং ওয়াটেজ নির্বাচন

আপনি আপনার লেজার প্রযুক্তি চিহ্নিত করেছেন এবং জানেন যে আপনি কোন ধাতুগুলি কাটবেন। এখন এসে গেছে গুরুত্বপূর্ণ প্রশ্ন: আপনার আসলে কতটা শক্তি দরকার? খুব কম শক্তি নির্বাচন করুন, এবং আপনার ধাতব লেজার কাটিং মেশিনটি ঘন উপাদানগুলির সাথে সংগ্রাম করবে বা অসহায় ধীর গতিতে চলবে। খুব বেশি শক্তি নির্বাচন করুন, এবং আপনি এমন ক্ষমতা পাচ্ছেন যা আপনি কখনও ব্যবহার করবেন না, ফলে রক্ষণাবেক্ষণের জটিলতা বৃদ্ধি পাবে।

লেজার শক্তি, কাটিং গতি এবং উপাদানের ঘনত্বের মধ্যে সম্পর্ক অনুমানের বিষয় নয়—এটি ভবিষ্যদ্বাণীযোগ্য প্যাটার্ন অনুসরণ করে যা আপনার সরঞ্জামের সিদ্ধান্তগুলিকে পরিচালিত করতে পারে। আপনি যদি একটি শীট মেটাল লেজার কাটিং মেশিন কেনার বিষয়ে মূল্যায়ন করছেন বা প্রস্তুতকারক পক্ষগুলির মধ্যে পছন্দ করছেন, এই গতিগুলি বোঝা আপনাকে আরও বুদ্ধিমানের মতো সিদ্ধান্ত নিতে সাহায্য করে।

আপনার প্রকল্পের প্রয়োজনের সাথে লেজার শক্তি মেলানো

লেজার পাওয়ারকে আপনার কাটিং মেটাল মেশিনের ইঞ্জিন হিসাবে ভাবুন। আরও ওয়াট মানে প্রতি সেকেন্ডে কাজের টুকরোতে আরও বেশি শক্তি প্রেরণ। এটি সরাসরি দুটি পরিমাপযোগ্য ফলাফলে পরিণত হয়: দ্রুত কাটিং গতি এবং বেশি পুরুত্বের উপকরণগুলি ভেদ করার ক্ষমতা।

অনুযায়ী অ্যাকটেক গ্রুপের ব্যাপক গাইড , লেজার পাওয়ার নির্বাচন আপনার প্রকৃত উৎপাদনের প্রয়োজনীয়তা বিশ্লেষণ থেকে শুরু করা উচিত—আকাঙ্ক্ষিত ক্ষমতা নয়। প্রথমে আপনি যে উপকরণ এবং পুরুত্বগুলি সবচেয়ে বেশি কাটবেন তা ম্যাপ করুন, তারপর এমন পাওয়ার লেভেল নির্বাচন করুন যা আপনার সাধারণ কাজের 80% কার্যকরভাবে পরিচালনা করতে পারে।

সাধারণ অ্যাপ্লিকেশনগুলির সাথে বিভিন্ন পাওয়ার রেঞ্জ কীভাবে খাপ খায় তা এখানে দেওয়া হল:

- 500W-1500W: 6mm এর নিচের পাতলা শীট মেটালের জন্য আদর্শ। 2 kW লেজার কাটিং মেশিন 10mm পর্যন্ত কার্বন স্টিল এবং 5mm পর্যন্ত স্টেইনলেসের জন্য সাধারণ ফ্যাব্রিকেশনের প্রায় সমস্ত প্রয়োজন মেটায়। এই সিস্টেমগুলি প্রোটোটাইপ দোকান, সাইনবোর্ড কোম্পানি এবং হালকা উত্পাদনের জন্য উপযুক্ত।

- 2000W-4000W: উৎপাদন পরিবেশের জন্য আদর্শ স্থান। এই লেজার ধাতব কাটিং মেশিনগুলি কার্যকারিতা এবং পরিচালন খরচের মধ্যে ভারসাম্য বজায় রাখে, উৎপাদন-যোগ্য গতিতে 22মিমি পর্যন্ত কার্বন ইস্পাত এবং 16মিমি পর্যন্ত স্টেইনলেস কাটতে সক্ষম।

- 6000W-12000W+ মোটা প্লেট প্রক্রিয়াকরণ বা অত্যন্ত উচ্চ আউটপুটের জন্য ভারী শিল্প অ্যাপ্লিকেশন। শিল্প তথ্য অনুসারে, 6kW সিস্টেমে 8মিমি স্টেইনলেস স্টিল কাটার গতি 3kW মেশিনের তুলনায় প্রায় 400% বেশি—উচ্চ পরিমাণ অপারেশনের জন্য বিনিয়োগের যৌক্তিকতা প্রমাণ করে।

ক্ষমতা, গতি এবং কিনারা গুণমানের মধ্যে সম্পর্ক গুরুত্বপূর্ণ আপসের সৃষ্টি করে। উচ্চতর ক্ষমতা দ্রুত কাটার অনুমতি দেয়, কিন্তু অতিরিক্ত গতি কিনারার ফিনিশকে ক্ষতিগ্রস্ত করতে পারে। তদ্বিপরীতভাবে, উচ্চ ক্ষমতায় ধীর গতি তাপ সৃষ্টি করতে পারে, কাটের প্রস্থ বাড়িয়ে তাপ-প্রভাবিত অঞ্চল তৈরি করে। অনুকূল ভারসাম্য খুঁজে পেতে হলে ক্ষমতাকে উপাদানের বৈশিষ্ট্য এবং গুণমানের প্রত্যাশার সাথে মিলিয়ে নিতে হবে।

| উপাদান | পুরুত্ব | সুপারিশকৃত পাওয়ার পরিসর | নোট |

|---|---|---|---|

| মিল্ড স্টিল | 1-6 মিমি | ১০০০-২০০০W | সম্ভাব্য উচ্চ গতি; অক্সিজেন সহায়তা সুপারিশ করা হয় |

| মিল্ড স্টিল | 8-16 মিমি | 3000-6000W | উৎপাদন গতিতে গুণগত কাট |

| মিল্ড স্টিল | 20মিমি+ | 6000-12000W+ | ভারী প্লেটের জন্য উল্লেখযোগ্য পাওয়ার বিনিয়োগ প্রয়োজন |

| স্টেইনলেস স্টীল | ১-৫mm | 1500-3000W | অক্সাইড-মুক্ত কিনারা পেতে নাইট্রোজেন সহায়তা |

| স্টেইনলেস স্টীল | 8-16 মিমি | 4000-10000W | অক্সিজেন কাটিংয়ের তুলনায় 30-50% বেশি পাওয়ার প্রয়োজন |

| অ্যালুমিনিয়াম | ১-৫mm | 2000-4000W | উচ্চ তাপ পরিবাহিতা বেশি পাওয়ারের দাবি করে |

| অ্যালুমিনিয়াম | 8মিমি+ | 6000W+ | পালিশ করা পৃষ্ঠতলে ব্যাক-রিফ্লেকশন নজরদারি করুন |

| কoper/ব্র্যাস | ১-৫mm | 2000-4000W | ফাইবার লেজার অপরিহার্য; উচ্চ পীক পাওয়ার সাহায্য করে |

যন্ত্রপাতি কেনা এবং আউটসোর্সিংয়ের মধ্যে তুলনা করার সময় আপনার ব্যবহারের হার বিবেচনা করুন। একটি ধাতু কাটার মেশিন হল উল্লেখযোগ্য মূলধন বিনিয়োগ, কিন্তু যদি আপনি প্রতিদিন উৎপাদন চালান, তবে সাধারণত 18-24 মাসের মধ্যে মালিকানা অর্থনৈতিকভাবে ভালো ফল দেয়। মাঝে মাঝে প্রকল্প বা বিভিন্ন ধরনের পুরুত্বের প্রয়োজনীয়তা থাকলে ভালোভাবে সজ্জিত একটি ফ্যাব্রিকেটরের সাথে অংশীদারিত্ব করা আরও আর্থিকভাবে যুক্তিযুক্ত।

কাটার গুণমানে সহায়ক গ্যাসের ভূমিকা

লেজার পাওয়ার শুধুমাত্র অর্ধেক গল্প বলে। আপনি যে সহায়ক গ্যাস নির্বাচন করেন—অক্সিজেন, নাইট্রোজেন বা সংকুচিত বায়ু—এটি মৌলিকভাবে পরিবর্তন করে যে কীভাবে সেই শক্তি ধাতুর সাথে মিথস্ক্রিয়া করে। ভুল গ্যাস নির্বাচন করুন, এবং এমনকি সবচেয়ে শক্তিশালী ধাতু কাটার মেশিনও হতাশাজনক ফলাফল দেয়।

LZK CNC-এর বিশ্লেষণ অনুযায়ী, প্রতিটি গ্যাসের ধরনের আলাদা সুবিধা এবং ত্রুটি রয়েছে:

অক্সিজেন (O₂) — গতি এবং ঘন উপাদান

অক্সিজেন শুধু গলিত ধাতুকে সরিয়ে দেয় না—এটি উত্তপ্ত ইস্পাতের সাথে এক্সোথার্মিকভাবে বিক্রিয়া করে, অতিরিক্ত তাপ উৎপন্ন করে যা কাটার গতি বাড়িয়ে দেয়। এই বিক্রিয়াশীল কাটার প্রক্রিয়াটি নিষ্ক্রিয় গ্যাস কাটার তুলনায় কম লেজার শক্তিতে ঘন কাট করার অনুমতি দেয়।

- উপযুক্ত: কার্বন স্টিল, ঘন প্লেট, উচ্চ-গতির উৎপাদন

- সুবিধা: কাটার গতি বৃদ্ধি পায়; 25মিমি+ পর্যন্ত উপাদানে কার্যকর

- অসুবিধা: কাটার কিনারায় জারণ স্তর তৈরি হয়, যা পেইন্ট আঠালো বা ওয়েল্ডিংয়ের জন্য পরিষ্কার করা প্রয়োজন

নাইট্রোজেন (N₂) — পরিষ্কার কিনারা এবং সূক্ষ্মতা

নিষ্ক্রিয় গ্যাস হিসাবে, নাইট্রোজেন কাটার সময় জারণ প্রতিরোধ করে, যার ফলে কোনও রঙ পরিবর্তন ছাড়াই পরিষ্কার, মসৃণ কিনারা তৈরি হয়। এটি অপরিহার্য যেখানে চেহারা গুরুত্বপূর্ণ বা যেখানে জারণ পরবর্তী প্রক্রিয়াগুলিতে বাধা দেয়।

- উপযুক্ত: স্টেইনলেস স্টিল, অ্যালুমিনিয়াম, সজ্জামূলক কাজ, খাদ্য-গ্রেড উপাদান

- সুবিধা: জারণ স্তর নেই; সমাবেশের জন্য প্রস্তুত উচ্চ-সূক্ষ্ম কাট

- অসুবিধা: ধীর কাটার গতি; উচ্চতর পরিচালন খরচ (নাইট্রোজেন অক্সিজেনের চেয়ে বেশি দামি)

সংকুচিত বায়ু — অর্থনৈতিক বিকল্প

বায়ুতে অক্সিজেন এবং নাইট্রোজেন উভয়ই থাকে, যা একটি মধ্যপন্থী সমাধান প্রদান করে। এটি সহজলভ্য এবং সস্তা, যা এটিকে এমন অ্যাপ্লিকেশনের জন্য আকর্ষক করে তোলে যেখানে কিনারার গুণগত মান গুরুত্বপূর্ণ নয়।

- উপযুক্ত জন্য: পাতলা মৃদু ইস্পাত, অগুরুত্বপূর্ণ অ্যাপ্লিকেশন, খরচ-সংবেদনশীল প্রকল্প

- সুবিধা: সর্বনিম্ন পরিচালন খরচ; পাতলা উপকরণে যথেষ্ট কার্যকারিতা

- অসুবিধা: কিছু জারণ ঘটে; বিশুদ্ধ নাইট্রোজেনের তুলনায় কিনারা কম মসৃণ; বিশুদ্ধ অক্সিজেনের তুলনায় ধীরগতি

ব্যবহারিক উপসংহার? আপনার অ্যাপ্লিকেশনের প্রয়োজনীয়তা অনুযায়ী আপনার সহায়ক গ্যাস নির্বাচন করুন। যদি আপনি কাঠামোগত অ্যাপ্লিকেশনের জন্য কার্বন স্টিল কাটছেন যা পরে রং করা হবে, তবে অক্সিজেন কাটিং দ্রুততা প্রদান করে এবং তেমন কোনও ত্রুটি থাকে না। স্টেইনলেস স্টিলের খাদ্য প্রক্রিয়াকরণ সরঞ্জাম বা দৃশ্যমান স্থাপত্য উপাদানের জন্য, নাইট্রোজেনের পরিষ্কার কিনারা অতিরিক্ত খরচের জন্য যুক্তিযুক্ত। এবং পাতলা উপকরণে সাধারণ দোকানের কাজের জন্য, সংকুচিত বায়ু খরচ কম রাখে এবং যথেষ্ট ফলাফল প্রদান করে।

শক্তির প্রয়োজনীয়তা এবং গ্যাস নির্বাচন আপনাকে সরঞ্জাম সরবরাহকারী বা উত্পাদন অংশীদারদের সাথে অর্থপূর্ণ আলোচনার জন্য প্রস্তুত করে। কিন্তু এই প্রযুক্তিগত বিষয়গুলি আসল প্রকল্পের খরচে কীভাবে পরিণত হয়? লেজার কাটিং-এর অর্থনীতি কয়েকটি অতিরিক্ত পরিবর্তনশীল নিয়ে গঠিত, যা পরীক্ষা করা উচিত।

খরচের কারণ এবং মূল্য স্বচ্ছতা

লেজার কাটিং মেশিনটি আপনার কত খরচ হবে? এই প্রশ্নটি স্টিকার মূল্যের বাইরেও পরিবর্তনশীলগুলির একটি শৃঙ্খলে নিয়ে যায়। সরঞ্জাম অর্জনের জন্য বাজেট করুন বা উত্পাদন অংশীদার থেকে প্রতি টুকরো খরচ গণনা করুন—আসল অর্থনীতি বোঝা আপনাকে ব্যয়বহুল অপ্রত্যাশিত ঘটনা এড়াতে এবং আপনার উৎপাদন বাস্তবতার সাথে সামঞ্জস্যপূর্ণ সিদ্ধান্ত নেওয়ার জন্য সাহায্য করে।

লেজার কাটিং মেশিনের দামের পরিসর একটি বিশাল আওতাকে জুড়ে— 500 ডলারের হবি ইউনিট থেকে শুরু করে 2 মিলিয়ন ডলারের শিল্প সিস্টেম পর্যন্ত। কিন্তু ক্রয়মূল্যটি কেবল শুরুর বিষয়। চালানোর খরচ, উপকরণের মূল্য, শ্রম এবং রক্ষণাবেক্ষণ—সবই এর অন্তর্ভুক্ত যা আপনি আসলে কাঁচা শীট ধাতুকে সম্পূর্ণ অংশে রূপান্তরিত করার জন্য প্রদান করবেন।

কিনুন বনাম আউটসোর্স সিদ্ধান্ত ফ্রেমওয়ার্ক

নির্দিষ্ট খরচে না যাওয়ার আগে, চলুন মৌলিক প্রশ্নটি নিয়ে আলোচনা করি: আপনি কি নিজস্ব ধাতু কাটার মেশিনে বিনিয়োগ করবেন নাকি একটি ফ্যাব্রিকেশন পরিষেবার সাথে অংশীদারিত্ব করবেন? উত্তরটি আপনার উৎপাদন পরিমাণ, প্রকল্পের জটিলতা এবং আপনি কত দ্রুত রিটার্ন দেখতে চান তার উপর নির্ভর করে।

অনুযায়ী SendCutSend-এর বিশ্লেষণ , শিল্প-গ্রেড লেজার কাটারের প্রাথমিক বিনিয়োগ 1-3 kW ক্ষমতা সহ ছোট আকারের মেশিনের জন্য 250,000 ডলার থেকে শুরু হয়ে মধ্যম পরিসরের সিস্টেমের জন্য 1 মিলিয়ন ডলারের বেশি হয়। অটোমেশন সুবিধা সহ উচ্চ-ক্ষমতাসম্পন্ন ফাইবার লেজারগুলি ঐচ্ছিক বৈশিষ্ট্য যোগ করার আগেই 2 মিলিয়ন ডলারের বেশি হতে পারে।

ব্যবসায়িক পরিস্থিতি অনুযায়ী সাধারণত এভাবেই অর্থনৈতিক হিসাব হয়:

| সিনিয়র | প্রস্তাবিত পদ্ধতি | প্রধান বিবেচনা |

|---|---|---|

| প্রোটোটাইপ চালানো (১-১০টি অংশ) | আউটসোর্স | মূলধন বিনিয়োগ ছাড়া; দ্রুত পুনরাবৃত্তি; শুধুমাত্র আপনার প্রয়োজনীয় জিনিসের জন্য অর্থ প্রদান |

| ছোট ব্যাচ (মাসিক ১০-১০০টি অংশ) | আউটসোর্স | নির্মাতারা প্রাপ্তির অর্থনীতি অর্জন করে; উপাদান নষ্ট গ্রাহকদের মধ্যে বন্টিত হয় |

| মাঝারি পরিমাণ (মাসিক ১০০-১০০০টি অংশ) | উভয়টি মূল্যায়ন করুন | ব্যবহার 60% ছাড়িয়ে গেলে মালিকানার জন্য ROI গণনা অনুকূল হয়ে ওঠে |

| উচ্চ পরিমাণ (মাসিক ১০০০+ অংশ) | মালিকানা বিবেচনা করুন | ২৪/৭ পরিচালন আরওআই সর্বাধিক করে; ৬-১০ মাসের পে-ব্যাক পিরিয়ড সাধারণত |

কাটার মেশিনটি প্রায় অবিরত চালাতে পারলে সরঞ্জামের মালিকানার জন্য এটি হয়ে ওঠে আদর্শ সুযোগ। অনুযায়ী IVYCNC-এর মূল্য নির্ধারণের গাইড , প্রত্যাশিত আরওআই সময়সীমা বিনিয়োগের পর্যায়ভিত্তিক উল্লেখযোগ্যভাবে পরিবর্তিত হয়:

- প্রবেশ পর্যায় ($৫,০০০-$১৫,০০০): ১২-১৮ মাসের পে-ব্যাক, $২,০০০-$৫,০০০ মাসিক আয়ের সম্ভাবনা সহ

- মধ্যম পর্যায় ($১৫,০০০-$৫০,০০০): ৮-১২ মাসের পে-ব্যাক, $৫,০০০-$১৫,০০০ মাসিক আয়ের সম্ভাবনা সহ

- শিল্প (৫০,০০০+ ডলার): মাসিক ১৫,০০০-৫০,০০০+ ডলার আয়ের সম্ভাবনার সাথে ৬-১০ মাসের মধ্যে বিনিয়োগ উদ্ধার

বিপরীত সম্পর্কটি লক্ষ্য করুন? উচ্চতর প্রাথমিক বিনিয়োগ প্রায়শই দ্রুততর রিটার্ন দেয় কারণ শিল্প সিস্টেমগুলি আরও দক্ষতার সাথে চলে, ঘন উপাদানগুলি পরিচালনা করে এবং তাদের ক্ষমতার জন্য প্রিমিয়াম মূল্য নির্ধারণ করে। আপনি যে সিএনসি লেজার কাটার মূল্য নির্বাচন করবেন তা আপনার বাস্তব উৎপাদন প্রক্ষেপণের সাথে মেলা উচিত—আশাবাদী আশার চেয়ে নয়।

অনেক ছোট থেকে মাঝারি দোকানের জন্য, আউটসোর্সিং আর্থিকভাবে যুক্তিযুক্ত অর্থ বহন করে। বড় ফ্যাব্রিকেটররা প্রায়শই বাল্কে উপকরণ কেনে এবং আপনার কাঁচামালের খরচের চেয়েও সস্তায় অংশগুলি মেশিন করে। আপনি লেজার অপারেশনের জন্য প্রয়োজনীয় বিশেষায়িত স্থান, অপারেটর প্রশিক্ষণ এবং নিয়ন্ত্রক পারমিটের প্রয়োজনীয়তা এড়িয়ে যান।

লেজার কাটিং অপারেশনে লুকানো খরচ

যদি আপনি সরঞ্জাম ক্রয়ের দিকে ঝুঁকছেন, তবে বিক্রয়ের জন্য থাকা লেজার কাটিং মেশিনের তালিকা আপনাকে ভুল প্রমাণিত করতে দেবেন না। অধিগ্রহণের মূল্য কেবল শুরুর দিকে। গ্লোরি লেজার থেকে শিল্প বিশ্লেষণ এটি নির্দেশ করে যে উপেক্ষিত খরচের কারণে অপারেশনের আজীবন সময়কালে প্রায়ই কম খরচের মেশিনগুলি ব্যয়বহুল হয়ে ওঠে।

ক্রেতাদের যে প্রধান খরচের বিষয়গুলি অসতর্ক করে তোলে সেগুলি হল:

- সুবিধার প্রয়োজনীয়তা: শিল্প লেজারগুলির জন্য উল্লেখযোগ্য ফ্লোর স্পেস, সঠিক বৈদ্যুতিক অবকাঠামো (প্রায়শই 480V থ্রি-ফেজ), এবং নিবেদিত ভেন্টিলেশন সিস্টেমের প্রয়োজন। মেশিনটি আসার আগেই বিদ্যমান স্থান রূপান্তর করা $10,000-$50,000 খরচ হতে পারে।

- আবশ্যকীয় পণ্য: নোজেল, সুরক্ষা লেন্স এবং ফোকাস অপটিক্সের নিয়মিত প্রতিস্থাপনের প্রয়োজন। নিম্নমানের মেশিনগুলি দ্রুত ক্ষয় হয়, কখনও কখনও প্রিমিয়াম সরঞ্জামের তুলনায় 2-3 গুণ বেশি ঘনঘন নোজেল পরিবর্তনের প্রয়োজন হয়।

- সহায়ক গ্যাস সরবরাহ: নাইট্রোজেন এবং অক্সিজেনের জন্য পরিচালন খরচ অঞ্চলভেদে ভিন্ন হয়, কিন্তু উচ্চ-আয়তন কাটিংয়ের ক্ষেত্রে শুধুমাত্র গ্যাসের জন্য মাসে হাজার হাজার ডলার খরচ হতে পারে। EPA, OSHA এবং স্থানীয় অগ্নি কর্তৃপক্ষ থেকে বিশেষ অনুমতি প্রয়োজন হয় সহায়ক গ্যাস তৈরি বা সঞ্চয় করার জন্য।

- শক্তি ব্যয়: কম দক্ষ মেশিনগুলি সরাসরি বৈদ্যুতিক বিলের পরিমাণ বৃদ্ধি করে। কম খরচের সরঞ্জামগুলিতে সাধারণত খারাপভাবে অপটিমাইজড মোটর এবং ড্রাইভ সিস্টেম ব্যবহার করা হয় যা সমতুল্য আউটপুটের জন্য 15-30% বেশি শক্তি খরচ করে।

- সফটওয়্যার লাইসেন্সিং: প্রিমিয়াম CAD/CAM বৈশিষ্ট্যগুলি সাধারণত মূল সফটওয়্যারের বাইরে অতিরিক্ত ফি প্রয়োজন করে। এন্টারপ্রাইজ-গ্রেড নেস্টিং এবং স্বয়ংক্রিয়করণ প্যাকেজগুলি বছরে উল্লেখযোগ্য অতিরিক্ত খরচ যোগ করতে পারে।

- শিক্ষাদান: অপারেটর সার্টিফিকেশন এবং চলমান দক্ষতা উন্নয়নের জন্য সময় ও অর্থ ব্যয় হয়। শেখার প্রক্রিয়ার সময় 2-4 সপ্তাহের উৎপাদনশীলতা হ্রাসের জন্য বাজেট করুন।

- ডাউনটাইম: অপ্রত্যাশিত বন্ধ হওয়া শুধু উৎপাদন বন্ধ করে না—এটি অর্ডার বিলম্বিত করে এবং গ্রাহকের সম্পর্ককে ক্ষতিগ্রস্ত করে। নিম্নমানের মেশিনগুলি চলমান ভারের অধীনে নিয়ন্ত্রণ ব্যবস্থার অস্থিতিশীলতা এবং উপাদানের ব্যর্থতা বেশি ঘনঘন অভিজ্ঞতা অর্জন করে।

মোট মালিকানা খরচের সূত্রটি এই কারণগুলি পরিমাপযোগ্য করতে সাহায্য করে: TCO = প্রাথমিক খরচ + (বার্ষিক পরিচালন খরচ × বছর) + রক্ষণাবেক্ষণ খরচ + প্রশিক্ষণ খরচ - পুনঃবিক্রয় মূল্য . IVYCNC এর সুপারিশ অনুযায়ী, শুধুমাত্র রক্ষণাবেক্ষণের জন্য মেশিনের মূল্যের 5-10% বাজেট করুন।

কেনাকাটা করার সময়, লেজার সরঞ্জামগুলির পাশাপাশি আপনি বিক্রয়ের জন্য ওয়েল্ডার বা প্লাজমা কাটারের তালিকাও দেখতে পেতে পারেন। যদিও এই সরঞ্জামগুলি বিভিন্ন উদ্দেশ্য পূরণ করে, লুকানো খরচের বিষয়টি একইভাবে প্রযোজ্য—প্রাথমিক মূল্য কখনই সম্পূর্ণ গল্প বলে না।

প্রতি টুকরোর মূল্য নির্ধারণের কারণগুলি কী?

আপনি যদি সরঞ্জাম কিনছেন বা ফ্যাব্রিকেটরদের কাছ থেকে উদ্ধৃতি চাইছেন, তবে মূল্য নির্ধারণকে প্রভাবিত করে এমন বিষয়গুলি বোঝা আপনাকে খরচ অনুকূলিত করতে সাহায্য করে। কয়েকটি পরস্পর সম্পর্কযুক্ত বিষয় আপনি প্রতি সমাপ্ত অংশের জন্য কত দাম দেবেন তা নির্ধারণ করে:

- উপকরণের ধরন এবং পুরুত্ব: তামা এবং অ্যালুমিনিয়ামের মতো প্রতিফলিত ধাতুগুলি ফাইবার লেজার প্রযুক্তি এবং আরও সতর্কতার সাথে প্রক্রিয়াকরণের প্রয়োজন। ঘন উপাদানগুলি কাটার গতিকে ব্যাপকভাবে ধীর করে দেয়, যা প্রতি অংশের জন্য মেশিনের সময় বাড়িয়ে দেয়।

- অংশের জটিলতা: অনেকগুলি দিক পরিবর্তনযুক্ত জটিল রূপগুলি সাধারণ জ্যামিতিক আকৃতির চেয়ে বেশি সময় নেয়। অভ্যন্তরীণ কাটআউটগুলি পিয়ার্স পয়েন্টের প্রয়োজন হয় যা চক্র সময় বাড়িয়ে দেয়।

- পরিমাণঃ বড় আকারের উৎপাদনে সেটআপ খরচ আরও বেশি পরিমাণ অংশের মধ্যে ছড়িয়ে পড়ে। উচ্চতর পরিমাণের ক্ষেত্রে উপাদান নেস্টিং দক্ষতা উন্নত হয়, যা বর্জ্যের শতকরা হার কমায়।

- কিনারার গুণমানের প্রয়োজনীয়তা: নাইট্রোজেন সহায়তা প্রয়োজন এমন অক্সাইড-মুক্ত কিনারা পোস্ট-প্রসেসিংয়ের প্রয়োজন হয় এমন অক্সিজেন-কাট অংশগুলির তুলনায় বেশি ব্যয়বহুল। কঠোর সহনশীলতা ধীর গতি এবং আরও সতর্কতার সাথে প্যারামিটার টিউনিংয়ের প্রয়োজন হয়।

- সেকেন্ডারি অপারেশন: বাঁকানো, ওয়েল্ডিং, ফিনিশিং এবং হার্ডওয়্যার প্রবেশ সবই চূড়ান্ত অংশের খরচে যোগ করে। কেবল কাটার কথা নয়, সম্পূর্ণ উৎপাদন কার্যপ্রণালী বিবেচনা করুন।

উপাদান বর্জ্য একটি বিশেষভাবে গুরুত্বপূর্ণ কারণ। অংশের জ্যামিতি এবং নেস্টিং দক্ষতার উপর নির্ভর করে, কাঁচামালের 10% থেকে 50% পর্যন্ত স্ক্র্যাপ হয়ে যায় যা পুনর্নবীকরণের প্রয়োজন হয়। শীট ব্যবহারের দক্ষ সফটওয়্যার বর্জ্য কমাতে সাহায্য করে, কিন্তু জটিল জ্যামিতি অবশ্যই আরও বেশি অবশিষ্ট উপাদান রেখে যায়।

এই মূল্য নির্ধারণের কারণগুলি বোঝা আপনাকে ফ্যাব্রিকেটরদের সাথে আরও ভাল আলোচনার অবস্থান এবং স্মার্ট যন্ত্রপাতি সিদ্ধান্ত গ্রহণে সক্ষম করে। কিন্তু খরচের বিবেচনা শুধু ডলারের মধ্যে সীমাবদ্ধ নয়—নিরাপত্তা প্রোটোকল এবং অপারেটর প্রয়োজনীয়তা লেজার কাটিং অপারেশনের জন্য আরেকটি মাত্রা যোগ করে যা সতর্কতার সাথে মনোযোগ দাবি করে।

লেজার কাটিং বনাম প্লাজমা এবং ওয়াটারজেট পদ্ধতি

লেজার কাটিং কি সবসময় সঠিক পছন্দ? অবশ্যই নয়। যদিও ফোকাসড আলোক রশ্মি অসাধারণ নির্ভুলতা প্রদান করে, প্লাজমা কাটিং এবং ওয়াটারজেট কাটিং-এর মতো বিকল্প প্রযুক্তি এমন পরিস্থিতিতে উত্কৃষ্ট কাজ করে যেখানে লেজারের ক্ষেত্রে ত্রুটি থাকে। কোন পদ্ধতি কোন ক্ষেত্রে গ্রহণযোগ্য তা বোঝা আপনাকে আপনার নির্দিষ্ট প্রকল্পের জন্য সঠিক পদ্ধতি নির্বাচনে সাহায্য করে—আপনার প্রয়োজনীয় ফলাফল অর্জন করার পাশাপাশি অর্থ সাশ্রয় করে।

এভাবে ভাবুন: আপনি একটি গাছের কাণ্ড কাটার জন্য স্ক্যালপেল ব্যবহার করবেন না, এবং সার্জারির জন্য চেইনস ব্যবহার করবেন না। ধাতব কাটার প্রযুক্তিগুলি একইভাবে কাজ করে—প্রতিটি সরঞ্জামের একটি নির্দিষ্ট ক্ষেত্র আছে যেখানে এটি অন্যদের চেয়ে ভাল করে।

যেখানে প্লাজমা কাটিং বেশি যুক্তিযুক্ত

প্লাজমা কাটিংয়ে উচ্চ চাপে নোজেলের মধ্য দিয়ে বাধ্যতামূলকভাবে তড়িৎ আয়নিত গ্যাস ব্যবহার করা হয়। শক্তি প্রয়োগ করা হলে, গ্যাস প্লাজমায় রূপান্তরিত হয়—পদার্থের চতুর্থ অবস্থা—যা ধাতু গলানোর জন্য যথেষ্ট উচ্চ তাপমাত্রা প্রাপ্ত হয় এবং গলিত স্ল্যাগ হিসাবে তাকে সরিয়ে ফেলে। টরম্যাকের প্রযুক্তি তুলনা অনুযায়ী প্লাজমা কাটিং ইস্পাত ও অ্যালুমিনিয়ামের মতো পরিবাহী উপকরণের জন্য সীমাবদ্ধ, কিন্তু এটি গতি, নমনীয়তা এবং কম কার্যকরী খরচের মাধ্যমে তার ঘাটতি পূরণ করে।

একটি প্লাজমা কাটার কখন সত্যিকার অর্থে উজ্জ্বল হয়? এই পরিস্থিতিগুলি বিবেচনা করুন:

- ঘন প্লেট প্রক্রিয়াকরণ: একটি সিএনসি প্লাজমা কাটার 160মিমি পর্যন্ত ঘনত্বের উপকরণ নিয়ে কাজ করতে পারে—যা লেজার কাটার ব্যবহারিক সীমা অতিক্রম করে। কাঠামোগত ইস্পাতের কাজের ক্ষেত্রে, প্লাজমা এখনও পছন্দের প্রযুক্তি।

- অপারেশনের জন্য বাজেট-সচেতন: এন্ট্রি-লেভেল সিএনসি প্লাজমা টেবিল সিস্টেমগুলি 16,000 ডলারের নিচে শুরু হয়, যেখানে তুলনামূলক লেজার ক্ষমতার জন্য আরও অনেক হাজার ডলার প্রয়োজন। ক্ষেত্রের কাজ এবং মেরামতের আবেদনের জন্য পোর্টেবল প্লাজমা কাটার আরও সাশ্রয়ী প্রবেশাধিকার প্রদান করে।

- মাঝারি-ঘন উপকরণের উপর গতি: 12-50মিমি পুরুত্বের প্লেটের ক্ষেত্রে, লেজারের তুলনায় প্লাজমা কাটিং সাধারণত গতিতে এগিয়ে থাকে এবং কাঠামোগত অ্যাপ্লিকেশনের জন্য গ্রহণযোগ্য কিনারার গুণমান প্রদান করে।

- বাইরে এবং ক্ষেত্রের কাজ: প্লাজমা সিস্টেমগুলি ধুলো, আবর্জনা এবং তাপমাত্রার পরিবর্তন সহ্য করতে পারে যা লেজার অপটিক্সকে ক্ষতিগ্রস্ত করতে পারে।

এর বিনিময়ে কী হয়? প্লাজমা কাটিং লেজারের তুলনায় বড় তাপ-প্রভাবিত অঞ্চল এবং খাঁড়া কিনারা উৎপন্ন করে। সাধারণত নির্ভুলতার মাত্রা ±0.5মিমি থেকে ±1.5মিমি পর্যন্ত হয়—অনেক অ্যাপ্লিকেশনের জন্য যথেষ্ট হলেও কঠোর নির্ভুলতার উপাদানের জন্য অপর্যাপ্ত। সিএনসি কাটিং প্লাজমা সিস্টেমগুলি নির্ভুলতা উল্লেখযোগ্যভাবে উন্নত করেছে, তবুও জটিল জ্যামিতির ক্ষেত্রে লেজারের নির্ভুলতার সমান হতে পারে না।

কাঠামোগত উপাদান, ভারী যন্ত্রপাতির অংশ এবং কৃষি যন্ত্রপাতি উৎপাদনকারী ফ্যাব্রিকেশন দোকানগুলির জন্য একটি প্লাজমা কাটার সিএনসি সেটআপ চমৎকারভাবে কাজ করে। যখন গতি এবং পুরুত্বের ক্ষমতার তুলনায় নির্ভুলতা কম গুরুত্বপূর্ণ হয়, তখন প্লাজমা আকর্ষক মান প্রদান করে।

ওয়াটারজেট কাটিং: সংবেদনশীল উপকরণের জন্য শীতল নির্ভুলতা

জল জেট কাটিংয়ের একটি মৌলিকভাবে ভিন্ন পদ্ধতি রয়েছে—এতে তাপের ব্যবহার হয় না। অনুযায়ী টেকনি ওয়াটারজেটের গাইড , 50,000 PSI-এর বেশি চাপে একটি সিরামিক নোজেলের মধ্য দিয়ে জল এবং একটি অ্যাব্রেসিভ (সাধারণত গার্নেট) ঠেলে দেওয়া হয়। এই উচ্চ বেগের স্রোত উপাদানের তাপীয় বৈশিষ্ট্য নির্বিশেষে উপাদানকে ক্ষয় করে।

লেজারের তুলনায় জল জেট কেন বেছে নেবেন? শীতল কাটিং প্রক্রিয়াটি তাপ-প্রভাবিত অঞ্চলকে সম্পূর্ণরূপে অপসারণ করে। তাপীয় বিকৃতির প্রতি সংবেদনশীল উপকরণ—কঠিন টুল স্টিল, টাইটানিয়াম খাদ, এবং তাপ-চিকিত্সায় আনা উপাদানগুলি—উপাদানের বৈশিষ্ট্যকে ক্ষতিগ্রস্ত না করেই পরিষ্কারভাবে কাটা যায়। এটি এয়ারোস্পেস অ্যাপ্লিকেশন এবং নির্ভুল টুলিং কাজের জন্য জল জেটকে অপরিহার্য করে তোলে।

জল জেট এমন উপকরণগুলিও কাটতে পারে যা লেজার কখনোই স্পর্শ করতে পারে না: কাচ, সিরামিক, পাথর এবং কম্পোজিটগুলি একই নির্ভুলতার সাথে কাটা যায়। যদি আপনার উৎপাদনে ধাতুর বাইরে মিশ্র উপকরণ জড়িত থাকে, তবে জল জেটের বহুমুখিতা একটি উল্লেখযোগ্য সুবিধা হয়ে দাঁড়ায়।

তবে, জল জেট কাটিংয়ের কয়েকটি উল্লেখযোগ্য ত্রুটি রয়েছে:

- উচ্চতর চালানির খরচ: গার্নেট অ্যাব্রেসিভের ব্যবহার উল্লেখযোগ্য খরচ বাড়িয়ে দেয়, এবং এটি রক্ষণাবেক্ষণের জন্য অস্বস্তিকর পরিস্থিতি তৈরি করে।

- ধীর কাটার গতি: যেখানে লেজার চমৎকার কাজ করে তা হল পাতলা ধাতু, সেখানে ওয়াটারজেট অনেক ধীরে কাজ করে।

- উপাদানের পুরুত্বের ব্যবহারিক সীমা: ওয়াটারজেট খুব ঘন উপকরণ কাটতে পারে, কিন্তু 150মিমি এর বেশি পুরুত্বের ক্ষেত্রে কার্যকারিতা উল্লেখযোগ্যভাবে কমে যায়।

যান্ত্রিক পদ্ধতি: সাধারণ কাটার জন্য গতি

ঐতিহ্যবাহী যান্ত্রিক কাটাকে উপেক্ষা করবেন না। যেসব ক্ষেত্রে তাপজনিত কাটা অপ্রয়োজনীয় হবে, সেখানে ছেদন, পাঞ্চিং এবং করাত এখনও প্রাসঙ্গিক।

যান্ত্রিক শিয়ারিং প্রচণ্ড শক্তি প্রয়োগ করে শীট ধাতু কেটে ফেলে—কোনো তাপ নেই, ব্লেড রক্ষণাবেক্ষণ ছাড়া কোনো খরচ নেই। পাতলা উপকরণের সরল রেখায় কাটার ক্ষেত্রে, শিয়ারিং প্রতিটি তাপজনিত পদ্ধতির চেয়ে দ্রুত এবং প্রতি কাটার খরচ অনেক কম। সীমাবদ্ধতা কী? জটিল আকৃতি কাটা সম্ভব নয়।

পাঞ্চিং স্ট্যান্ডার্ড হোল প্যাটার্নযুক্ত সরল জ্যামিতির উচ্চ-আয়তন উৎপাদনে দক্ষ। লেজার কাটিং এর মতো নমনীয় না হলেও, প্রাপ্য টুলিংয়ের মধ্যে ডিজাইনগুলি ফিট করার ক্ষেত্রে পাঞ্চিং আরও দ্রুত অংশ উৎপাদন করে। ফাস্টেনার ছিদ্র এবং পুনরাবৃত্তিমূলক প্যাটার্নের জন্য, লেজার সময়ের তুলনায় পাঞ্চিং প্রায়শই আরও অর্থনৈতিক প্রমাণিত হয়।

সয়িং দক্ষতার সাথে বার স্টক এবং কাঠামোগত আকৃতি পরিচালনা করে। যখন আপনার I-বিম, টিউবিং বা কঠিন রাউন্ডগুলি দৈর্ঘ্য অনুযায়ী কাটার প্রয়োজন হয়, তাপীয় কাটিং সরঞ্জাম সেট আপ করার চেয়ে সয়গুলি কাজটি দ্রুততর এবং সস্তায় সম্পন্ন করে।

কাটিং প্রযুক্তি জুড়ে নির্ভুলতা তুলনা

সঠিক প্রযুক্তি নির্বাচন করতে আপনার নির্দিষ্ট প্রয়োজনীয়তার বিরুদ্ধে একাধিক ফ্যাক্টর ওজন করা প্রয়োজন। নিম্নলিখিত তুলনা আপনাকে পদ্ধতিগুলিকে অ্যাপ্লিকেশনের সাথে মেলানোতে সহায়তা করার জন্য প্রযুক্তি-নিরপেক্ষ নির্দেশনা প্রদান করে:

| গুণনীয়ক | লেজার কাটিং | প্লাজমা কাটা | জলজেট কাটিং |

|---|---|---|---|

| নির্ভুলতার সহনশীলতা | ±0.003mm থেকে ±0.1mm | ±0.5mm থেকে ±1.5mm | ±0.025mm থেকে ±0.13mm |

| কাটিং গতি (পাতলা উপকরণ) | অত্যন্ত দ্রুত (প্রতি মিনিটে 20 মি পর্যন্ত) | দ্রুত | ধীর থেকে মাঝারি |

| কাটিং গতি (মোটা উপকরণ) | মাঝারি; 20mm এর বেশি উল্লেখযোগ্যভাবে ধীর হয় | দ্রুত; মোটা প্লেটগুলিতে গতি বজায় রাখে | ধীর; বেধ জুড়ে সামঞ্জস্যপূর্ণ |

| উপাদানের পুরুত্বের পরিসর | সাধারণত 25-30মিমি পর্যন্ত; উচ্চ ক্ষমতা সহ 50মিমি+ | 160মিমি পর্যন্ত | 300মিমি+ পর্যন্ত সম্ভব |

| তাপ-প্রভাবিত অঞ্চল | ছোট; ন্যূনতম তাপীয় বিকৃতি | বড়; উল্লেখযোগ্য তাপীয় প্রভাব | কোনটিই নয়; ঠান্ডা কাটিং প্রক্রিয়া |

| প্রান্তের গুণগত মান | চমৎকার; প্রায়ই কোনও সমাপ্তকরণের প্রয়োজন হয় না | কাঁচা; গ্রাইন্ডিং প্রয়োজন হতে পারে | চমৎকার; মসৃণ, বার-মুক্ত |

| চালু খরচ | মাঝারি (বিদ্যুৎ, সহায়ক গ্যাস) | নিম্ন (বিদ্যুৎ, খরচযোগ্য ইলেকট্রোড) | উচ্চ (ধাতব, পাম্প রক্ষণাবেক্ষণ) |

| সজ্জা খরচ | উচ্চ ($50,000-$2M+) | নিম্ন থেকে মাঝারি ($15,000-$150,000) | উচ্চ ($100,000-$500,000+) |

| উপাদানগত সামঞ্জস্য | ধাতু, কিছু প্লাস্টিক, কাঠ | শুধুমাত্র পরিবাহী ধাতু | প্রায় যেকোনো উপাদান |

| সেরা প্রয়োগ | নির্ভুল অংশ; পাতলা-মাঝারি ধাতু; উচ্চ পরিমাণ | কাঠামোগত ইস্পাত; মোটা প্লেট; বাজেট অপারেশন | তাপ-সংবেদনশীল উপকরণ; কম্পোজিট; মিশ্র উৎপাদন |

আপনার প্রকল্পের জন্য সঠিক পদ্ধতি নির্বাচন

তাহলে আপনি কোন প্রযুক্তি বেছে নেবেন? এই সিদ্ধান্ত কাঠামোটি প্রয়োগ করুন:

- লেজার কাটিং বেছে নিন যখন সর্বোচ্চ নির্ভুলতা গুরুত্বপূর্ণ, যখন উচ্চ পরিমাণে মাঝারি থেকে পাতলা ধাতু প্রক্রিয়াকরণ করা হয়, অথবা যখন কিনারার গুণমানের প্রয়োজনীয়তা দ্বিতীয় পর্যায়ের ফিনিশিংয়ের প্রয়োজন দূর করে।

- প্লাজমা কাটিং বেছে নিন যখন ঘন গাঠনমূলক ইস্পাতের সাথে কাজ করা হয়, যখন বাজেটের সীমাবদ্ধতা সরঞ্জাম বিনিয়োগকে সীমাবদ্ধ করে, অথবা যখন ±1মিমি সহনশীলতা আপনার প্রয়োজনীয়তা পূরণ করে। একটি প্লাজমা কাটিং টেবিল সেটআপ অর্থনৈতিকভাবে অধিকাংশ ভারী ফ্যাব্রিকেশনের প্রয়োজনীয়তা মেটায়।

- ওয়াটারজেট কাটিং বেছে নিন যখন উপকরণগুলি তাপ-সংবেদনশীল, যখন অ-ধাতব বা কম্পোজিট কাটা হয়, অথবা যখন আপনার প্রয়োগের জন্য শূন্য তাপীয় বিকৃতি বাধ্যতামূলক হয়।

- যান্ত্রিক পদ্ধতি বেছে নিন যখন খুব উচ্চ পরিমাণে সাধারণ আকৃতি উৎপাদন করা হয়, যখন সোজা কাটা আপনার কাজের প্রাধান্য পায়, অথবা যখন আপনার জ্যামিতির জন্য তাপীয় প্রক্রিয়াগুলি কোন সুবিধা দেয় না।

অনেক ফ্যাব্রিকেশন দোকানগুলি একাধিক প্রযুক্তি বজায় রাখে কারণ কোনও একক পদ্ধতি প্রতিটি কাজকে সর্বোত্তমভাবে পরিচালনা করতে পারে না। প্রতিটি কোথায় শ্রেষ্ঠ তা বোঝা আপনাকে সঠিক সরঞ্জামে কাজ পাঠাতে সাহায্য করে—অথবা উপযুক্ত ক্ষমতা সহ সঠিক ফ্যাব্রিকেশন অংশীদার নির্বাচন করতে সাহায্য করে।

আপনি যে কোনও কাটিং প্রযুক্তি নির্বাচন করুন না কেন, নিরাপত্তা প্রোটোকল এবং অপারেটরের প্রয়োজনীয়তা গুরুতর মনোযোগ দাবি করে। পদ্ধতি অনুযায়ী ঝুঁকি ভিন্ন হয়, কিন্তু সমস্ত ধাতু কাটার কাজের জন্য উপযুক্ত প্রশিক্ষণ, সরঞ্জাম এবং পদ্ধতির প্রয়োজন হয়।

নিরাপত্তা প্রোটোকল এবং অপারেটরের প্রয়োজনীয়তা

এখানে একটি বাস্তবতা যাচাই যা বেশিরভাগ সরঞ্জামের ব্রোশিওর উপেক্ষা করে: লেজার দিয়ে ধাতু কাটা গুরুতর ঝুঁকি জড়িত যা শ্রদ্ধা দাবি করে। আমরা ইস্পাতকে বাষ্পীভূত করার জন্য যথেষ্ট শক্তিশালী ফোকাস করা শক্তি, শত শত অ্যাম্পিয়ার টানা বৈদ্যুতিক সিস্টেম এবং সময়ের সাথে ফুসফুসকে ক্ষতিগ্রস্ত করতে পারে এমন বায়ুবাহিত কণার কথা বলছি। তবুও অনেক দোকান কিছু ভুল না হওয়া পর্যন্ত নিরাপত্তাকে একটি পরবর্তী চিন্তা হিসাবে দেখে।

এই ঝুঁকিগুলি সম্পর্কে জানা ভয় পাওয়ার বিষয় নয়—এটি হল উপযুক্ত সুরক্ষা ব্যবস্থা সহ আত্মবিশ্বাসের সঙ্গে কাজ করার বিষয়। আপনি যদি নিজে কাজ চালাচ্ছেন বা উৎপাদন অংশীদারদের মূল্যায়ন করছেন, সুরক্ষা প্রোটোকলগুলি কেমন হওয়া উচিত তা জানা থাকলে আপনি পেশাদার কার্যক্রম এবং কোণ-কাটা দোকানগুলির মধ্যে পার্থক্য করতে পারবেন।

লেজার কাটিং অপারেশনের জন্য প্রয়োজনীয় ব্যক্তিগত সুরক্ষা সজ্জা

ইঞ্জিনিয়ারিং নিয়ন্ত্রণ ব্যর্থ হলে ব্যক্তিগত সুরক্ষা সজ্জা (পিপিই) আপনার শেষ প্রতিরক্ষার ধারা গঠন করে। লেজার ঝুঁকি সম্পর্কিত OSHA-এর টেকনিক্যাল ম্যানুয়াল ক্লাস IV শিল্প লেজার—যে শ্রেণীটি বেশিরভাগ ধাতব কাটিং সরঞ্জামকে কভার করে—একইসঙ্গে সরাসরি দৃষ্টি সম্পর্কিত ঝুঁকি, বিক্ষিপ্ত প্রতিফলনের ঝুঁকি এবং আগুনের ঝুঁকি তৈরি করে।

উপযুক্ত সুরক্ষা আসলে কেমন হওয়া উচিত? শুরু করুন আপনার চোখ দিয়ে। লেজার নিরাপত্তা চশমা অবশ্যই আপনার সরঞ্জাম থেকে নির্গত নির্দিষ্ট তরঙ্গদৈর্ঘ্যের সাথে মিল রাখবে। একটি ফাইবার লেজার 1064 ন্যানোমিটারে কাজ করে যেখানে CO2 সিস্টেমগুলি 10,600 ন্যানোমিটারে নির্গত হয়—একটি তরঙ্গদৈর্ঘ্যের জন্য কার্যকর সুরক্ষামূলক লেন্স অন্যটির বিরুদ্ধে শূন্য সুরক্ষা প্রদান করে। আলোকিক ঘনত্ব (OD) রেটিং-এরও গুরুত্ব রয়েছে। OSHA-এর হিসাব অনুযায়ী, একটি 5-ওয়াট আর্গন লেজার সরাসরি বিম সুরক্ষার জন্য OD 5.9 বা তার বেশি সহ চশমার প্রয়োজন।

চশমার পাশাপাশি, কার্যকর ধাতব কাজের অপারেশনের জন্য প্রয়োজন:

- অগ্নি-প্রতিরোধী পোশাক: স্পার্ক এবং গলিত ছিটা কৃত্রিম কাপড়ে আগুন ধরাতে পারে। তুলা বা চিকিত্সাধীন উপকরণ পোড়ার ঝুঁকি কমায়।

- চামড়ার তৈরি হাতের তোয়ালে: গরম কাজের টুকরো এবং সদ্য কাটা অংশগুলির তীক্ষ্ণ প্রান্ত থেকে হাতকে সুরক্ষা দেয়।

- নিরাপত্তা জুতা: ইস্পাতের আগা ওয়ালা জুতো পড়ে যাওয়া উপকরণ থেকে রক্ষা করে এবং স্থিতিশীল ভিত্তি প্রদান করে।

- শ্রবণ সুরক্ষা: উচ্চ-ক্ষমতা সম্পন্ন লেজার এবং সহায়ক গ্যাস সিস্টেমগুলি শব্দের মাত্রা উৎপন্ন করে যা দীর্ঘ সময় ধরে কাজ করার সময় সুরক্ষার প্রয়োজন হয়।

- শ্বাস-রক্ষা: যখন ধোঁয়া নিষ্কাশন ব্যবস্থা অতিরিক্ত চাপে থাকে বা রক্ষণাবেক্ষণের সময়, উপযুক্ত মাস্ক কণা শ্বাসগ্রহণ প্রতিরোধ করে।

আপনি যে ধাতু কাটার যন্ত্রটি ব্যবহার করছেন তা নির্দিষ্ট PPE প্রয়োজনীয়তা নির্ধারণ করে। সর্বদা নিশ্চিত করুন যে আপনার লেজারের স্পেসিফিকেশন অনুযায়ী সুরক্ষা সরঞ্জামের রেটিং মিলে—সাধারণ সুরক্ষা চশমা শিল্প লেজার তরঙ্গদৈর্ঘ্য থেকে রক্ষা করবে না।

উপাদানের ধরন অনুযায়ী ভেন্টিলেশনের প্রয়োজনীয়তা

যখন লেজার শক্তি ধাতুকে বাষ্পে পরিণত করে, তখন এটি কেবল অদৃশ্য হয়ে যায় না। এই প্রক্রিয়াটি ধাতব কণা, অক্সাইড এবং সম্ভাব্য ক্ষতিকর যৌগ সমৃদ্ধ একটি ধোঁয়া তৈরি করে। স্ন্যাপমেকারের লেজার ধোঁয়া নিরাপত্তা বিশ্লেষণ অনুযায়ী , এই ধোঁয়াতে ক্ষুদ্র কণা, উদ্বায়ী জৈব যৌগ (VOCs) এবং উপাদান-নির্ভর ঝুঁকি থাকতে পারে যা আপনি কী কাটছেন তার উপর ভিত্তি করে ব্যাপকভাবে পরিবর্তিত হয়।

জিঙ্ক অক্সাইডের ধোঁয়া নির্গত হয় যখন গ্যালভানাইজড ইস্পাত কাটা হয়, যা "মেটাল ফিউম ফিভার" সৃষ্টি করে—এমন উপসর্গ যা ফ্লু-এর মতো এবং রপ্তানির কয়েক ঘণ্টা পরে দেখা দেয়। আস্তরণের ধরন অনুযায়ী আস্তরিত উপকরণ আরও ভয়াবহ যৌগ নির্গত করতে পারে। এমনকি "পরিষ্কার" ধাতুও অতি সূক্ষ্ম কণা তৈরি করে যা ফুসফুসের কলার মধ্যে গভীরভাবে প্রবেশ করার মতো পর্যাপ্ত ছোট।

OSHA নোঞ্জিয়াস ফিউমগুলি থ্রেশহোল্ড লিমিট ভ্যালু (TLVs) বা পারমিটেড এক্সপোজার লিমিট (PELs)-এর নিচে নামানোর জন্য যথেষ্ট ভেন্টিলেশনের প্রয়োজন নির্ধারণ করে। বাস্তবে বাস্তবায়নের ক্ষেত্রে সাধারণত নিম্নলিখিতগুলি জড়িত:

- স্থানীয় নিষ্কাশন ভেন্টিলেশন: উৎসের কাছেই ফিউমগুলি ধরে ফেলুন যাতে তারা ছড়িয়ে পড়ার আগেই নিষ্কাশন করা যায়। কাটার অঞ্চলের চারপাশে সঠিকভাবে নকশাকৃত আবদ্ধ স্থান নিষ্কাশনকে সাধারণ ঘরের ভেন্টিলেশনের উপর নির্ভর করার চেয়ে অনেক বেশি কার্যকর করে তোলে।

- ডাক্টিং বিবেচনা: ডাক্টওয়ার্কে ন্যূনতম বাঁক রাখুন, ফাঁকগুলি লিকেজের বিরুদ্ধে সিল করা নিশ্চিত করুন এবং নিষ্কাশন সিস্টেমের ক্ষমতা অনুযায়ী ডাক্টিংয়ের আকার নির্ধারণ করুন।

- ফিল্ট্রেশন সিস্টেম: হেপা ফিল্টারগুলি ক্ষুদ্র কণা আটকে রাখে, যেখানে সক্রিয় কার্বন গ্যাসীয় দূষণকারীদের পরিচালনা করে। উভয় প্রযুক্তির সমন্বয়ে গঠিত বহু-পর্যায়ের ব্যবস্থাগুলি ব্যাপক সুরক্ষা প্রদান করে।

- বাতাসের প্রবাহ মনিটরিং: নিয়মিত যাচাই করা যে নিষ্কাশন ব্যবস্থাগুলি কাজের অঞ্চলে পর্যাপ্ত আটক ধরনের গতি বজায় রাখছে।

মিশ্র উপকরণ বা আবৃত ধাতু নিয়ে কাজের ক্ষেত্রে, শিল্প-গ্রেড ধোঁয়া নিষ্কাশক অপরিহার্য হয়ে ওঠে। এই ব্যবস্থাগুলি ঘনীভূত কণা ভার সামলায় যা সাধারণ HVAC ব্যবস্থাগুলি পরিচালনা করতে পারে না, দূষণকারীদের ধরন এবং স্থানীয় নিয়মাবলীর উপর নির্ভর করে কর্মক্ষেত্রে পরিষ্কার বাতাস ফিরিয়ে দেয় বা বাইরে নিষ্কাশিত করে।

সুবিধার নিরাপত্তা এবং জরুরি প্রস্তুতি

সুবিধার মধ্যে প্রকৌশলগত নিয়ন্ত্রণগুলি ব্যক্তিগত আচরণের উপর নির্ভরশীল নয় এমন সুরক্ষা প্রদান করে। OSHA লেজার নিরাপত্তা কর্মসূচির জন্য ANSI Z 136.1 মানকে রেফারেন্স হিসাবে উল্লেখ করে, যা Class IIIB এবং Class IV লেজার স্থাপনের জন্য নির্দিষ্ট নিয়ন্ত্রণ প্রয়োজন করে।

সাধারণ অপারেশনের সময় বীম এক্সপোজার প্রতিরোধের জন্য উপযুক্ত আবদ্ধকরণ প্রয়োজন। OSHA নির্দেশিকা অনুসারে, আলোক ঘনত্ব 10 W/cm² এর বেশি হওয়া সত্ত্বেও যে আবদ্ধকরণ উপকরণগুলি আগুন ধরে না যায় তা ব্যবহার করা আবশ্যিক—প্লাস্টিকের উপকরণগুলি নিষিদ্ধ নয়, তবে বীমের সংস্পর্শে এলে তাদের জ্বলনশীলতা এবং বিষাক্ত ধোঁয়া উৎপাদনের সম্ভাবনা সম্পর্কে সতর্কভাবে মূল্যায়ন করা প্রয়োজন।

আবদ্ধকরণের বাইরেও, সম্পূর্ণ সুবিধার নিরাপত্তার মধ্যে অন্তর্ভুক্ত রয়েছে:

- ইন্টারলকড অ্যাক্সেস পয়েন্ট: দরজা এবং অ্যাক্সেস প্যানেল যা খোলা হলে লেজার অপারেশন বন্ধ করে দেয়, রক্ষণাবেক্ষণ বা অপ্রত্যাশিত প্রবেশের সময় দুর্ঘটনাজনিত এক্সপোজার প্রতিরোধ করে।

- সতর্কতা ব্যবস্থা: আলোকিত সাইন যা নিয়ন্ত্রিত এলাকায় প্রবেশের সমস্ত পথ থেকে দৃশ্যমান হয় এবং লেজার চালু আছে কিনা তা নির্দেশ করে।

- জরুরি বন্ধ ব্যবস্থা: স্পষ্টভাবে চিহ্নিত, সহজে প্রাপ্য স্টপ যা তাত্ক্ষণিকভাবে সিস্টেমটিকে ডি-এনার্জাইজ করে।

- অগ্নিনির্বাপন ব্যবস্থা: ন্যাশনাল ফায়ার প্রোটেকশন অ্যাসোসিয়েশনের NFPA 115 মান লেজার অগ্নি সুরক্ষা প্রয়োজনীয়তা কভার করে, যার মধ্যে বীম আগুন ধরার সম্ভাবনা এবং উপযুক্ত অগ্নিনির্বাপন ব্যবস্থার মূল্যায়ন অন্তর্ভুক্ত রয়েছে।

- অlectricity নিরাপত্তা: শিল্প লেজারগুলি উল্লেখযোগ্য পরিমাণ বিদ্যুৎ গ্রহণ করে। বিদ্যুতে আঘাত এবং অগ্নিকাণ্ডের ঝুঁকি প্রতিরোধের জন্য জাতীয় বৈদ্যুতিক কোড (ANSI/NFPA 70) স্থাপনের প্রয়োজনীয়তা নিয়ন্ত্রণ করে।

কার্যকর শীট ধাতব কাটার যন্ত্রের ক্রিয়াকলাপের জন্য লিখিত আদর্শ কার্যপ্রণালী (SOP)-এর প্রয়োজন, যাতে স্বাভাবিক কার্যকলাপ, রক্ষণাবেক্ষণ প্রক্রিয়া এবং জরুরি প্রতিক্রিয়া অন্তর্ভুক্ত থাকে। ANSI Z 136.1 Class IV লেজারের জন্য SOP বাধ্যতামূলক করে এবং Class IIIB সিস্টেমের জন্য এটি সুপারিশ করে।

প্রশিক্ষণ ও সার্টিফিকেশনের প্রয়োজনীয়তা

যন্ত্রপাতি নিজে থেকে নিরাপদে কাজ করে না—প্রশিক্ষিত অপারেটররাই নিয়ন্ত্রিত ধাতব কাজের যন্ত্র ব্যবহার এবং এড়ানো যায় এমন দুর্ঘটনার মধ্যে পার্থক্য তৈরি করে। OSHA চাই যে একজন নির্দিষ্ট লেজার নিরাপত্তা কর্মকর্তা (LSO) Class IIIB এবং Class IV লেজার ক্রিয়াকলাপ তদারকি করবেন এবং নিয়ন্ত্রণ ব্যবস্থা মেনে চলা নিশ্চিত করবেন।

অপারেটর প্রশিক্ষণের মধ্যে অন্তর্ভুক্ত হওয়া উচিত:

- লেজার কার্যকলাপ এবং ঝুঁকি চেনার মৌলিক নীতি

- যন্ত্র-নির্দিষ্ট প্রক্রিয়া এবং প্যারামিটার সেটিং

- PPE নির্বাচন, পরীক্ষা এবং সঠিক ব্যবহার

- আগুন সংক্রান্ত প্রতিক্রিয়া এবং চিকিৎসা জরুরি অবস্থা সহ জরুরি প্রক্রিয়া

- ধোঁয়া নিষ্কাশন ব্যবস্থার কাজ এবং ফিল্টারের রক্ষণাবেক্ষণ

- অস্বাভাবিক পরিচালনা অবস্থার সনাক্তকরণ

কিছু রাজ্য অপারেটর লাইসেন্সিং বা প্রতিষ্ঠানগত নিবন্ধনের প্রয়োজনীয়তা সহ লেজার নিয়ন্ত্রণ বজায় রাখে। আরিজোনা, ফ্লোরিডা এবং আরও অনেকগুলি রাজ্য ফেডারেল মানের চেয়ে বেশি প্রয়োজনীয়তা চালু করেছে। অপারেশন শুরুর আগে আপনার স্থানীয় এলাকার প্রয়োজনীয়তা যাচাই করুন।

ব্যাপক নিরাপত্তা চেকলিস্ট

যেকোনো লেজার কাটিং অপারেশন শুরু করার আগে, এই প্রধান উপাদানগুলি সঠিকভাবে স্থাপিত আছে কিনা তা যাচাই করুন:

- সমস্ত কর্মীদের জন্য উপযুক্ত তরঙ্গদৈর্ঘ্যের রেটিং এবং আলোকীয় ঘনত্ব সহ লেজার নিরাপত্তা চশমা উপলব্ধ আছে কিনা

- ফিল্টার গুলি গ্রহণযোগ্য অবস্থায় আছে কিনা তা নিশ্চিত করে ধোঁয়া নিষ্কাশন ব্যবস্থা কার্যকর আছে কিনা

- এনক্লোজার ইন্টারলক পরীক্ষা করা হয়েছে এবং কার্যকর

- সতর্কতামূলক সাইন গুলি জ্বলছে এবং সমস্ত প্রবেশদ্বার থেকে দৃশ্যমান

- জরুরি থামানোর অবস্থান জানা আছে এবং পৌঁছানো যায়

- বৈদ্যুতিক এবং ধাতব আগুনের জন্য উপযুক্ত অগ্নিনির্বাপক সরঞ্জাম খুব কাছাকাছি থাকা উচিত

- প্রক্রিয়াজাতকরণের জন্য ব্যবহৃত উপকরণগুলির জন্য উপাদান নিরাপত্তা তথ্য শীট (ম্যাটেরিয়াল সেফটি ডেটা শীট) পাওয়া যাবে

- বর্তমান সার্টিফিকেশন সহ প্রশিক্ষিত অপারেটর উপস্থিত থাকবেন

- লিখিত এসওপি (SOP) পর্যালোচনা করা হয়েছে এবং সহজলভ্য

- কাজের জায়গাটি জ্বলনশীল উপকরণ এবং প্রতিফলিত পৃষ্ঠ থেকে মুক্ত রাখা হবে

নিরাপত্তা প্রোটোকলগুলি অতিরিক্ত বোধ হতে পারে, কিন্তু এগুলি আপনার কার্যক্রমের সবচেয়ে মূল্যবান সম্পদ—কাজ করা মানুষদের রক্ষা করে। পেশাদার ফ্যাব্রিকেটররা শুধুমাত্র অনুগমনের জন্য নয়, বরং কারণ দীর্ঘমেয়াদে ধারাবাহিক নিরাপদ অনুশীলন ধারাবাহিক গুণমান উৎপাদনকে সক্ষম করে, তাই তারা কঠোর নিরাপত্তা কর্মসূচি বজায় রাখেন।

নিরাপত্তার মৌলিক বিষয়গুলি প্রতিষ্ঠিত হওয়ার পর, আপনি লেজার-কাট উপাদানগুলি কীভাবে শিল্পগুলিতে ব্যবহৃত হয় তা অন্বেষণ করতে প্রস্তুত—অটোমোটিভ চ্যাসিস অংশ থেকে শুরু করে স্থাপত্য ইনস্টালেশন পর্যন্ত।

শিল্পের প্রয়োগ এবং বাস্তব বিশ্বের ব্যবহারের ক্ষেত্র

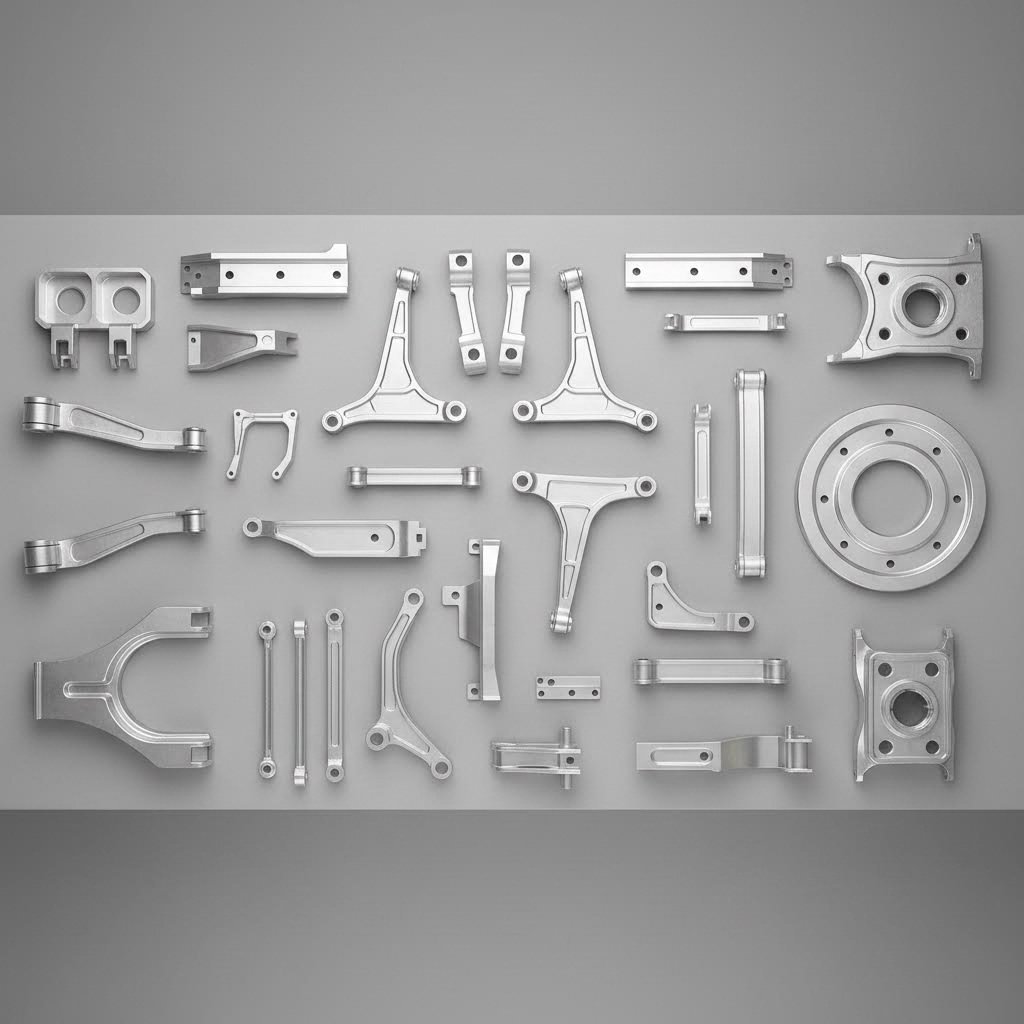

এই সূক্ষ্ম কাটিংয়ের ফলাফল আসলে কোথায় প্রয়োগ হয়? আপনি যে গাড়ি চালান তা থেকে শুরু করে জীবন বাঁচানোর মতো চিকিৎসা যন্ত্রপাতি— লেজার-কাট ধাতব উপাদানগুলি আমাদের দৈনিক জীবনের অবিচ্ছেদ্য অংশ, প্রায়শই অদৃশ্যভাবে এমন পণ্যগুলির সঙ্গে যুক্ত যা আমরা সাধারণভাবে গ্রহণ করি। এই প্রয়োগগুলি বোঝার মাধ্যমে এটি স্পষ্ট হয়ে ওঠে যে কেন প্রায় প্রতিটি উৎপাদন খাতে শীট মেটাল ফ্যাব্রিকেশন অপরিহার্য হয়ে উঠেছে।

এই প্রযুক্তির প্রভাব কেবল আকৃতি কাটার চেয়ে অনেক বেশি দূরে প্রসারিত। আধুনিক ধাতব ফ্যাব্রিকেশন কার্যক্রম কাঁচামালকে সম্পূর্ণ সমাবেশে রূপান্তরিত করার জন্য লেজার কাটিংকে ভিত্তি হিসাবে ব্যবহার করে। বিভিন্ন শিল্প কীভাবে এই সূক্ষ্মতা কাজে লাগায় তা আসুন জেনে নেওয়া যাক।

অটোমোটিভ এবং এয়ারস্পেস অ্যাপ্লিকেশন

যে কোনও অটোমোটিভ উত্পাদন সুবিধা ঘুরে দেখুন, এবং আপনি প্রতিটি কোণায় লেজার-কাট কম্পোনেন্ট খুঁজে পাবেন। চ্যাসিস কম্পোনেন্ট, ব্র্যাকেট, কাঠামোগত শক্তিশালীকরণ এবং বডি প্যানেলগুলি সবই প্রযুক্তির অতুলনীয় নির্ভুলতা এবং পুনরাবৃত্তিমূলকতার সুবিধা পায়। যখন আপনি প্রতিদিন হাজার হাজার অভিন্ন অংশ উৎপাদন করছেন, তখন সিএনসি ফ্যাব্রিকেশন যে সামঞ্জস্য দেয় তা অপরিহার্য হয়ে ওঠে।

অনুযায়ী আমেরিকান লেজার কো. , অটোমোটিভ অ্যাপ্লিকেশনগুলি শিল্প লেজার কাটিংয়ের জন্য সবচেয়ে গুরুত্বপূর্ণ খাতগুলির মধ্যে একটি হিসাবে দাঁড়িয়েছে। কারণগুলি স্পষ্ট: চ্যাসিস এবং সাসপেনশন কম্পোনেন্টগুলিতে সহনশীলতার প্রয়োজনীয়তা কোনও পরিবর্তনের জন্য জায়গা রাখে না। এমনকি আধ মিলিমিটার দ্বারা অফ একটি ব্র্যাকেটও পুরো উত্পাদন লাইনের মধ্যে ছড়িয়ে পড়া সমস্যা তৈরি করতে পারে।

কোন নির্দিষ্ট উপাদানগুলি লেজার কাট করা হয়? এই নমুনাটি বিবেচনা করুন:

- চ্যাসিস ব্র্যাকেট এবং মাউন্টিং প্লেট: এমন কাঠামোগত উপাদান যার ফাস্টেনার এবং সারিবদ্ধকরণ বৈশিষ্ট্যগুলির জন্য গর্তের স্থাপনের প্রয়োজন হয়

- সাসপেনশন সিস্টেম অংশ: নিয়ন্ত্রণ বাহুর শক্তিকরণ, স্প্রিং মাউন্ট এবং শ shoক অ্যাবসর্বার ব্র্যাকেট যেখানে শক্তি ওজন অপ্টিমাইজেশনের সাথে মিলিত হয়

- বডি গাঠনিক উপাদান: দরজার শক্তিকরণ, খুঁটি উপাদান এবং দুর্ঘটনার গঠনমূলক উপাদানগুলি নির্দিষ্ট বিকৃতির বৈশিষ্ট্যের জন্য ডিজাইন করা হয়েছে

- তাপ ঢাল এবং নিষ্কাশন উপাদান: জটিল আকৃতি যা শুধুমাত্র স্ট্যাম্পিং ডাই দিয়ে উৎপাদন করা অব্যবহারযোগ্য হবে

কঠোর মানের মানদণ্ড পূরণকারী অটোমোটিভ সরবরাহকারীদের জন্য, IATF 16949 প্রত্যয়ন প্রধান OEM সরবরাহ চেইনে প্রবেশের টিকিট হয়ে ওঠে। এই অটোমোটিভ মান ব্যবস্থাপনা মানটি প্রোটোটাইপিং থেকে শুরু করে বৃহৎ উৎপাদন পর্যন্ত ধারাবাহিক প্রক্রিয়া নিশ্চিত করে। এমন উৎপাদনকারীরা যেমন শাওই (নিংবো) ধাতু প্রযুক্তি লেজার কাটিং এবং ধাতু স্ট্যাম্পিং ক্ষমতাকে একত্রিত করে, চ্যাসিস, সাসপেনশন এবং গঠনমূলক উপাদানগুলির জন্য IATF 16949-প্রত্যয়িত মান প্রদান করে। তাদের 5-দিনের দ্রুত প্রোটোটাইপিং ক্ষমতা পণ্য উন্নয়ন চক্রকে ত্বরান্বিত করে, যখন ব্যাপক DFM সমর্থন উৎপাদন টুলিং প্রয়োগের আগে নকশাগুলি অনুকূলিত করতে প্রকৌশলীদের সাহায্য করে।

বিমান চলন আরও বেশি নির্ভুলতা দাবি করে। বিমানের উপাদানগুলির জন্য হালকা কিন্তু শক্তিশালী উপকরণের প্রয়োজন—প্রায়শই টাইটানিয়াম, অ্যালুমিনিয়াম খাদ এবং বিশেষ ধরনের ইস্পাত, যা সাধারণ কাটিং পদ্ধতিকে চ্যালেঞ্জ করে। বিমান চলনের ক্ষেত্রে লেজার কাটা ধাতব পাতগুলির মধ্যে থাকতে পারে:

- ওজন কমানোর জন্য ছিদ্রযুক্ত গঠনমূলক পাঁজর এবং স্পার

- অ্যাভিওনিক্স মাউন্টিংয়ের জন্য ব্র্যাকেট সংযোজন

- ইঞ্জিন উপাদানের তাপ প্রতিরোধক আবরণ

- অভ্যন্তরীণ প্যানেল ফ্রেমিং যাতে অপরিহার্য সংযোগকারী বিন্দু একীভূত থাকে

তাপ-প্রভাবিত অঞ্চলের সমস্যা যা নির্মাণ ইস্পাতে গ্রহণযোগ্য হতে পারে, বিমান চলনের ক্ষেত্রে তা গুরুত্বপূর্ণ হয়ে ওঠে। তাই নাইট্রোজেন-সহায়তা কাটিং এই অ্যাপ্লিকেশনগুলিতে প্রাধান্য পায়—উপকরণের বৈশিষ্ট্যগুলি অক্ষত রেখে সেই জ্যামিতিক নির্ভুলতা অর্জন করে যা উড়ানের জন্য অপরিহার্য উপাদানগুলির জন্য প্রয়োজন হয়।

স্থাপত্য এবং সজ্জামূলক প্রয়োগ

কারখানার মেঝের বাইরে একটু এগিয়ে গেলে, লেজার কাটিং একটি শিল্পগত মাধ্যমে পরিণত হয়। বিশ্বব্যাপী ভবনের ফ্যাসাডে লেজার-কাট সজ্জামূলক ধাতব প্যানেলগুলি স্থাপত্যের অভিব্যক্তি হয়ে উঠেছে। এই প্রযুক্তি অসম্ভবকে সম্ভব করে তোলে—হাজার হাজার প্যানেলের মধ্যে সামঞ্জস্যপূর্ণ নির্ভুলতার সঙ্গে জৈবিক বক্ররেখা, জটিল জ্যামিতিক টেসেলেশন এবং কাস্টম শিল্প নকশা কাটার ক্ষেত্রে, যা ঐতিহ্যবাহী উৎপাদন পদ্ধতিতে অর্থনৈতিকভাবে অসম্ভব ছিল।

স্থাপত্য প্রয়োগগুলির মধ্যে রয়েছে:

- ভবনের বাহ্যিক অংশ: আলো প্রবেশ নিয়ন্ত্রণ করে এমন পারফোরেটেড প্যানেল এবং দৃষ্টি কোণ পরিবর্তনের সাথে সাথে গতিশীল দৃশ্য প্রভাব তৈরি করে

- অভ্যন্তরীণ পার্টিশন: দৃশ্য সংযোগ বজায় রাখার সময় স্থানগুলিকে বিভক্ত করে এমন সজ্জামূলক স্ক্রিন

- সিঁড়ির উপাদান: উঠান এবং হ্যান্ড্রেল প্যানেলের জন্য লেজার-কাট ইস্পাত প্যানেল

- সাইনেজ এবং পথ নির্দেশনা: কর্পোরেট ব্র্যান্ডিং, ভবন চেনাশোনা এবং দিকনির্দেশক ব্যবস্থার জন্য ব্যক্তিগতকৃত ধাতব সাইন

- পাবলিক আর্ট ইনস্টালেশন: একাধিক লেজার-কাট উপাদান একত্রিত করে তৈরি বৃহদাকার ভাস্কর্যমূলক উপাদান

সাইনেজ শিল্পটি বিশেষত ডাইমেনশনাল অক্ষর এবং লোগোর জন্য লেজার কাটিং গ্রহণ করে। শিল্প বিশ্লেষণ অনুযায়ী, খুচরা দোকান, কর্পোরেট ব্র্যান্ডিং এবং ওয়েফাইন্ডিং সিস্টেম—সবগুলোই লেজার-কাট সূক্ষ্মতা থেকে উপকৃত হয় যা একাধিক সাইনের মধ্যে সামঞ্জস্য নিশ্চিত করে—ব্র্যান্ড চেনার জন্য এটি অপরিহার্য।

স্থাপত্য কাজের জন্য লেজার-কাট ধাতব প্যানেলগুলি কী করে আকর্ষণীয় করে তোলে? এই প্রক্রিয়াটি একক অপারেশনে সজ্জামূলক নকশা কাটা এবং কাঠামোগত মাউন্টিং বৈশিষ্ট্য উভয়কেই নিয়ন্ত্রণ করে। প্রান্তের গুণমানের সাধারণত কোনো দ্বিতীয় সমাপ্তির প্রয়োজন হয় না, যা বড় প্যানেল রানের জন্য শ্রম খরচ কমায় এবং সামগ্রিক দৃশ্যমানতার সামঞ্জস্য নিশ্চিত করে।

ইলেকট্রনিক্স, মেডিকেল এবং শিল্প প্রয়োগ

সমাপ্ত পণ্যগুলিতে লেজার-কাট করা সমস্ত উপাদান দৃশ্যমান নয়। ইলেকট্রনিক্স এনক্লোজার—সার্কিট বোর্ড এবং উপাদানগুলি ধারণকারী শীট মেটালের বাক্স—একটি বিশাল প্রয়োগের শ্রেণী উপস্থাপন করে। কানেক্টর, ডিসপ্লে, ভেন্টিলেশন এবং মাউন্টিং হার্ডওয়্যারের জন্য এই এনক্লোজারগুলিতে সঠিক কাটআউটের প্রয়োজন। লেজার কাটিং মাত্রার সঠিকতা প্রদান করে যা নিশ্চিত করে যে অ্যাসেম্বলির সময় কোনো পরিবর্তন ছাড়াই উপাদানগুলি ফিট করবে।

মেডিকেল ডিভাইস উৎপাদন সঠিকতাকে আরেকটি স্তরে নিয়ে যায়। সার্জিক্যাল যন্ত্রপাতি, ইমপ্লান্ট উপাদান এবং ডায়াগনস্টিক সরঞ্জামের আবরণ প্রায়শই লেজার-কাট স্টেইনলেস স্টিল বা টাইটানিয়াম অংশ নিয়ে গঠিত। পরিষ্কার প্রান্ত এবং কঠোর সহনশীলতা ব্যাকটেরিয়া ধারণ করা বা স্টেরাইল প্রক্রিয়াকরণে বাধা দেওয়া যে কোনও বার্স অপসারণ করে। 3ERP-এর বিশ্লেষণ যেমন উল্লেখ করেছে, এয়ারোস্পেস এবং মেডিকেল ডিভাইসের মতো শিল্পগুলি শীট মেটাল লেজার কাটিং-এর উপর নির্ভর করে কারণ এটি প্রোটোটাইপিং এবং উৎপাদন উভয় অংশের জন্য সঠিকতা, গতি এবং বহুমুখিত্বকে একত্রিত করে।

শিল্প যন্ত্রপাতি আরও একটি চ্যালেঞ্জিং প্রয়োগের পরিবেশ তৈরি করে। প্রয়োজনীয়তা বিবেচনা করুন:

- মেশিন গার্ড এবং নিরাপত্তা আবদ্ধ স্থান: অপারেটরের দৃষ্টিশক্তি এবং প্রবেশাধিকারের জন্য সুনির্দিষ্ট খোলা অংশ, যদিও সুরক্ষা বজায় রাখা হয়

- নিয়ন্ত্রণ প্যানেলের ফেসপ্লেট: সুইচ, ডিসপ্লে এবং সূচকগুলির জন্য সঠিক কাটআউট

- কনভেয়ার সিস্টেমের উপাদান: ব্র্যাকেট, গাইড এবং কাঠামোগত উপাদান যা সংযোজনের সময় সঠিকভাবে সারিবদ্ধ হতে হবে

- কৃষি সরঞ্জাম: কঠোর পরিবেশে কাজের জন্য ওয়্যার প্লেট, শিল্ড এবং কাঠামোগত উপাদান

প্রোটোটাইপ থেকে উৎপাদন প্রবাহে

হয়তো লেজার কাটিংয়ের সবথেকে বড় প্রভাব হল এটি কীভাবে ধারণা এবং উৎপাদনের মধ্যে ব্যবধান কমায়। ঐতিহ্যবাহী উৎপাদন পদ্ধতি ব্যয়বহুল টুলিং-এর প্রয়োজন ছিল—স্ট্যাম্পিং ডাই, পাঞ্চ এবং ফিক্সচার, যা একবার প্রয়োগ করার পর নকশার পরিবর্তনকে অসম্ভবভাবে ব্যয়বহুল করে তোলে। লেজার কাটিং সেই বাধা দূর করে।

শিল্প পর্যবেক্ষণ অনুযায়ী, স্টার্টআপ এবং ইঞ্জিনিয়ারিং দলগুলি প্রোটোটাইপের জন্য লেজার কাটারের উপর ভারীভাবে নির্ভর করে কারণ ডিজিটাল ফাইল থেকে শারীরিক অংশে দ্রুত পরিবর্তন পরীক্ষা এবং পরিশোধনকে দ্রুত করে তোলে। ঐতিহ্যবাহী টুলিংয়ের তুলনায় প্রাথমিক পর্যায়ের উন্নয়নে লেজার কাটিং খরচ আকাশছোঁয়াভাবে হ্রাস করে।

আধুনিক ফ্যাব্রিকেশন ওয়ার্কফ্লো সাধারণত কীভাবে লেজার কাটিং একীভূত করে:

- ডিজিটাল ডিজাইন: সম্পূর্ণ মাত্রার স্পেসিফিকেশন সহ অংশের জ্যামিতি সংজ্ঞায়িত করে CAD মডেল

- লেজার কাটিং: সূক্ষ্ম বৈশিষ্ট্য এবং আকৃতি সহ শীট স্টক থেকে কাটা হয়েছে এমন ফ্ল্যাট প্যাটার্ন

- আকৃতি প্রদানের কাজ: সিএনসি প্রেস ব্রেকগুলি ফ্ল্যাট অংশগুলিকে ত্রিমাত্রিক আকৃতিতে বাঁকায়

- ওয়েল্ডিং এবং অ্যাসেম্বলি: একাধিক উপাদান সম্পূর্ণ অ্যাসেম্বলিগুলিতে যুক্ত হয়

- ফিনিশিং: পাউডার কোটিং, প্লেটিং বা অন্যান্য পৃষ্ঠ চিকিত্সা অংশটি সম্পন্ন করে

এই একীভূত পদ্ধতির অর্থ হল একটি প্রোটোটাইপ যা উৎপাদন অংশগুলির মতো ঠিক কাজ করে—একটি হাতে তৈরি আনুমানিক যা আলাদভাবে আচরণ করতে পারে। যখন আপনি ফিট এবং ক্রিয়াকলাপ যাচাই করছেন, তখন সেই নির্ভুলতা বিপুল প্রভাব ফেলে।

দ্রুত প্রোটোটাইপিংয়ের সুবিধা প্রাথমিক উন্নয়নের পরেও বিস্তৃত। উৎপাদন চালুকরণের সময় প্রকৌশলগত পরিবর্তনগুলি মহাবিপদের পরিবর্তে নিয়ন্ত্রণযোগ্য হয়ে ওঠে। একটি মাউন্টিং হোলের অবস্থান পরিবর্তন করতে হবে? CAD ফাইলটি আপডেট করুন এবং তাৎক্ষণিকভাবে নতুন অংশগুলি কাটুন—কোনও ডাই পরিবর্তন বা টুলিং বিলম্ব নেই। শাওয়ির মতো 12-ঘন্টার উদ্ধৃতি প্রতিক্রিয়া এবং 5-দিনের প্রোটোটাইপিং ক্ষমতা সহ দ্রুত প্রতিক্রিয়া প্রদানকারী উৎপাদকরা পুনরাবৃত্তিমূলক নকশা চক্রগুলির মাধ্যমে পণ্য উন্নয়ন দলগুলিকে গতি বজায় রাখতে সাহায্য করে।

উৎপাদন স্কেলিংয়ের জন্য, লেজার কাটিং স্বয়ংক্রিয় উপাদান হ্যান্ডলিং এবং রোবটিক সিস্টেমের সাথে সহজেই একীভূত হয়। অনুযায়ী PAR Systems স্বয়ংক্রিয় লেজার কাটিং সিস্টেমগুলি অটোমেটিক ক্যালিব্রেশন ব্যবহার করে পুরো অংশের পরিসরের মধ্যে সঠিক টুল টিপ মুভমেন্ট নিশ্চিত করে—একটি অংশ বা এক মিলিয়ন অংশ উৎপাদন করছেন কিনা তা নির্বিশেষে ধ্রুব মান নিশ্চিত করে।

আপনি যদি প্রোটোটাইপ তৈরি করছেন বা ভলিউম উৎপাদনে চালু করছেন, সেক্ষেত্রে এগিয়ে যাওয়ার জন্য সঠিক ফ্যাব্রিকেশন অংশীদার নির্বাচন করা প্রয়োজন। কী খুঁজবেন তা বোঝা এবং আপনার ডিজাইনগুলিকে সাফল্যের জন্য কীভাবে প্রস্তুত করবেন—এই বিষয়গুলি মসৃণ প্রকল্প বাস্তবায়ন এবং হতাশাজনক বিলম্বের মধ্যে পার্থক্য তৈরি করে।

আপনার ধাতব কাটার প্রকল্পের সাথে শুরু করা

আপনি প্রযুক্তির মৌলিক বিষয়গুলি শিখেছেন, উপাদানের সামঞ্জস্য বুঝতে পেরেছেন এবং খরচের কারণগুলি অনুসন্ধান করেছেন। এখন এসে গেছে বাস্তব প্রশ্ন: আপনি আসলে আপনার লেজার কাটিং প্রকল্পের সাথে কীভাবে এগিয়ে যাবেন? আপনি যদি 'আমার কাছাকাছি ধাতব ফ্যাব্রিকেটর' খুঁজছেন বা সরঞ্জাম ক্রয় মূল্যায়ন করছেন, ডিজাইন ধারণা থেকে শেষ পর্যন্ত অংশগুলির পথ সফল প্রকল্পগুলিকে হতাশাজনক অভিজ্ঞতা থেকে আলাদা করে রাখে—এমন ভাবে পূর্বানুমেয় পদক্ষেপগুলি অনুসরণ করে।

ভালো খবর কি? আপনার নিজের হাতে প্রতিটি প্রযুক্তিগত বিস্তারিত জানা দরকার নেই। যে প্রশ্নগুলি জিজ্ঞাসা করা উচিত তা জানা, আপনার ফাইলগুলি সঠিকভাবে প্রস্তুত করা এবং এমন অংশীদারদের নির্বাচন করা যাদের ক্ষমতা আপনার প্রয়োজনীয়তার সাথে মেলে—এটাই গুরুত্বপূর্ণ। চলুন সেই সিদ্ধান্ত কাঠামোটি দেখে নেওয়া যাক যা দ্রুততার সাথে প্রকল্পগুলি এগিয়ে নেয়।

সঠিক নির্মাণ অংশীদার নির্বাচন

আমার কাছাকাছি একটি নির্ভরযোগ্য ধাতব নির্মাতা খোঁজা শুধুমাত্র কাছাকাছি হওয়ার চেয়ে বেশি কিছু। পিনাকল প্রিসিশনের নির্দেশনা অনুযায়ী, সঠিক অংশীদার শুধু অংশগুলি কাটার চেয়ে বেশি মান যোগান দেয়—তারা দক্ষতা, গুণগত নিয়ন্ত্রণ এবং প্রকল্প সম্পন্ন করার সময়কে উন্নত করে। কিন্তু অসংখ্য বিকল্প থাকা সত্ত্বেও, আপনি কীভাবে ভালো অংশীদারদের যথেষ্ট ভালো থেকে আলাদা করবেন?

এই গুরুত্বপূর্ণ বিষয়গুলি মূল্যায়ন করে শুরু করুন:

- সার্টিফিকেশন এবং অ্যাক্রেডিটেশন: ISO 9001-এর মতো মানের মানদণ্ডগুলি পদ্ধতিগত মান ব্যবস্থাপনাকে চিহ্নিত করে। অটোমোটিভ অ্যাপ্লিকেশনের জন্য, IATF 16949 সার্টিফিকেশন অপরিহার্য হয়ে ওঠে—এটি প্রধান OEM সরবরাহ শৃঙ্খলে প্রবেশের টিকিট। এয়ারোস্পেস কাজের জন্য AS9100D অনুসরণ প্রয়োজন হতে পারে। এই সার্টিফিকেশনগুলি কেবল কাগজপত্র নয়; এগুলি ক্রমাগত অংশের মানের দিকে নিয়ে যায় এমন কঠোর প্রক্রিয়া নিয়ন্ত্রণগুলি নির্দেশ করে।

- ক্ষমতার পরিধি: ওয়ার্কশপটি কি আপনার সম্পূর্ণ ফ্যাব্রিকেশন ওয়ার্কফ্লো পরিচালনা করতে পারে? ধাতুর জন্য লেজার কাটার কেবল শুরুর বিষয়। ফর্মিং, ওয়েল্ডিং, ফিনিশিং এবং অ্যাসেম্বলি সহ একীভূত ক্ষমতাগুলি খুঁজুন। শেষ পর্যন্ত পরিষেবা প্রদানকারী অংশীদাররা একাধিক বিক্রেতাদের মধ্যে সমন্বয়ের ঝামেলা দূর করে।

- ডিএফএম সমর্থন: উৎপাদনের জন্য ডিজাইন দক্ষতা অর্ডার-নেওয়া থেকে প্রকৃত অংশীদারদের আলাদা করে। গুণগত ফ্যাব্রিকেটররা কাটা শুরু হওয়ার আগে আপনার ডিজাইনগুলি সক্রিয়ভাবে পর্যালোচনা করে, সম্ভাব্য সমস্যাগুলি চিহ্নিত করে। এই প্রতিক্রিয়া লুপটি অর্থ এবং সময়সীমা উভয়ই বাঁচায়। যেমন উৎপাদনকারীরা শাওই (নিংবো) ধাতু প্রযুক্তি ডিজাইনকে উৎপাদনের আগেই অপটিমাইজ করতে সাহায্য করে এমন ব্যাপক DFM সমর্থন প্রদান করুন—যা অন্যথায় অসেম্বলির সময় উপস্থিত হওয়া সমস্যাগুলি ধরতে সক্ষম হয়।

- আবর্তন সময়: দ্রুত গতি গুরুত্বপূর্ণ, বিশেষ করে পণ্য উন্নয়নের সময়। দ্রুত উদ্ধৃতি প্রতিক্রিয়া অপারেশনাল দক্ষতার নির্দেশ দেয়—১২-ঘন্টার উদ্ধৃতি আবর্তন সময় সংস্থার মধ্যে সরলীকৃত প্রক্রিয়ার ইঙ্গিত দেয়। প্রোটোটাইপিংয়ের জন্য, ত্বরিত সময়সীমা সম্পর্কে জিজ্ঞাসা করুন। ৫-দিনের দ্রুত প্রোটোটাইপিং সক্ষমতা প্রদানকারী অংশীদাররা উন্নয়ন চক্রগুলিকে এগিয়ে রাখে।

- স্কেলিং ক্ষমতা: আমার কাছাকাছি ধাতব ফ্যাব কি বৃদ্ধি মোকাবেলা করতে পারে? প্রোটোটাইপ দিয়ে শুরু করা সাধারণ, কিন্তু একই অংশীদার উৎপাদনের পরিমাণে স্কেল করতে পারবে সে বিষয়ে আপনার আস্থা থাকা দরকার। ক্ষমতা, স্বয়ংক্রিয়করণ ক্ষমতা এবং উচ্চ পরিমাণে তারা কীভাবে গুণমান বজায় রাখে সে বিষয়ে জিজ্ঞাসা করুন।

রেফারেন্স চেক করা এড়িয়ে যাবেন না। কোন শিল্প খাতগুলিতে পরিষেবা দেওয়া হয়েছে তা জানতে সম্ভাব্য অংশীদারদের কাছ থেকে জিজ্ঞাসা করুন এবং গ্রাহকদের যোগাযোগের তথ্য চান। আপনার খাতে অভিজ্ঞ একটি দোকান প্রযোজ্য নির্দিষ্ট প্রয়োজনীয়তা এবং মানগুলি বোঝে। শিল্প বিশেষজ্ঞদের মতে, মূল্যের চেয়ে খ্যাতি বেশি গুরুত্বপূর্ণ—যখন গুণমান সর্বোচ্চ গুরুত্বপূর্ণ হয়, তখন সবচেয়ে কম খরচের পদ্ধতি কমই সেরা ফলাফল দেয়।

কিনবেন, আউটসোর্স করবেন না হয় হাইব্রিড?

নির্মাতাদের সাথে যোগাযোগ করার আগে, আপনার কৌশলগত পদ্ধতি পরিষ্কার করুন। সিদ্ধান্তের কাঠামোটি তিনটি বিকল্পে বিভক্ত:

সরঞ্জাম ক্রয় করুন যখন আপনার কাছে ধারাবাহিক, উচ্চ-পরিমাণের চাহিদা থাকে এবং 60% এর বেশি ব্যবহারের হার বজায় রাখতে পারেন। একটি শীট মেটাল কাটার উল্লেখযোগ্য মূলধন বিনিয়োগ প্রতিনিধিত্ব করে কিন্তু স্কেলে প্রতি ইউনিটের সবচেয়ে কম খরচ দেয়। পূর্বানুমানযোগ্য কাজের ভার এবং লেজার অপারেশনগুলি সমর্থনের জন্য অবস্থার সাথে নিবেদিত উৎপাদন সুবিধার জন্য এই পথটি যুক্তিযুক্ত।

সম্পূর্ণরূপে আউটসোর্স করুন যখন আপনার চাহিদা মাঝে মাঝে হয়, অত্যন্ত পরিবর্তনশীল হয়, অথবা আপনি এখনও পণ্য উন্নয়নের পর্যায়ে থাকেন। আমার কাছাকাছি ধাতু কর্মশালা খোঁজা প্রায়শই এমন দক্ষ অংশীদারদের দিকে নিয়ে যায় যারা আপনার নির্দিষ্ট নির্দেশ অনুযায়ী ধাতু লেজার কাটিং করতে পারে এবং আপনার পক্ষ থেকে কোনও মূলধন বিনিয়োগ ছাড়াই। আপনি শুধুমাত্র আপনার প্রয়োজনীয় জিনিসের জন্য অর্থ প্রদান করুন, এমন সরঞ্জাম এবং দক্ষতার সুবিধা নিন যা অভ্যন্তরীণভাবে উন্নয়ন করতে বছরের পর বছর লাগবে।

সংকর পদ্ধতি অনেক ক্ষেত্রেই এটি কাজ করে। হয়তো আপনি নিজেদের মধ্যে নিয়মিত কাটিং কাজ করেন কিন্তু আপনার সরঞ্জামের বাইরের ক্ষমতা প্রয়োজন হলে তা বাইরে প্রেরণ করেন। অথবা ডিজাইন স্থিতিশীল হওয়ার পরে অভ্যন্তরীণ উৎপাদনে স্কেলিং করার সময় আপনি বাইরে প্রোটোটাইপিং করেন। চাহিদা বৃদ্ধির সময় অতিরিক্ত ক্ষমতার জন্য অংশীদারদের খুঁজে পেতে "আমার কাছাকাছি CNC মেশিন" অনুসন্ধান করতে পারে।

আপনার ডিজাইন ফাইলগুলি সাফল্যের জন্য প্রস্তুত করা

আপনার CAD ফাইলগুলি হল নকশা উদ্দেশ্য এবং চূড়ান্ত অংশগুলির মধ্যে যোগাযোগের সেতু। খারাপ ফাইল প্রস্তুতি দীর্ঘস্থায়ী হয়, ভুল বোঝাবুঝি এবং প্রত্যাশার সাথে মেলে না এমন অংশগুলি তৈরি করে। ডেটাম অ্যালয়ের গাইড অনুসারে , আপনার ডিজাইনগুলি ত্রুটিহীন, সূক্ষ্মভাবে কাটা অংশে রূপান্তরিত হওয়ার দিকে একটি ছোট প্রস্তুতি অনেক দূরে যায়।

এই ফাইল প্রস্তুতির প্রয়োজনীয় বিষয়গুলি অনুসরণ করুন:

- পরিষ্কার 2D CAD ফরম্যাট ব্যবহার করুন: DWG এবং DXF ফাইলগুলি সর্বজনীনভাবে কাজ করে। কাটার ফাইল থেকে শিরোনাম ব্লক, মাত্রা রেখা এবং বিবরণ সরিয়ে দিন—এগুলি পৃথকভাবে PDF-এ রেফারেন্সের জন্য সরবরাহ করুন। ওভারল্যাপিং, ডুপ্লিকেট বা ফ্রেম ছাড়া প্রতি ফাইলে শুধুমাত্র একটি উপাদান অন্তর্ভুক্ত করুন।

- অবিচ্ছিন্ন রেখা নিশ্চিত করুন: সমস্ত কাটার পথ সম্পূর্ণ এবং বদ্ধ হতে হবে। ভাঙা, ড্যাশ করা বা ওভারল্যাপ করা রেখাগুলি কাটা শুরু করার আগে পরিষ্কার করার প্রয়োজন। লেজার সিস্টেমগুলি খণ্ডিত জ্যামিতি ব্যাখ্যা করতে পারে না, যার ফলে ফ্যাব্রিকেটরদের আপনার ফাইলগুলি মেরামত করার সময় বিলম্ব ঘটে।

- ড্রয়িংগুলি 1:1 স্কেল করুন: সর্বদা প্রকৃত আকারে এক্সপোর্ট করুন। স্কেল মিল না হওয়ার ফলে অংশগুলি খুব ছোট বা খুব বড় কাটা হয়—এমন একটি সহজেই এড়ানো যায় এমন ত্রুটি যা উপকরণ এবং সময় নষ্ট করে।

- কার্ফ অ্যালাউন্স বুঝুন: লেজার বিম কাটার সময় উপাদানটি সরিয়ে ফেলে, যা একটি কাটার প্রস্থ তৈরি করে যাকে কার্ফ বলা হয়। এই উপাদান অপসারণের বিষয়টি বিবেচনায় নিয়ে গুরুত্বপূর্ণ মাত্রা ডিজাইন করুন, অথবা এটি উল্লেখ করুন যে মাত্রাগুলি কাটার কেন্দ্ররেখা নির্দেশ করে না হয় চূড়ান্ত প্রান্তের অবস্থান নির্দেশ করে।

- সহনশীলতা স্পষ্টভাবে উল্লেখ করুন: Jiga-এর DFM গাইড অনুযায়ী, লেজার কাটিং সাধারণত অধিকাংশ অ্যাপ্লিকেশনের জন্য ±0.1মিমি-এর মধ্যে সহনশীলতা অর্জন করে। কোন মাত্রাগুলি গুরুত্বপূর্ণ এবং কোনগুলির নমনীয়তা বেশি তা নির্ধারণ করুন। এটি নির্মাতাদের যেখানে সবচেয়ে বেশি প্রয়োজন সেখানে সঠিকতা অগ্রাধিকার দিতে সাহায্য করে।

জ্যামিতির বাইরে, উপাদানের স্পেসিফিকেশনগুলি সম্পূর্ণভাবে উল্লেখ করুন। উপাদানের ধরন, পুরুত্ব, গ্রেড এবং কোনও পৃষ্ঠের সমাপ্তির প্রয়োজনীয়তা চিহ্নিত করুন। আপনার অংশটির বাঁকানো, আবরণ বা অন্য কোনও পোস্ট-প্রসেসিং প্রয়োজন হলে, নির্মাতারা যাতে সম্পূর্ণ কাজের প্রবাহ পরিকল্পনা করতে পারেন সেজন্য সেই প্রয়োজনগুলি আগেভাগেই চিহ্নিত করুন।

ধাপে ধাপে প্রকল্প চালু প্রক্রিয়া

শুরু করার জন্য প্রস্তুত? ধারণা থেকে কাটিং-এ দক্ষতার সাথে এগিয়ে যাওয়ার জন্য এই প্রমাণিত ক্রমটি অনুসরণ করুন:

- আপনার প্রয়োজনীয়তা স্পষ্টভাবে নির্ধারণ করুন: কাউকে যোগাযোগ করার আগে, আপনার প্রয়োজনগুলি নথিভুক্ত করুন—উপাদানের ধরন এবং পুরুত্ব, পরিমাণ, সহনশীলতার প্রয়োজন, পৃষ্ঠের সমাপ্তির প্রত্যাশা এবং সময়সীমার বাধ্যবাধকতা। আপনি যত বেশি নির্দিষ্ট হবেন, তত বেশি নির্ভুল উদ্ধৃতি পাবেন।

- আপনার CAD ফাইলগুলি প্রস্তুত করুন: জ্যামিতি পরিষ্কার করুন, 1:1 স্কেলে মাত্রা যাচাই করুন এবং প্রতিটি অনন্য অংশের জন্য আলাদা ফাইল তৈরি করুন। নির্মাতার তথ্যের জন্য মাত্রা এবং নোট সহ একটি PDF অন্তর্ভুক্ত করুন।

- একাধিক উৎস থেকে উদ্ধৃতি অনুরোধ করুন: তিন থেকে পাঁচটি সম্ভাব্য অংশীদারের সাথে যোগাযোগ করুন। প্রত্যেককে একই তথ্য প্রদান করুন যাতে উদ্ধৃতিগুলি সরাসরি তুলনা করা যায়। মূল্যের বাইরেও দেখুন—দ্রুত প্রতিক্রিয়া, জিজ্ঞাসিত প্রশ্ন এবং প্রদত্ত DFM প্রতিক্রিয়া মূল্যায়ন করুন।

- DFM প্রতিক্রিয়া পর্যালোচনা করুন: গুণগত নির্মাতারা সম্ভাব্য সমস্যা বা অপ্টিমাইজেশনের সুযোগগুলি চিহ্নিত করবে। তাদের পরামর্শগুলি গুরুত্বের সাথে বিবেচনা করুন—তারা হাজার হাজার অনুরূপ প্রকল্প দেখেছে এবং কী কাজ করে তা জানে।

- উপাদান এবং সমাপ্তির বিবরণ নিশ্চিত করুন: নিশ্চিত করুন যে উদ্ধৃত উপকরণগুলি আপনার প্রয়োজনীয়তা মেটাচ্ছে। পৃষ্ঠতলের সমাপ্তির প্রত্যাশা এবং পোস্ট-প্রসেসিংয়ের প্রয়োজনীয়তা নিয়ে আলোচনা করুন। এখানে ভুল বোঝাবুঝি সবচেয়ে সাধারণ প্রকল্প ব্যর্থতার কারণ হয়।

- একটি নমুনা বা প্রোটোটাইপ অনুমোদন করুন: উৎপাদনের পরিমাণের জন্য, প্রথমে প্রোটোটাইপ যাচাইয়ে বিনিয়োগ করুন। এটি পূর্ণ উৎপাদনে নিশ্চিত হওয়ার আগে অংশটি ক্রিয়াকলাপের প্রয়োজনীয়তা পূরণ করছে কিনা তা নিশ্চিত করে। দ্রুত প্রোটোটাইপিং ক্ষমতা—যেমন 5-দিনের পরিণতি—সময়সূচীর প্রভাব কমিয়ে দেয়।

- গুণমান চেকপয়েন্ট স্থাপন করুন: পরিদর্শনের মানদণ্ড এবং গ্রহণযোগ্যতার মান সংজ্ঞায়িত করুন। গুরুত্বপূর্ণ অ্যাপ্লিকেশনের জন্য, প্রক্রিয়াকরণের সময় পরিদর্শন এবং চূড়ান্ত যাচাইয়ের প্রোটোকল নিয়ে আলোচনা করুন।

- পুনরাবৃত্তির জন্য পরিকল্পনা করুন: প্রথম নিবন্ধগুলি খুব কমই নিখুঁতভাবে আসে। আপনার সময়সূচীতে পরিমার্জন চক্রের জন্য সময় যোগ করুন। দ্রুত প্রতিক্রিয়াশীল ক্ষমতা সহ অংশীদাররা আপনাকে গতি হারানোর ছাড়াই দ্রুত পুনরাবৃত্তি করতে সাহায্য করে।

সমস্যা প্রতিরোধের জন্য যোগাযোগ

সবচেয়ে সফল প্রকল্পগুলির মধ্যে সবসময় সক্রিয় যোগাযোগ থাকে। ধরে নেবেন না যে নির্মাতারা অস্পষ্ট বিবরণগুলি সঠিকভাবে ব্যাখ্যা করবে—আপনার উদ্দেশ্য স্পষ্টভাবে উল্লেখ করুন। গুরুত্বপূর্ণ যোগাযোগের বিষয়গুলির মধ্যে রয়েছে:

- গুরুত্বপূর্ণ বৈশিষ্ট্যসমূহ: কোন মাত্রা এবং বৈশিষ্ট্যগুলি কার্যকরভাবে গুরুত্বপূর্ণ, আর কোনগুলিতে নমনীয়তা রয়েছে তা চিহ্নিত করুন।

- প্রান্তের গুণমানের প্রত্যাশা: উল্লেখ করুন যে অক্সাইড-স্তরের প্রান্তগুলি গ্রহণযোগ্য কিনা নাকি নাইট্রোজেন-কাট পরিষ্কার প্রান্তগুলি প্রয়োজন।

- পরিমাণ বিবেচনা: আলোচনা করুন যে পরিমাণ পরিবর্তিত হতে পারে কিনা। মূল্য দক্ষতার জন্য অপ্টিমাল ব্যাচ আকার সম্পর্কে নির্মাতারা পরামর্শ দিতে পারেন।

- সময়সীমার নমনীয়তা: যদি সময়সূচীতে শিথিলতা থাকে, তা উল্লেখ করুন—বাড়তি খরচ যুক্ত হয় যা বাস্তবসম্মত সময়সীমা থাকলে এড়ানো যেতে পারে।

- দীর্ঘমেয়াদী সম্পর্কের সম্ভাবনা: যদি এই প্রকল্পটি চলমান কাজের দিকে নিয়ে যেতে পারে, তা উল্লেখ করুন। প্রায়শই নির্মাতারা বৃদ্ধির সম্ভাবনা সহ সম্পর্কগুলিতে অতিরিক্ত মনোযোগ দেয়।

মনে রাখবেন, আপনার ফ্যাব্রিকেশন পার্টনারের সাফল্য নির্ভর করে আপনার সাফল্যের উপর। সেরা সম্পর্কগুলি লেনদেনমূলক নয়, বরং সহযোগিতামূলক বোধ হয়। আপনি যদি ভালোভাবে প্রস্তুত হন, পরিষ্কারভাবে যোগাযোগ করেন এবং এমন পার্টনারদের নির্বাচন করেন যাদের দক্ষতা আপনার প্রয়োজনের সাথে মিলে যায়, তবে প্রতিটি লেজার কাটিং প্রকল্পকে মসৃণ কার্যকরীকরণ এবং চমৎকার ফলাফলের জন্য অবস্থান করা হয়।

লেজার কাটিং মেটাল সম্পর্কে প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

1. ধাতু লেজার কাটিং-এর খরচ কত?

মেটাল লেজার কাটিংয়ের খরচ একাধিক উপাদানের উপর ভিত্তি করে ব্যাপকভাবে পরিবর্তিত হয়। প্রতি পিস মূল্যনীতি নির্ভর করে উপাদানের ধরন ও পুরুত্ব, অংশের জটিলতা, পরিমাণ এবং কিনারার গুণমানের প্রয়োজনীয়তার উপর। সাধারণত প্রতি কাজের জন্য সেটআপ খরচ $15-30 এর মধ্যে হয়, আর অতিরিক্ত কাজের জন্য শ্রম ফি ঘন্টায় প্রায় $60 হয়। সরঞ্জাম ক্রয়ের ক্ষেত্রে, শিল্প লেজার কাটারগুলি প্রবেশপথের সিস্টেমের জন্য 250,000 ডলার থেকে শুরু হয়ে স্বয়ংক্রিয় উচ্চ-ক্ষমতাসম্পন্ন ফাইবার লেজারের ক্ষেত্রে 2 মিলিয়ন ডলারের বেশি হয়। অপারেটিং খরচের মধ্যে রয়েছে বিদ্যুৎ, সহায়ক গ্যাস (অক্সিজেন বা নাইট্রোজেন), খরচযোগ্য উপকরণ এবং রক্ষণাবেক্ষণ—রক্ষণাবেক্ষণের জন্য মেশিনের মূল্যের 5-10% বার্ষিক বাজেট করা হয়।

2. লেজার কাটার দিয়ে কোন কোন ধাতু কাটা যায়?

লেজার কাটারগুলি মাইল্ড স্টিল, স্টেইনলেস স্টিল, অ্যালুমিনিয়াম, তামা, পিতল এবং টাইটানিয়াম সহ বিভিন্ন ধাতু প্রক্রিয়াকরণের জন্য কার্যকর। প্রতিফলনের হার কম হওয়ায় মাইল্ড স্টিল কাটা সবচেয়ে সহজ। স্টেইনলেস স্টিল চমৎকার কিনারা গুণমান দেয়। অ্যালুমিনিয়াম এবং তামার মতো প্রতিফলক ধাতুগুলি CO2 লেজারের পরিবর্তে ফাইবার লেজার প্রযুক্তি প্রয়োজন করে যাতে বীম প্রতিফলনের সমস্যা এড়ানো যায়। টাইটানিয়ামের ওজনের তুলনায় সবচেয়ে বেশি শক্তি থাকে এবং এটি সাধারণত এয়ারোস্পেস এবং চিকিৎসা অ্যাপ্লিকেশনে ব্যবহৃত হয়। লেজার পাওয়ারের উপর নির্ভর করে উপাদানের পুরুত্বের ক্ষমতা—3000W সিস্টেম 20mm কার্বন স্টিল এবং 10mm স্টেইনলেস স্টিল পর্যন্ত কাটতে পারে।

3. ফাইবার লেজার কাটিং এবং CO2 লেজার কাটিং এর মধ্যে তুলনা কী?

ফাইবার লেজারগুলি CO2 সিস্টেমের তুলনায় প্রায় 35% বৈদ্যুতিক দক্ষতায় কাজ করে, যা CO2 এর ক্ষেত্রে 10-20%। এর ফলে অপারেটিং খরচ কম হয়। ফাইবার লেজারগুলি অ্যালুমিনিয়াম এবং তামা সহ প্রতিফলিত ধাতু কাটাতে উত্কৃষ্ট, 20 মিটার প্রতি মিনিট গতিতে পাতলা উপকরণ কাটতে পারে এবং 100,000 ঘন্টা পর্যন্ত আয়ুসহ ন্যূনতম রক্ষণাবেক্ষণের প্রয়োজন হয়। 20 মিমির বেশি পুরু উপকরণে CO2 লেজার ফাইবারের চেয়ে ভালো করে, ভারী প্লেটগুলিতে মসৃণ কাটের প্রান্ত তৈরি করে। CO2 সিস্টেমগুলি কাঠ, অ্যাক্রিলিক এবং প্লাস্টিক সহ অ-ধাতব উপকরণগুলি পরিচালনা করতে পারে, যা মিশ্র উপকরণের উৎপাদন পরিবেশের জন্য এগুলিকে আরও বহুমুখী করে তোলে।

4. ধাতু কাটার জন্য লেজার কাটিংয়ের ক্ষেত্রে কী কী নিরাপত্তা সতর্কতা প্রয়োজন?

লেজার কাটিংয়ের নিরাপত্তা একাধিক স্তরের সুরক্ষার প্রয়োজন। অপারেটরদের তরঙ্গদৈর্ঘ্য-নির্দিষ্ট লেজার সুরক্ষা চশমা, উপযুক্ত আলোক ঘনত্ব রেটিং, জ্বলন-প্রতিরোধী পোশাক, চামড়ার তৈরি হাত ও ইস্পাত-খচিত জুতা পরা আবশ্যিক। ধোঁয়া নিষ্কাশন ব্যবস্থা সহ উপযুক্ত ভেন্টিলেশন অপরিহার্য— জ্যালভানাইজড ইস্পাত কাটার সময় দস্তা অক্সাইডের ধোঁয়া নির্গত হয় যা ধাতব ধোঁয়া জ্বরের কারণ হতে পারে। সুবিধাগুলিতে অবশ্যই লকযুক্ত আবদ্ধ কক্ষ, সতর্কতামূলক সাইনবোর্ড, জরুরি বন্ধ করার ব্যবস্থা এবং অগ্নি নিরোধক ব্যবস্থা থাকা আবশ্যিক। OSHA Class IV লেজারের জন্য একজন নির্দিষ্ট লেজার সুরক্ষা কর্মকর্তার (Laser Safety Officer) প্রয়োজন এবং অপারেটরদের ঝুঁকি চেনার, জরুরি পদ্ধতি এবং সরঞ্জাম-নির্দিষ্ট প্রোটোকল সম্পর্কে প্রশিক্ষণ নেওয়া আবশ্যিক।

5. আমার কখন লেজার কাটিং সরঞ্জাম কেনা উচিত এবং কখন আউটসোর্সিং করা উচিত?

যখন আপনার 60% এর বেশি ব্যবহারের হারের সাথে ধ্রুবক উচ্চ-পরিমাণ প্রয়োজন থাকে তখন সরঞ্জাম ক্রয় করুন—এটি সাধারণত বিনিয়োগের পরিমাণের উপর নির্ভর করে 6-18 মাসের মধ্যে ROI দেয়। প্রোটোটাইপ রান, মাসে 100টির কম অংশ বা অত্যন্ত পরিবর্তনশীল উৎপাদনের প্রয়োজনের জন্য আউটসোর্স করুন। বাল্ক ক্রয় এবং অপটিমাইজড অপারেশনের কারণে শিল্প ফ্যাব্রিকেটররা প্রায়শই আপনার কাঁচামালের খরচের চেয়ে সস্তায় অংশ তৈরি করে। এমন হাইব্রিড পদ্ধতি বিবেচনা করুন যেখানে নিয়মিত কাটিং অভ্যন্তরীণভাবে ঘটে এবং বিশেষায়িত কাজ বাহ্যিক অংশীদারদের কাছে যায়। শুধুমাত্র সরঞ্জামের মূল্য নয়, সুবিধার প্রয়োজন, প্রশিক্ষণ, খরচযোগ্য উপকরণ এবং রক্ষণাবেক্ষণসহ মোট মালিকানা খরচ মূল্যায়ন করুন।

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —