স্ট্যাম্পড স্টিল কন্ট্রোল আর্ম মেরামত করা যায়? একটি নিরাপত্তা গাইড

সংক্ষেপে

স্ট্যাম্পড স্টিলের কন্ট্রোল আর্মগুলি প্রযুক্তিগতভাবে মেরামত করা সম্ভব হলেও, এটি খুব কমই সুপারিশকৃত সমাধান। ঠাণ্ডা ঘূর্ণিত ইস্পাতের ক্ষেত্রে অভিজ্ঞ পেশাদার দ্বারা ছোট ছোট ফাটল ওয়েল্ডিং করা যেতে পারে, কিন্তু একটি গুরুত্বপূর্ণ সাসপেনশন উপাদান ব্যর্থ হওয়ার সাথে যুক্ত নিরাপত্তা ঝুঁকি প্রায়শই সম্ভাব্য খরচ সাশ্রয়ের চেয়ে বেশি হয়। ক্ষতি, ক্ষয় বা ক্ষয়ক্ষতি জড়িত অধিকাংশ পরিস্থিতির জন্য, নতুন OEM অংশ দিয়ে কন্ট্রোল আর্ম প্রতিস্থাপন করা বা শক্তিশালী কাস্ট বা ফোর্জড স্টিলের বিকল্পে আপগ্রেড করা সবচেয়ে নিরাপদ এবং নির্ভরযোগ্য পদক্ষেপ।

স্ট্যাম্পড স্টিলের কন্ট্রোল আর্ম মেরামতের সম্ভাব্যতা

যখন একটি স্ট্যাম্পড ইস্পাতের কন্ট্রোল আর্ম—আপনার গাড়ির ফ্রেমকে স্টিয়ারিং নাকাসির সঙ্গে সংযুক্ত করার একটি গুরুত্বপূর্ণ উপাদান—ফাটল ধরে, তখন প্রথমেই প্রশ্ন ওঠে যে একটি সাধারণ মেরামত কি যথেষ্ট হবে। স্ট্যাম্পড স্টিলের বাহুগুলি ইস্পাতের চাদরগুলিকে একটি নির্দিষ্ট আকৃতিতে চাপ দিয়ে তৈরি করা হয় এবং তারপর ওয়েল্ডিং করে জোড়া দেওয়া হয়। কিছু অভিজ্ঞ মেকানিকদের মতে, এই ধরনের "কোল্ড রোল স্ট্যাম্পড স্টিল" বিদেশী উপকরণ দিয়ে তৈরি নয় এবং এটি ওয়েল্ড করা যেতে পারে। তবে, এমন মেরামতের সম্ভাবনা খুবই শর্তসাপেক্ষ এবং ঝুঁকিপূর্ণ।

সফল মেরামত সাধারণত খুব নির্দিষ্ট পরিস্থিতিতে সীমাবদ্ধ থাকে, যেমন একটি ছোট, পরিষ্কার চুলের রেখা ফাটল। এই প্রক্রিয়াটির জন্য একটি উচ্চ দক্ষ ওয়েল্ডারকে ফাটলটি 'পরিষ্কার' করতে হবে, যা নিশ্চিত করে যে কাঠামোগত অখণ্ডতা পুনরুদ্ধার করতে এটি নতুন ধাতু দিয়ে পূরণ করার আগে ক্ষতি সম্পূর্ণরূপে সরানো হয়েছে। এটা কোনো নবীনের কাজ নয়। একটি নিয়ন্ত্রণ বাহুতে যে কোনও মেরামত প্রচেষ্টা যা বাঁকা, উল্লেখযোগ্যভাবে ক্ষয় হয়ে যায়, বা বুশিং মাউন্ট বা বল জয়েন্ট সকেটগুলির মতো সমালোচনামূলক চাপের পয়েন্টগুলির কাছে ক্ষতিগ্রস্থ হয় তা দৃ strongly়ভাবে নিরুৎসাহিত করা হয়।

এমনকি যদি একটি সোল্ডার নিখুঁতভাবে সম্পন্ন করা হয়, সোল্ডার প্রক্রিয়া থেকে তাপ আশেপাশের ধাতুর মেজাজ পরিবর্তন করতে পারে, সম্ভাব্য নতুন দুর্বল পয়েন্ট তৈরি করতে পারে। মূল সমস্যা হল যে একটি নিয়ন্ত্রণ বাহু ব্রেকিং, ত্বরণ, বাঁক এবং রাস্তার ত্রুটি থেকে ক্রমাগত গতিশীল চাপের অধীনে থাকে। একটি ব্যর্থ সোল্ডার গাড়ির নিয়ন্ত্রণের একটি বিপর্যয়কর ক্ষতি হতে পারে। এই কারণে, যদিও প্রযুক্তিগতভাবে সম্ভব, স্ট্যাম্প করা ইস্পাত নিয়ন্ত্রণ বাহু ঢালাই একটি সমাধান যা অত্যন্ত সতর্কতার সাথে যোগাযোগ করা উচিত।

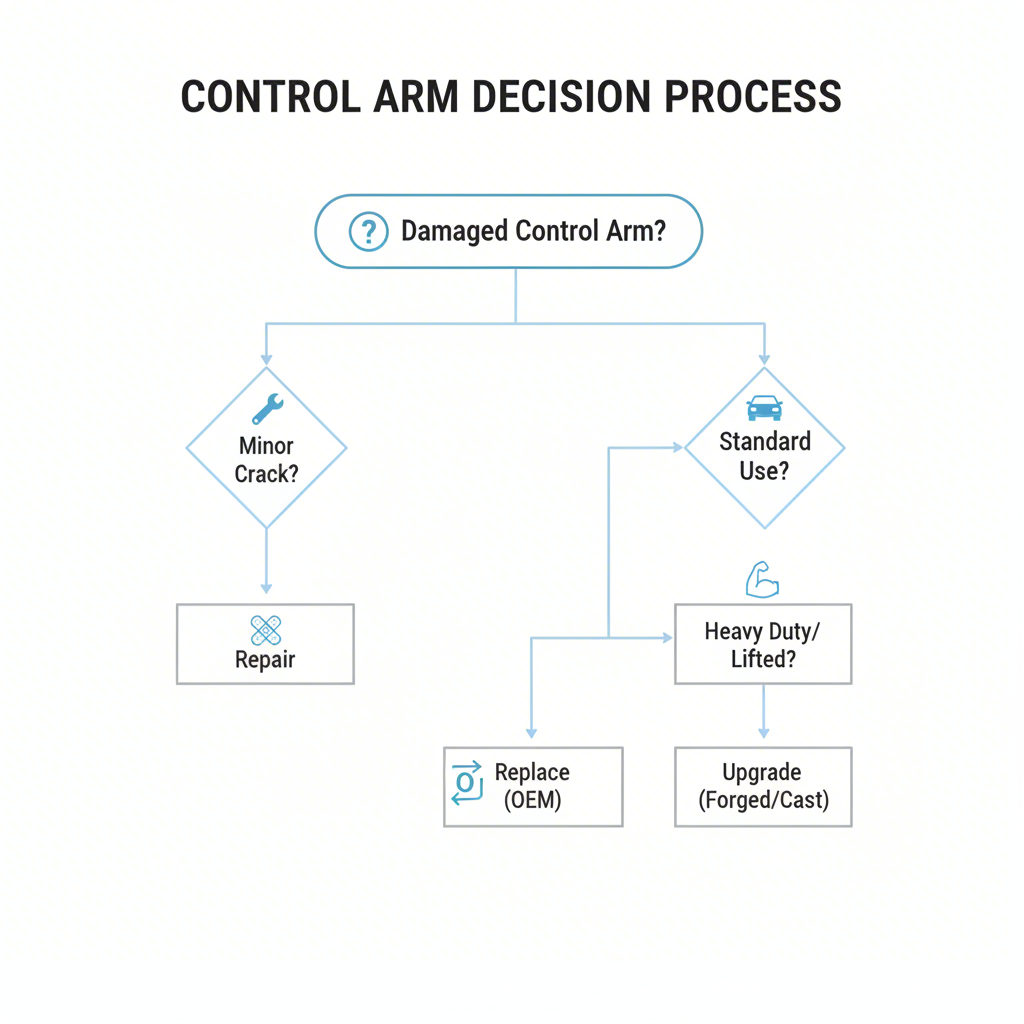

মেরামত বনাম প্রতিস্থাপন: একটি গুরুত্বপূর্ণ সিদ্ধান্ত কাঠামো

ক্ষতিগ্রস্ত কন্ট্রোল আর্ম মেরামত করা না প্রতিস্থাপন করা হবে, সেই সিদ্ধান্ত নেওয়ার সময় খরচ, নিরাপত্তা এবং দীর্ঘমেয়াদী নির্ভরযোগ্যতা বিবেচনা করা হয়। শুধুমাত্র একটি সাধারণ ওয়েল্ডিং-এর মাধ্যমে মেরামত করলে প্রথমে সবচেয়ে সস্তা বিকল্প মনে হতে পারে, কিন্তু এটি সবচেয়ে বেশি ঝুঁকি বহন করে। অন্যদিকে, প্রতিস্থাপন করলে মানসিক শান্তি পাওয়া যায় এবং এটি অধিকাংশ অটোমোটিভ পেশাদারদের দ্বারা সুপারিশকৃত আদর্শ পদ্ধতি। একক কন্ট্রোল আর্ম প্রতিস্থাপনের খরচ প্রায় $400 থেকে $1,000 পর্যন্ত হতে পারে, যার মধ্যে শ্রম খরচ উল্লেখযোগ্য অংশ জুড়ে থাকে। এই কাজের সাথে প্রায়শই বল জয়েন্ট এবং বুশিংয়ের মতো সংশ্লিষ্ট উপাদানগুলি প্রতিস্থাপন করা হয়, এবং তার পরে চাকার সঠিক সাজানো (wheel alignment) বাধ্যতামূলক হয়ে ওঠে।

প্রায়শই এক-এর-জন্য-এক প্রতিস্থাপনের বাইরেও চয়েসটি চলে যায়। অনেক যানবাহন মালিক, বিশেষ করে ট্রাক বা এসইউভি যাদের হাতে, যারা লেভেলিং কিটের মতো পরিবর্তন করার পরিকল্পনা করেন, তারা স্ট্যাম্পড স্টিলের ভাঙা আর্মকে উন্নয়নের একটি সুযোগ হিসাবে দেখেন। স্ট্যাম্পড স্টিলের আর্মগুলি কম শক্তিশালী হওয়ার জন্য পরিচিত, এবং নতুন সাসপেনশন জ্যামিতির অধীনে বল জয়েন্টগুলি খুলে যাওয়ার মতো সমস্যাগুলি সাধারণভাবে উদ্বেগের বিষয়। আরও টেকসই কাস্ট আয়রন বা ফোর্জড স্টিল কন্ট্রোল আর্মে আপগ্রেড করা যানবাহনের ভবিষ্যতের কর্মক্ষমতা এবং নিরাপত্তার জন্য শক্তি এবং দীর্ঘায়ু বৃদ্ধি করতে পারে, যা একটি বুদ্ধিমান বিনিয়োগ হিসাবে দাঁড়ায়।

আপনার সিদ্ধান্ত নেওয়ার জন্য সহায়তা করার জন্য, আপনার মেকানিকের সাথে আলোচনার সময় নিম্নলিখিত বিষয়গুলি বিবেচনা করুন:

| Option | অনুমান করা খরচ | নিরাপত্তা এবং ভরসা | স্থায়িত্ব | জন্য সেরা |

|---|---|---|---|---|

| ওয়েল্ড মেরামত | কম (ওয়েল্ডারের শ্রম) | কম থেকে মাঝারি (ব্যর্থ হওয়ার উচ্চ ঝুঁকি) | প্রশ্নাতীত | অগুরুত্বপূর্ণ যানবাহনে ছোট ছোট পরিষ্কার ফাটল, এবং শুধুমাত্র যদি একজন বিশেষজ্ঞ দ্বারা করা হয়। |

| ওইএম প্রতিস্থাপন | মাঝারি ($400 - $1,000) | উচ্চ (কারখানার মান পুনরুদ্ধার করে) | ভালো (মূল যন্ত্রাংশের আয়ুর সাথে মিলে যায়) | ক্ষয়, ক্ষুবণ বা সামান্য ধাক্কার কারণে ক্ষতিগ্রস্ত অধিকাংশ সাধারণ যাত্রীবাহী যান। |

| আফটারমার্কেট আপগ্রেড | মাঝারি থেকে উচ্চ | খুব উচ্চ (প্রায়শই OEM স্পেসের চেয়ে বেশি) | চমৎকার | ট্রাক, এসইউভি, পারফরম্যান্স যান বা সাসপেনশন পরিবর্তনকৃত (উত্তোলন, ইত্যাদি) যানগুলি। |

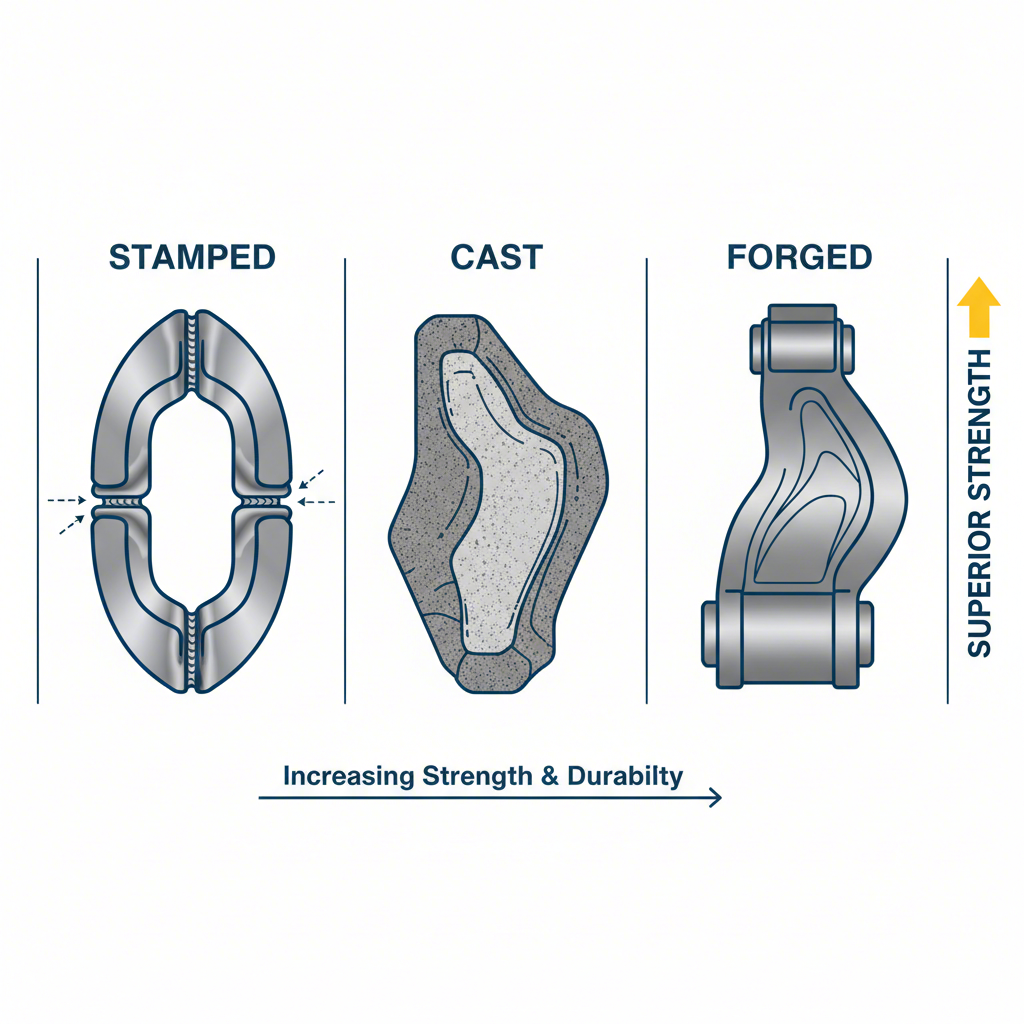

কন্ট্রোল আর্মের উপাদান সম্পর্কে ধারণা: স্ট্যাম্পড বনাম কাস্ট বনাম ফোর্জড

সব কন্ট্রোল আর্ম সমান তৈরি হয় না। উৎপাদন পদ্ধতি এবং ব্যবহৃত উপাদানের ওপর তাদের শক্তি, ওজন এবং খরচের সরাসরি প্রভাব পড়ে। প্রতিস্থাপন বা আপগ্রেড বিবেচনা করার সময়, বিশেষ করে আপনার যানের জন্য, এই পার্থক্যগুলি বোঝা অত্যন্ত গুরুত্বপূর্ণ।

স্ট্যাম্পড স্টিল: এটি সবচেয়ে সাধারণ এবং ব্যয়বহুল প্রকার, যা অনেক আধুনিক যাত্রী গাড়িতে পাওয়া যায়। এটি স্টিলের শীটকে দুই ভাগে ছাঁটাই করে এবং তারপর একসাথে ঝালাই করে তৈরি করা হয়। যদিও তারা স্ট্যান্ডার্ড ড্রাইভিং অবস্থার জন্য পর্যাপ্ত, তারা সাধারণত তিনটি ধরনের মধ্যে কম টেকসই। এই উপাদানগুলির গুণমান নির্ভর করে নির্ভুল উত্পাদন উপর। অটোমোবাইল নির্মাতাদের জন্য উচ্চমানের অংশ সংগ্রহ করা অপরিহার্য এবং বিশেষায়িত সরবরাহকারী যেমন শাওয়াই (নিংবো) মেটাল টেকনোলজি কো., লিমিটেড প্রোটোটাইপিং থেকে শুরু করে ভর উৎপাদন পর্যন্ত যথার্থ ধাতব স্ট্যাম্পিং সমাধান সরবরাহের উপর দৃষ্টি নিবদ্ধ করা, উপাদানগুলি আইএটিএফ ১৬৯৪৯ এর মতো কঠোর শিল্প মান পূরণ করে তা নিশ্চিত করা।

কাস্ট আয়রন/অ্যালুমিনিয়াম: ঢালাই নিয়ন্ত্রণ বাহু একটি ছাঁচে ঢালা ধাতু ঢালাই দ্বারা তৈরি করা হয়। ঢালাই লোহা খুব শক্তিশালী এবং নমন প্রতিরোধী, এটিকে ভারী দায়িত্বের যানবাহন যেমন ট্রাক এবং এসইউভিগুলির জন্য একটি জনপ্রিয় পছন্দ করে তোলে যা কঠোর অবস্থার সাথে সহ্য করে। ঢালাই অ্যালুমিনিয়াম লোহার চেয়ে হালকা এবং শক্তি এবং ওজন সাশ্রয়ের একটি ভাল ভারসাম্য সরবরাহ করে, প্রায়শই যানবাহনে ব্যবহৃত হয় যেখানে চালনা কর্মক্ষমতা হ্রাস করার জন্য অস্পর্শ ওজন হ্রাস করা অগ্রাধিকার।

গঠিত ইস্পাত/অ্যালুমিনিয়াম: কাঠের কাঠের একটি কঠিন টুকরা প্রচণ্ড চাপের অধীনে গরম করা হয় এবং চাপের অধীনে আকৃতির মধ্যে চাপ দেওয়া হয়। এই প্রক্রিয়া ধাতুর অভ্যন্তরীণ শস্য কাঠামোকে সারিবদ্ধ করে, যার ফলে একটি অংশ তৈরি হয় যা ব্যতিক্রমীভাবে শক্তিশালী এবং ক্লান্তি এবং আঘাতের প্রতিরোধী। কাঠের নিয়ন্ত্রণ বাহু সর্বোচ্চ স্তরের শক্তি এবং স্থায়িত্ব প্রদান করে, যা তাদের পারফরম্যান্স, অফ-রোড এবং ভারী দায়িত্ব অ্যাপ্লিকেশনের জন্য প্রিমিয়াম পছন্দ করে।

| উপাদান প্রকার | উৎপাদন প্রক্রিয়া | প্রধান সুবিধাসমূহ | প্রধান অসুবিধা | সাধারণ যানবাহন প্রকার |

|---|---|---|---|---|

| স্ট্যাম্পড ইস্পাত | স্টিলের শীট, চাপানো এবং ঝালাই করা | উৎপাদনের জন্য সস্তা, হালকা ওজন | কম টেকসই, বাঁক / ফাটল প্রবণ | স্ট্যান্ডার্ড ব্যক্তিগত গাড়ি এবং হালকা ট্রাক |

| কাস্ট আয়রন/অ্যালুমিনিয়াম | একটি ছাঁচে ঢালাই করা গলিত ধাতু | খুব শক্ত (লোহা), ওজন তুলনায় ভাল শক্তি (অ্যালুমিনিয়াম) | ভারী (লোহা), কাঠের চেয়ে বেশি ভঙ্গুর | ভারী-ডুয়িং ট্রাক, এসইউভি, কিছু পারফরম্যান্স গাড়ি |

| কাঠের/অ্যালুমিনিয়াম | ধাতু উত্তপ্ত এবং আকৃতির মধ্যে চাপানো | উত্কৃষ্ট শক্তি এবং ক্লান্তি প্রতিরোধ | উৎপাদন সবচেয়ে ব্যয়বহুল | উচ্চ-কার্যকারিতা গাড়ি, অফ-রোড যানবাহন, প্রিমিয়াম ট্রাক |

আপনার নিয়ন্ত্রণ বাহুগুলি কীভাবে চিহ্নিত করবেন এবং ব্যর্থতার লক্ষণগুলি কীভাবে সনাক্ত করবেন

আপনি মেরামত বা প্রতিস্থাপনের বিষয়ে সিদ্ধান্ত নেওয়ার আগে, আপনাকে প্রথমে আপনার গাড়ির কোন ধরনের নিয়ন্ত্রণ বাহন রয়েছে তা সনাক্ত করতে হবে এবং সম্ভাব্য সমস্যার লক্ষণগুলি সনাক্ত করতে হবে। প্রথম পদক্ষেপ হল একটি চাক্ষুষ পরিদর্শন। স্ট্যাম্প করা ইস্পাত বাহু সাধারণত দুটি সি-চ্যানেল টুকরো একসাথে welded হয়, তাই আপনি প্রায়ই প্রান্ত বরাবর একটি seam দেখতে পারেন। ছাঁটাই করা এবং কাঠের অস্ত্র একক, কঠিন ধাতু টুকরা মত দেখায়।

আপনার কন্ট্রোল আর্মগুলি ইস্পাত কিনা তা নিশ্চিত করার একটি সহজ ও কার্যকর উপায় হল চুম্বক পরীক্ষা। যদি একটি চুম্বক কন্ট্রোল আর্মে দৃঢ়ভাবে লেগে থাকে, তবে এটি ইস্পাতের তৈরি (স্ট্যাম্পড বা কাস্ট আয়রন)। যদি না লাগে, তবে সম্ভবত এটি কাস্ট অ্যালুমিনিয়ামের তৈরি। আপনার নির্দিষ্ট যানবাহনের জন্য সঠিক প্রতিস্থাপন অংশ বা আপগ্রেড বিকল্প নিয়ে আপনার এবং আপনার মেকানিকের আলোচনার জন্য এই দ্রুত পরীক্ষাটি সাহায্য করতে পারে।

আরও গুরুত্বপূর্ণভাবে, আপনার কন্ট্রোল আর্মের ব্যর্থতার লক্ষণগুলি চিনতে সক্ষম হতে হবে। সময়ের সাথে চাপ এবং পরিবেশের প্রভাবের কারণে এই উপাদানগুলি ক্ষয়প্রাপ্ত হয়। এই লক্ষণগুলি উপেক্ষা করা বিপজ্জনক হতে পারে। নিম্নলিখিত লক্ষণগুলির যেকোনোটির প্রতি সতর্ক থাকুন:

- খটখট বা ধাক্কা শব্দ: আপনার গাড়ির সামনের দিক থেকে আসা শব্দ, বিশেষ করে বাঁক, গতি বাধা বা খারাপ ভূখণ্ডের উপর দিয়ে যাওয়ার সময়, প্রায়শই কন্ট্রোল আর্ম অ্যাসেম্বলিতে ক্ষয়প্রাপ্ত বুশিং বা বল জয়েন্টের দিকে ইঙ্গিত করে।

- স্টিয়ারিং হুইল কম্পন: উচ্চতর গতিতে, বিশেষ করে কাঁপুনি বা কম্পনশীল স্টিয়ারিং হুইল হতে পারে একটি লক্ষণ যে কন্ট্রোল আর্ম বুশিং ক্ষয়প্রাপ্ত হয়েছে, যা চাকার অতিরিক্ত গতির কারণ হয়।

- ঢিলেঢালা বা অস্পষ্ট স্টিয়ারিং: যদি আপনার গাড়িটি রাস্তায় দুলতে থাকে বা স্টিয়ারিং প্রতিক্রিয়া ঢিলেঢালা এবং অস্পষ্ট হয়, তবে এটি নিয়ন্ত্রণ আর্মের দুর্বলতার কারণে আপনার স্টিয়ারিং লিঙ্কেজ ক্ষতিগ্রস্ত হওয়ার ইঙ্গিত দিতে পারে।

- অসম টায়ারের পরিধান: নিয়ন্ত্রণ আর্মের ক্ষয়ক্ষত উপাদানগুলি আপনার যানবাহনের সারিবদ্ধতা নষ্ট করে দিতে পারে, যার ফলে আপনার টায়ারের ভিতরের বা বাইরের কিনারাগুলি ট্রেডের অন্যান্য অংশের তুলনায় অনেক দ্রুত ক্ষয় হয়ে যায়।

- দৃশ্যমান ক্ষতি বা ক্ষয়: দৃশ্যমান পরীক্ষায় যদি বিশেষ মাত্রায় মরচে ধরা, ফাটল বা বাঁকা নিয়ন্ত্রণ আর্ম দেখা যায়, তবে এটি একটি তাৎক্ষণিক সতর্কতা সংকেত।

যদি আপনি এই লক্ষণগুলির মধ্যে কোনওটি লক্ষ্য করেন, তবে আপনার যানবাহনটি একজন যোগ্য মেকানিক দ্বারা পরীক্ষা করানো অত্যন্ত জরুরি। নিয়ন্ত্রণ আর্মের ত্রুটি একটি গুরুতর নিরাপত্তা সমস্যা যা বিলম্ব ছাড়াই সমাধান করা উচিত।

নিরাপত্তাকে অগ্রাধিকার: নিয়ন্ত্রণ আর্ম মেরামতি সম্পর্কে চূড়ান্ত সিদ্ধান্ত

যদিও খুব সীমিত পরিস্থিতিতে স্ট্যাম্পড ইস্পাত নিয়ন্ত্রণ বাহুতে ওয়েল্ডিংয়ের ধারণা কারিগরি দিক থেকে সম্ভব, তবু অটোমোটিভ সম্প্রদায়ের মধ্যে প্রতিস্থাপনের পক্ষেই সম্মতি বেশি। আপনার গাড়ির সাসপেনশন এবং স্টিয়ারিং সিস্টেমের জন্য নিয়ন্ত্রণ বাহু একটি মৌলিক অংশ, যেখানে ব্যর্থতার কোনও সুযোগ নেই। চাপের মুখে ওয়েল্ডিংয়ের ব্যর্থতা বা মেরামতের প্রক্রিয়ায় চারপাশের ধাতু দুর্বল হয়ে যাওয়ার সম্ভাবনা এমন ঝুঁকি তৈরি করে যা সামান্য খরচ বাঁচানোর জন্য মোটেও উপযুক্ত নয়।

অবশেষে, সবসময় নিরাপত্তাকে সর্বোচ্চ অগ্রাধিকার দিয়ে সিদ্ধান্ত নেওয়া উচিত। ক্ষতিগ্রস্ত বা পরিধানযুক্ত নিয়ন্ত্রণ বাহুটি একটি গুণগত OEM বা উন্নত আফটারমার্কেট অংশ দিয়ে প্রতিস্থাপন করলে গাড়ির অখণ্ডতা ফিরে পাওয়া যায় এবং ভবিষ্যদ্বাণীযোগ্য, নিরাপদ হ্যান্ডলিং নিশ্চিত করা হয়। যখন আপনি একটি ক্লাঙ্ক শব্দ শুনবেন বা কম্পন অনুভব করবেন, তখন এটিকে অসুবিধা হিসাবে না দেখে আপনার গাড়িতে একটি গুরুত্বপূর্ণ নিরাপত্তা বিনিয়োগের সুযোগ হিসাবে দেখুন।

প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

1. কাস্ট আয়রন এবং ষ্ট্যাম্পড ইস্পাত নিয়ন্ত্রণ বাহুগুলির মধ্যে পার্থক্য কী?

স্ট্যাম্পড ইস্পাতের কন্ট্রোল আর্মগুলি চাপা এবং ওয়েল্ডেড ইস্পাতের শীট থেকে তৈরি, যার ফলে এগুলি হালকা ও সস্তা হয়, তাই অনেক যাত্রীবাহী গাড়িতে এগুলি সাধারণ। খাদ্য লোহার কন্ট্রোল আর্মগুলি গলিত লোহা ছাঁচে ঢালার মাধ্যমে তৈরি করা হয়, যার ফলে ভারী, আরও দৃঢ় অংশ তৈরি হয় যা ট্রাক এবং এসইউভির মতো কঠোর অবস্থায় কাজ করে এমন ভারী যানবাহনের জন্য উপযুক্ত।

2. আমার কাছে স্ট্যাম্পড স্টিল কন্ট্রোল আর্ম আছে কিনা তা কীভাবে বুঝব?

স্ট্যাম্পড ইস্পাত এবং কাস্ট অ্যালুমিনিয়াম আলাদা করার সবচেয়ে সহজ পদ্ধতি হল চুম্বক পরীক্ষা: চুম্বক ইস্পাতে লেগে থাকবে কিন্তু অ্যালুমিনিয়ামে নয়। স্ট্যাম্পড ইস্পাত এবং কাস্ট আয়রন আলাদা করতে, সিম (seam) খুঁজুন। স্ট্যাম্পড ইস্পাতের আর্মগুলি সাধারণত দুটি অর্ধেককে ওয়েল্ডিং করে তৈরি করা হয়, তাই আপনি প্রায়শই একটি দৃশ্যমান সিম বা ওয়েল্ড লাইন দেখতে পাবেন, যেখানে কাস্ট আর্মগুলি একক, কঠিন টুকরোর মতো দেখায়।

3. স্ট্যাম্পড এবং ফোর্জড কন্ট্রোল আর্মের মধ্যে পার্থক্য কী?

প্রাথমিক পার্থক্যটি হল শক্তি, যা উৎপাদন প্রক্রিয়া থেকে আসে। স্ট্যাম্পড অ্যার্মগুলি চাপা ইস্পাতের পাত থেকে সংযুক্ত করা হয়। ফোর্জড কন্ট্রোল আর্মগুলি ধাতবের একটি কঠিন টুকরোকে উত্তপ্ত করে এবং এটিকে আকৃতি দেওয়ার জন্য অপরিসীম চাপ প্রয়োগ করে তৈরি করা হয়। এই ফোর্জিং প্রক্রিয়াটি ধাতবের অভ্যন্তরীণ গ্রেনগুলিকে সারিবদ্ধ করে, যা স্ট্যাম্পড অ্যার্মের তুলনায় উল্লেখযোগ্যভাবে শক্তিশালী এবং ক্লান্তি ও আঘাতের প্রতি বেশি প্রতিরোধী উপাদান তৈরি করে।

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —