অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়া: সেরা অনুশীলনের গাইড

আধুনিক গাড়ি তৈরিতে অটোমোটিভ মেটাল স্ট্যাম্পিং এর ভূমিকা

যখন আপনি একটি গাড়ি মালপত্র সরিয়ে দেখেন, তখন কি কখনও ভেবেছেন যে এর বডি প্যানেল, ব্রাকেট এবং জটিল উপাদানগুলি কীভাবে এত নিখুঁতভাবে গঠিত হয়? উত্তরটি হল অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ায়—আজকের যানবাহন উত্পাদনের একটি প্রধান ভিত্তি। এই পদ্ধতিটি সমতল ধাতব শীটগুলিকে উচ্চ-মানের, স্থিতিশীল এবং খরচে কম খরচে অংশগুলিতে রূপান্তরিত করে যা প্রতিটি গাড়ির মূল অংশ গঠন করে।

অটোমোবাইল শিল্পের জন্য কেন মেটাল স্ট্যাম্পিং আবশ্যিক?

হাজার বা এমনকি লক্ষাধিক অভিন্ন গাড়ির অংশ উত্পাদনের চ্যালেঞ্জের কথা কল্পনা করুন, যার প্রতিটি অংশের ক্ষেত্রেই কঠোর সহনশীলতা এবং জটিল আকৃতি রয়েছে। জটিল শোনাচ্ছে? ঠিক এখানেই মেটাল স্ট্যাম্পিং গাড়ি উত্পাদনে এর প্রকৃত মূল্য প্রকাশ করে:

- নির্ভুলতা: বিশেষায়িত স্ট্যাম্পিং ডাইস এবং উন্নত প্রেসগুলি ধাতুকে নির্ভুল আকৃতিতে গঠন করে, নিরাপত্তা এবং নির্ভরযোগ্যতার জন্য শিল্পের কঠোর মানগুলি প্রতিটি অংশ মেনে চলে।

- কার্যকারিতা: উচ্চ-গতি এবং উচ্চ-পরিমাণ উত্পাদনের জন্য এই প্রক্রিয়াটি ডিজাইন করা হয়েছে, উৎপাদকদের খরচ নিয়ন্ত্রণ করে বৈশ্বিক চাহিদা পূরণের অনুমতি দেয়।

- বহুমুখিতা: ফেন্ডার এবং চ্যাসিস উপাদানগুলি থেকে শুরু করে কাস্টম ব্রাকেট এবং অ্যাফটারমার্কেট অ্যাক্সেসরিজ পর্যন্ত, আধুনিক যানগুলিতে স্ট্যাম্পড অংশগুলি সর্বত্র ব্যবহৃত হয়।

- খরচ-কার্যকারিতা: উপকরণের অপচয় কমিয়ে এবং উত্পাদন প্রবাহিত করে, স্ট্যাম্পিং গ্রাহকদের জন্য গাড়িগুলিকে সস্তা রাখে যাতে মানের কোনো ত্রুটি না হয়।

শিল্প পূর্বাভাস অনুযায়ী, স্ট্যাম্পিং প্রযুক্তির অব্যাহত উন্নয়ন এবং গাড়ির ডিজাইনে ধাতব উপাদানগুলির বৃদ্ধি পাওয়া ব্যবহারের জন্য ধাতব স্ট্যাম্পড অটোমোটিভ অংশগুলির চাহিদা প্রায় 150 বিলিয়ন ডলারে পৌঁছানোর পথে।

এই গাইডে আপনি কী শিখবেন?

এই ব্যাপক নিবন্ধটি আপনাকে পরিচয় করিয়ে দেবে:

- অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ার মূল নীতিগুলি এবং পদক্ষেপের পর পদক্ষেপ বিশ্লেষণ

- গাড়ি তৈরির মূল কৌশল এবং প্রযুক্তি সমূহ

- উপকরণের পছন্দ, মান নিয়ন্ত্রণ পদক্ষেপ এবং শিল্পের সেরা অনুশীলনগুলি

- অটোমোটিভ মেটাল স্ট্যাম্পিংয়ের ভবিষ্যতের গঠনে আগামী প্রবণতা এবং নবায়ন

যে কোনও প্রকৌশলী, ক্রেতা বা অটোমোটিভ উৎসাহীদের জন্য, অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ার মৌলিক বিষয়গুলি বুঝতে পারলে তাঁরা উপলব্ধি করতে পারবেন যে কীভাবে নির্ভুলতা, দক্ষতা এবং নবায়ন একত্রিত হয়ে আগামী দিনের গাড়িগুলি তৈরি করছে।

মেটাল স্ট্যাম্পিং কী?

কখনও কি ভেবেছেন কীভাবে একটি সমতল ধাতব টুকরো থেকে একটি চকচকে গাড়ির ফেন্ডার, একটি শক্তিশালী ব্র্যাকেট বা জটিল চ্যাসিস উপাদান তৈরি হয়? এর উত্তর হল শীট মেটাল স্ট্যাম্পিং প্রক্রিয়ায়— যা অটোমোটিভ উত্পাদনের একটি প্রধান ভিত্তি এবং যা নির্ভুল প্রকৌশল এবং উচ্চ-গতির দক্ষতার সমন্বয় ঘটায়। কিন্তু এই রূপান্তরের সময় ঠিক কী ঘটে এবং কেন লক্ষ লক্ষ অভিন্ন অংশ উৎপাদনের জন্য এটি এতটাই কার্যকর?

শীট মেটাল স্ট্যাম্পিং প্রক্রিয়া বোঝা

এর মূল অংশে, মেটাল স্ট্যাম্পিং হল একটি উত্পাদন পদ্ধতি যেখানে সমতল ধাতব শীটগুলি—প্রায়শই ব্লাঙ্ক নামে পরিচিত—বল, বিশেষজ্ঞ ডাইস এবং স্ট্যাম্পিং প্রেসের সংমিশ্রণ ব্যবহার করে নির্দিষ্ট আকৃতিতে গঠন করা হয়। কোনও ময়দা টুকরোকে কুকি কাটারের মধ্যে রেখে চাপ দেওয়ার কথা কল্পনা করুন; ময়দা কাটারের আকৃতি ধারণ করে। মেটাল স্ট্যাম্পিং-এ নীতিটি অনুরূপ, তবে অনেক বড় এবং আরও নির্ভুল স্কেলে।

- ব্লাঙ্ক: ইস্পাত বা অ্যালুমিনিয়ামের সমতল শীটগুলি কেটে আকার অনুযায়ী করে স্ট্যাম্পিং প্রেসে ঢোকানো হয়।

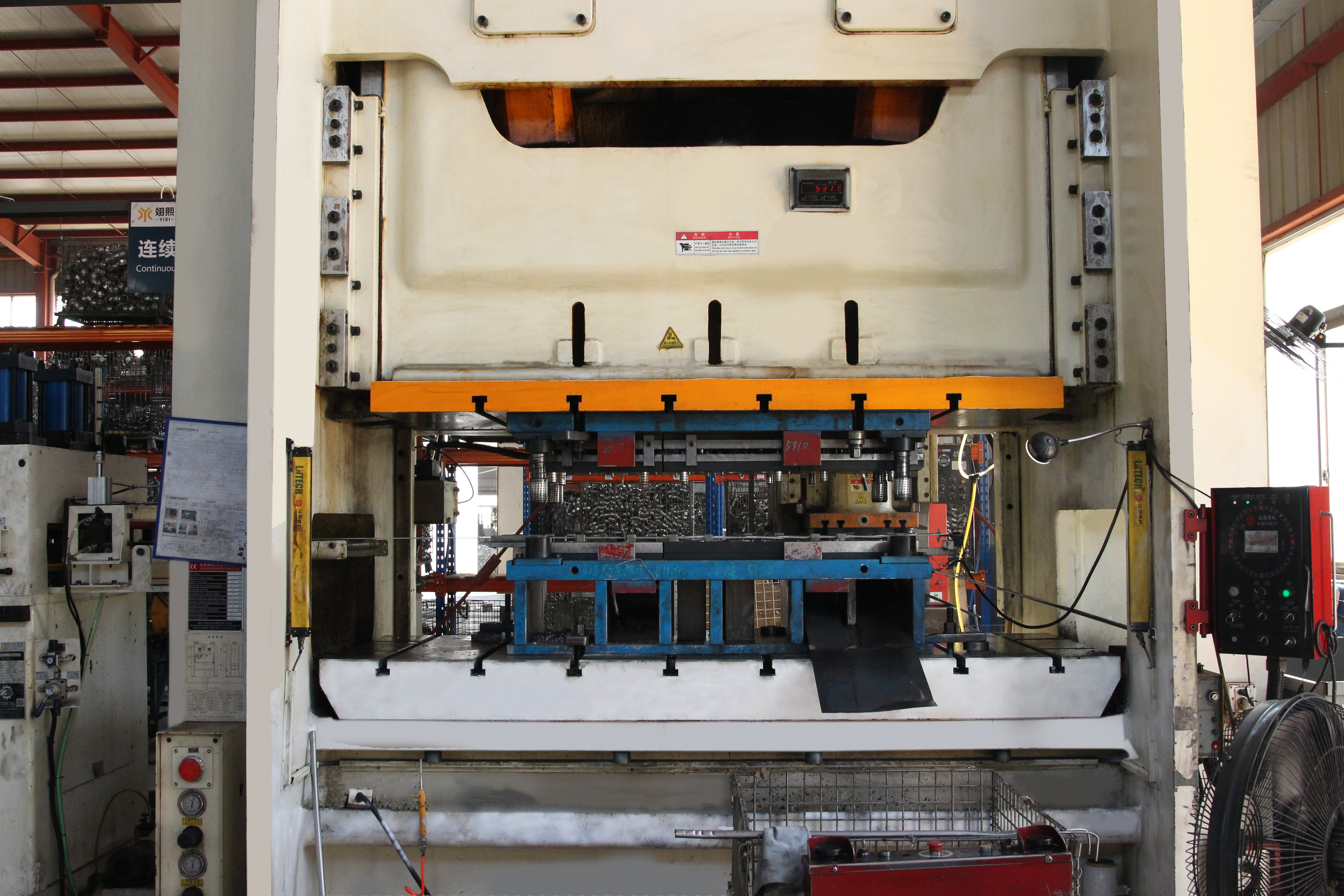

- স্ট্যাম্পিং প্রেস: এই মেশিনটি যান্ত্রিক, হাইড্রোলিক বা সার্ভো-চালিত সিস্টেম ব্যবহার করে উল্লেখযোগ্য বল প্রয়োগ করে, ব্লাঙ্কটিকে একটি ডাইয়ের মধ্যে ঠেলে দেয়—যেমনটি প্রয়োজন হয় তেমন আকৃতি দেয়, কাটে বা পাঞ্চ করে।

- ডাইস: যথারীতি নির্মিত সরঞ্জামগুলি অংশটির চূড়ান্ত আকৃতি এবং বৈশিষ্ট্যগুলি নির্ধারণ করে। প্রতিটি উপাদানের জন্য ডাইগুলি কাস্টম তৈরি করা হয়, যা নির্ভুলতা এবং পুনরাবৃত্তি নিশ্চিত করে।

ব্লাঙ্কিং, পিয়ার্সিং, বেঁকিং এবং ড্রয়িংয়ের মতো সতর্কভাবে নিয়ন্ত্রিত পদক্ষেপগুলির মাধ্যমে স্ট্যাম্পিং প্রক্রিয়া ক্রমান্বয়ে কাঁচামালকে জটিল, ত্রিমাত্রিক অটোমোটিভ অংশে রূপান্তরিত করে (টুলিং মেটাল) .

অটোমোটিভ অংশগুলির জন্য স্ট্যাম্পিং কেন আদর্শ?

যখন আপনি আধুনিক গাড়ির দিকে তাকান, তখন আপনি এর ধাতব অংশগুলির বৈচিত্র্য এবং জটিলতা লক্ষ্য করবেন। স্ট্যাম্পিং কয়েকটি গুরুত্বপূর্ণ কারণে এই চাহিদা মেটাতে সন্তুলিতভাবে উপযুক্ত:

- কার্যকারিতা: স্ট্যাম্পিং প্রেসগুলি প্রতি ঘন্টায় হাজার হাজার অংশ উৎপাদন করতে পারে, যা উচ্চ-ভলিউম অটোমোটিভ উৎপাদনের জন্য এটিকে নিখুঁত করে তোলে।

- পুনরাবৃত্তি সাধনযোগ্যতা: একবার সেট আপ করার পরে, প্রক্রিয়াটি স্থির ফলাফল দেয়, প্রতিটি অংশ কঠোর শিল্প সহনশীলতা মেটানো নিশ্চিত করে।

- নির্ভুলতা: উন্নত ডাই ডিজাইন এবং প্রেস প্রযুক্তির মাধ্যমে জটিল আকৃতি, কঠোর বেঁক, এবং জটিল বৈশিষ্ট্যগুলি অর্জন করা সম্ভব হয়—শতাংশের মাত্র এক হাজার অংশ পর্যন্ত সহনশীলতা নিয়ে।

- খরচ-কার্যকারিতা: উৎপাদন স্বয়ংক্রিয়করণ এবং অপচয় কমিয়ে আনার মাধ্যমে স্ট্যাম্পিং বড় এবং জটিল অংশগুলির জন্যও ব্যয় নিয়ন্ত্রণযোগ্য রাখতে সাহায্য করে।

ধরুন, একটি গাড়ির দরজার প্যানেল তৈরির কথা। স্ট্যাম্পিং প্রক্রিয়ার মাধ্যমে প্রস্তুতকারকরা কয়েক সেকেন্ডের মধ্যে প্যানেলটিকে আকৃতি দিতে পারেন, কেটে ফেলতে পারেন এবং ছিদ্র করতে পারেন, প্রায় কোনও পরিবর্তন ছাড়াই হাজার হাজার বার প্রক্রিয়াটি পুনরাবৃত্তি করতে পারেন। এই ধরনের দক্ষতা এবং নির্ভুলতা অটোমোটিভ ব্র্যান্ডগুলির জন্য অত্যন্ত গুরুত্বপূর্ণ যেগুলির মান এবং কম খরচে উভয় ক্ষেত্রেই সরবরাহ করা প্রয়োজন।

ফ্ল্যাট শীট থেকে শেষ করা অংশ: পদক্ষেপ অনুসারে স্ট্যাম্পিং প্রক্রিয়া

তাহলে, একটি সাধারণ শীট কীভাবে একটি শেষ অটোমোটিভ অংশে পরিণত হয়? সাধারণত জড়িত পদক্ষেপগুলির একটি দ্রুত ওভারভিউ এখানে:

- উপকরণ প্রস্তুতি: ধাতব শীটগুলি নির্বাচন করা হয় এবং ব্ল্যাঙ্কগুলিতে কাটা হয়।

- খাওয়ানোঃ ব্ল্যাঙ্কগুলি ম্যানুয়ালি বা স্বয়ংক্রিয় সিস্টেমের মাধ্যমে স্ট্যাম্পিং প্রেসে খাওয়ানো হয়।

- আকৃতি দেওয়া: প্রেস এবং ডাই একসাথে এক বা একাধিক অপারেশনের মাধ্যমে ধাতুটিকে কাঙ্খিত আকৃতিতে আকৃতি দেয়, কাটা হয় বা ছিদ্র করা হয়।

- ফিনিশিং: অতিরিক্ত প্রক্রিয়া যেমন ট্রিমিং, ডেবারিং বা পৃষ্ঠ চিকিত্সার মাধ্যমে চূড়ান্ত স্পেসিফিকেশন অর্জনের জন্য অংশগুলি পার হতে পারে।

- পরীক্ষা: সমাপ্ত অংশগুলি অসেম্বলি বা চালানের আগে মান এবং মাত্রিক নির্ভুলতা পরীক্ষা করা হয়।

এই সুশৃঙ্খল পদ্ধতি নিশ্চিত করে উচ্চমানের ফলাফল এবং দ্রুত, বৃহদাকার উৎপাদনের প্রয়োজনীয়তা সমর্থন করে থাকে। পরবর্তীতে, আমরা এই ধাপগুলি বিস্তারিতভাবে বিশ্লেষণ করব, প্রতিটি পর্যায় কীভাবে গুরুত্বপূর্ণ অটোমোটিভ উপাদানগুলি তৈরিতে অবদান রাখে তা তুলে ধরব।

অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ার প্রধান ধাপসমূহ

যখন আপনি একটি গাড়ির চকচকে ফেন্ডার বা একটি শক্তিশালী চেসিস ব্র্যাকেটের কথা কল্পনা করেন, তখন কি কখনও ভেবেছেন যে কীভাবে একটি সাদামাটা ধাতব শীট এমন নির্ভুল আকৃতিতে রূপান্তরিত হয়? এই রূপান্তর সংঘটিত হয় গাড়ি উৎপাদনে স্ট্যাম্পিং প্রক্রিয়া নামে পরিচিত পদক্ষেপগুলির একটি সুসংগত সিরিজ দ্বারা। চলুন এই প্রধান পর্যায়গুলি বিশ্লেষণ করি, বাস্তব অটোমোটিভ উদাহরণসহ, যাতে আপনি প্রতিটি পদক্ষেপ কীভাবে প্রতিটি গাড়ির অংশগুলি গঠন করে তা দৃশ্যমানভাবে বুঝতে পারেন।

মেটাল স্ট্যাম্পিং প্রক্রিয়া প্রবাহ চার্ট বোঝা

গাড়ির ধাতব স্ট্যাম্পিং প্রক্রিয়াকে একটি প্রবাহ চিত্র হিসাবে ভাবুন - সতর্কতার সাথে নিয়ন্ত্রিত অপারেশনের একটি ক্রম। প্রতিটি পর্যায় পূর্ববর্তীটির উপর নির্ভর করে, নিশ্চিত করে যে চূড়ান্ত অংশটি গুণমান, ফিট এবং কার্যকারিতার কঠোর মানগুলি পূরণ করে। এখানে সরলীকৃত প্রবাহটি দেখুন যা আপনি অধিকাংশ গাড়ি কারখানায় পাবেন:

- উপকরণ প্রস্তুতি এবং ব্লাঙ্কিং

- পিয়ের্সিং

- বাঁকানো

- অঙ্কন/গঠন

- সমাপ্তি এবং পরিদর্শন

আসুন প্রতিটি পদক্ষেপ অনুসরণ করি, তাদের গুরুত্বের ব্যাখ্যা করতে ব্যবহারিক গাড়ি উদাহরণ ব্যবহার করি।

1. উপকরণ প্রস্তুতি এবং ব্লাঙ্কিং

সবকিছু শুরু হয় বৃহৎ কুণ্ডলী বা ধাতুর পাত দিয়ে - সাধারণত ইস্পাত বা অ্যালুমিনিয়াম। এগুলি আনকয়েলড হয় এবং ছোট, পরিচালনযোগ্য টুকরাে কাটা হয় যাকে বলা হয় ব্লাঙ্ক । ব্লাঙ্কিং হল পাত থেকে অংশটির মূল রূপরেখা কাটার প্রক্রিয়া। একটি কুকিজ কাটার যন্ত্র দিয়ে ময়দা কাটার কথা কল্পনা করুন; ব্লাঙ্কিং দরজার প্যানেল, ফেন্ডার বা ব্রাকেটের মতো অংশগুলির প্রাথমিক আকৃতি তৈরি করে। এই পদক্ষেপটি মৌলিক, কারণ এটি পরবর্তী সমস্ত অপারেশনের জন্য কাঁচা আকার এবং সীমানা নির্ধারণ করে।

২. ছিদ্র

একবার ব্লাঙ্ক প্রস্তুত হয়ে গেলে, পরবর্তী পদক্ষেপ হল পিয়ার্সিং—অংশটিতে ছিদ্র বা খোলা স্থান তৈরি করা। এগুলি মাউন্টিং বোল্ট, তারের লাইন, হ্যান্ডেল বা অন্যান্য বৈশিষ্ট্যের জন্য হতে পারে। উদাহরণস্বরূপ, চেসিস ব্রাকেটে যে মাউন্টিং ছিদ্রগুলি দেখা যায় বা দরজার প্যানেলে জানালার খোলা অংশগুলি এই পর্যায়ে তৈরি করা হয়। অংশের জটিলতার উপর নির্ভর করে ব্লাঙ্কিংয়ের একই ডাইয়ে পিয়ার্সিং করা হয়, কিন্তু আলাদা অপারেশনও হতে পারে।

৩. বাঁকানো

এখন সমতল ব্লাঙ্ক ত্রিমাত্রিক আকৃতি নিতে শুরু করে। বেঁকে যাওয়া মানে ধাতুকে একটি সোজা রেখা বরাবর বিকৃত করে কোণ বা বক্রতা তৈরি করা। সিট ব্রাকেটের তীক্ষ্ণ ভাঁজ বা ফেন্ডারের ধারে সূক্ষ্ম বক্রতা ভাবুন। অটোমোটিভ অংশগুলির শক্তি এবং দৃঢ়তা যোগ করার জন্য বেঁকে যাওয়া অত্যন্ত গুরুত্বপূর্ণ, যাতে গাড়ি চালানোর সময় সেগুলি ভার এবং চাপ সহ্য করতে পারে।

4. ড্রয়িং/ফর্মিং

এখানেই সত্যিকারের আকর্ষণ শুরু হয়। ড্রইং বা ডিপ ড্রইং ধাতুকে টেনে বা প্রসারিত করে জটিল ত্রিমাত্রিক আকৃতি তৈরি করে। এই পদ্ধতিতে তেলের পাত্র, চাকার খাঁচা বা গাড়ির ঢাকনার বক্র পৃষ্ঠের মতো গভীর অংশগুলি তৈরি করা হয়। ড্রইংয়ের জন্য নির্ভুল ডাই ডিজাইন এবং ভাঁজ বা ছিদ্র রোধের জন্য সতর্ক নিয়ন্ত্রণের প্রয়োজন। ফর্মিং একটি ব্যাপক শব্দ যার মধ্যে ড্রইংয়ের পাশাপাশি অন্যান্য আকৃতি তৈরির কাজ যেমন মৃদু বক্ররেখা বা দেহের প্যানেলগুলিতে পাওয়া যায় তা অন্তর্ভুক্ত থাকে।

5. সমাপ্তকরণ এবং পরিদর্শন

চূড়ান্ত পদক্ষেপগুলি প্রতিটি অংশ নির্দিষ্ট মান পূরণ করছে কিনা তা নিশ্চিত করে। সমাপ্তকরণে অতিরিক্ত উপকরণ কাটার প্রক্রিয়া, ধারগুলি মসৃণ করা বা ক্ষয় প্রতিরোধের জন্য পৃষ্ঠ চিকিত্সা প্রয়োগ করা হতে পারে। পরিদর্শনে মাত্রিক নির্ভুলতা, পৃষ্ঠের গুণমান এবং কাঠামোগত সামগ্রিকতা পরীক্ষা করা হয়। এই পরীক্ষা পাশ করার পরেই অংশগুলি সমাবেশ বা আরও প্রক্রিয়াজাতকরণের জন্য পাঠানো হয়।

বাস্তব উদাহরণ: প্রতিটি যানবাহনে স্ট্যাম্পড অংশ

- ফেন্ডার এবং দেহ প্যানেল: ড্রয়িং এবং ফর্মিংয়ের মাধ্যমে খালি অবস্থা থেকে আকৃতি তৈরি করা হয়, মাউন্টিং ছিদ্রের জন্য পিয়ার্সিং এবং চূড়ান্ত ফিটিংয়ের জন্য ট্রিমিং করা হয়।

- চ্যাসিস কম্পোনেন্টস: বেন্ডিং এবং ড্রয়িংয়ের মাধ্যমে ফ্লোর প্যান, ক্রস মেম্বার এবং পিলারগুলি তাদের শক্তি এবং জ্যামিতি অর্জন করে।

- ব্রাকেট এবং রেইনফোর্সমেন্টস: প্রায়শই ছোট খালি অবস্থা থেকে তৈরি, এই অংশগুলি নির্দিষ্ট স্পেসিফিকেশন অনুযায়ী বেঁকিয়ে এবং পিয়ার্স করা হয়, রেডিয়েটর থেকে শুরু করে সিট ফ্রেম সমর্থন করে।

"একটি গাড়ির শরীরের উপরে এবং অদৃশ্য যে ধাতু দেখা যায় তা সম্ভবত স্ট্যাম্পিংয়ের মাধ্যমে তৈরি করা হয়েছে।"

অটোমোটিভ উত্পাদনে প্রতিটি পদক্ষেপ কীভাবে মূল্য যোগ করে

ধাতু স্ট্যাম্পিং প্রক্রিয়ার প্রতিটি পর্যায় স্থিতিশীলতা, গতি এবং মান অর্জনের জন্য নির্মিত হয়। জটিল আকৃতিগুলিকে পরিচালনযোগ্য পদক্ষেপে ভাগ করে নেওয়ার মাধ্যমে উত্পাদনকারীরা প্রতি ঘন্টায় হাজার হাজার অভিন্ন অংশ উত্পাদন করতে পারেন, যা আধুনিক যানবাহনের ডিজাইন এবং নিরাপত্তার চাহিদা পূরণ করে থাকে। এই প্রক্রিয়াটি সামঞ্জস্যযোগ্য, যা নিখুঁত সমাপ্তি সহ বৃহদাকার বহিঃসজ্জা থেকে শুরু করে গঠনমূলক সংযোজনের মতো অদৃশ্য অংশগুলি প্রদান করে যা প্রয়োজনীয় স্থানে শক্তি প্রদান করে।

এই প্রধান পদক্ষেপগুলি বোঝা কেবলমাত্র গাড়ি উত্পাদনে স্ট্যাম্পিং প্রক্রিয়াকে সহজতর করে তোলে না, বরং বিভিন্ন ধরনের স্ট্যাম্পিং পদ্ধতি অনুসন্ধানের জন্যও পর্যায় স্থাপন করে যা বিভিন্ন ধরনের অটোমোটিভ উপাদান সমাধানের জন্য ব্যবহৃত হয়। পরবর্তীতে, আমরা স্ট্যাম্পিং অপারেশনের প্রধান ধরনগুলি এবং কীভাবে সেগুলি নির্দিষ্ট উত্পাদন প্রয়োজনীয়তার সাথে মেলে তা নিয়ে আলোচনা করব।

অটোমোটিভ উত্পাদনে ব্যবহৃত ধাতু স্ট্যাম্পিং পদ্ধতির ধরন

যখন আপনি একটি গাড়ির ইঞ্জিনের ঢাকনা খুলে ভিতরে বা ক্যাবিনের ভিতরে তাকান, তখন আপনি অসংখ্য ধাতব অংশ দেখতে পাবেন—প্রতিটির আকৃতি, পুরুত্ব এবং কাজ আলাদা। কিন্তু আপনি কি জানেন যে এইসব অংশগুলি তৈরির জন্য শুধুমাত্র একটি মাত্র স্ট্যাম্পিং পদ্ধতি নয়? আসলে অটোমোটিভ উত্পাদনে বিভিন্ন ধরনের স্ট্যাম্পিং প্রক্রিয়া ব্যবহার করা হয়, যা বিভিন্ন অ্যাপ্লিকেশনের জন্য আলাদা সুবিধা প্রদান করে। চলুন প্রধান স্ট্যাম্পিং পদ্ধতিগুলি—প্রগ্রেসিভ ডাই স্ট্যাম্পিং, ট্রান্সফার ডাই স্ট্যাম্পিং এবং ডিপ ড্রন স্ট্যাম্পিং অটোমোটিভ সম্পর্কে বিস্তারিত জেনে নিই এবং দেখে নিই কোথায় কোনটি ব্যবহৃত হয়।

প্রগ্রেসিভ ডাই স্ট্যাম্পিং: উচ্চ আয়তনের জন্য দ্রুত গতি

কখনও কি ভেবেছেন কীভাবে প্রস্তুতকারকরা রেকর্ড সময়ের মধ্যে হাজার হাজার অভিন্ন ব্র্যাকেট বা ক্লিপ তৈরি করেন? প্রগ্রেসিভ ডাই স্ট্যাম্পিং হল এর উত্তর। এই প্রক্রিয়ায়, ধাতুর একটি দীর্ঘ ফিতা একক ডাইয়ের মধ্যে দিয়ে একাধিক স্টেশনের মধ্য দিয়ে যায়। প্রতিটি স্টেশন নির্দিষ্ট কাজ—যেমন কাটা, বাঁকানো বা ছিদ্র করা করে, তাই ফিতা যখন ডাই থেকে বের হয়ে আসে তখন একটি সম্পূর্ণ অংশ প্রস্তুত থাকে।

- সুবিধা: উচ্চ-ভলিউম উত্পাদনের জন্য অত্যন্ত দ্রুত এবং দক্ষ; ন্যূনতম ম্যানুয়াল পরিচালনা; বড় পার্ট জুড়ে ধ্রুবক মান।

- সীমাবদ্ধতা: প্রাথমিক টুলিং খরচ বেশি; জটিল বা বড় অংশগুলির জন্য কম নমনীয়তা; সরল, সমতল থেকে মধ্যম আকৃতির উপাদানগুলির জন্য সেরা।

- প্রধান অ্যাপ্লিকেশন: ব্র্যাকেট, ক্লিপ, সংযোগকারী এবং প্রতিরোধমূলক প্লেটের মতো ছোট থেকে মাঝারি আকারের অটোমোটিভ অংশ।

প্রগ্রেসিভ ডাই স্ট্যাম্পিং কে একটি ভালো তেল দেওয়া সমবায় লাইন হিসেবে চিন্তা করুন, যেখানে প্রতিটি পদক্ষেপ স্বয়ংক্রিয় এবং সর্বোচ্চ আউটপুটের জন্য সঠিকভাবে সময় নেয়। আপনি যখন দ্রুততা, পুনরাবৃত্তি এবং লাখ লাখ অভিন্ন অংশের জন্য ব্যয়-দক্ষতার প্রয়োজন হয় তখন এই প্রক্রিয়াটি আদর্শ।

ট্রান্সফার ডাই স্ট্যাম্পিং: জটিল আকৃতির জন্য নমনীয়তা

যদি আপনার একটি বড় বা আরও জটিল অংশ তৈরির প্রয়োজন হয় - কিছু যা একাধিক অপারেশন এবং সতর্ক পরিচালনার প্রয়োজন হয়? এখানেই ট্রান্সফার ডাই স্ট্যাম্পিংয়ের প্রয়োজন হয়। এখানে, প্রতিটি ডাই স্টেশন থেকে পরবর্তী স্টেশনে প্রতিটি ব্ল্যাঙ্কগুলি যান্ত্রিকভাবে বা ম্যানুয়ালি স্থানান্তরিত করা হয়, প্রতিটি স্টেশনে বিভিন্ন অপারেশন যেমন পাঞ্চিং, বেঁকে যাওয়া, বা আঁকার কাজ করা হয়। এই পদ্ধতি অংশের অভিমুখ এবং ডিজাইনে বেশি নমনীয়তা দেয়।

- সুবিধা: জটিল আকৃতি এবং বড় অংশগুলি পরিচালনা করে; একক চক্রে একাধিক গঠনকারী অপারেশন সমর্থন করে; সংক্ষিপ্ত এবং দীর্ঘ উৎপাদন চালানোর জন্য উপযুক্ত।

- সীমাবদ্ধতা: উচ্চ পরিচালন এবং সেটআপ খরচ; প্রতিটি রানের জন্য দীর্ঘ সেটআপ সময়; ডাই ডিজাইনে রক্ষণাবেক্ষণ এবং নির্ভুলতার জন্য দক্ষ শ্রমের প্রয়োজন।

- প্রধান অ্যাপ্লিকেশন: স্ট্রাকচারাল কম্পোনেন্ট, বড় ব্র্যাকেট এবং জটিল অ্যাসেম্ব্লিগুলি যা প্রগ্রেসিভ ডাইস দিয়ে তৈরি করা যাবে না।

ট্রান্সফার ডাই স্ট্যাম্পিং কে একটি রিলে রেস হিসাবে কল্পনা করুন, যেখানে প্রতিটি স্টেশন পার্টটি পরবর্তী স্টেশনে হস্তান্তর করে, এবং প্রতিটি ধাপের সাথে সাথে জটিলতা বৃদ্ধি পায়। এটি হল এমন পার্টগুলির জন্য প্রধান পদ্ধতি যেগুলি একাধিক ফরমিং অ্যাকশন বা বিশেষ পরিচালনার প্রয়োজনীয়তা রাখে।

ডিপ ড্রন স্ট্যাম্পিং: চ্যালেঞ্জিং পার্টগুলির জন্য নিরবচ্ছিন্ন শক্তি

আপনি কি কখনও লক্ষ্য করেছেন যে জ্বালানি পাম্প বা এয়ারব্যাগ ইনফ্লেটরের মতো উপাদানগুলিতে নিরবচ্ছিন্ন, জলরোধী ধাতব আবরণ রয়েছে? এগুলি প্রায়শই ডিপ ড্রন স্ট্যাম্পিং ব্যবহার করে তৈরি করা হয়—একটি বিশেষাবদ্ধ প্রক্রিয়া যা সমতল ধাতব শীটগুলিকে ফাঁপা, কাপ-আকৃতির পার্টে পরিণত করে যাদের গভীরতা তাদের ব্যাসের চেয়ে বেশি। ডিপ ড্রন স্ট্যাম্পিং অটোমোটিভ অ্যাপ্লিকেশনগুলি শক্তি এবং নির্ভুলতা উভয়েরই দাবি রাখে, এবং নির্দিষ্ট গুরুত্বপূর্ণ উপাদানগুলির জন্য এই পদ্ধতিকে অপরিহার্য করে তোলে।

- সুবিধা: নিরবচ্ছিন্ন, টেকসই, জলরোধী পার্ট উৎপাদন করে; গভীর গহ্বরযুক্ত জটিল আকৃতি তৈরির সুযোগ দেয়; বৃহৎ পরিমাণ উৎপাদনের জন্য অত্যন্ত দক্ষ এবং খরচ-কার্যকর।

- সীমাবদ্ধতা: বিশেষজ্ঞদের ডাই ডিজাইনের প্রয়োজন; যেসব অংশের গভীরতা ব্যাস অতিক্রম করে তাদের জন্য সবচেয়ে উপযুক্ত; খুব কম পরিমাণে বা অগভীর অংশের ক্ষেত্রে অর্থনৈতিক নাও হতে পারে।

- প্রধান অ্যাপ্লিকেশন: এয়ারব্যাগ ইনফ্লেটর, ABS ব্রেক মডিউল, থার্মোস্ট্যাট হাউজিং, জ্বালানি পাম্পের অংশ এবং অন্যান্য উপাদানগুলি বায়ু বা জলরোধী অখণ্ডতা প্রয়োজন।

গাড়ির চাপপূর্ণ পরিবেশে যেসব অংশগুলি শক্তিশালী এবং জটিল হওয়ার পাশাপাশি লিক বা ব্যর্থতার কারণ হতে পারে এমন সিমগুলি থেকে মুক্ত হওয়া প্রয়োজন হলে গভীর টানা স্ট্যাম্পিং সবচেয়ে ভালো।

স্ট্যাম্পিং পদ্ধতি তুলনা করুন: আপনার অংশের জন্য কোনটি সেরা?

| পদ্ধতি | জন্য সেরা | সুবিধা | সীমাবদ্ধতা |

|---|---|---|---|

| প্রগতিশীল ডাই স্ট্যাম্পিং | উচ্চ-পরিমাণ, সরল-থেকে-মাঝারি জটিলতার অংশ | গতি, স্থিতিশীলতা, প্রতি অংশের কম খরচ | উচ্চ টুলিং খরচ, কম নমনীয়তা |

| ট্রান্সফার ডাই স্ট্যাম্পিং | জটিল, বৃহদাকার, বা বহু-অপারেশন অংশ | নমনীয়তা, জটিল ডিজাইন সমর্থন করে | উচ্চ সেটআপ/অপারেশনাল খরচ, ধীরে |

| গভীর টানা স্ট্যাম্পিং | সিমলেস, গভীর, খোলা অংশগুলি | শক্তি, রিসেল প্রতিরোধ, উচ্চ দক্ষতা | বিশেষাবদ্ধ ডাইস, উথলা অংশগুলির জন্য কম উপযুক্ত |

আপনার অংশের আকার, জটিলতা, প্রয়োজনীয় পরিমাণ এবং কার্যকারিতার প্রয়োজনীয়তার উপর নির্ভর করে সঠিক স্ট্যাম্পিং পদ্ধতি বেছে নেওয়া। প্রতিটি পদ্ধতিকে কাজের সাথে ম্যাচ করে নিয়ে অটোমোটিভ প্রস্তুতকারকরা মান, গতি এবং খরচের মধ্যে নিখুঁত ভারসাম্য বজায় রাখেন। পরবর্তীতে, আমরা দেখব কীভাবে উপকরণ নির্বাচন এবং পৃষ্ঠতল চিকিত্সা অটোমোটিভ জগতে স্ট্যাম্পড অংশগুলির কার্যকারিতা এবং স্থায়িত্বকে আরও প্রভাবিত করে।

অটোমোটিভ মেটাল স্ট্যাম্পিংয়ে উপকরণ এবং পৃষ্ঠতল চিকিত্সা

যখন আপনি একটি গাড়ির শক্তি, নিরাপত্তা বা এমনকি তার জ্বালানি দক্ষতা সম্পর্কে চিন্তা করেন, কখনও কি ভেবেছেন কতটা ধাতুর পছন্দ নির্ধারণ করে? উত্তর: আপনি যতটা আশা করেন তার চেয়ে বেশি। সঠিক অটোমোটিভ মেটাল স্ট্যাম্পিং উপকরণ আজকালকার গাড়িগুলোতে প্রতিটি ষ্ট্যাম্পড অংশের পারফরম্যান্স, স্থায়িত্ব এবং মূল্য নিশ্চিত করার জন্য এটি একটি গুরুত্বপূর্ণ পদক্ষেপ। তবে এটি কেবল ধাতুটির বিষয়টি নয়— সুরক্ষা এবং এই উপাদানগুলোকে উন্নত করার বিষয়ে পৃষ্ঠতল চিকিত্সা এবং সমাপ্তি বিকল্পগুলো একটি প্রধান ভূমিকা পালন করে।

অটোমোটিভ মেটাল ষ্ট্যাম্পিং-এ ব্যবহৃত সাধারণ উপকরণ

প্রতিটি তার অনন্য শক্তির জন্য বেছে নেওয়া ধাতুগুলির উপর অটোমোটিভ প্রস্তুতকারকরা নির্ভর করেন। এখানে সবচেয়ে জনপ্রিয় উপকরণগুলি এবং কেন তারা পছন্দ করা হয় তার একটি দ্রুত বিশ্লেষণ রয়েছে:

- স্টিল: গাড়ি তৈরির পিছনে ইস্পাত হল মূল উপাদান, এর শক্তি, আকৃতি ধারণ করার ক্ষমতা এবং কম খরচে পাওয়া যাওয়ায় এটি অত্যন্ত মূল্যবান। চাপের মুখেও এটি আকৃতি ধরে রাখে এবং ভারী ভার সহ্য করতে পারে, যা বডি প্যানেল থেকে শুরু করে চেসিস উপাদানগুলির জন্য এটিকে আদর্শ পছন্দ করে তোলে। ইস্পাতকে অন্যান্য উপাদান দিয়ে মিশ্রিত করা বা তাপ চিকিত্সা প্রয়োগ করে এর কঠোরতা এবং মরিচা প্রতিরোধ ক্ষমতা আরও বাড়ানো যেতে পারে। উচ্চ-শক্তি সম্পন্ন কিন্তু কম খরচের মিশ্র ধাতু (HSLA) ইস্পাত অটোমোটিভ শিল্পে বিশেষভাবে জনপ্রিয় কারণ এটি ওজনের তুলনায় চমৎকার শক্তি প্রদান করে এবং মরিচা প্রতিরোধ ক্ষমতা বাড়িয়ে দেয়, যার ফলে গাড়িগুলি হালকা হয় কিন্তু স্থায়িত্ব কমে না।

- অ্যালুমিনিয়াম খাদ: গাড়ির ওজন কমাতে চান এবং জ্বালানি দক্ষতা বাড়াতে চান? অ্যালুমিনিয়াম হল আপনার পছন্দ। এটি হালকা, মরিচা প্রতিরোধ করতে পারে এবং তবুও চমৎকার শক্তি প্রদান করে। আধুনিক গাড়িগুলিতে বডি প্যানেল, হুড এবং গাঠনিক অংশগুলিতে অ্যালুমিনিয়াম মিশ্র ধাতু ব্যবহার করা হয়, বিশেষত যেখানে প্রতি পাউন্ড ওজন কমানো যায় সেখানে গাড়ির কার্যকারিতা বাড়ানো এবং নিঃসৃত পদার্থ কমানো সম্ভব।

- কপার অ্যালয় (ব্রাস, ব্রোঞ্জ): স্ট্রাকচারাল পার্টের জন্য যেহেতু এটি সাধারণ নয়, তবুও তামার খাদগুলি ব্যবহৃত হয় যেখানে তড়িৎ পরিবাহিতা এবং ক্ষয় প্রতিরোধ গুরুত্বপূর্ণ, যেমন ওয়্যারিং কম্পোনেন্ট এবং সংযোগকারী অংশগুলিতে। এদের নরম প্রকৃতি জটিল ও বিস্তারিত ষ্ট্যাম্পিং কাজের জন্য এদের আদর্শ করে তোলে।

এই উপকরণগুলির মধ্যে বেছে নেওয়া শুধুমাত্র খরচের ব্যাপার নয় - এটি কাজের সাথে সঠিক ধাতু মেলানোর ব্যাপার। উদাহরণস্বরূপ, উচ্চ-চাপযুক্ত ব্র্যাকেটের জন্য স্টিল আদর্শ, যেখানে একটি হালকা হুডের জন্য অ্যালুমিনিয়াম বেছে নেওয়া হতে পারে। নিজেকে জিজ্ঞাসা করুন: অংশটি শক্তিশালী, হালকা, ক্ষয় প্রতিরোধী হতে হবে, নাকি এগুলির সবকটি?

উপকরণ নির্বাচনের গুরুত্ব

- পারফরম্যান্স: সঠিক উপকরণ নির্বাচন করা হলে ষ্ট্যাম্পড অংশটি দৈনিক পরিধান, আঘাত এবং পরিবেশগত প্রভাব সহ্য করতে পারবে।

- ওজন হ্রাস: অ্যালুমিনিয়ামের মতো হালকা উপকরণ জ্বালানি দক্ষতা উন্নত করতে এবং নিঃসৃতি কমাতে সাহায্য করে, আধুনিক অটোমেকারদের জন্য এটি একটি প্রধান লক্ষ্য।

- খরচ: উপকরণের দাম, প্রক্রিয়াকরণের কঠিনতা এবং দীর্ঘমেয়াদী স্থায়িত্ব সবকিছু ষ্ট্যাম্পড অংশগুলির মোট মালিকানা খরচকে প্রভাবিত করে।

কল্পনা করুন ভুল খাদ দিয়ে তৈরি করা একটি গাড়ির দরজা - খুব ভারী হলে এটি কার্যকরী দক্ষতা কমিয়ে দেয়; আবার খুব নরম হলে দুর্ঘটনার সময় গাড়ির যাত্রীদের নিরাপদে রাখতে পারে না। এজন্য অটোমোটিভ মেটাল ষ্ট্যাম্পিং প্রক্রিয়ায় উপকরণ নির্বাচন খুব কঠোরভাবে নিয়ন্ত্রিত হয়।

ষ্ট্যাম্পড পার্টসের জন্য জনপ্রিয় পৃষ্ঠতল চিকিত্সা

যথাযথ সুরক্ষা ছাড়া সেরা ধাতুও দীর্ঘস্থায়ী হয় না। এখানেই ষ্ট্যাম্পড পার্টসের জন্য পৃষ্ঠতল চিকিত্সা এর প্রয়োজন, যা স্থায়িত্ব এবং চেহারা উভয়ই উন্নত করে। এখানে কয়েকটি সাধারণ ফিনিশিং পদ্ধতি দেওয়া হলো:

- প্লাটিংঃ যেমন দস্তা, নিকেল বা এমনকি মূল্যবান ধাতুর মতো অন্য ধাতুর পাতলা স্তর প্রয়োগ করা হয় যা ক্ষয় প্রতিরোধ, তড়িৎ পরিবাহিতা এবং দৃষ্টিনন্দন উপস্থিতি উন্নত করে। পার্টের আকার এবং জটিলতার উপর নির্ভর করে বিভিন্ন প্রক্রিয়া যেমন রিল-টু-রিল, ব্যারেল বা র্যাক প্লেটিং ব্যবহার করে প্লেটিং করা যেতে পারে।

- পাউডার কোটিং এবং ই-কোটিং: এই কোটিংগুলি চিপিং, স্ক্র্যাচিং এবং মরিচা প্রতিরোধে দৃঢ় এবং সমান ফিনিশ সরবরাহ করে। বিশেষ করে পরিবেশের সংস্পর্শে থাকা বহিরঙ্গ উপাদানগুলির জন্য এগুলি খুব কার্যকর।

- ইলেক্ট্রোপলিশিং: এই প্রক্রিয়াটি ধাতুর পৃষ্ঠকে মসৃণ ও পরিষ্কার করে, দূষণ অপসারণ করে এবং উপস্থিতি এবং ক্ষয় প্রতিরোধ উভয়কে বাড়ায়। কঠোর সহনশীলতা বা জটিল আকৃতি সহ অংশগুলির জন্য এটি বিশেষভাবে মূল্যবান।

- ডেবারিং: স্ট্যাম্পিংয়ের পরে, ছোট বার্স বা তীক্ষ্ণ ধারগুলি থেকে যেতে পারে। ডেবারিং এই ত্রুটিগুলি অপসারণ করে, ফিট, নিরাপত্তা এবং সমাপ্তির মান উন্নত করে।

- তাপ চিকিত্সাঃ স্ট্যাম্পড অংশগুলিকে সাবধানে উত্তপ্ত এবং শীতল করে উত্পাদকরা শক্তি, কঠোরতা এবং সবলতা বাড়াতে পারে - পরিধান এবং ক্ষয় প্রতিরোধ উন্নত করার সময়।

অংশের কার্য এবং পরিবেশের উপর ভিত্তি করে প্রতিটি পৃষ্ঠের চিকিত্সা নির্বাচন করা হয়। উদাহরণস্বরূপ, রাস্তার লবণ প্রতিরোধের জন্য অনুরূপ ব্রাকেটগুলি জিংক-প্লেট করা যেতে পারে, যেখানে দৃশ্যমান ট্রিম অংশগুলি একটি পাউডার কোট পাবে একটি দোষহীন সমাপ্তির জন্য।

সবকিছু একত্রিত করা

সংক্ষেপে, সঠিক সমন্বয়ের মাধ্যমে অটোমোটিভ মেটাল স্ট্যাম্পিং উপকরণ এবং পরিমিত পৃষ্ঠ চিকিত্সা নিশ্চিত করে যে প্রতিটি স্ট্যাম্পড অংশ কেবলমাত্র কার্যক্ষমতার প্রয়োজনীয়তা পূরণ করে না বরং বছরের পর বছর ধরে ব্যবহার সহ্য করে। আপনি এগিয়ে গেলে দেখবেন কীভাবে মান নিয়ন্ত্রণ এবং শিল্প মানগুলি প্রতিটি স্ট্যাম্পড অটোমোটিভ উপাদানের প্রতিশ্রুতি পূরণ করে তা নিশ্চিত করে, কারখানার মেঝে থেকে শুরু করে মুক্ত রাস্তায়।

অটোমোটিভ মেটাল স্ট্যাম্পিং-এ মান নিয়ন্ত্রণ এবং শিল্প মান

যখন আপনি একটি গাড়ির নিখুঁত বডি প্যানেল বা একটি ব্র্যাকেট দেখেন যা নিখুঁতভাবে ফিট হয়, তখন কি কখনও ভেবেছেন যে কীভাবে প্রস্তুতকারকরা এমন স্থিতিশীল মান নিশ্চিত করেন—প্রতিটি অংশের পর প্রতিটি অংশ, বছরের পর বছর? উত্তরটি রয়েছে শক্তিশালী অটোমোটিভ স্ট্যাম্পিং মান নিয়ন্ত্রণ সিস্টেম এবং আন্তর্জাতিকভাবে স্বীকৃত শিল্প মানগুলির মধ্যে যেমন IATF 16949 অটোমোটিভ স্ট্যাম্পিং । চলুন দেখে নিই এই মানগুলি আপনার জন্য কী অর্থ বহন করে এবং কীভাবে স্ট্যাম্পিং প্রক্রিয়ার প্রতিটি পদক্ষেপকে গঠন করে।

অটোমোটিভ স্ট্যাম্পিং-এ মান নিয়ন্ত্রণ কেন এত গুরুত্বপূর্ণ?

কল্পনা করুন একটি ত্রুটিপূর্ণ চ্যাসিস উপাদান যদি কোনও যানের মধ্যে চলে যায়। এটি সংযোজনের দেরি, ওয়ারেন্টি দাবি বা এমনকি নিরাপত্তা প্রত্যাহারের কারণ হতে পারে। এজন্য মান নিয়ন্ত্রণ শুধুমাত্র শেষের দিকে একটি চেকপয়েন্ট নয়—এটি স্ট্যাম্পিং প্রক্রিয়ার প্রতিটি পর্যায়ে অন্তর্ভুক্ত করা হয়, কাঁচামাল নির্বাচন থেকে শুরু করে চূড়ান্ত পরিদর্শন পর্যন্ত। আপনি লক্ষ্য করবেন যে সেরা প্রস্তুতকারকরা মানকে একটি নিরবচ্ছিন্ন যাত্রা হিসাবে দেখে, একক ঘটনা হিসাবে নয়।

- স্থিতিশীলতা: প্রতিটি স্ট্যাম্পড অংশকে কঠোর সহনশীলতা পূরণ করতে হবে যাতে সমাপ্ত যানবাহনে সঠিক ফিটিং, কার্যকারিতা এবং নিরাপত্তা নিশ্চিত হয়।

- নির্ভরযোগ্যতা: অংশগুলি ব্যবহারের বছরের পর বছর ধরে, পরিবেশের প্রভাব এবং বিভিন্ন ভার সহ্য করতে হবে ব্যর্থতা ছাড়াই।

- সম্মতি: গ্রাহক এবং নিয়ন্ত্রক প্রয়োজনীয়তা পূরণ করা অটোমোটিভ উত্পাদনে অপরিহার্য।

IATF 16949 বোঝা: স্বর্ণ মান

আপনি কি IATF 16949 সম্পর্কে শুনেছেন? এটি ইন্টারন্যাশনাল অটোমোটিভ টাস্ক ফোর্স দ্বারা প্রস্তুত অটোমোটিভ খণ্ডের জন্য প্রধান মান ব্যবস্থাপনা পদ্ধতি (QMS) মান। এই কঠোর কাঠামোটি প্রস্তুতকারকদের আহ্বান জানায়:

- পণ্যের মান প্রভাবিত করে এমন প্রতিটি প্রক্রিয়া নথিভুক্ত করুন এবং নিয়ন্ত্রণ করুন

- গ্রাহক-নির্দিষ্ট প্রয়োজনীয়তা চিহ্নিত করুন এবং পূরণ করুন

- মেট্রিক্স এবং ডেটা বিশ্লেষণের মাধ্যমে প্রক্রিয়াগুলি ক্রমাগত উন্নত করুন

- প্রতিকূল পরিস্থিতি প্রবণতা সহ পরিচালনা করুন এবং প্রতিরোধমূলক পদক্ষেপ বাস্তবায়ন করুন

- স্ট্যাটিসটিক্যাল প্রক্রিয়া নিয়ন্ত্রণ (SPC) এবং ব্যর্থতা মোড এবং প্রভাব বিশ্লেষণ (FMEA) এর মতো উন্নতি সাধনকারী সরঞ্জামগুলি ব্যবহার করুন

- শক্তিশালী সরবরাহকারী মান ব্যবস্থাপনা এবং ট্রেসেবিলিটি বজায় রাখুন

এই নীতিগুলি অনুসরণ করে কোম্পানিগুলি শুধুমাত্র মান মেনে চলে না, কিন্তু দক্ষতা বাড়ায়, অপচয় কমায় এবং পণ্যগুলি সরবরাহ করে যা গ্রাহকের প্রত্যাশা পূরণ করে বা ছাড়িয়ে যায় (স্মিথার্স) .

অটোমোটিভ মেটাল স্ট্যাম্পিং-এ প্রধান মান নিয়ন্ত্রণ ব্যবস্থা

তাহলে, স্ট্যাম্পিং ফ্লোরে মান নিয়ন্ত্রণ কেমন দেখায়? এখানে একটি ব্যবহারিক বিশ্লেষণ দেওয়া হলো:

- ম্যাটেরিয়াল পরীক্ষা: প্রতিটি ধাতুর ব্যাচ ব্যবহারের আগে বেধ, কঠোরতা এবং রচনা পরীক্ষা করা হয়, শুরু থেকেই ত্রুটি প্রতিরোধ করা হয়।

- টুল এবং ডাই পরিদর্শন: ডাইগুলি নিয়মিত পরিধান বা ক্ষতির জন্য পরীক্ষা করা হয়, প্রতিটি স্ট্যাম্পড অংশ ডিজাইন স্পেসিফিকেশন মেলে তা নিশ্চিত করে।

- প্রেস সেটআপ যাচাইকরণ: উৎপাদন শুরুর আগে স্ট্যাম্পিং প্রেসগুলি ক্যালিব্রেটেড এবং সারিবদ্ধ করা হয়, ভুল সারিবদ্ধতা বা অসম্পূর্ণ স্ট্যাম্পিংয়ের ঝুঁকি কমিয়ে আনে।

- প্রক্রিয়াসম্পন্ন পরিদর্শন: বাস্তবিক সময়ের পরীক্ষা - সেন্সর, ক্যামেরা বা ম্যানুয়াল গেজ ব্যবহার করে - অংশের মাত্রা এবং পৃষ্ঠতলের সমাপ্তি পর্যবেক্ষণ করে, তারতম্যগুলি সময়মতো ধরে ফেলে।

- পরিসংখ্যানগত প্রক্রিয়া নিয়ন্ত্রণ (এসপিসি): উৎপাদনকালীন তথ্য সংগ্রহ এবং বিশ্লেষণ করা হয় প্রবণতা, পরিবর্তন বা অস্বাভাবিকতা খুঁজে বার করার জন্য, দ্রুত সংশোধনমূলক পদক্ষেপের অনুমতি দেয়।

- চূড়ান্ত পরিদর্শন: সম্পন্ন অংশগুলি মাত্রিক নির্ভুলতা, পৃষ্ঠের গুণমান এবং কাঠামোগত অখণ্ডতার জন্য ব্যাপক পরীক্ষা করা হয়, একত্রীকরণ বা চালানের আগে।

- উপকরণ ট্রেসেবিলিটি: প্রতিটি অংশের উৎপত্তি ট্র্যাক করা হয়, পরবর্তীতে কোনও সমস্যা পাওয়া গেলে দ্রুত ধারণ এবং সংশোধন করার অনুমতি দেয়।

প্রস্তুতকারকরা প্রতিটি ধাপে মানের পরিমাপ কী হবে তা প্রত্যেক অপারেটরের জানা থাকে এমন করে বিস্তারিত নথিপত্র— চিত্র, কাজের নির্দেশাবলী, পরিদর্শনের রেকর্ড— রক্ষণাবেক্ষণ করেন।

অবিচ্ছিন্ন উন্নতি এবং ত্রুটি প্রতিরোধে চালনা

গাড়ির স্ট্যাম্পিং-এ মান নিয়ন্ত্রণ ভুলগুলি ধরার মধ্যেই শেষ হয় না। সেরা প্রস্তুতকারকরা পরিদর্শনের প্রতিক্রিয়া, গ্রাহকদের প্রতিক্রিয়া এবং অভ্যন্তরীণ অডিট থেকে প্রাপ্ত তথ্য ব্যবহার করে মূল কারণগুলি চিহ্নিত করে এবং সংশোধন বা প্রতিরোধমূলক পদক্ষেপ গ্রহণ করে। FMEA-এর মতো সরঞ্জামগুলি ত্রুটিগুলি ঘটার আগেই সম্ভাব্য ব্যর্থতা সম্পর্কে সতর্ক করতে সাহায্য করে, যেখানে নিয়মিত প্রশিক্ষণ দলগুলিকে সতর্ক রাখে এবং নতুন চ্যালেঞ্জগুলির সাথে সাথে প্রক্রিয়াগুলি উন্নত হতে দেয়।

- চালু উন্নয়ন: দক্ষতা এবং কার্যকারিতা বাড়ানোর জন্য মান ব্যবস্থাপনা পদ্ধতিগুলি নিয়মিত পর্যালোচনা ও আপডেট করুন।

- কর্মচারীদের প্রশিক্ষণ: পরিমাপ, পরিদর্শন এবং ত্রুটি প্রতিরোধের সর্বশেষ পদ্ধতিগুলি দিয়ে দলগুলিকে সজ্জিত করুন।

- সরবরাহকারী নিরীক্ষা: নিশ্চিত করুন যে সমস্ত সরবরাহকারীরা একই উচ্চ মানদণ্ড মেনে চলে, সরবরাহ চেইন জুড়ে মান সমর্থন করে।

প্রতিটি স্তরে মান অন্তর্ভুক্ত করে গাড়ি তৈরির ধাতু স্ট্যাম্পিং প্রক্রিয়া , প্রস্তুতকারকরা নির্ভয়ে শিল্পের সর্বোচ্চ প্রত্যাশা পূরণকারী অংশগুলি সরবরাহ করতে পারেন। পরবর্তীতে, আসুন দেখি কীভাবে উদ্ভাবন এবং ডিজিটাল সরঞ্জামগুলি স্ট্যাম্পিংয়ের মান এবং দক্ষতা পরবর্তী পর্যায়ে নিয়ে যাচ্ছে।

কীভাবে ডিজিটাল উত্পাদন অটোমোটিভ মেটাল স্ট্যাম্পিং পরিবর্তন করছে

আপনার কখনও কি মনে হয়েছে কীভাবে গাড়ি প্রস্তুতকারকরা হালকা, আরও জটিল এবং উচ্চতর মানের অংশগুলির চাহিদা মেটাচ্ছেন— তবুও খরচ কমাচ্ছেন এবং উৎপাদন গতি বাড়াচ্ছেন? উত্তরটি অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ার মধ্য দিয়ে ছড়িয়ে পড়া নবতম উদ্ভাবনের ঢেউয়ে নিহিত রয়েছে। আসুন অনুসন্ধান করি কীভাবে স্ট্যাম্পিংয়ে ডিজিটাল উত্পাদন, স্বয়ংক্রিয়করণ এবং উন্নত DFM (ডিজাইন ফর ম্যানুফ্যাকচারাবিলিটি) সরঞ্জামগুলি শিল্পকে পুনর্গঠন করছে এবং আপনি যখন একজন প্রস্তুতকারক, প্রকৌশলী বা অটোমোটিভ প্রেমিক হিসাবে তার কী অর্থ হয়।

স্বয়ংক্রিয়করণ: নির্ভুলতা এবং উৎপাদনশীলতার শক্তি

কল্পনা করুন এমন একটি স্ট্যাম্পিং ফ্লোর যেখানে রোবট এবং স্মার্ট মেশিনগুলি পুনরাবৃত্তিমূলক, বিপজ্জনক বা অত্যন্ত নির্ভুল কাজগুলি সম্পন্ন করে। ভবিষ্যতের কথা মনে হচ্ছে? কিন্তু এটি ইতিমধ্যে বাস্তবতা। স্বয়ংক্রিয়তা অটোমোটিভ স্ট্যাম্পিংয়ের একটি প্রধান শক্তিতে পরিণত হয়েছে, যেখানে রোবটগুলি এখন মেটাল ব্লাঙ্কগুলি প্রেসে ফিড করা থেকে শুরু করে চূড়ান্ত অংশগুলি জোড়া লাগানো পর্যন্ত সবকিছু করে থাকে। স্বয়ংক্রিয়তা কাজ করতে থাকলে আপনি যা লক্ষ্য করবেন:

- উচ্চ উৎপাদনশীলতা: স্বয়ংক্রিয় স্ট্যাম্পিং লাইনগুলি দিন-রাত চলতে থাকে, অল্প সময়ের বিরতিতে হাজার হাজার অংশ তৈরি করে। রোবটগুলি এমন কাজগুলি করে যা আগে ম্যানুয়াল লেবারের মাধ্যমে ঘন্টার পর ঘন্টা সময় নিত, যা মানুষের কর্মীদের আরও জটিল সমস্যা সমাধানের জন্য মুক্ত করে দেয়।

- অপরিবর্তিত গুণগত মান: রোবটদের কখনো ক্লান্তি আসে না বা ফোকাস হারায় না, এবং এর ফলে প্রতিটি স্ট্যাম্পড অংশ কঠোর সহনশীলতা এবং মানের মানদণ্ড পূরণ করে থাকে, যা গুরুত্বপূর্ণ অটোমোটিভ উপাদানগুলির জন্য অপরিহার্য।

- উন্নত নিরাপত্তা: স্বয়ংক্রিয়তা কর্মক্ষেত্রে আঘাতের ঝুঁকি কমিয়ে দেয় কারণ এটি বিপজ্জনক বা পুনরাবৃত্তিমূলক কাজগুলি সম্পন্ন করে থাকে, যার ফলে কারখানার মেঝেটি সকলের জন্য নিরাপদ হয়ে ওঠে।

- অভিযোজনযোগ্যতা: আধুনিক রোবটগুলি সেন্সর এবং এমনকি কৃত্রিম বুদ্ধিমত্তা দিয়ে সজ্জিত, যা বাস্তব সময়ে সমঞ্জস করার এবং উপকরণ বা অংশগুলির সারিবদ্ধতার মধ্যে পার্থক্য মোকাবেলা করার অনুমতি দেয়।

মানুষ এবং প্রযুক্তির মিশ্রণের মাধ্যমে প্রস্তুতকারকরা অটোমোটিভ অংশগুলির স্ট্যাম্পিং এবং সমাবেশ করতে স্ট্রিমলাইন করছেন, গতি এবং নির্ভরযোগ্যতা উভয়ই বাড়িয়ে তুলছেন।

স্ট্যাম্পিংয়ে ডিজিটাল উত্পাদন: স্মার্টার সিদ্ধান্ত, দ্রুত ফলাফল

আপনি যদি কোনও সরঞ্জাম ব্যর্থতা ঘটার আগেই তা ভবিষ্যদ্বাণী করতে পারেন, অথবা নতুন ডিজাইনের স্পেসিফিকেশন পূরণের জন্য উৎপাদন লাইনগুলি তাৎক্ষণিকভাবে সামঞ্জস্য করতে পারেন? স্ট্যাম্পিংয়ে ডিজিটাল উত্পাদনের প্রতিশ্রুতি হল এটিই। স্মার্ট সেন্সর, আইওটি ডিভাইস এবং ক্লাউড-ভিত্তিক বিশ্লেষণের মাধ্যমে শিল্প 4.0 নীতি গ্রহণ করে, অটোমোটিভ স্ট্যাম্পারদের কাছে তাদের অপারেশনের প্রতিটি দিক সম্পর্কে বাস্তব সময়ের ডেটা অ্যাক্সেসযোগ্য হয়ে উঠছে।

- ভবিষ্যদ্বাণীমূলক রক্ষণাবেক্ষণ: স্ট্যাম্পিং প্রেসগুলির কম্পন, তাপমাত্রা এবং পরিধান নিরীক্ষণ করে সেন্সরগুলি, ব্রেকডাউন ঘটার আগে দলগুলিকে সম্ভাব্য সমস্যাগুলির সতর্ক করে দেয়। এই প্রাক্-প্রতিক্রিয়াশীল পদ্ধতি অপ্রত্যাশিত ডাউনটাইম কমায় এবং সরঞ্জামের জীবনকাল বাড়ায়।

- ডেটা-ভিত্তিক অপ্টিমাইজেশন: স্ক্র্যাপ হার, সাইকেল সময় এবং শক্তি ব্যবহারের মতো প্রধান কর্মক্ষমতা সূচকগুলি ট্র্যাক করে, প্রস্তুতকারকরা প্রক্রিয়াগুলিতে অসুবিধা চিহ্নিত করতে এবং সর্বোচ্চ দক্ষতার জন্য প্রক্রিয়াগুলি নিখুঁতভাবে সাজাতে পারে।

- ডিজিটাল টুইনস: স্ট্যাম্পিং প্রক্রিয়ার ভার্চুয়াল মডেলগুলি অপারেশন অনুকরণ করে, প্রকৌশলীদের অদক্ষতা চিহ্নিত করতে, পরিবর্তনগুলি পরীক্ষা করতে এবং কারখানার মেঝেতে সমস্যা হওয়ার আগেই তা প্রতিরোধ করতে সাহায্য করে।

এই ডিজিটাল সরঞ্জামগুলি দ্রুত বাজারের চাহিদা পরিবর্তনের প্রতি দ্রুত প্রতিক্রিয়া জানায়, গুণগত নিয়ন্ত্রণ আরও কঠোর করে এবং আরও দক্ষ উৎপাদন পরিকল্পনা করে—আজকের দ্রুতগামী অটোমোটিভ বিশ্বে অপরিহার্য সুবিধা।

ডিএফএম অটোমোটিভ মেটাল স্ট্যাম্পিং: সাফল্যের জন্য ডিজাইন করা

আপনি যখন একটি নতুন অংশ তৈরি করছেন, তখন আপনি কীভাবে নিশ্চিত হবেন যে এটি কেবল কার্যকর হবে না, বরং উৎপাদন করা সহজ এবং খরচে কার্যকর হবে? এখানে ডিএফএম (ডিজাইন ফর ম্যানুফ্যাকচারিবিলিটি) সরঞ্জামগুলি প্রবেশ করে। এই উন্নত সফটওয়্যার সমাধানগুলি প্রকৌশলীদের সাহায্য করে এমন অংশগুলি ডিজাইন করতে যা প্রারম্ভ থেকেই স্ট্যাম্পিংয়ের জন্য অপ্টিমাইজড হবে:

- প্রারম্ভিক সমস্যা সনাক্তকরণ: ডিএফএম সরঞ্জামগুলি সিএডি মডেলগুলি বিশ্লেষণ করে যেসব বৈশিষ্ট্যগুলি ত্রুটি, ডাইগুলিতে অত্যধিক পরিধান বা উৎপাদন বিলম্বের কারণ হতে পারে তা চিহ্নিত করে।

- উপকরণ এবং প্রক্রিয়া নির্বাচন: বিভিন্ন উপকরণ এবং স্ট্যাম্পিং প্রযুক্তি অনুকরণ করে প্রকৌশলীরা শক্তি, ওজন এবং উৎপাদনযোগ্যতার জন্য সেরা সংমিশ্রণটি নির্বাচন করতে পারেন।

- দ্রুত প্রোটোটাইপিং: ভার্চুয়াল অনুকরণগুলি শারীরিক প্রোটোটাইপগুলির প্রয়োজনীয়তা কমিয়ে দেয়, উন্নয়নকে দ্রুত করে এবং খরচ কমিয়ে দেয়।

ডিএফএম অটোমোটিভ মেটাল স্ট্যাম্পিংয়ের সাহায্যে প্রস্তুতকারকরা দ্রুত বাজারে আনতে পারেন অভিনব, হালকা এবং জটিল অংশগুলি—যখন পরীক্ষা-নিরীক্ষা এবং ত্রুটি কমিয়ে এবং নিয়ত মান নিশ্চিত করে।

পরবর্তী কী? স্ট্যাম্পিং নবায়নের ভবিষ্যত

- সহযোগী রোবট (Cobots): মানুষের পাশাপাশি নিরাপদে কাজ করার জন্য তৈরি করা, কোবটগুলি পরিদর্শন বা নির্ভুল সমবায় সহ কাজগুলি নিতে পারে, যা আরও বাড়ায় উৎপাদনশীলতা।

- স্বয়ংক্রিয় মান নিয়ন্ত্রণ: মেশিন দৃষ্টি ব্যবস্থাগুলি এখন অংশগুলি প্রকৃত সময়ে পরিদর্শন করে, সূক্ষ্ম ত্রুটিগুলি ধরে এবং নিশ্চিত করে যে প্রতিটি উপাদান কঠোর মান পূরণ করে।

- দ্রুত উৎপাদন: নমনীয়, পুনর্বিন্যস্তযোগ্য স্ট্যাম্পিং লাইনগুলি অটোমোটিভ নির্মাতাদের মডেল বা কাস্টম ডিজাইনের মধ্যে দ্রুত স্যুইচ করতে দেয় - সহজেই পরিবর্তিত হওয়া গ্রাহক পছন্দগুলি পূরণ করে।

সংক্ষেপে, স্বয়ংক্রিয়তা, ডিজিটাল উৎপাদন এবং DFM সরঞ্জামগুলির সমন্বয় অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়াকে বিপ্লবী পরিবর্তন এনেছে। এই অগ্রগতিগুলি নির্মাতাদের সময়কাল হ্রাস করতে, নির্ভুলতা উন্নত করতে এবং হালকা, জটিল অংশগুলি সরবরাহ করতে সাহায্য করে যা আধুনিক যানগুলি দ্বারা চাওয়া হয়। আপনার পরবর্তী অটোমোটিভ প্রকল্প বিবেচনা করার সময়, এই প্রবণতাগুলি মনে রাখবেন - এগুলি গাড়ি উৎপাদনের ভবিষ্যতকে গঠন করছে। পরবর্তী অংশে, আমরা আলোচনা করব কীভাবে আপনার উপাদানগুলি সর্বোচ্চ মান এবং নবায়নের মানদণ্ড পূরণ করছে তা নিশ্চিত করতে সঠিক স্ট্যাম্পিং অংশীদার বেছে নেবেন।

সঠিক অটোমোটিভ মেটাল স্ট্যাম্পিং অংশীদার বেছে নেওয়া

যখন আপনাকে একটি নতুন যানবাহন প্ল্যাটফর্মের জন্য স্ট্যাম্পড কম্পোনেন্ট সংগ্রহের দায়িত্ব দেওয়া হয়, তখন ঝুঁকি অনেক বেশি হয়। সঠিক সরবরাহকারী আপনার স্মুথ লঞ্চ এবং ব্যয়বহুল উত্পাদনের সমস্যার মধ্যে পার্থক্য তৈরি করতে পারে। তাহলে, আপনি কীভাবে অটোমোটিভ মেটাল স্ট্যাম্পিং কোম্পানি এবং নিশ্চিত করবেন যে আপনি অটোমোটিভ স্ট্যাম্পিং সরবরাহকারী বেছে নিচ্ছেন যা আপনার প্রকল্পের প্রয়োজনীয়তা সত্যিই পূরণ করে?

অটোমোটিভ স্ট্যাম্পিং সরবরাহকারী মূল্যায়নে প্রধান কারকগুলি

কল্পনা করুন আপনি সম্ভাব্য অংশীদারদের একটি ছোট তালিকা মূল্যায়ন করছেন। আপনি কী খুঁজছেন? আপনার সিদ্ধান্তকে পরিচালিত করার জন্য এখানে একটি ব্যবহারিক চেকলিস্ট রয়েছে:

| মূল্যায়নের কারক | কেন এটা ব্যাপার | কি দেখতে হবে |

|---|---|---|

| প্রকৌশলী দক্ষতা | আপনার যন্ত্রাংশগুলি উত্পাদনযোগ্যতার জন্য ডিজাইন করা হয়েছে এবং খরচ, মান এবং কার্যকারিতার জন্য অপ্টিমাইজ করা হয়েছে কিনা তা নিশ্চিত করে। | অভিজ্ঞ প্রকৌশল দল, DFM সরঞ্জামগুলির অ্যাক্সেস এবং প্রোটোটাইপ উন্নয়নের জন্য সমর্থন। |

| মান সার্টিফিকেশন | কঠোর শিল্প মানদণ্ড এবং নিয়মিত যন্ত্রাংশ মানের সাথে মেল খাওয়া নিশ্চিত করে। | IATF 16949 বা ISO 9001 এর মতো সার্টিফিকেশন; দৃঢ় মান নিয়ন্ত্রণ ব্যবস্থা; নথিভুক্ত পরিদর্শন প্রক্রিয়া। |

| উৎপাদন স্কেলিং | আপনার প্রকল্পের পরিবর্তনের সাথে সাথে উৎপাদন বৃদ্ধি বা হ্রাস করতে সাহায্য করে। | নিম্ন- এবং উচ্চ-পরিমাণ অর্ডারের সাথে প্রমাণিত রেকর্ড এবং নিজস্ব সরঞ্জাম সহ নমনীয় ক্ষমতা। |

| উপকরণ ও প্রক্রিয়া ক্ষমতা | হালকা অ্যালুমিনিয়াম প্যানেল থেকে শুরু করে উচ্চ-শক্তি সম্পন্ন ইস্পাত ব্র্যাকেট পর্যন্ত বিভিন্ন অটোমোটিভ অ্যাপ্লিকেশন সমর্থন করে। | বিভিন্ন ধাতু, গেজ এবং পৃষ্ঠতল চিকিত্সা দিয়ে কাজ করার ক্ষমতা; উন্নত গঠন এবং মেশিনিং প্রযুক্তি। |

| প্রমাণিত অভিজ্ঞতা | অনুরূপ প্রকল্প থেকে শেখা পাঠ এবং শীর্ষ OEM-এর সাথে প্রতিষ্ঠিত সম্পর্ক ব্যবহার করে ঝুঁকি হ্রাস করে। | কেস স্টাডি, ক্লায়েন্ট রেফারেন্স এবং অগ্রণী অটোমোটিভ ব্র্যান্ডগুলির সাথে কাজের পোর্টফোলিও। |

| স্বচ্ছতা ও যোগাযোগ | সহজ প্রকল্প ব্যবস্থাপনা এবং দ্রুত সমস্যা সমাধানের সুবিধা করে। | স্পষ্ট মূল্যনির্ধারণ, খোলা আপডেট এবং সমস্যা সমাধানের প্রতিক্রিয়াশীল পদ্ধতি। |

গভীরে যাওয়া: জিজ্ঞাসা করার জন্য ব্যবহারিক প্রশ্নসমূহ

- প্রসবধর্মী নকশা (ডিএফএম) বিশ্লেষণ থেকে শুরু করে প্রোটোটাইপিং, টুলিং এবং ভর উৎপাদন পর্যন্ত সরবরাহকারী কি এন্ড-টু-এন্ড সমর্থন দিচ্ছেন?

- তাদের মান ব্যবস্থা এবং সার্টিফিকেশনগুলি কি আপ-টু-ডেট এবং স্বাধীনভাবে নিরীক্ষিত?

- চাহিদার অপ্রত্যাশিত বৃদ্ধির সাথে মানিয়ে নেওয়ার জন্য কি তারা দ্রুত স্কেল করতে পারেন?

- বৈশ্বিক ওইএমই বা অনুরূপ অটোমোটিভ প্রকল্পগুলিতে তাদের রেকর্ড কী?

- তারা কি সমাবেশ, পৃষ্ঠতল চিকিত্সা বা যোগাযোগ সমর্থনের মতো মূল্য যুক্ত পরিষেবা সরবরাহ করেন?

- তাদের মূল্য নির্ধারণের কাঠামো কতটা স্বচ্ছ? সেখানে কি কোনও গোপন ফি আছে বা পরিষ্কার, সম্পূর্ণ মূল্য উল্লেখ করা আছে?

এই প্রশ্নগুলির উত্তরগুলি আপনাকে কেবলমাত্র অংশ সরবরাহকারীদের থেকে প্রকৃত অংশীদারদের পৃথক করতে সাহায্য করবে।

কেন সরবরাহকারী নির্বাচন আপনার সম্পূর্ণ প্রকল্পকে প্রভাবিত করে

সঠিক ষ্ট্যাম্পিং অংশীদার বাছাই করা শুধুমাত্র দাম বা লিড সময়ের বিষয়টি নয়। এটি হল আপনার মান, নবায়ন এবং দক্ষতার লক্ষ্যগুলি সমর্থনকারী একটি সম্পর্ক গড়ে তোলা। সেরা সরবরাহকারীরা আপনাকে ব্যয়বহুল ডিজাইন ত্রুটি এড়াতে, বাজারে আনার সময় কমাতে এবং নিশ্চিত করতে সাহায্য করে যে প্রতিটি অংশ কঠোর অটোমোটিভ মান মেনে চলছে। উপকরণ নির্বাচন এবং প্রক্রিয়া অপ্টিমাইজেশনে তাদের দক্ষতা আপনার যানগুলির জন্য হালকা, শক্তিশালী এবং আরও নির্ভরযোগ্য উপাদানের ফলস্বরূপ হতে পারে।

শাওই: ব্যাপক ষ্ট্যাম্পিং সমর্থনের একটি বিশ্বস্ত উদাহরণ

কল্পনা করুন এমন এক সরবরাহকারীর সাথে কাজ করছেন যিনি শুধুমাত্র উচ্চ-নির্ভুলতার স্ট্যাম্পড পার্টস সরবরাহ করেন না, পাশাপাশি আপনার পণ্যের জীবনচক্রের প্রতিটি পর্যায়ে আপনার সঙ্গী হয়ে থাকেন। শাওই এই পদ্ধতির এক উজ্জ্বল উদাহরণ। তাদের পরিষেবাগুলি দ্রুত প্রোটোটাইপিং এবং DFM বিশ্লেষণ থেকে শুরু করে কম এবং বেশি পরিমাণে উৎপাদন পর্যন্ত সমস্ত কিছু নিয়ে গঠিত, যা IATF 16949 সার্টিফায়েড মান নিয়ন্ত্রণ ব্যবস্থার অধীনে পরিচালিত হয়। উন্নত প্রকৌশল সমর্থন, নিজস্ব টুলিং এবং বিভিন্ন ধাতু ও পৃষ্ঠতল চিকিত্সার কাজ সম্পন্ন করার ক্ষমতা থাকার কারণে শাওই আপনার সরবরাহ চেইন সহজতর করে দেয় এবং ঝুঁকি কমিয়ে দেয়। বৃহত আন্তর্জাতিক অটোমোটিভ প্রতিষ্ঠানগুলির সাথে তাদের প্রমাণিত অভিজ্ঞতা জটিল এবং উচ্চ পরিমাণ দায়িত্বমূলক প্রকল্পে তাদের কার্যক্ষমতা প্রদর্শন করে। শাওইয়ের অটো স্ট্যাম্পিং সমাধান সম্পর্কে আরও জানুন .

শেষ পর্যন্ত, সঠিক অংশীদার আপনাকে নবায়নের ক্ষমতা প্রদান করবে, খরচ নিয়ন্ত্রণ করবে এবং স্বয়ংচালিত শিল্পের পরিবর্তনশীল চাহিদা পূরণ করবে। আপনি এগিয়ে যাওয়ার সময় মনে রাখবেন যে সরবরাহকারী নির্বাচন হল একটি কৌশলগত সিদ্ধান্ত - যা আপনার পরবর্তী যানবাহন প্রোগ্রামের সাফল্যকে গঠন করতে পারে। চূড়ান্ত অংশে, আমরা প্রধান পয়েন্টগুলি পুনরায় দেখাব এবং ভবিষ্যতের প্রসারের জন্য আপনার স্ট্যাম্পিং প্রক্রিয়া অপ্টিমাইজ করার জন্য পরামর্শ দেব।

সংক্ষিপ্ত বিবরণ এবং পরবর্তী পদক্ষেপ

যখন আপনি কাঁচা ধাতব শীট থেকে নির্ভুল প্রকৌশল গঠিত গাড়ির উপাদানগুলির যাত্রার কথা ভাববেন, তখন পরিষ্কার হয়ে যাবে যে স্বয়ংচালিত ধাতু স্ট্যাম্পিং প্রক্রিয়া কেবল ধাতু গঠনের চেয়ে অনেক কিছু বেশি - এটি প্রকৌশল দক্ষতা, প্রক্রিয়া শৃঙ্খলা এবং বুদ্ধিদুপ্ত সিদ্ধান্ত গ্রহণের সংমিশ্রণ। কিন্তু আপনি কীভাবে আপনার শেখা জিনিসগুলি নিয়ে এগিয়ে যাবেন এবং আসলে স্বয়ংচালিত ধাতু স্ট্যাম্পিং অপ্টিমাইজ করুন আপনার ব্যবসার জন্য প্রকল্পগুলি?

স্বয়ংচালিত স্ট্যাম্পিং সাফল্যের সেরা পদ্ধতি

- উৎপাদনযোগ্যতার জন্য ডিজাইন: স্ট্যাম্পিং সীমাবদ্ধতা বিবেচনা করে এবং DFM টুলগুলি ব্যবহার করে খরচ বহুল সমস্যাগুলি তারাতাড়ি ধরার জন্য শক্তিশালী অংশের ডিজাইন দিয়ে শুরু করুন। অপটিমাইজড টুলিং এবং চিন্তাশীল ডিজাইন উৎপাদনের সমস্যা প্রতিরোধ এবং দীর্ঘমেয়াদী খরচ কমাতে পারে।

- ম্যাটেরিয়াল নির্বাচন: পারফরম্যান্স, ওজন এবং খরচের ভারসাম্য রক্ষাকারী ধাতু বেছে নিন। গাড়ির দীর্ঘায়ুতে গুরুত্বপূর্ণ দৃঢ়তা এবং মরিচা প্রতিরোধ বাড়ানোর জন্য পৃষ্ঠের চিকিত্সা বিবেচনা করা ভুলবেন না।

- অটোমেশন এবং ডিজিটাল টুলগুলি গ্রহণ করুন: সামঞ্জস্য বাড়ানোর জন্য অটোমেশন এবং ডিজিটাল উত্পাদন কৌশল অন্তর্ভুক্ত করুন, ত্রুটি কমান, এবং প্রক্রিয়া অপটিমাইজেশন প্রতি সময় সাড়া দিন। প্রতিযোগিতামূলক থাকার জন্য এখন প্রিডিক্টিভ রক্ষণাবেক্ষণ এবং ডেটা ভিত্তিক সমন্বয় অপরিহার্য হয়ে উঠেছে।

- প্রতিটি পদক্ষেপে মান নিয়ন্ত্রণ: IATF 16949 এর মতো শিল্প মান অনুসরণ করুন এবং কঠোর পরিদর্শন প্রোটোকল প্রয়োগ করুন। ত্রুটি কমানো এবং উচ্চ মানদণ্ড বজায় রাখার জন্য ক্রমাগত উন্নতি এবং কর্মচারীদের প্রশিক্ষণ অপরিহার্য।

- সরবরাহকারী অংশীদারিত্ব: এমন একটি স্ট্যাম্পিং অংশীদারের সাথে কাজ করুন যিনি প্রান্ত থেকে প্রান্ত পর্যন্ত সমর্থন, প্রমাণিত দক্ষতা এবং আপনার পরিবর্তিত প্রয়োজনগুলি পূরণের জন্য স্কেলযোগ্যতা সরবরাহ করেন। সঠিক অংশীদার আপনাকে উন্নয়ন সহজতর করতে, বিলম্ব এড়াতে এবং নিয়ত মান নিশ্চিত করতে সাহায্য করতে পারেন।

অটোমোটিভ স্ট্যাম্পিং প্রক্রিয়ার সেরা অনুশীলন প্রয়োগ করা হচ্ছে

ধরুন আপনি একটি নতুন যানবাহন মডেল চালু করছেন বা একটি গুরুত্বপূর্ণ উপাদান আপডেট করছেন। উপরে উল্লিখিত সেরা অনুশীলনগুলি প্রয়োগ করে আপনি মসৃণ উন্নয়ন চক্র, কম অপ্রত্যাশিত ঘটনা এবং আরও পূর্বানুমানযোগ্য খরচ লক্ষ্য করবেন। শুরু করার জন্য এখানে একটি দ্রুত চেকলিস্ট রয়েছে:

| অ্যাকশন | লাভ |

|---|---|

| প্রারম্ভিক DFM পর্যালোচনায় অংশগ্রহণ করুন | উৎপাদনের আগে ডিজাইনের ত্রুটি ধরুন |

| উপাদান নির্বাচনে সহযোগিতা করুন | কর্মক্ষমতা এবং খরচের জন্য অপ্টিমাইজ করুন |

| প্রধান উৎপাদন পর্যায়গুলি স্বয়ংক্রিয় করুন | আউটপুট এবং মান বৃদ্ধি করুন |

| রিয়েল-টাইম মান পর্যবেক্ষণ প্রয়োগ করুন | খুচরা এবং পুনঃকাজ কমান |

| সম্পূর্ণ-পরিষেবা স্ট্যাম্পিং অংশীদার নির্বাচন করুন | সরবরাহ চেইন সরলীকরণ, ঝুঁকি কমান |

পরবর্তী পদক্ষেপের জন্য প্রস্তুত?

আপনি যদি একজন ইঞ্জিনিয়ার, ক্রয় ম্যানেজার বা অটোমোটিভ প্রকল্প পরিচালক হন, তাহলে অপ্টিমাইজড মেটাল স্ট্যাম্পিংয়ের পথটি তথ্যসহ সিদ্ধান্ত এবং সঠিক অংশীদারিত্বের সাথে শুরু হয়। যদি আপনি এমন একজন অংশীদারের সন্ধান করছেন যিনি প্রোটোটাইপিং থেকে শুরু করে বৃহৎ উৎপাদন পর্যন্ত নির্ভুলতা, নমনীয়তা এবং প্রান্ত থেকে প্রান্ত পর্যন্ত সমর্থন প্রদান করতে পারেন, তাহলে Shaoyi এর মতো বিশেষজ্ঞদের সাথে যোগাযোগ করার বিষয়টি বিবেচনা করুন। তাদের ব্যাপক পদ্ধতি এবং বিশ্ব পরিচালনা কর্তৃপক্ষের (ওইএম) সাথে প্রমাণিত রেকর্ড আপনার প্রকল্পের লক্ষ্যগুলি অর্জন করতে, খরচ কমাতে এবং শীর্ষ মান নিশ্চিত করতে সাহায্য করবে—বহু সরবরাহকারী পরিচালনা করার চাপ ছাড়াই অথবা দেরির ঝুঁকি ছাড়াই।

এগুলো গ্রহণ করে অটোমোটিভ স্ট্যাম্পিং প্রক্রিয়ার সেরা অনুশীলন আপনি দ্রুত পরিবর্তনশীল শিল্পে আপনার দলকে সাফল্যের জন্য প্রস্তুত করবেন। এখন এই অন্তর্দৃষ্টি কাজে লাগানোর সময় এসেছে এবং আত্মবিশ্বাসের সাথে আপনার পরবর্তী অটোমোটিভ প্রকল্পটি এগিয়ে নিয়ে যান।

অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়া সম্পর্কিত প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

1. অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়া কী এবং এটি কেন গুরুত্বপূর্ণ?

অটোমোটিভ মেটাল স্ট্যাম্পিং প্রক্রিয়ায় স্ট্যাম্পিং প্রেস এবং ডাইস ব্যবহার করে সমতল ধাতব শীটগুলিকে নির্ভুল যানবাহন অংশে রূপান্তর করা হয়। এটি উচ্চ মানের, সমান এবং খরচে কম খরচে উপাদানগুলি স্কেলে উত্পাদন করতে অত্যন্ত গুরুত্বপূর্ণ, যা অটোমোটিভ নির্মাতাদের কঠোর শিল্প মানগুলি পূরণ করতে এবং দক্ষতার সাথে নির্ভরযোগ্য যানবাহন সরবরাহ করতে সহায়তা করে।

2. অটোমোটিভ মেটাল স্ট্যাম্পিং-এ জড়িত প্রধান পদক্ষেপগুলি কী কী?

প্রধান পদক্ষেপগুলির মধ্যে রয়েছে উপাদান প্রস্তুতি এবং ব্ল্যাঙ্কিং, পিয়ার্সিং, বেঁকে যাওয়া, টানার বা আকৃতি দেওয়া এবং পরিদর্শনের সাথে সমাপ্তি। প্রতিটি পর্যায় নির্দিষ্ট স্পেসিফিকেশন অনুযায়ী ধাতুকে আকৃতি দেয়, যাতে ফেন্ডার, চ্যাসিস উপাদান এবং ব্রাকেটের মতো অংশগুলি কার্যকারিতা এবং নিরাপত্তা প্রয়োজনীয়তা পূরণ করে।

3. অটোমোটিভ মেটাল স্ট্যাম্পিং-এ সাধারণত কোন উপাদানগুলি ব্যবহৃত হয়?

শক্তি এবং স্থায়িত্বের জন্য অটোমোটিভ স্ট্যাম্পিং সাধারণত ইস্পাতের বিভিন্ন গ্রেড এবং হালকা অ্যাপ্লিকেশনের জন্য অ্যালুমিনিয়াম খাদ ব্যবহার করে। অংশগুলির কার্যকারিতা অনুযায়ী উপাদান নির্বাচন করা হয়, যেমন ক্ষয় প্রতিরোধ এবং চেহারা উন্নত করার জন্য প্লেটিং বা পাউডার কোটিংয়ের মতো পৃষ্ঠ চিকিত্সা যুক্ত করা হয়।

4. কিভাবে মান নিয়ন্ত্রণ স্ট্যাম্পড অটোমোটিভ অংশগুলির নির্ভরযোগ্যতা নিশ্চিত করে?

অটোমোটিভ স্ট্যাম্পিংয়ে মান নিয়ন্ত্রণ IATF 16949 এর মতো কঠোর মান অনুসরণ করে। এর মধ্যে অন্তর্ভুক্ত রয়েছে কাঁচা উপাদান পরিদর্শন, ডাই এবং প্রেস যাচাই, প্রক্রিয়াকরণের সময় পরীক্ষা, পরিসংখ্যানগত প্রক্রিয়া নিয়ন্ত্রণ এবং চূড়ান্ত পরিদর্শন যা মাত্রিক নির্ভুলতা এবং দীর্ঘমেয়াদী কার্যকারিতা নিশ্চিত করে।

5. অটোমোটিভ মেটাল স্ট্যাম্পিং সরবরাহকারী নির্বাচন করার সময় আপনার কী বিবেচনা করা উচিত?

শক্তিশালী প্রকৌশল দক্ষতা, সার্টিফাইড মান সিস্টেম, স্কেলযোগ্য উত্পাদন ক্ষমতা, বিবিধ উপকরণের বিকল্প এবং অগ্রণী অটোমোটিভ ব্র্যান্ডগুলির সাথে প্রমাণিত অভিজ্ঞতা সহ একটি সরবরাহকারী খুঁজুন। শাওয়ি এর মতো কোম্পানিগুলি এন্ড-টু-এন্ড সমর্থন, অ্যাডভান্সড DFM বিশ্লেষণ এবং আপনার প্রকল্পটি স্ট্রিমলাইন করতে বিশ্ব জুড়ে OEMগুলির সাথে অভিজ্ঞতা অফার করে।

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —

ছোট ছোট ব্যাচ, উচ্চ মান। আমাদের তাড়াতাড়ি প্রোটোটাইপিং সার্ভিস যাচাইকরণকে আরও তাড়াতাড়ি এবং সহজ করে —