ما هو الفوسفاتة؟ الأنواع، ومتى يُستخدم كل نوع، ولماذا

ما هو الفسفتة ولماذا تُستخدم؟

معنى الفسفتة في تشطيب المعادن

هل سبق وتساءلت لماذا تدوم بعض أجزاء السيارة لفترة أطول، أو لماذا يلتصق الطلاء بشكل أفضل على بعض الأسطح المعدنية؟ الجواب غالبًا يكمن في عملية تُعرف باسم الفسفاطة . ببساطة، الفسفتة هي عبارة عن معالجة كيميائية تحويلية تحوّل الطبقة الخارجية للمعدن - عادةً الفولاذ الكربوني أو الفولاذ منخفض السبيكة - إلى طبقة بلورية متماسكة من طلاء الفوسفات . هذه الطبقة ليست طلاءً أو طلياً معدنيًا. بل هي سطح جديد يتم إنشاؤه من خلال تفاعل كيميائي، ويُصمم لتحسين مقاومة التآكل، والالتصاق بالطلاء، وخصائص التشحيم عبر صناعات مثل صناعة السيارات، والمثبتات، والأجهزة المنزلية، ومعدات حقول النفط.

كيف تتكون طبقة الفسفتة التحويلية

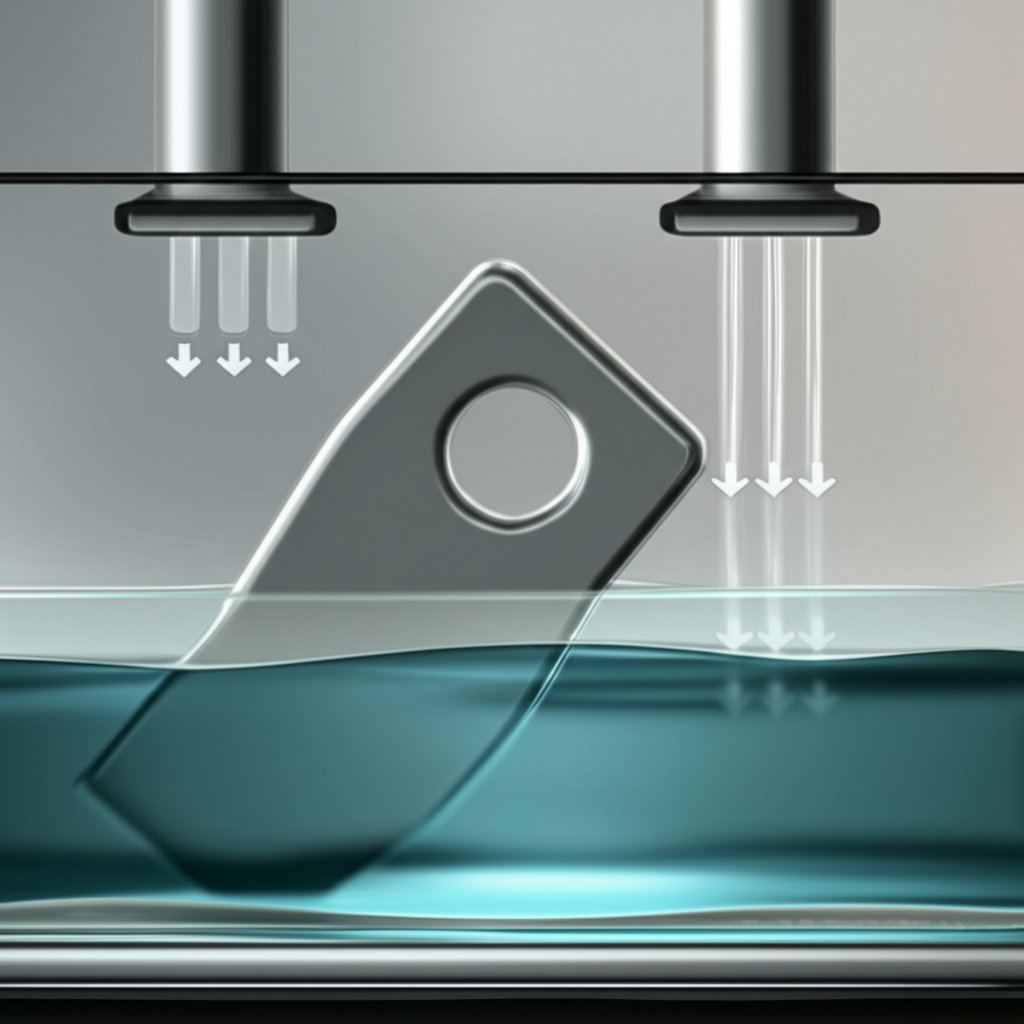

يبدو معقدًا؟ تخيل غمر جزء معدني في حمام خاص يحتوي على حمض الفوسفوريك وأيونات المعادن مثل الزنك أو الحديد أو المنغنيز. يتفاعل الحمض بلطف مع المعدن، ومع تقدم التفاعل، تتكون بلورات الفوسفات وترتكز على السطح، مشكلة طبقة متجانسة مجهرية تُعرف باسم طبقة تحويل الفوسفات . تُسمى هذه العملية أحيانًا بالفسفرة، وتُعدَّ بعناية حسب نوع المعدن الأساسي والنتيجة الأداء المرغوبة. على سبيل المثال، وعلى الرغم من أن الصلب هو المادة الأساسية الأكثر شيوعًا، فإن التركيبات الكيميائية المتخصصة تتيح إجراء الفسفرة على الألومنيوم أو الصلب المطلي بالزنك أيضًا (المصدر) .

الفوائد والمقايضات المتأصلة

لماذا يختار المصنعون الفسفرة مقارنةً بغيرها من المعالجات الأولية؟ إليك قائمة سريعة بما ستلاحظه عند استخدام تشطيب فوسفاتي عالي الجودة:

- تحسن كبير في التصاق الطلاء — يلتصق الطلاء بشكل أفضل ويستمر لفترة أطول

- مقاومة التآكل تحت الطبقات — يحمي المعدن من الصدأ والأضرار البيئية

- تقليل التصاق والارتداء — وهو أمر مهم بشكل خاص للربطات، والتروس، والأجزاء المكونة

- تفعيل سطحي متسق — يضمن طلاءً موحدًا في العمليات اللاحقة

غالبًا ما يتم اختيار الفوسفاتة نظرًا لفعاليتها من حيث التكلفة، وموثوقيتها، وقدرتها على تقديم نتائج متسقة كطبقة أساسية للطلاءات أو المزلقات اللاحقة. ومع ذلك، من المهم أن نتذكر أن طبقة التحويل الفوسفاتية وحدها ليست بديلاً عن طبقة عازلة كاملة في البيئات القاسية. وتعتمد قدرتها الوقائية على التنظيف السليم، ومراقبة الحمام الكيميائي، والمعالجة اللاحقة. وفي حالة عدم توفر هذه العوامل، قد تفشل حتى أفضل تشطيب فوسفاتي في تحقيق التوقعات.

مكانة الفوسفاتة بين المعالجات الأولية

على عكس الدهانات أو الطلاءات، فإن عملية الفوسفاتة هي خطوة تحويل أساسية—غالبًا تكون الأولى في سلسلة العمليات قبل الدهن، أو الطلاء بالمسحوق، أو التزييت. وتُقدَّر هذه العملية بشكل خاص في تصنيع السيارات، حيث تساعد ألواح الهيكل والمثبتات على مقاومة التآكل، وكذلك في أجزاء الآلات وحقول النفط حيث تكون القابلية للتشحيم وتحمل البلى أمراً بالغ الأهمية. وتوجد إصدارات متخصصة من هذه العملية للألومنيوم والفولاذ المطلي بالزنك، لكن معظم التطبيقات تركز على الركائز الفولاذية والحديدية.

تُعد الفوسفاتة خطوة تحويل أساسية تجعل الطبقات اللاحقة أكثر كفاءة، وتمتد مدة بقائها، وتُطبَّق بشكل أكثر اتساقاً.

باختصار، إذا كنت تقوم بالتقييم ما هي عملية الفوسفاتة لفكر في مشروعك القادم كعلاج سطحي استراتيجي يُفعّل أداءً أفضل للدهانات، والمواد التشحيمية، وحتى الأجزاء المعدنية بدون طلاء. ستوجهك الأقسام التالية خلال أنواع الفوسفات الرئيسية، وضوابط العمليات خطوة بخطوة، وقوالب ضمان الجودة، واستكشاف الأخطاء وإصلاحها، ونصائح واضحة للاختيار—لكي تتمكن من اختيار نوع التحويل الفوسفاتي المناسب لاحتياجاتك.

كيف يعمل عملية الفوسفاتة

أساسيات إعداد السطح

عندما تدخل إلى مصنع حديث فوسفاتة قد تبدو تدفقات العمل متقدمة تقنيًا، لكن الخطوات الأساسية تظل عملية ومنهجية. لماذا يعد إعداد السطح أمرًا بالغ الأهمية؟ لأن أداء أي طلاء فوسفات على الصلب يعتمد أولًا على مدى نظافة السطح ونشاطه. تخيل محاولة طلاء معدن به زيوت أو غبار—لن يتماسك الطلاء. لهذا السبب تبدأ كل عملية فوسفاتة ناجحة بنظافة صارمة وفحص دقيق.

- الفحص الأولي وتحديد الشوائب: يتم فحص الأجزاء بحثًا عن الزيوت أو الصدأ أو أي شوائب أخرى. يساعد ذلك في اختيار طريقة التنظيف المناسبة ويضمن تخصيص العملية لكل دفعة.

- التنظيف الميكانيكي أو الكيميائي: قد تتطلب الشوائب العنيدة عملية نفخ بالرمل أو منظفات خاصة قبل المتابعة.

- إزالة الشحوم بالقلويات: يتم إزالة الشحوم وزيوت الورشة باستخدام حمام ساخن قلوي. هذه خطوة ضرورية للحصول على نتائج متسقة في الفوسفاتة النتائج (المصدر) .

- شطف بالماء: يزيل الشطف المنظفات المتبقية، ويمنع التفاعلات غير المرغوب فيها في المراحل اللاحقة.

- التنشيط (إذا تم استخدامه): تستخدم بعض العمليات علاجًا مسبقًا لتحفيز تكوّن بلورات فوسفات دقيقة ومتجانسة—وهي مهمة بشكل خاص للأجزاء ذات الأشكال المعقدة.

نظرة عامة على خطوات التحويل

- تطبيق الفوسفاتة (بالغمر أو بالرش): هنا تحدث التفاعلات الكيميائية الرئيسية. يتم إما غمر الأجزاء أو رشها بحلوى فوسفاتية تحتوي على مركبات الحديد أو الزنك أو المنغنيز. يعتمد الاختيار بين الغمر والرش على هندسة الجزء وحجم الإنتاج ونوع المعالجة بالفوسفات المطلوب. على سبيل المثال، الفوسفاتة الزنكية تُستخدم غالبًا لأجسام السيارات عبر خطوط الرش، في حين قد تخضع الأجزاء الثقيلة للغمر للحصول على تشطيب أكثر متانة.

- شطف تمهيدي (شطفات): بعد عملية الفوسفاتة، يضمن الشطف الجيد عدم بقاء أي كيماويات زائدة، والتي قد تتداخل مع الطبقات اللاحقة.

- المعالجة اللاحقة/السداد (اختياري): يمكن تطبيق سداد كروماتي أو غير كروماتي لتعزيز مقاومة التآكل والالتصاق بالطلاء. يُوصى باستخدام عوامل المعالجة اللاحقة المدعومة بتوثيق تقني واضح لضمان أداء مستقر.

التجفيف والمناورة

- تجفيف: يتم تجفيف الأجزاء باستخدام الهواء الساخن أو الأفران أو سكاكين الهواء استعدادًا للطلاء أو التخزين. ويمنع التجفيف الصحيح بقع الماء ويكفل بقاء طبقة الفوسفات سليمة.

- الطلاء أو التخزين المحمي: أصبحت الأجزاء المعالجة الآن جاهزة للطلاء أو الطلاء بالمسحوق أو التشحيم أو التخزين المؤقت. إن التنفيذ الجيد لـ غسيل الفوسفات يعني أن المعدن أصبح مهيئًا لأي عملية تالية.

العوامل الحرجة وقائمة الجاهزية

عبر جميع مراحل فوسفاتة ، تحدد عدة عوامل جودة الطلاء:

- سطح نظيف خالٍ من الزيوت قبل عملية الفوسفاتة

- تحريك مستمر لحمام المعالجة والتحكم في درجة الحرارة

- شطفات نظيفة وغير ملوثة بين الخطوات

- الحد الأدنى من الوقت بين الشطف والفسفرة والتجفيف

- إعادة تعبئة الحوض بشكل خاضع للرقابة — تعديل المواد الكيميائية حسب الحاجة للحصول على نتائج موحدة

قبل نقل الأجزاء إلى المرحلة التالية، تحقق من:

- عدم وجود تمزق مائي (تمتد المياه بالتساوي عبر السطح)

- مظهر غير لامع ومتجانس من طبقة الفسفرة

- عدم وجود شوائب أو بقايا مرئية

- تصريف مناسب — لا تجمع للمياه ولا خطوط

نقاط اتخاذ القرار: الغمر مقابل الرش، الحديد مقابل الزنك مقابل المنغنيز

غالبًا ما يعتمد اختيار العملية المناسبة على تصميم الجزء والاستخدام المقصود له. يُفضل الغمر للأجزاء الثقيلة أو المعقدة أو التي تتعرض لارتداء شديد، في حين تناسب خطوط الرش الأشكال البسيطة ذات الإنتاج المرتفع. وتُعد فسفرة الحديد فعالة من حيث التكلفة للدهانات الأساسية، الفوسفاتة الزنكية يُختار الفوسفات الحديدي لحماية متفوقة من التآكل، ويُستخدم المنغنيز عندما تكون قابلية التشحيم أمرًا بالغ الأهمية. إذا كانت هناك حاجة إلى دقة في درجة الحموضة أو درجة الحرارة أو زمن الغمر، فيجب الرجوع إلى المعايير ذات الصلة أو البيانات الفنية المقدمة من المورد. بشكل عام، فإن ضمان انتظام ترطيب القطعة العاملة، وتحريك سائل الحمام بشكل كافٍ، وتقليل التأخيرات بين الخطوات إلى أدنى حد ممكن، هي عوامل رئيسية لضمان الجودة.

تذكّر أن الهدف من كل طلاء فوسفات على الصلب هو توفير قاعدة متسقة ولصيقة لأي عملية تالية—سواء كانت طلاءً، أو مسحوقًا، أو زيتًا. سيُساعدك القسم التالي على اختيار نوع الفوسفات المناسب لتطبيقك، مع مقارنة خيارات الحديد والزنك والمنغنيز حسب الوظيفة واحتياجات الصناعة.

أنواع طلاءات الفوسفات ومتى يجب استخدامها

المقارنة السريعة بين الحديد والزنك والمنغنيز

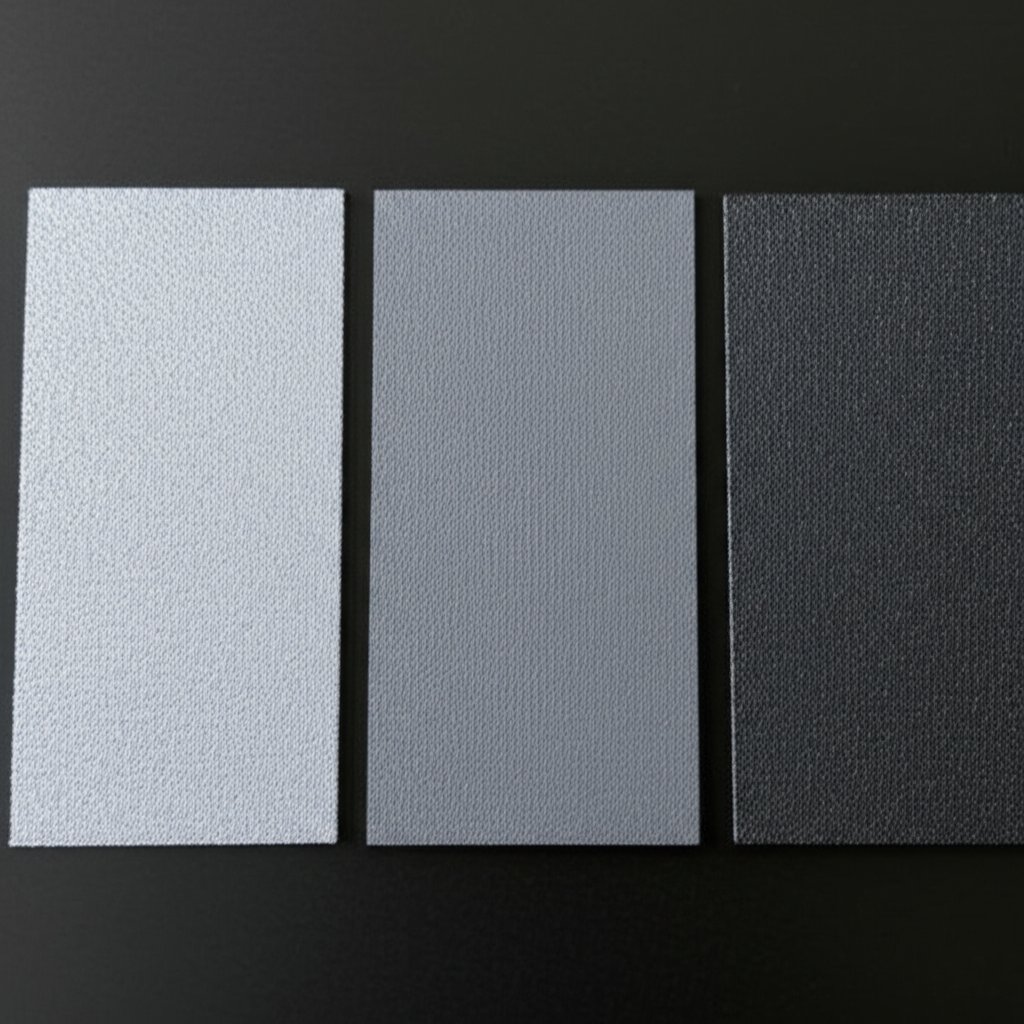

عندما تقرر أي نوع من التشطيب الفوسفاتي هو الأفضل لمشروعك، فإن مقارنة الاختلافات الأساسية جنبًا إلى جنب أمرٌ مفيد. كل نوع — حديد، زنك، ومنجنيز — يقدّم فوائد فريدة لتلبية احتياجات صناعية محددة. دعونا نستعرض المزايا العملية والمقايضات لكل نوع:

| نوع الفوسفات | الوظيفة الأساسية | الطلاءات النهائية النموذجية | مقاومة التآكل (تحت الطلاء) | المقاومة للتآكل/الانزلاق | الصناعات/التطبيقات الشائعة |

|---|---|---|---|---|---|

| طلاء الفوسفات الحديدي | قاعدة للطلاء، وحماية معتدلة من التآكل | طلاء سائل، طلاء بودرة | جيدة (للبيئات المعتدلة) | منخفض (غير ماص للزيوت) | الأجهزة، الألواح الهيكلية للسيارات، الرفوف، السلع الاستهلاكية |

| طلاء فوسفات الزنك | قاعدة الطلاء، طلاء مضاد للتآكل، التشكيل البارد | الطلاء السائل، الطلاء بالمسحوق، الزيت، الشمع | ممتاز (الأفضل بين الفوسفات) | متوسط (يمتص المزلقات جيدًا) | هيكل السيارات، المعدات الثقيلة، المثبتات، الجيش، الإنشاءات |

| الطلاء الفوسفاتي المنغنيزي | التآكل الأولي، الانزلاق، الحماية أثناء التشغيل الأولي | الزيت، الشمع، الدهان الخفيف | جيدة جدًا (عند تزييتها)، متوسطة (عريضة) | عالية (الأفضل للأجزاء المتحركة) | التروس، المحامل، المثبتات، أدوات حقول النفط، الأجزاء الداخلية للمحرك |

اختيار وزن الفيلم والبنية البلورية

ليست جميع التشطيبات الفوسفاتية متساوية—حتى داخل النوع الواحد، ستجد خيارات بسمك أفلام مختلفة وأحجام بلورات متباينة. إليك كيفية مطابقة المناسب طلاء الفوسفات بالنسبة لتطبيقك:

- الطلاءات الأثقل: اختر الأغشية ذات الوزن الأعلى والبلورات الخشنة عندما تحتاج إلى احتفاظ قصوى بالزيت أو الشمع—وهي مثالية لـ الطلاء الفوسفاتي المنغنيزي على المثبتات والتروس، أو الثقيلة طلاء فوسفات الزنك للتشكيل البارد ومنع الصدأ.

- الطلاءات الأخف، ذات البلورات الدقيقة: اختر هذه للهندسات المعقدة أو عندما يكون السطح الناعم الجاهز للدهن أمرًا بالغ الأهمية. يُعد فوسفات الحديد وفوسفات الزنك الخفيف من الخيارات الشائعة في خطوط الرش عالية الإنتاجية، حيث تكون المظهر الموحّد والالتصاق بالطلاء هما العاملان الأكثر أهمية.

إن أداء طبقة الفوسفات لا يتعلق فقط بالسماكة، بل أيضًا بهيكل البلورة. فالطبقات الكثيفة والرقيقة تساعد على التصاق الطلاء ومقاومة التآكل، في حين تمتص الطبقات الخشنة ذات البنية المفتوحة الزيت لتوفير تزييت ممتاز وحماية أفضل ضد البلى.

التوصيات الخاصة بالصناعات

- هيكل السيارة الأبيض والألواح: غالبًا ما يستخدم طلاء فوسفات الحديد كقاعدة طلاء اقتصادية في البيئات المعتدلة. ولتحقيق مقاومة أفضل للتأكل، خاصةً في هيكل الشاسيه، يُفضّل استخدام طلاء فوسفات الزنك.

- المثبتات، التروس ومكونات المحرك: يُعد تشطيب الفوسفات المنجنيز الخيار المثالي للتآكل الأولي والتكسير والانزلاق، خاصةً عندما يتم تزييت القطعة بعد المعالجة. وغالبًا ما ترى هذا النوع من التشطيب على هيئة فوسفات أسود على الأجزاء المتحركة الحرجة.

- المعدات الثقيلة والعسكرية: يُفضل الطلاء بالفوسفات الزنك لامتلاكه حماية ممتازة ضد تآكل تحت الطبقة ولتوافقه مع طبقات علوية متعددة، بما في ذلك الزيوت والشموع.

- الأجهزة المنزلية والسلع الاستهلاكية: يُستخدم فوسفات الحديد على نطاق واسع نظرًا لبساطته وفعاليته من حيث التكلفة في الحالات التي لا يُطلب فيها مقاومة شديدة للتآكل.

من المهم أن تتذكر: إن علم المعادن والعمليات التشكيلية السابقة ونظافة السطح يمكن أن تؤثر على النتائج بقدر تأثير تركيبة الحمام نفسه. حتى أفضل الطلاء الفوسفاتي المنغنيزي أو طلاء فوسفات الزنك سوف يفشل في تحقيق النتائج إذا لم يتم تحضير الركيزة بشكل صحيح.

اختر طلاءً أثقل وخشناً عند الحاجة إلى احتفاظ بالزيت أو مقاومة للبلى؛ واختر تشطيباً أخف ذا بلورات دقيقة للأشكال المعقدة أو عندما يكون مظهر الطلاء أمراً بالغ الأهمية.

باختصار، اختيار تشطيب الفوسفات المناسب يدور حول مطابقة الوظيفة مع البيئة والعملية اللاحقة. سواء كنت بحاجة إلى تشطيب فوسفات المنغنيز لحماية مرحلة التشغيل الأولي، أو طبقة فوسفات حديد اقتصادية للخطوط الطلاء، فإن فهم هذه الاختلافات يساعدك على اتخاذ أفضل خيار لتطبيقك. بعد ذلك، سنستعرض كيف تتفاعل طبقات الفوسفات مع الدهانات والأساسيات لتحقيق التحكم طويل الأمد بالتآكل والالتصاق.

الفوسفاتة من أجل التصاق الطلاء والتحكم في التآكل

لماذا يحسن الفوسفات من التصاق الطلاء

هل سبق وتساءلت لماذا تقاوم بعض الأجزاء المعدنية المصبوغة التشقق أو التموج أو الصدأ لسنوات، في حين تفشل أخرى بسرعة؟ السر غالبًا ما يكون في تحضير السطح — وبشكل خاص، في استخدام الفوسفاتة. عندما تقوم بتطبيق طبقة فوسفاتية، فإنك تُكوّن طبقة بلورية دقيقة على المعدن. هذه الطبقة ليست للتزيين فحسب؛ بل توفر تأثير ربط مجهري فريد. تخيل وجود ملايين القمم والوديان الصغيرة جدًا على المستوى المجهرى. يمكن لمادة التمهيدي للطلاء، مثل مادّة أولية للطلاء فوسفات الزنك ، أن تتخلل هذه المناطق، وتثبت في مكانها وتكوّن رابطة أقوى بكثير مع المعدن الموجود تحتها. ويضمن هذا الربط المجهري، إلى جانب تحسين طاقة السطح للمعدن المعالج، التصاق الطلاء أو طلاء البودرة بشكل أكثر انتظامًا ومقاومته للتقشر مع مرور الوقت.

توافق المادة الأولية وترتيبها

الحصول على أقصى استفادة من التشطيب الفوسفاتي لا يعتمد فقط على الطبقة نفسها، بل أيضًا على ما يليها. إليك قائمة تحقق لممارسات أفضل عند التحضير للطلاء أو الطلاء بالمسحوق:

- التنظيف الشامل: قم بإزالة الزيوت، والغبار، والتآكل غير المرتبط تمامًا قبل عملية الفوسفة.

- النقل السريع إلى مرحلة الطلاء: انقل الأجزاء إلى مرحلة الطلاء في أقرب وقت ممكن بعد التجفيف لمنع ظهور الصدأ الفوري أو التلوث.

- البرايمر المتوافق: استخدم برايمر مُعد خصيصًا للالتصاق بالأسطح المعالجة بالفوسفات، مثل مادّة أولية للطلاء فوسفات الزنك للصلب.

- التعامل بعناية: تجنب لمس الطبقة الفوسفاتية أو تلويثها قبل الطلاء أو الطلاء بالمسحوق.

تُعد عملية الفوسفة فعالة بشكل خاص كخطوة تحضيرية لكل من الطلاء السائل والطلاء بالمسحوق، بما في ذلك على معدن صفحي مطلي بالمسحوق تساعد طبقة الفوسفات في منع مشكلات مثل انبعاث الغازات أو التصاق ضعيف، بشرط أن تكون نظيفة وجافة ومغلّفة بشكل صحيح قبل الطلاء.

حقائق معالجة الصدأ: الطلاء فوق الصدأ والتحكم في التآكل

قد ترى منتجات يتم تسويقها لـ الطلاء فوق الصدأ ، ولكن إليك ما يجب معرفته للحصول على نتائج موثوقة وطويلة الأمد: بينما يمكن لأصباغ متخصصة معينة أن تحبس الصدأ الموجود وتبطئ من انتشاره، فإن الأداء الأكثر قابلية للتنبؤ يأتي من إزالة أكبر قدر ممكن من التآكل غير المرغوب فيه، وتنظيف السطح تنظيفاً جيداً، ثم تطبيق طلاء تحويلي مثل الفوسفاتة قبل الطلاء (غير الدهانات) يضمن هذا الأسلوب التصاق نظام الطلاء الجديد بقاعدة مستقرة ومقاومة للتآكل، بدلاً من التصاقه بالصدأ المتفتت الذي قد يُضعف التشطيب النهائي.

بالنسبة للزنك، يتساءل الكثيرون: هل الزنك المطلي مقاوم للصدأ؟ يُوفر الطلاء بالزنك طبقة تضحية تحمي الفولاذ من خلال التفاعل مع الأكسجين أولاً. ومع ذلك، فهذا ليس حلاً دائمًا—فمع مرور الوقت، وبخاصة في البيئات القاسية أو البحرية، يضعف الزنك ويصبح الفولاذ عرضة للتآكل. ولتحقيق أقصى درجات المتانة، فإن الجمع بين المعالجة المسبقة بالفوسفات والزنك مع أوليات متوافقة وطبقات نهائية يُعد استراتيجية مثبتة.

إن متانة الطلاء تعتمد على جودة تحضير السطح—فالفسفرة ترفع من مستوى الأداء على المدى الطويل.

توافق الطلاء البودري: تجنّب الأخطاء الشائعة

تعتبر المعادن المُعالَجة بالفوسفات مرشحة ممتازة للطلاء البودري، ولكن فقط إذا كانت طبقة الفوسفات نظيفة ومغلقة وجافة تمامًا. وإلا فقد تواجه مشاكل مثل انبعاث الغازات (فقاعات أو ثقوب صغيرة) أو التصاق ضعيف. معدن صفحي مطلي بالمسحوق ، تأكد دائمًا من أن السطح المعالج بالفوسفات يجتاز اختبار انقطاع الماء ولا يحتوي على ملوثات قبل نقله إلى الفرن. يساعدك هذا الاهتمام الإضافي في ضمان أن تشطيب الطلاء بالمسحوق يقدم جاذبية بصرية وحماية قوية من التآكل.

مع توفر أساس المعالجة الفوسفاتية، يمكنك بناء نظام طلاء أو طلاء بالمسحوق مقاوم للصدأ ويبدو رائعًا ويستمر لسنوات بثقة. بعد ذلك، سنغوص في أسس التحكم في العملية وإدارة الحمام—لكي تتمكن من الحفاظ على نتائج متسقة وعالية الجودة في كل مرة.

أساسيات التحكم في العملية وإدارة الحمام للحصول على نتائج متسقة في المعالجة الفوسفاتية

مراقبة الحمام وأساسيات التمدّد الكيميائي (التتر)

هل سبق وتساءلت لماذا تكون دفعة واحدة من الصلب المعالج بالفوسفات ذات تشطيب ممتاز بينما تفشل أخرى؟ تكمن الإجابة في التحكم في العملية. إدارة عملية الطلاء التحويلية بالفوسفات تعني تتبع المتغيرات الصحيحة واستخدام المواد الكيميائية الخاصة بالفوسفاتة والاستجابة السريعة للتغيرات. يبدو الأمر معقدًا؟ دعونا نبسطه حتى تتمكن من الحفاظ على طلاءاتك متسقة وأداءً عاليًا.

- التحاليل اليومية لحمض الكلي/الحر: يُعد التحليل الدوري خط الدفاع الأول لديك. استخدم طريقة المورد لقياس الحمض الكلي (الحمضية الكلية) والحمض الحر (الجزء التفاعلي). تخبرك هذه الأرقام ما إذا كان حوضك ضمن النطاق الأمثل لتكوين طبقة تحويل الفوسفات الزنك المتينة zinc phosphate conversion coating أو iron phosphate pretreatment .

- التحقق من درجة الحرارة: تعمل أحواض الفوسفات بشكل أفضل في درجات حرارة عالية ومستقرة — غالبًا فوق 180°فهرنهايت. إذا كانت درجة الحرارة منخفضة جدًا يتوقف التفاعل؛ وإذا كانت مرتفعة جدًا، فإنك تجازف بتآكل المعدن أو تكوين طبقات خشنة وبكميات حبيبية.

- فحص الرواسب: تُنتج جميع عمليات الفوسفات رواسب كمنتج ثانوي. تحقق من قاع الخزان وفخاخ الرواسب يوميًا. قد تشير التراكمات الزائدة إلى اختلال توازن الحوض أو تلوث مفرط.

- فحوصات توصيلية الشطف: بعد الفوسفاتة، يجب أن تكون عمليات الشطف نظيفة ومنخفضة التوصيلية. قد تشير القراءات العالية إلى وجود انتقال كيميائي أو شطف غير كافٍ، مما قد يؤثر على المراحل اللاحقة طبقة الفوسفاتة متسقة.

- تسجيل مدة التواجد في الحوض: احتفظ بسجل لمدة بقاء كل قطعة في الحوض. تساعد الأوقات الثابتة للبقاء في الحوض على ضمان توحيد سماكة الطبقة البنائية والبنية البلورية.

| التاريخ/الوردية | رقم الحوض | درجة الحرارة | الحمض الحر/الكلي | مسرِّع | ملاحظة الرواسب | توصيلية شطف المياه | الإضافات | ملاحظات | الحروف الأولى |

|---|---|---|---|---|---|---|---|---|---|

| 06/01 صباحًا | فوس-1 | 185°ف | 6.0/1.0 | موافق | ضوء | منخفض | لا شيء | — | JS |

إعادة التعبئة والتحكم في السحب الخارجي

كيف تحافظ على حوضك في النطاق المثالي؟ أضف المحاليل المركزّة بناءً على نتائج التحليل الحجمي، ومعدل الإنتاج، ونوعية الفيلم المرئية. إذا انخفض الحمض الحر أو الحمض الكلي عن القيمة المستهدفة، فقم بإضافة المزيد من المادة المناسبة المواد الكيميائية الخاصة بالفوسفاتة . إذا لاحظت طلاءً غير متساوٍ أو رقيقًا جدًا، فتحقق من حدوث انخفاضات في درجة الحرارة أو من وجود سحب خارجي مفرط — عندما تسحب القطع كمية كبيرة جدًا من المحلول خارج الحوض. يمكن أن تساعد أنظمة الجرعات التلقائية، ولكن حتى التعديلات اليدوية تكون فعّالة إذا قمت بتوثيق التغييرات ومراقبة الاتجاهات. تذكّر، إن إعادة التعبئة لا تعني فقط الإضافة؛ بل تعني استعادة التوازن الصحيح لـ عملية الطلاء التحويلية بالفوسفات .

مصادر التلوث والإشارات الدالة عليه

حتى أفضل الأحواض إداريًا قد تتعرض للتلوث. فيما يلي المشتبه بهم الرئيسيون الذين يجب مراقبتهم:

- الزيوت الناتجة عن التنظيف غير الكافي قبل iron phosphate pretreatment

- أملاح المياه العسرة التي يمكن أن تترسب وتخل بالتوازن الكيميائي

- جزيئات الصلب والشوائب الناتجة عن مراحل المعالجة السابقة

- التلوث المتقاطع من المواد الكيميائية السابقة أو المنظفات غير المتوافقة

قم بفحص خزاناتك وتنظيفها بانتظام، واتبع إرشادات المورد بشأن تغيير الدورة الدورية للمحاليل للحفاظ على التلوث تحت السيطرة. إذا لاحظت تغيرات مفاجئة في مظهر الطلاء—مثل التكتل، أو تغير اللون، أو الرواسب الزائدة—فابدأ بالتحقيق فورًا. وستساعدك السجلات المنتظمة والتحليل المستمر للاتجاهات في اكتشاف المشكلات قبل أن تؤثر على الصلب المعالج بالفوسفات إنتاجك.

ربط التحكم في العملية بجودة الطلاء

لماذا كل هذا الجهد؟ لأن التحكم الدقيق في العملية يؤدي إلى تشكيل طبقة موحدة، وأداء موثوق، وحدوث أقل للمفاجآت غير المرغوبة أثناء عمليات الدهان أو التشكيل اللاحقة. تخيل أنك أرسلت دفعة من القطع إلى عملية الدهان، فقط لتكتشف وجود التصاق ضعيف أو تشطيب غير متساوٍ—غالبًا ما يعود السبب الجذري إلى معامل تم تخطيه في طبقة الفوسفاتة المحلول. ومن خلال استخدام قائمة المراجعة وسجل المحاليل المذكورة أعلاه، ستمنح كل دفعة أفضل فرصة للنجاح. عملية الطلاء التحويلية بالفوسفات .

هل أنت مستعد لاتخاذ الخطوة التالية؟ في القسم القادم، سنغطي قوالب قبول الفحص والتوثيق—لكي تتمكن من التحقق من الجودة والحفاظ على استمرارية عمليتك في المسار الصحيح في كل مرة.

قوالب قبول الفحص والتوثيق لضمان جودة الفوسفاتة الموثوقة

معايير القبول التي يمكن للمؤلفين اعتمادها

عند إدارة خط الفوسفاتة، كيف تتأكد من أن الأجزاء المغطاة بالفوسفات مغطاة بالفوسفات تفي بالمتطلبات في كل مرة؟ إن معايير القبول الواضحة والقابلة للتنفيذ تُحدث فرقاً كبيراً. فيما يلي جدول عملي يمكنك استخدامه لتوحيد فحوصات الجودة لأي طلاء فوسفات على الصلب أو طلاء فوسفات على الألومنيوم التطبيق:

| السمة | معايير القبول | طريقة الاختبار/المرجع |

|---|---|---|

| مظهر | تشطيب غير لامع ومتجانس، بدون بقع عارية، أو مواد لزجة أو بقع بيضاء؛ ولون متسق (من الرمادي إلى الأسود للصلب، وفق المواصفات) | الفحص البصري تحت إضاءة 50 لومن/قدم فأكثر 2(538 لومن)؛ انظر TT-C-490H، 3.5.1 |

| التصاق | أقل من 5٪ من الطلاء يتم إزالته بواسطة الشريط اللاصق؛ التقييم الأدنى 4B (اختبار الشريط) | ASTM D3359 (اختبار الشبكة/الشريط)؛ TT-C-490H، 3.5.6 |

| وزن/سمك الطلاء | ضمن نطاق المورد/العقد (مثلاً: النطاق النموذجي مثل 1.1–11.8 غ/م² لفوسفات الزنك و0.2–1.0 غ/م² لفوسفات الحديد) | إزالة الوزن وفقًا لـ TT-C-490H، A.4.5–A.4.9 أو MIL-DTL-16232G، 4.7.3 |

| النظافة | لا تشكل المياه نقاطاً (تنتشر المياه بشكل متساوٍ)؛ لا توجد أوساخ مرئية أو تآكل | ASTM F21/F22 (اختبار عدم تشكل المياه للنقاط)؛ TT-C-490H، 3.3.1، 4.7.3.1 |

| المعالجة اللاحقة (إذا لزم الأمر) | وجود مادة الختم/الزيت حسب المواصفات؛ لا بقايا زائدة | مرئي/لمس؛ ورقة عملية المورد |

طرق الفحص وأخذ العينات: تخطيط عملي للضوابط النوعية

يبدو معقدًا؟ إليك قائمة مراجعة يمكن مسحها ضوئيًا لمساعدتك في إعداد خطة فحص قوية لـ مُعالج فوسفاتيًا الأجزاء، سواء كنت تعمل على خط إنتاج عالي الحجم أو عملية دفعات متخصصة:

- تعريف الدفعة: التجميع حسب الركيزة، ونوع الطلاء، ودفعة العملية أو الوردية (انظر TT-C-490H، 4.3.2).

- حجم العينة: اتبع خطة الجودة الداخلية الخاصة بك، ولكن الممارسة النموذجية هي أخذ عينتين على الأقل من العينات لكل دفعة أو إنتاج يومي.

- اختبار وزن الطبقة: قم بإزالة الطبقات واوزن القسائم الاختبارية وفقًا لـ TT-C-490H، A.4.5–A.4.9 أو MIL-DTL-16232G، 4.7.3.

- اختبار التصاق: استخدم اختبار الشريط المتشابك (ASTM D3359) بعد تطبيق الطلاء. بالنسبة لـ طبقة تحويل الفوسفات الحديدي ، تحقق من أن الطلاء لا يتقشر أو يتقشر.

- مقاومة التآكل: رش الملح (ASTM B117) أو التآكل الدوري (GMW14872) حسب المواصفات الواردة في العقد أو الرسم.

- الاحتفاظ بالوثائق: احتفظ بسجلات نتائج الاختبارات، وسجل الحمام، والتفتيش لكل دفعة وفقًا للمواصفة TT-C-490H، البند 6.13.

لـ طلاء فوسفات على الألومنيوم ، تأكد من استخدام الألواح الاختبارية الخاصة بالألومنيوم والمتطلبات الواردة في المواصفة MIL-DTL-5541 أو TT-C-490H، وسجّل أي انحرافات أو خطوات عملية خاصة.

أمثلة على صياغة المواصفات للعقود والرسومات

تحتاج إلى بند جاهز للاستخدام في أمر الشراء القادم أو الرسم؟ إليك قالب يمكنك تكييفه لطلاء الفوسفات الصلب أو الاحتياجات الشائعة الأخرى:

توفير طبقة تحويل فوسفات مناسبة كأساس للطلاء على أجزاء من الصلب الكربوني أو الألومنيوم. يجب أن تشمل العملية التنظيف، الشطف، التحويل، الشطف مرة أخرى، المعالجة اللاحقة (إذا تم تحديدها)، والتجفيف. استخدم الفوسفات الحديدي أو الزنك حسب المحدد في الرسم؛ ويجب أن يكون مظهر الطبقة موحدًا دون وجود بقع أو مناطق عارية. تحقق من وزن الطلاء والالتصاق وفقًا لمعايير ASTM/ISO المعمول بها. احتفظ بسجلات ضبط الجودة والتفتيش لكل دفعة.

مراجع معايير مثل ASTM D3359 (الالتصاق)، ASTM B117 (رذاذ الملح)، وTT-C-490H أو MIL-DTL-16232G للمعايير الخاصة بالعملية وقبولها (انظر TT-C-490H للتفاصيل) .

نموذج سجل الدفعة ووثائق ضمان الجودة

الحفاظ على التنظيم أمر أساسي للامتثال ومعالجة المشكلات. فيما يلي جدول سجل دفعة بسيط يمكنك تنفيذه لكل تشغيلة من مغطاة بالفوسفات الأجزاء:

| أمر العمل | رقم الجزء | القاعدة | مسار العملية | أرقام الخزانات | الأوقات (البدء/الانتهاء) | العامل | النتائج/القياسات | التوزيع | إجراءات عدم المطابقة |

|---|---|---|---|---|---|---|---|---|---|

| WO-2024-001 | 12345A | فولاذ | فوسفات الحديد/الرش | P1، R1 | 08:00–09:30 | JD | وزن الطبقة: 3.2 غ/م² 2; التصاق: 4B؛ المظهر: نجاح | مقبول | — |

لمزيد من ضمان الجودة الشامل، يمكنك إضافة حقول لظروف البيئة، أو التعليمات الخاصة، أو روابط للصور الرقمية. بالنسبة إلى مُعالج فوسفاتيًا الألومنيوم، يُرجى ملاحظة أي انحرافات في العملية أو نتائج الاختبارات الخاصة.

باتباع هذه القوالب والرجوع إلى المعايير المعتمدة، ستتمكن من تبسيط عملية الفحص، وتسريع عمليات التدقيق، وضمان أن كل طلاء فوسفات على الصلب أو أن جزء الألومنيوم يلبي توقعات عميلك. بعد ذلك، سنعالج استكشاف الأخطاء وإصلاحها—لمساعدتك في تشخيص العيوب وتصحيحها بسرعة حتى تظل عملية التصنيع تحت السيطرة.

استكشاف أخطاء عيوب الفوسفاتة في الصلب وإجراءات التصحيح

تشخيص العيب من المظهر الخارجي

عند تشغيل خط الفوسفاتة، حتى المشغلين ذوي الخبرة قد يواجهون مفاجآت—مثل طلاء غير منتظم، أو ألوان غريبة، أو طلاء لا يلتصق بشكل جيد. هل يبدو هذا مألوفًا؟ دعونا نحلل ما تعنيه هذه الأعراض، لكي تتمكن من الفوسفاتة أجزاء الصلب بثقة وثبات. فيما يلي جدول عملي يمكنك استخدامه لتشخيص العيوب الشائعة وتصحيحها ومنعها في فوسفاتة الصلب و فوسفاتة المنغنيز الخطوط.

| العرض | الأسباب المحتملة | الإجراءات التصحيحية | التدابير الوقائية |

|---|---|---|---|

| مناطق غير منتظمة أو عارية | تنظيف ضعيف (زيت/صدأ)، حمض منخفض، مسرّع مستنفد، وقت عملية قصير، درجة حرارة منخفضة | إعادة تنظيف الأجزاء، التحقق من كيمياء الحمام والتعديل وفقًا لمعايرة المورد، زيادة الوقت/درجة الحرارة، تحسين التنشيط | التحقق من فعالية التنظيف، تشديد جدول المعايرة ومراقبة الحمام، والحفاظ على حمام التنشيط المناسب |

| ملمس خشن، رملي؛ التصاق ضعيف | حمام عتيق جدًا (طمي مرتفع)، حمض حر مرتفع، وقت معالجة مفرط، نمو بلوري خشن | إزالة الطمي، تعديل نسبة الحمض (FA/TA)، تقليل وقت المعالجة، تجديد الحمام عند الحاجة | مراقبة محتوى الطمي، والحفاظ على نسبة FA/TA ضمن النطاق المحدد من قبل المورد، وتجنب الإفراط في المعالجة |

| تكوّن الصدأ الأبيض بسرعة؛ فشل اختبار الرش الملحي | طبقة فوسفات رقيقة، إغلاق غير كافٍ، تلوث الشطف (كلوريدات/كبريتات) | زيادة وزن الطلاء (ضبط الحمام، الوقت، درجة الحرارة)، تطبيق مانع تسرب بعد المعالجة، واستخدام ماء شطف منزوع الأيونات | تحقق بانتظام من سماكة الطلاء، وتأكد من تطبيق السدادة، وضمان نقاء ماء الشطف |

| أوساخ داكنة/سوداء؛ بقع صفراء أو داكنة | الإفراط في الحفر، تلوث الحمام (المعادن الثقيلة)، ارتفاع درجة حرارة الحمام، الشطف السيئ | تجديد مراحل الشطف، التحكم في درجة حرارة الحمام، تنقية الحمام (بالترشيح)، التحييد والشطف بعد التخليل | الالتزام بحدود التوصيلية في مراحل الشطف، ومراقبة درجة حرارة الحمام، وتجنب مصادر المياه الملوثة |

| التغميق أو نمو البلورات غير المنتظم | حمام ملوث، تراكم زائد للحديد، رواسب عالية | تفريغ جزئي، ترشيح، إزالة الرواسب حسب الجدول الزمني | إضافة نظام ترشيح، زيادة عمليات إزالة الرواسب، ومراقبة محتوى الحديد 2+المستويات |

| تماسك ضعيف للطلاء، تشكل فقاعات، تقشر | الزيوت المتبقية، التنشيط غير الكافي، الشطف الرديء، طبقة الفوسفات السميكة جدًا أو الرخوة | مراجعة خطوات التنظيف والتنشيط، والتحقق من سطح خالٍ من انقطاع الماء، وتحسين عملية الفوسفاتة (تجنب البلورات الخشنة)، وتحسين الشطف | توحيد خطوات التحضير، وتقليل الوقت حتى الطلاء، وضمان شطف كامل |

| تكوّن طمي كثيف | تحميل عالٍ، اهتزاز منخفض، أكسدة، انتقال الحديد من عملية التنقية | زيادة الاهتزاز، وتحديد مواعيد منتظمة لإزالة الطمي، والتحكم في محتوى الحديد | ضبط زاوية الرف / تصريف السوائل، والحفاظ على جودة عملية التنقية، وتثبيت نظام تصفية |

الإجراءات التصحيحية والوقائية

تخيل أنك تلاحظ طبقة فوسفاتية سوداء غير منتظمة طبقة فوسفاتية سوداء غير منتظمة أو ملاحظة وجود طبقة زائدة من الرواسب في قاع الخزان. ماذا بعد؟ لا تكتفِ بإصلاح المشكلة الفورية—وثّق السبب الجذري في سجل الدفعة الخاصة بك وقم بمراجعة منطق إعادة التعبئة لديك. تأتي العديد من المشكلات المتكررة في عمليات الفوسفاتة من خطوات التنظيف التي تم تجاهلها، أو الحمامات القديمة، أو المراقبة غير المتسقة. إن تشديد جدول التعيين الكيميائي، والتحقق من اختبار انكسار الماء، وضمان التحريك المناسب سيساعدك على الحصول على الفوسفاتة أجزاء بنتائج أقل إدهاشًا.

- لمسة نهائية غير لامعة ومتجانسة—بدون بقع لامعة أو عارية

- أنماط تصريف متسقة—بدون خطوط أو بقع

- عدم حدوث انكسار للماء—يجب أن ينسكب الماء بشكل موحد عبر السطح

هذه المؤشرات تؤكد أن عمليتك تسير وفق المسار الصحيح. إذا كان هناك شيء غير سليم، تصرف سريعًا: راجع خطوة التنظيف، وتحقق من كيمياء الحمام، وافحص عمليات الشطف. بالنسبة للمشكلات المستمرة، راجع النشرات الفنية لموردك للحصول على الحدود المحددة—لا تحزر الأرقام أبدًا ولا تقوم بأي تعديلات دون بيانات.

ربط العيوب بالأسباب السابقة لها

فكّر في استكشاف الأخطاء وإصلاحها كعملية تحقيق. على سبيل المثال، إذا لاحظت التصاقًا ضعيفًا للطلاء بعد فوسفاتة المنغنيز ، قم بالتتبع العكسي خلال عملية العمل: هل كانت خطوة التنظيف فعّالة؟ هل تحققت من جودة التنشيط والشطف؟ هل كانت كيمياء الحمام تحت السيطرة؟ غالبًا ما يكون السبب الجذري للعيب موجودًا في مرحلة سابقة. من خلال تتبع الأعراض والأسباب بشكل منهجي، يمكنك منع تكرار المشكلات والحفاظ على تشطيبات عالية الجودة دفعة تلو الأخرى.

من خلال استخدام هذا النهج في استكشاف الأخطاء وإصلاحها، ستتمكن من الحفاظ على سير عملياتك بسلاسة. بعد ذلك، سنرشدك خلال عملية اختيار مزوّد معالجة فوسفاتية مؤهل للسيارات والتعاون معه — لضمان جاهزية كل قطعة للوصول إلى خط النهاية. فوسفاتة الصلب و طبقة فوسفاتية سوداء غير منتظمة عملياتك

اختيار شريك المعالجة الفوسفاتية للسيارات

متى يجب تفويض المعالجة الفوسفاتية لمكونات السيارات

تخيل أنك تقوم بتنفيذ مشروع جديد في مجال السيارات — مع مواعيد نهائية ضيقة، ومواصفات صارمة، ولا مجال للخطأ. متى يجب أن تفكر في الاستعانة بمصادر خارجية لأعمال الفوسفاتة؟ غالبًا ما يعتمد الجواب على حجم الإنتاج، ومتطلبات الجودة، وما إذا كانت خطوطك الداخلية قادرة على تقديم نتائج متسقة تتماشى مع معايير صناعة السيارات. إذا كنت بحاجة إلى شهادة IATF 16949، أو عمليات ختم/تشطيب متكاملة، أو تسليم سريع للنماذج الأولية والإنتاج الضخم، فإن الشريك المتخصص يمكنه مساعدتك على اجتياز خط النهاية بثقة باستخدام طلاء البودرة.

ما الذي يجب أن تسأله من شريك مؤهل في مجال السيارات

يبدو الأمر معقدًا؟ لا يجب أن يكون كذلك. فيما يلي قائمة تحقق من الأسئلة الضرورية والمعايير الأساسية التي توجه بحثك عن مزود موثوق للفوسفاتة لمكونات المعادن المستخدمة في صناعة السيارات:

- الشهادة: هل يمتلك المزود شهادة IATF 16949 لإدارة الجودة في صناعة السيارات؟

- القدرات المتكاملة: هل يمكنه التعامل مع عمليات الختم، والتشغيل، والفوسفاتة، وطلاء خط التشطيب بالبودرة ضمن سير عمل واحد؟

- التحكم في العمليات: كيف يقومون بمراقبة كيمياء الحمام، ووزن الطلاء، والحفاظ على سجلات العملية؟

- PPAP/القدرة على التتبع: هل يقدمون وثائق عملية موافقة قطع الإنتاج بالكامل (PPAP) وإمكانية تتبع الدفعات؟

- التوافق مع خط الطلاء: هل سيندمج تشطيب الفوسفات الخاص بهم بسلاسة مع خط الطلاء أو طلاء المسحوق الخاص بك في المراحل اللاحقة؟

- تشغيل العينات: هل تتوفر عينات تجريبية وعينات تأكيد للتأهيل؟

- تقارير الفحص والاختبار: هل يمكنك مراجعة بيانات اختبار التصاق، والتآكل، والتجانس (ASTM/ISO)؟

- السرعة والمرونة: ما مدى سرعة تكيّفهم مع التغييرات في التصميم أو الطلبات العاجلة؟

إنشاء قائمة مختصرة من الموردين: من يجب أخذهم بعين الاعتبار؟

إليك كيفية تنظيم قائمتك المختصرة لخدمات الفوسفاتة في صناعة السيارات، مع التركيز على الخيارات المحلية والعالمية على حد سواء. ابدأ بالموردين الذين يظهرون أنظمة جودة قوية، وتكاملًا متقدمًا في العمليات، وسجلًا حافلًا في التسليم لقطاع السيارات:

| المزود | النقاط الرئيسية للقوة | الشهادات | القدرات النموذجية في صناعة السيارات |

|---|---|---|---|

| خدمات شاوي للـفوسفاتة المعدنية في صناعة السيارات | فوسفاتة مخصصة، طلاء نهائياً بالمسحوق، ختم/تصنيع/تشطيب شامل من البداية حتى النهاية، تصنيع أولي سريع | IATF 16949 | هيكل السيارة، البطانات، الدعامات، الإنتاج الضخم، دفعات صغيرة، تصنيع أولي |

| كليفلاند فوسفاتينغ | فوسفاتة السيارات والصناعية، دعم محلي | ISO 9001، خاص بالصناعة | لوحات الهيكل، المشابك، قطع الغيار الأصلية |

| Parker Rust Proof of Cleveland | الفسفرة التقليدية، Parker Rust Proof، تشطيبات الزيت والشمع | خاص بالصناعات | المشابك، الأجزاء المعدنية، هيكل السيارة |

| American Metal Coatings | طلاء بالمسحوق عالي السعة، الفسفور الزنك والمنغنيز، الطلاء الكهربائي (E-coat) | ISO 9001 | السيارات، الأجهزة المنزلية، المعدات الثقيلة |

مطابقة نوع الفسفور للتطبيق

ليست جميع المشاريع بحاجة إلى نفس التشطيب الفوسفوري. ولتحسين التصاق الطلاء وحماية الهياكل أو الدعامات من التآكل، يُعد الفسفور الزنك الخيار الشائع. أما إذا كانت المشابك أو التروس أو البطانات الخاصة بك تتطلب تقليل الاحتكاك أو حماية أثناء مرحلة التشغيل الأولي، فإن الفسفور المنغنيز هو خيار مناسب. يجب دائمًا التحقق من اختيارك باستخدام دفعات تجريبية؛ وفحص توافق طلاء المسحوق في خط التشطيب، وتماسك الطلاء، ونتائج اختبارات التآكل قبل الانتقال إلى الإنتاج الكامل.

اختيار الشريك المناسب للمسامير الفوسفاتية لا يتعلق فقط بالسعر — بل ابحث عن أنظمة جودة مثبتة، وقدرات تشطيب متكاملة، واستعداد لتشغيل دفعات تجريبية تتماشى مع متطلباتك الواقعية.

من خلال استخدام هذا النهج المنظم، ستقلل من المفاجآت وتكفل جاهزية أجزاء السيارات الخاصة بك لكل عملية لاحقة، بدءًا من الكبس وحتى طلاء الخط النهائي بالبودرة. لمزيد من التفاصيل حول القدرات الشاملة لشركة Shaoyi، بما في ذلك النماذج الأولية السريعة والمسامير الفوسفاتية المخصصة للسيارات، راجع صفحة الخدمة . قم دائمًا بطلب عروض أسعار تنافسية وتجارب تشغيل تجريبية للعثور على الأنسب لمتطلبات مشروعك.

الأسئلة الشائعة حول المسامير الفوسفاتية

1. ما الغرض من المسامير الفوسفاتية؟

يحوّل الفوسفاتة سطح الصلب أو المعادن الأخرى إلى طبقة فوسفاتية بلورية، مما يعزز مقاومة التآكل، ويحسّن التصاق الطلاء، ويقلل من التآكل. وتُستخدم هذه العملية على نطاق واسع في صناعات السيارات والمسامير والأجهزة لضمان استمرارية الطلاء لفترة أطول وأداء أفضل.

2. ما هي الأنواع الثلاثة للفوسفاتة؟

الأنواع الرئيسية هي الفوسفاتة الحديدية، والفوسفاتة الزنكية، والفوسفاتة المنغنيزية. وتُعد الفوسفاتة الحديدية خيارًا اقتصاديًا للقواعد الأساسية للطلاء، بينما توفر الفوسفاتة الزنكية حماية ممتازة من التآكل والالتصاق بالطلاء، وتُفضّل الفوسفاتة المنغنيزية في التطبيقات التي تتطلب تزييتًا ومقاومة للتآكل مثل التروس والمسامير.

3. ما هي عملية الفوسفة؟

تتضمن عملية الفوسفة، أو عملية الفوسفاتة، تنظيف المعدن، وتطبيق محلول الفوسفات (بالغمر أو الرش)، ثم شطفه، وأحيانًا إغلاق السطح. وهذا يكوّن طبقة فوسفاتية موحدة تستعد بها سطوح المعادن للطلاء أو للمعالجة الإضافية.

4. هل يمكن استخدام الفوسفاتة على المعادن بخلاف الصلب؟

نعم، وعلى الرغم من أن عملية الفوسفاتة تُطبَّق عادةً على الصلب الكربوني وسبائك الصلب قليلة السبيكة، فإن وجود تركيبات كيميائية متخصصة يسمح بتطبيق طلاءات فوسفاتية فعالة على الألومنيوم والصلب المغطى بالزنك، مما يوسع نطاق استخدامها عبر مختلف الصناعات.

5. كيف أختار نوع الطلاء الفوسفاتي المناسب لتطبيقي؟

يعتمد الاختيار على وظيفة الجزء والبيئة التي يعمل فيها: استخدم الفوسفات الحديدي للبيئات الخفيفة ولأساس الطلاء، والفوسفات الزنك لمقاومة التآكل الأفضل والالتصاق الجيد بالطلاء، والفوسفات المنجنيز للقطع التي تتطلب خصائص تزييت أو حماية من البلى. ويضمن الاستشارة مع مزوِّد مؤهل الحصول على أفضل تطابق مع احتياجاتك.

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —