ما هو كبريتات الألومنيوم؟ توقف عن التشويش: ملح الألومنيوم، الصيغة، الاستخدامات

ما المقصود بكبريتات الألومنيوم وكيفية التعرف عليها

ما هي كبريتات الألومنيوم بالفعل

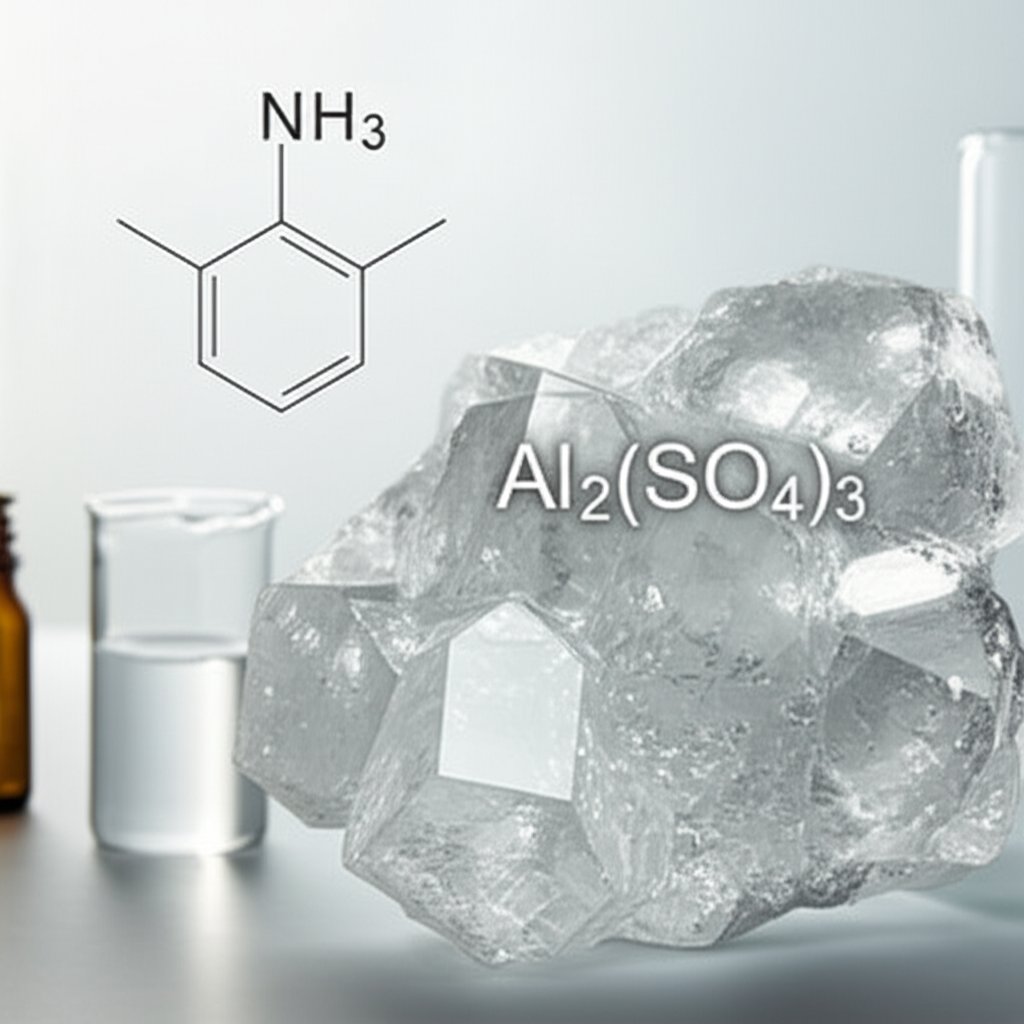

ما هي كبريتات الألومنيوم؟ ببساطة، كبريتات الألومنيوم هي ملح غير عضوي بصيغة كيميائية AL 2(SO 4)3. قد ترى أنه مكتوب على شكل Al2(SO4)3 أو، بشكل أقل شيوعًا، al2so43 على ملصقات المنتجات وشهادات السلامة. يتكون هذا المركب من الألومنيوم والكبريتر والأكسجين، ويظهر عادةً على شكل مادة صلبة بلورية (تشبه الرمال) بيضاء اللون وخالية من الرائحة أو على شكل مسحوق.

هل تتساءل أين يمكنك مصادفة كبريتات الألومنيوم فعليًا؟ إنها موجودة في كل مكان حولك في محطات معالجة المياه، وصيانة مسابح السباحة، وتحمّض التربة في الزراعة، وحتى في صناعة الورق وتلوين الأقمشة. دورها الرئيسي هو بمثابة المكثف عند إضافته إلى الماء، يؤدي إلى تكتل الشوائب الصغيرة بحيث يمكن تصفيتها. ويجعل ذلك كبريتات الألومنيوم ضرورية لإنتاج مياه الشرب الآمنة ولتصفية مياه المسبح الغائمة. وفي البستنة، تُستخدم غالبًا لتقليل درجة حموضة التربة للنباتات التي تحب الأحماض مثل الهيدرانجيا.

الزاج مقابل توضيح كبريتات الألومنيوم

هنا تبدأ الالتباسات غالبًا: يشير الكثير من الناس إلى "الزاج" عندما يقصدون في الواقع كبريتات الألومنيوم. ولكن في العالم الكيميائي، "الزاج" هو مصطلح أوسع. فنيًا، يشير الزاج إلى عائلة أملاح الكبريتات المزدوجة ذات الصيغة العامة XAl(SO 4)2·12H 2O، حيث X هو أيون أحادي التكافؤ مثل البوتاسيوم أو الأمونيوم. الزاج الأكثر شيوعًا في الصناعة هو زاج البوتاسيوم، وليس كبريتات الألومنيوم. ومع ذلك، على العديد من ملصقات المنتجات وفي المحادثات اليومية، يُستخدم "الزاج" بشكل متبادل مع كبريتات الألومنيوم، مما قد يؤدي إلى أخطاء عند شراء المواد الكيميائية أو قراءة كشوف بيانات السلامة.) Affinity Chemical )

- كبريتات الألمنيوم (Al 2(SO 4)3)

- كبريتات الألمنيوم (الكتابة البريطانية)

- كوروندو (تُستخدم أحيانًا لكبريتات الألومنيوم، ولكن أيضًا للأملاح المزدوجة)

- كرب الألومنيوم لصناعة الورق

- كبريتات الألومنيوم الثلاثية

- حمض الكبريتيك، ملح الألومنيوم (3:2)

- الكتابات الخاطئة الشائعة: كرب الألومنيوم , كرب الألومنيوم السلفاتي

كبريتات الألومنيوم = Al 2(SO 4)3; ويُكتب أيضًا على شكل Al2(SO4)3.

كيفية التعرف على Al2(SO4)3 على الملصقات

عندما تقوم بمسح ملصق كيميائي أو ورقة بيانات سلامة (SDS) أو طلبية شراء، ابحث عن هذه المعرفات لتجنب الالتباس:

- الصيغة الكيميائية: AL 2(SO 4)3أو al2so43

- رقم CAS: 10043-01-3

- الأسماء: كبريتات الألمنيوم , كبريتات الألمنيوم , كوروندو (مع السياق)، أو كبريتات الألومنيوم الثلاثية

ستلاحظ أن كبريتات الألومنيوم تُدرج غالبًا على أنها "عامل تجفيف" في معالجة المياه أو مواد تطهير المسابح، وكمُثبّت للتربة أو "عامل تثبيت الصبغة" في المنتجات الزراعية والمنسوجات. تحقق مجددًا من التهجئة، حيث أن "aliuminum sulfate" و"aluminum solfate" أخطاء شائعة قد تؤدي إلى تعطيل عمليات البحث عبر الإنترنت أو طلبات الشراء.

البيانات والخصائص الأساسية التي يمكنك الاعتماد عليها

التركيب الجزيئي لـ Al 2(SO 4)3

عند التعامل مع المواد الكيميائية أو البحث عنها، فإن معرفة الأساسيات بشكل سريع يمكن أن توفر الوقت وتمنع الأخطاء. إذن، ما هي الحقائق الأساسية حول صيغة كبريتات الألومنيوم الكيميائية؟ الشكل النقي الخالي من الماء يُعبّر عنه بالصيغة التالية AL 2(SO 4)3. هذه الصيغة هي المفتاح لتحديد المنتج الصحيح، سواء رأيتها على ورقة بيانات السلامة أو على ملصق الشحن أو في طلبية شراء. 2(SO 4)3الوزن الجزيئي لـ Al — ويُعرف أيضًا باسم وزن كبريتات الألومنيوم الجزيئي —هو 342.15 غرام/مول للشكل اللامائي، ولكن هذا يمكن أن يتغير إذا ارتبط الماء (لمزيد من المعلومات أدناه). الـ رقم CAS لكبريتات الألومنيوم هو 10043-01-3.(Pub Chem )

| الممتلكات | القيمة / الوصف |

|---|---|

| رقم CAS | 10043-01-3 |

| الصيغة الكيميائية | AL 2(SO 4)3 |

| الوزن الجزيئي (اللامائي) | 342.15 غرام/مول |

| الهيدرات الشائعة | AL 2(SO 4)3·16H 2O، Al 2(SO 4)3·18H 2أكسجين |

| الأشكال المادية | مسحوق أبيض، حبيبات، بلورات كبيرة، أو محلول واضح |

| الذوبان في الماء | قابلة للذوبان بشكل كبير (31.2 غرام/100 مل عند 0 درجة مئوية؛ 89.0 غرام/100 مل عند 100 درجة مئوية) |

| الحموضة النموذجية (حلول 5٪) | 2.9 أو أكثر |

| مظهر | بلورات أو مسحوقات بيضاء لامعة و بلا رائحة |

أشكال رطوبة (مثل: Al 2(SO 4)3·1418H 2أ) تغيير الكتلة المولية الظاهرةتفقد دائماً الملصق قبل الجرعة أو الخلط.

المواد الهيدروجينية والأشكال الفيزيائية النموذجية

يبدو معقداً؟ تخيل شراء كيس مكتوب عليه "كبريت الألومنيوم" لكن ليس دائماً هو المسحوق النقي والجاف. في الممارسة العملية، سوف تواجه في كثير من الأحيان مرطباً أشكال، حيث يتم ربط جزيئات الماء لكل وحدة صيغة. الأكثر شيوعاً هي الإصدارات 14 هيدرات، 16 هيدرات، و 18 هيدرات. هذا يعني كتلة جزيئية للكبريتيد الألومنيومي يمكن أن يختلف الجرعة بشكل كبير حسب الوزن دون تأكيد الهيدرات يمكن أن يؤدي إلى علاج ناقص أو مفرط. الأشكال المبتلطة عادة ما تكون أكثر استقراراً للتخزين ، لكنها تزن أكثر لكل وحدة من المكون النشط.

تشمل الأشكال المادية:

- مسحوق جاف (غير مُحيط أو مُرطّب)

- الحبيبات أو بلورات كبيرة

- محلول سائل (مذوب مسبقاً ليتم تناول الجرعة)

يتم اختيار كل شكل بناءً على احتياجات المعالجةيتم تخزين المسحوق والبلورات بشكل جيد وتسليمها بكثافة، في حين يتم تفضيل السوائل في كثير من الأحيان للجرعات الآلية في معالجة المياه.

الدولولية في الحل

لماذا يهم الذوبانية؟ عندما تضيف كبريتات الألومنيوم إلى الماء، فإنها تذوب بسرعة، حتى عند درجات حرارة منخفضة (ال صيغة كبريتات الألومنيوم تذوب بسهولة في الماء). هذا يجعل من السهل تحضير محلول مخزون للجرعات. ولكن، أثناء الذوبان، يقلل من قيمة الرقم الهيدروجيني للمحلول - عادةً ما تكون للمحلولات العملية (مثل خليط 5%) قيمة pH تبلغ حوالي 2.9 أو أعلى. هذا التأثير الحمضي هو جزء أساسي من دورها كعامل تجلط في معالجة المياه ويمكن أن يؤثر على كيمياء المسابح أو التربة.

باختصار، يجب دائمًا:

- تحقق من صيغة كبريتات الألومنيوم ومن نوع الهيدرات الموجودة على الملصق

- تعديل الجرعة وفقًا للوزن الجزيئي لـ al 2(SO 4)3وأي ماء موجود في الهيدرات

- الانتباه إلى أن قيمة الرقم الهيدروجيني للمحلول قد تنخفض، مما يؤثر على المواد المضافة الأخرى أو عمليات المصنع

توضيح طرق التصنيع والأشكال والدرجات

كيف يُصنع الألومينيوم الصناعي

هل تساءلت يومًا كيف يُصنع الألومينيوم للمنتجات التي تستخدمها يوميًا؟ إن عملية تصنيع كبريتات الألومنيوم (المعروفة أيضًا باسم الألومينيوم) متنوعة بشكل مدهش وتعتمد على المواد الخام ودرجة المنتج المرغوبة. وعادةً ما يُنتج الألومينيوم من خلال التفاعل بين هيدروكسيد الألومنيوم أو خام البوكسيت مع حمض الكبريتيك . ويؤدي هذا التفاعل إلى تشكيل كبريتات الألمنيوم والماء، مما ينتج مركبًا يُستخدم في معالجة المياه وصناعة الورق والمزيد. فيما يلي التفاعل الأساسي الذي يمكن العثور عليه في العديد من المصانع الصناعية:

- هيدروكسيد الألومنيوم (Al(OH) 3) + حمض الكبريتيك (H 2لذا 4) → كبريتات الألومنيوم (Al 2(SO 4)3) + الماء (H 2O)

تتضمن طريقة أخرى التفاعل المباشر بين معدن الألومنيوم وحمض الكبريتيك، مما ينتج كبريتات الألومنيوم وغاز الهيدروجين. كما توجد حتى طريقة تاريخية يتم فيها تحميص أو تعريض معادن طبيعية مثل صخر الشِّبَّاك لعوامل الطقس، مما يؤدي إلى إنتاج حمض الكبريتيك الذي يتفاعل مع المعادن الغنية بالألومنيوم لتكوين الشب. وهذا يجيب السؤال الكلاسيكي: من أين يأتي الشب؟ —يمكن الحصول عليه من المعادن الطبيعية والعمليات الصناعية على حد سواء.

فهم الدرجات والشهادات

ليست كل كبريتات الألومنيوم متساوية. إن الطريق المستخدم في التصنيع والمواد الخام تحدد الدرجة و نقاء المنتج النهائي. إليك الجانب العملي: إذا كنت تقوم بمعالجة مياه الشرب، فستحتاج إلى منتج معتمد وفقًا لمعايير NSF/ANSI القياسية 60، والتي تضمن أنه يلبي معايير صارمة فيما يتعلق بالصحة والنقاء. وفي حالة استخدامه في معالجة الأغذية أو لتغذية الدواجن، تنطبق معايير أعلى. أما الدرجة التقنية فتُستخدم عادةً في التطبيقات الصناعية حيث لا يُشترط النقاء العالي.

ولأي درجة، اطلب دائمًا وتحقق من شهادة تحليل (COA) و ورقة بيانات السلامة (SDS) للتحقق من حدود التلوث والتأكد من ملاءمة المنتج لتطبيقك. تساعدك هذه الوثائق على تجنب المفاجآت، مثل وجود حديد أو معادن ثقيلة غير مرغوب فيها في العمليات الحساسة. Affinity Chemical )

| الدرجة | الأشكال النموذجية | التطبيقات الشائعة | الشهادات/المقاييس |

|---|---|---|---|

| اِصطِلاحِيّ | مسحوق، حبيبات، سائل | صناعة الورق، المياه الصناعية، صباغة | مواصفات صناعية عامة |

| مياه الشرب (NSF/ANSI 60) | سائل، مسحوق | معالجة مياه البلديات | حاصل على شهادة NSF/ANSI 60 |

| درجة غذائية | بودرة، حبيبات | معالجة الأغذية، إدارة فضلات الدواجن | يتوافق مع معايير سلامة الأغذية |

| لدواجن | حبيبات، بودرة | مُعدِّل لفضلات الدواجن | مواصفات زراعية متخصصة |

اختيار كبريتات الألومنيوم السائلة مقابل الأشكال الجافة

عند شراء كبريتات الألومنيوم، ستواجه خيارًا أساسيًا: الألومينيوم السائل أو بالشكل الجاف (بودرة/حبيبات)؟ إليك ما يجب مراعاته:

- كبريتات الألومنيوم السائلة (محلول مسبق الذوبان) أسهل في الجرعات التلقائية، وتقلل من التعرض للغبار، وهي مناسبة لمحطات معالجة المياه على نطاق واسع. ومع ذلك، فإنها أثقل في الشحن وقد تكون لها فترة صلاحية أقصر.

- الأشكال الجافة (بودرة، حبيبات، أو كريستالات) أكثر كثافة، وتُخزن لفترة أطول، وهي مناسبة للجرعات على نطاق صغير أو في الأماكن التي تكون فيها مساحة التخزين محدودة. وتحتاج إلى خلط مع الماء قبل الاستخدام ويمكن أن تُنتج غبارًا إذا لم تُعالج بحذر.

يعتمد الاختيار على احتياجات عملياتك. على سبيل المثال، قد تفضل محطة مياه المدينة استخدام الألومينيوم السائل للجرعة المستمرة، بينما قد يختار مصنع ورق منتجًا حبيبيًا للخلط الدفعي. وفي جميع الحالات، يجب التأكد من محتوى هيدرات الألومينيوم لأن ماء التبلر يؤثر على حسابات التخزين والجرعة على حد سواء.

قبل الشراء، راجع دائماً بيانات الجودة المضافة و COA للتأكد من أن المنتج يفي بمتطلبات النقاء والتشريعات خاصةً بالنسبة للاستخدامات الحساسة مثل الطعام أو مياه الشرب.

فهم عملية التصنيع و خيارات الصف سوف يساعدك على اختيار الكبريتيد الألومنيوم المناسب لاحتياجاتك بعد ذلك، دعونا نستكشف كيف يتم تطبيق هذه الأشكال في سيناريوهات الجرعة والعلاج في العالم الحقيقي.

التطبيقات، الجرعة، وبروتوكول اختبار الجرة

تم تبسيط جرعة معالجة المياه

عندما تكون مسؤولاً عن المياه النظيفة والآمنة سواء في محطة بلدية أو في نظام مجتمع صغير معالجة مياه كبريتات الألومنيوم الجرعة الصحيحة مهمة يبدو معقداً؟ السر هو أن تبدأ بـ اختبار الجرة ، طريقة عملية تسمح لك بمعرفة بالضبط كمية الألومنيوم (كبريتات الألومنيوم) التي تحتاجها لمصدر المياه الخاص بك. هذا يمنع الإفراط أو الافتقار إلى الجرعة، مما يوفر المال ويحافظ على جودة المياه عالية.

- جمع العينات: املأ عدة مرطبان نظيفة أو أكواب قياسية بكميات متساوية من ماءك الخام (عادةً 1000 ملليلتر لكل منها).

- قياس جودة الماء: سجّل درجة الحموضة والحرارة والتعكر. فهذه العوامل تؤثر على كفاءة سульفات الألومنيوم.

- تحضير المحلول المركّز: أذب 10 غرامات من كبريتات الألومنيوم في 1000 ملليلتر من الماء المقطر. يعادل كل ملليلتر من هذا المحلول 10 مليغرام/لتر (جزء في المليون) عند إضافته إلى 1000 ملليلتر من الماء.

- الجرعة التدريجية: أضف كميات متزايدة من محلول سульفات الألومنيوم إلى كل مرطبان (مثلاً 1 ملليلتر، 1.5 ملليلتر، 2 ملليلتر، إلخ). ويُنتج هذا نطاقاً من الجرعات يمكن مقارنتها.

- الخلط: قلّب بقوة لمدة دقيقة واحدة لمحاكاة الخلط السريع، ثم برفق لمدة 30 دقيقة لمحاكاة التلبد. اترك المرطبان لتستقر لمدة ساعة على الأقل.

- التقييم البصري: راقب كل مرطبان. الجرعة المثلى تُنتج تجمعات كبيرة سريعة الترسيب وماءً صافياً في الأعلى. الجرعة القليلة جداً تترك الماء عكراً، بينما الجرعة الكثيرة جداً تُنتج تجمعات هشة لا تستقر جيداً. نِسك )

- يتشكل القذف ويترسب في القاع

- الماء الصافي فوق القذف المترسب

- وقت الترسيب الأقصر يعني معالجة أكثر فعالية

- الغيظ أو القذف المعلق يشير إلى الجرعة المنخفضة أو المرتفعة

بمجرد العثور على الجرعة المثالية، قم بتحجيمها وفقًا لنظامك. هذه الطريقة تُعد أساس معالجة المياه باستخدام الكاولين ضرورية لتحسين التنقية المائية باستخدام الالوم الأداء.

قم دائمًا باختبار الرقم الهيدروجيني قبل وبعد الجرعات. تعتمد فعالية كبريتات الألومنيوم على الرقم الهيدروجيني، ويمكن أن يؤدي التعديل غير السليم إلى تقليل كفاءة المعالجة أو إتلاف المعدات.

تدفق عملية التخثير في المسبح

هل نظرت يومًا إلى مسبح عكر وتساءلت كيف يمكنك تنقيته بسرعة؟ كبريتات الألومنيوم لمسبح السباحة هي الحل المثالي لمديري ومالكي المسبح. إليك طريقة عملها: عند إضافتها إلى ماء المسبح، ترتبط كبريتات الألومنيوم بالجسيمات الدقيقة، مشكلة ترسبات ثقيلة تغوص إلى القاع لتسهيل إزالتها.

- وازن مسبحك: تأكد من أن الرقم الهيدروجيني (pH) بين 7.0 و 8.0 للحصول على أفضل النتائج. قم بالتعديل حسب الحاجة.

- أوقف الفلترة: أوقف تشغيل المضخة ودع الماء يهدأ ويصبح ثابتًا.

- أضف المادة الكيميائية: انثر كبريتات الألومنيوم بشكل متساوٍ على سطح الماء. المعدل المعتاد هو 1–2 رطلاً لكل 10000 غالون، ولكن تحقق دائمًا من ملصق المنتج.

- انتظر وراقب: اترك البركة بدون تدخل لمدة 12–24 ساعة. سترى طبقة من الجسيمات المتكتلة تستقر في القاع.

- شفط إلى المصرف: قم بشفط الجسيمات المتكتلة بعناية. لا تستخدم إعداد الفلتر، وذلك لمنع الانسداد.

- استئناف الترشيح: أعد تشغيل المضخة وتحقق من وضوح الماء.

- يصبح الماء أكثر وضوحًا بشكل ملحوظ خلال يوم واحد

- تختلف مدة الاستقرار حسب حجم البركة ودرجة الحرارة

- تقل الأحمال على الفلتر بعد إزالة الجسيمات المتكتلة

- إذا استمرت التعكر، كرر العملية أو تحقق من قيمة الرقم الهيدروجيني

للحصول على أفضل النتائج مع كبريتات الألومنيوم في مسابح السباحة ، اتبع دائمًا تعليمات الملصق والإرشادات الأمنية.

تحلية التربة للنباتات المحبة للحمضية

عندما تكون تربة حديقتك شديدة القلوية، قد تواجه النباتات المحبة للحمضية مثل الهدرانج (الكاميليا الزهرية) والتوت الأزرق والآذريون مشكلة في النمو. استخدام كبريتات الألومنيوم للتربة طريقة فعالة وسريعة لخفض درجة الحموضة وخلق البيئة المناسبة لهذه النباتات كي تزدهر. ولكن كيف تعمل؟

عند تطبيقها وريها، تتفاعل كبريتات الألومنيوم مع الماء لتحرير أيونات الهيدروجين، مما يزيد من حموضة التربة بسرعة أكبر من البدائل مثل الكبريت الصلب.

- تزداد زرقة أزهار الهدرانج في التربة الحمضية (بفضل توفر أيونات الألومنيوم)

- يصبح لون أوراق التوت الأزرق والآذريون أكثر خضرة ويزداد نموها قوة

- تنخفض درجة حموضة التربة خلال أسابيع - وليس شهور

- يمكن أن يؤدي الاستخدام المفرط إلى حروق في الأوراق أو توقف في النمو

الاستخدام بسيط:

- قم بفحص درجة حموضة التربة قبل الاستخدام – الهدف هو 4.5–5.5 لمعظم النباتات المحبة للحمضية

- استخدم ملعقة طعام إلى ملعقتين لكل جالون من التربة، أو رطل إلى رطلين لكل 100 قدم مربع في الأسرّة

- اروِ جيدًا بعد النشر لحل المنتج وتوزيعه بشكل متساوٍ

- كرر الاستخدام بجرعات صغيرة حسب الحاجة، وأعد فحص درجة الحموضة في كل مرة

للمجبنة، اذب ملعقة طعام لكل جالون ماء واسكبها حول القاعدة للحصول على أزهار زرقاء. للحوش، انشر 5 أرطال لكل 1000 قدم مربع واروِ جيدًا. مزرعة الحذاء القديم )

ابدأ دائمًا بفحص درجة الحموضة واستخدم كميات صغيرة، خاصة إذا كنت تستخدم كبريتات الألومنيوم لأول مرة. الاستخدام المفرط يمكن أن يجعل التربة حمضية جدًا ويضر نباتاتك. اروِ جيدًا بعد الاستخدام لتجنب حروق الأوراق والتأكد من التوزيع المتساوي.

باتباع هذه الإرشادات خطوة بخطوة، ستستفيد قدر الإمكان معالجة المياه باستخدام الكاولين سواء كنت تقوم بتنقية مياه الشرب، أو تنظيف مسبح، أو العناية بالنباتات التي تحب الأحماض. بعد ذلك، سنغطي إرشادات السلامة والتعامل الأساسية لضمان فعالية وسلامة كل تطبيق.

السلامة في التعامل وإرشادات ورقة البيانات الأمنية (SDS)

نظرة سريعة على السلامة: معدات الحماية الشخصية (PPE) والتعامل

عند التعامل مع كبريتات الألومنيوم — سواء في معالجة المياه، أو صيانة المسابح، أو البستنة — فإن السلامة العملية أمر لا يقبل الجدل. يبدو الأمر معقدًا؟ تخيل التعامل مع مسحوق يمكنه تهيج الجلد والعينين، أو سائل يكون حامضيًا أكثر مما تتوقع. هذا هو السبب في أن اتباع روتين واضح للسلامة ضروري، وكذلك الرجوع إلى ورقة البيانات الأمنية (SDS) لكبريتات الألومنيوم أو ورقة البيانات الأمنية لكبريتات الألومنيوم (MSDS) قبل الاستخدام هو خطوة ذكية دائمًا.

- ارتدِ معدات الحماية الشخصية المناسبة: نظارات مغلقة أو واقية الوجه، قفازات مطاطية/نيوبرين/PVC، وملابس عمل طويلة الأكمام لتغطية الجلد المعرض. لإنزال المواد الساخنة أو الحمية، أضف بدلة أكثر سلاسة واحذية قوية.

- نصائح التعامل: تجنب إنشاء أو استنشاق الغبار. استخدم في مناطق ذات تهوية جيدة. لا تأكل أو تشرب أو تدخن أبدًا في الأماكن التي يتم التعامل فيها مع كبريتات الألومنيوم.

- الخلط الآمن: أضف دائمًا كبريتات الألومنيوم إلى الماء — وليس العكس — لمنع حدوث رشقات خطرة أو تفاعلات عنيفة.

- الاستعداد للطوارئ: احتفظ بمحطات غسيل العين وغرف الاستحمام الأمنية بالقرب من مناطق العمل. احفظ نسخة من ورقة بيانات سلامة كبريتات الألومنيوم (SDS) بالقرب من مكان العمل للاستشارة السريعة.

أضف دائمًا المادة الكيميائية إلى الماء، وليس الماء إلى المادة الكيميائية.

خطوات الإسعافات الأولية السريعة

تحدث الحوادث بسرعة، لكن معرفة ما يجب القيام به تحدث فرقًا كبيرًا. إليك ما يجب عليك فعله إذا تعرضت لمخاطر الشبة:

- التعرض للعينين: اغسل العينين بالماء الجارٍ لمدة 15 دقيقة على الأقل، مع رفع الجفون. ازَل العدسات اللاصقة إذا كان ذلك سهلاً. إذا استمرت التهيجات، اطلب المساعدة الطبية فورًا.

- التعرض للجلد: قم بسرعة بإزالة الملابس الملوثة. اشطف الجلد تحت الماء الجارٍ لمدة 15 دقيقة على الأقل. اغسل الملابس قبل استخدامها مرة أخرى. إذا استمر التهيج، احصل على استشارة طبية.

- الاستنشاق: انتقل إلى مكان مفتوح. إذا كان التنفس صعبًا، اطلب المساعدة الطبية. استخدم التنفس الاصطناعي إذا توقف التنفس.

- الابتلاع: اغسل الفم. قم بالتخفيف باستخدام الماء أو الحليب إذا كان الشخص واعيًا - لا تُحدث القيء. اتصل بمركز السموم أو طبيب إذا ابتُلع أكثر من بضع قطرات أو ظهرت أعراض.

احتفظ بعناوين الاتصال الطارئ مثل مركز السموم المحلي و Chemtrec في أماكن قريبة من مناطق التخزين والاستخدام لتسهيل اتخاذ الإجراءات السريعة.

أساسيات التخزين والاستجابة للانسكابات

يساعد التخزين السليم والاستجابة السريعة للانسكابات في منع مخاطر كبريتات الألومنيوم وحماية الأشخاص والبيئة. تخيل كيسًا متسربًا في غرفة رطبة - وفي حالة عدم اتخاذ الاحتياطات، فإنك تعرّض نفسك لخطر التآكل أو التعرض العرضي أو حتى الضرر البيئي.

- التخزين: احتفظ بكبريتات الألومنيوم في عبواتها الأصلية المُصنَّعة والمُلصَقة بوضوح والمصنوعة من البولي بروبلين أو البولي إيثيلين أو PVC أو الفولاذ المقاوم للصدأ 316. احفظها في مكان بارد وجاف، بعيدًا عن أشعة الشمس المباشرة والمواد غير المتوافقة (وخاصة القواعد ومركبات الهيبوكلوريت).

- الفصل: لا تُخزن أبدًا مع مواد كيميائية قد تتفاعل لتكوين منتجات ثانوية خطرة، مثل غاز الكلور.

- استجابة للانسكاب: للانسكابات الصغيرة، امتصاصها باستخدام الرمال أو الفيرميكيوليت. للانسكابات الجافة، اجمعها بمكنسة أو مجرفة وضعها في وعاء مغلق. اغسل الرواسب بكمية كبيرة من الماء، وإذا لزم الأمر، عادلها باستخدام كربونات الصوديوم أو الجير. للانسكابات السائلة، قم بحصرها وجمعها للتخلص منها - ولا تقم بصبها في المجاري أو الممرات المائية.

- معدات الحماية الشخصية أثناء التنظيف: ارتدِ دائمًا القفازات والنظارات الواقية والملابس الواقية أثناء التنظيف. تأكد من التهوية الكافية عند تعديل أو تنظيف الانسكابات.

للانسكابات الكبيرة، اتبع خطة الطوارئ الخاصة بمؤسستك وأبلغ السلطات البيئية المختصة حسب الحاجة. راجع دائمًا ورقة بيانات سلامة كبريتات الألومنيوم (MSDS) للحصول على إرشادات مفصلة ومتطلبات تنظيمية.

حدود التعرض وتصنيفات الخطر

- حد التعرض المسموح به من OSHA: 2.0 ملغ/م³ (كـ Al)

- حد ACGIH المسموح به: 2.0 ملغ/م³ (كـ Al)

- السمية الحادة: LD50 (فموي، الفأر) > 5000 ملغ/كلغ (خطر حاد منخفض، ولكن تجنب البلع)

- تصنيف NFPA للصحة: 1 (خطر خفيف)؛ مُهيج للعينين والجلد عند البلل

باتباع هذه الممارسات الجيدة والاحتفاظ بورقة بيانات سلامة الألومنيوم سلفات (SDS) الخاصة بك في متناول اليد، ستقلل من المخاطر وتحقيق بيئة عمل أكثر أمانًا. بعد ذلك، دعونا نستعرض التأثير البيئي ومبادئ الامتثال حتى تتمكن من التعامل مع أسئلة التخلص والمتطلبات التنظيمية بثقة.

التأثير البيئي ومبادئ الامتثال

الاعتبارات البيئية والتخلص

عند استخدامك لسلفات الألومنيوم في معالجة المياه أو في البستنة، هل سبق وخطر ببالك ماذا يحدث إذا انتهى بها الأمر بكميات كبيرة في البيئة؟ تخيل انسكابًا يصل إلى نهر محلي، أو تسرّبًا زائدًا في التربة. في حين أن سلفات الألومنيوم في معالجة المياه تُعدّ فعّالة للغاية في إزالة الملوثات، إلا أنها تأتي أيضًا مع مسؤوليات بيئية. فيما يلي بعض الإرشادات العملية التي يجب اتباعها وتجنّبها لمساعدتك في إدارة التخلص والتصريف بشكل آمن:

- DO تحقق من اللوائح المحلية قبل التخلص من أي محلول أو طمي متبقٍ.

- DO احتوِ التسرب وإدارته وفقًا لما هو منصوص عليه في ورقة بيانات السلامة الخاصة بالمنتج (SDS).

- DO استخدم خدمات التخلص من النفايات الخطرة المعتمدة للتخلص من الكميات الكبيرة أو النفايات المركزة.

- لا لا تسمح بجريان التسرب عبر مصارف الصرف أو المجاري المائية الطبيعية أو على التربة المكشوفة.

- لا لا تتخلص من كبريتات الألومنيوم بالقرب من المواطن المائية دون التحييد المناسب والموافقة التنظيمية.

- لا لا تهمل قياس الرقم الهيدروجيني (pH) - حيث يمكن أن تؤدي مياه الجريان غير المنظمة إلى زيادة حموضة المياه والتربة، مما يؤثر على النباتات والحيوانات.

اتبع اللوائح المحلية ومتطلبات تصريح التصريف الخاص بمنشأتك.

من الحكمة دائمًا استشارة السلطات البيئية المحلية، خاصة إذا كنت تدير عمليات على نطاق واسع أو تطبيقات متكررة. التخلص السليم يحافظ على الامتثال ويوفر الحماية للنظم البيئية المحيطة.

الألومنيوم المتبقي وسياقه بالنسبة لصحة الإنسان

هل كبريتات الألومنيوم ضارة؟ يبدو الأمر مقلقًا، لكن دعونا نحلله. في معالجة المياه بكبريتات الألمنيوم من DEVELOP ، تُستخدم المادة بجرعات مُحكمة التحكم. يتفاعل معظم الألومنيوم ويترسب، لكن كمية صغيرة — تُعرف باسم بقايا — يمكن أن تبقى في المياه المعالجة. تضع الهيئات التنظيمية مثل إدارة الغذاء والدواء (FDA) والوزارة الأمريكية للزراعة (USDA) حدودًا صارمة لمخلفات الألومنيوم لحماية الصحة العامة. بالنسبة لمعظم الأنظمة، تتراوح مخلفات الألومنيوم بعد المعالجة بين 0.05–0.2 ملغ/لتر، وهي نسبة تُعتبر آمنة للمياه الصالحة للشرب إذا تم التحكم في الرقم الهيدروجيني والجرعات بشكل صحيح ( Elchemy ).

ومع ذلك، فإن تناول كميات كبيرة من الألومنيوم مثير للقلق، خاصة بالنسبة للمجموعات الضعيفة. أشارت الدراسات إلى وجود ارتباط محتمل بين التعرض العالي للألومنيوم والأمراض التنكسية العصبية مثل مرض الزهايمر، وكذلك تأثيره على صحة العظام بسبب تدخله في امتصاص الكالسيوم. الأشخاص المصابون باضطرابات في الكلى، والأطفال، وكبار السن، هم الأكثر حساسيةً لـ تأثيرات الألومنيوم في الجسم (Palintest لهذا السبب، من المهم للغاية مراقبة مستويات الألومنيوم في مياه الشرب والتحكم فيها. إذًا، هل كبريتات الألومنيوم مادة سامة؟ في حال استخدامها بشكل طبيعي ومنضبط، لا تُعتبر سامة حادة، ولكن يمكن أن يكون التعامل غير السليم معها أو ابتلاع المنتجات المركزة منها ضارًا.

المحاور التنظيمية التي يجب أن تكون على دراية بها

هل تتساءل إن كانت تطبيقاتك متوافقة مع المعايير؟ يتم تحديد الإطارات التنظيمية الخاصة بتجريف وتصريف كبريتات الألومنيوم على المستوى الاتحادي والولائي والمحلي. وفي معالجة المياه، ستحتاج إلى الالتزام بمعايير الألومنيوم المتبقي ودرجة الحموضة في المياه المتدفقة. يجب على المستخدمين الصناعيين والبلديين الاحتفاظ بسجلات لاستخدام المواد الكيميائية والنفايات الناتجة ونتائج المراقبة لتأكيد الامتثال أثناء الفحوصات.

هذا ما يجب أن تضعه في اعتبارك:

- تحقق من التصاريح الخاصة بالتصريف والمتطلبات المتعلقة بالإبلاغ عن منشأتك.

- اطلع على ورقة بيانات السلامة الخاصة بالمنتج لمعرفة طرق التخلص الموصى بها والاستجابة للانسكابات.

- قم بإجراء اختبارات معملية للتأكد من أن المواد المتبقية ودرجة الحموضة ضمن الحدود المسموح بها قبل التصريف.

- ابقَ على اطلاعٍ بالتحديثات من وكالات مثل وكالة حماية البيئة (EPA) وإدارة الغذاء والدواء (FDA) والهيئات المحلية للمياه.

بالنسبة لبستاني المنازل، فإن الخطر الرئيسي هو الإفراط في الاستخدام، مما قد يؤدي إلى تحمض التربة أو حرق جذور النباتات. ابدأ دائمًا باختبار التربة واستخدمه بكميات صغيرة ومدروسة. هل يُعد الشب سامًا للبشر؟ لا، إذا استُخدم حسب الإرشادات، ولكن التعرض المركّز أو الاستخدام غير الصحيح يمكن أن يسبب تهيجًا أو تأثيرات صحية أكثر خطورة. وإذا كنت غير متأكد أبدًا، فاستشر الجهة المحلية المختصة بالبيئة أو الصحة العامة.

من خلال فهمك لهذه القيادات الأساسية المتعلقة بالبيئة والصحة، ستتمكن من التعامل مع كبريتات الألومنيوم بثقة ومسؤولية. بعد ذلك، سنوضح لك كيفية الحصول على المنتج الصحيح بأمان من خلال دليل الشراء الخاص بنا.

دليل الشراء

كيفية اختيار الدرجة والشكل المناسبين

عندما تحتاج إلى كبريتات الألومنيوم، فإن السؤال الأول هو: أي درجة وشكل يناسبان تطبيقك؟ تخيل أنك تقوم بالشراء لمحطة مياه، أو مزرعة، أو خط إنتاج. يمكن أن تبدو الخيارات مُربكة—بودرة، حبيبات، رقائق (جافة)، سائلة، درجة صناعية، درجة الأغذية، أو درجة مياه الشرب. ولكن اتخاذ الخيار الصحيح يصبح أسهل عندما تقوم بتقسيمه حسب الاستخدام النهائي واحتياجات المناولة.

| الدرجة | الشكل/التركيز | التطبيقات الشائعة | التغليف | الوثائق |

|---|---|---|---|---|

| اِصطِلاحِيّ | حبيبي، بودرة، رقائق (جاف)؛ سائل (تركيزات مختلفة) | المياه الصناعية، صناعة الورق، الصباغة | أكياس، براميل، أكياس كبيرة، حاويات بلاستيكية متوسطة، ناقلات شاحنة | ورقة البيانات الأمنية (SDS)، شهادة التحليل (COA) (عند الطلب) |

| درجة مياه الشرب | بودرة، رقائق، أو سائل (نقاء عالي، حديد منخفض) | معالجة مياه الشرب ومجاري الصرف البلدية | أكياس، براميل، حاويات سائل، ناقلات شاحنة | أوراق بيانات السلامة (SDS)، وشهادة المطابقة (COA)، وشهادة NSF/ANSI 60 أو ما يعادلها |

| درجة غذائية | مسحوق، حبيبات (أعلى درجة نقاء) | معالجة الأغذية، تحسين فرشة الدواجن | أكياس، براميل | أوراق بيانات السلامة (SDS)، وشهادة المطابقة (COA)، وشهادات سلامة الأغذية |

ستلاحظ أن الأشكال السائلة تسهل من عملية الجرعات وتُفضل في الإعدادات الكبيرة أو الآلية، لكنها أثقل في الشحن وقد تتطلب تخزينًا خاصًا. الأشكال الجافة (مسحوق، حبيبات، رقائق) أسهل في الجرعات اليدوية، وتُخزن لفترة أطول، وغالبًا ما تكون أكثر اقتصادية للمستخدمين الصغار. تأكد دائمًا من نوع الهيدرات والتركيز—فهذا يؤثر على الجرعة والأداء.

أين تشتري وما يجب التحقق منه على الملصقات

هل تتساءل " أين يمكنني شراء كبريتات الألومنيوم " أو تبحث عن "كبريتات ألومنيوم بالقرب مني"؟ لديك عدة خيارات عملية:

- موزعي المواد الكيميائية الصناعية — الأفضل للطلبات الكبيرة أو التوريد المستمر

- موزعي معالجة المياه — يقدمون منتجات معتمدة للاستخدام البلدي والمسابح

- تجار الأسمدة الزراعية — يوفرون مواد لتعديل درجة حموضة التربة للحدائق والزراعة

- بائعين إلكترونيين موثوقين — مناسب للطلبات الصغيرة أو الدرجات الخاصة

عندما تكون جاهزًا لتقديم الطلب، تحقق دائمًا من النقاط التالية:

- الدرجة والنقاء: هل هي درجة تقنية، صالحة للشرب، أو مخصصة للأغذية؟ تحقق من انخفاض محتوى الحديد إذا كانت الوضوح أو اللون مهمين.

- نوع الهيدرات: هذا يؤثر على كمية المكون الفعّال الذي تحصل عليه لكل رطل أو لتر.

- ورقة البيانات الأمنية (SDS) وشهادة المطابقة (COA): اطلب الوثائق الأحدث للتأكد من السلامة والامتثال والأداء.

- الشهادات: للاستخدام في مياه الشرب أو الأغذية، ابحث عن علامات مثل NSF/ANSI 60، أو سلامة الأغذية، أو ما يعادلها.

- تاريخ الانتهاء/العمر الافتراضي: للأغراض الحساسة، تحقق من شهادة التحليل (COA) أو اسأل المورد عن مدة الصلاحية ( Sigma-Aldrich ).

لا تتردد في طلب العينات من البائعين أو طلب توضيحات حول الملصقات إذا كنت غير متأكد. هذا مهم بشكل خاص إذا كنت تشتري من مورد جديد أو تقوم بشراء كميات كبيرة. إذا كنت تبحث عن " أين يمكن شراء كبريتات الألومنيوم " لأول مرة، اختر الشركات التي توفر وثائق شفافة ودعمًا سريع الاستجابة.

الاعتبارات المتعلقة بالتكلفة والخدمات اللوجستية

السعر هو دائمًا عنصر مهم، لكنه لا يتعلق فقط بالتكلفة المعلنة. تخيل طلب صهريج من كبريتات الألومنيوم السائلة لمنشأة صغيرة — قد تفوق تكاليف الشحن الادخار المالي. فيما يلي بعض العوامل العملية المتعلقة بالتكلفة والخدمات اللوجستية التي يجب أخذها بعين الاعتبار عند قيامك بـ شراء كبريتات الألومنيوم :

- عادةً ما تقلل الطلبات الكبيرة من سعر الوحدة، لكنها تتطلب تخزينًا أكبر واستثمارًا أوليًا أكثر

- تزيد تكاليف الشحن للأشكال السائلة بسبب الوزن وقد تحتاج إلى حاويات خاصة

- الأشكال الجافة أرخص في الشحن، وأسهل في التخزين، ولها مدة صلاحية أطول

- تتفاوت أوقات التوصيلسأل دائما عن مواعيد التسليم قبل وضع طلب كبير أو عاجل

- بعض الموردين، وخاصة في الصين، يقدمون أسعار تنافسية جداً للحجم الكبير، ولكن التحقق من الجودة وموثوقية التسليم هو المفتاح

- الشهادات: ISO، NSF/ANSI، أو سلامة الأغذية حسب الحاجة

- مواعيد التسليم: تأكيد قبل الطلب، وخاصة بالنسبة للشحنات الدولية

- سياسات الإرجاع: تأكد من أنك تفهم شروط الإرجاع / التبادل

- الدعم: الوصول إلى المشورة التقنية وخدمة ما بعد البيع

عندما تقارن خيارات أين تشتري كبريتات الألومنيوم أو من أين يمكنني شراء كبريتات الألومنيوم لا يقتصر الأمر على السعر فحسب، بل يقتصر الأمر أيضاً على الوثائق، وموثوقية التسليم، والدعم الفني. بالنسبة للاحتياجات المستمرة، يمكن لبناء علاقة مع مورد موثوق به أن يضمن الجودة والإمدادات المتسقة.

جاهز لشراء كبريتات الألومنيوم المناسبة؟ مع هذه النصائح، ستتجنب الأخطاء وتحصل على أفضل قيمة لتطبيقك. بعد ذلك، دعونا نحل المشكلات الشائعة في التطبيق ونضمن حصولك على النتائج التي تتوقعها.

نتائج التشخيص والممارسات المثلى لتطبيقات كبريتات الألومنيوم

تشخيص مياه عكرة أو بطيئة الترسيب

هل سبق أن عالجت بركة أو مسبح أو خزان مياه باستخدام كبريتات الألومنيوم ووجدت أن الماء لا يزال عكرًا أو بطيئًا في الوضوح؟ يبدو الأمر محبطًا، لكنك لست وحدك — هذه واحدة من أكثر التحديات شيوعًا التي يواجهها المستخدمون. الخبر السار هو أن معظم المشكلات تعود إلى عنصرين رئيسيين — الجرعة ودرجة الحموضة (pH). تذكر، كبريتات الألومنيوم درجة الحموضة التحكم في الأمر مهم بقدر تحديد الجرعة الصحيحة، لأن فعالية التخثير تعتمد على البقاء ضمن النطاق الأمثل لدرجة الحموضة. إذا كنت تسأل 'هل كبريتات الألومنيوم قابلة للذوبان؟' — نعم، إذ تذوب بسهولة في الماء، ولكن الأداء يعتمد على كيمياء النظام الخاص بك.

- الماء الغائم بعد إضافة الجرعة: الأسباب المحتملة: جرعة منخفضة جداً، أو درجة الحموضة خارج النطاق الأمثل (عادةً ما يكون النطاق الأمثل بين 6.5 و7.5 في معالجة المياه)، أو خلط غير كافٍ. ما يجب القيام به: قم بإجراء اختبار الجر (Jar Test) لضبط الجرعة بدقة، وتأكد من أن درجة الحموضة ضمن النطاق المستهدف، وقم بالخلط بشكل أكثر شمولاً.

- تكتلات بطيء في الترسيب: الأسباب المحتملة: جرعة زائدة (تصبح التكتلات خفيفة جداً)، أو ماء بارد جداً، أو خلط غير كافٍ. ما يجب القيام به: قلل الجرعة تدريجياً، وزيّن وقت الخلط، وسمح بوقت أطول للترسيب. قم بتعديل درجة الحرارة إذا أمكن ذلك.

- تكتلات صغيرة أو إعادة تعليق: الأسباب المحتملة: زيادة في كمية الشبة أو درجة الحموضة منخفضة جداً. ما يجب القيام به: قلل الجرعة، وأضف جير مطفأ لتعديل الرقم الهيدروجيني إذا انخفض بسرعة ( منتدى Pond Boss ).

الرقم الهيدروجيني القريب من المعدل الأمثل للتجلط مهم بنفس قدر أهمية الجرعة.

منع البقع ومشاكل المعدات

هل لاحظتَ بقعًا بيضاء أو زرقاء على أسطح حمامات السباحة، أو لاحظتَ انسداد فلتر حمام السباحة لديك أسرع من المعتاد؟ غالبًا ما تنجم بقع الأسطح ومشاكل المعدات عن سوء الاستخدام أو قلة التنظيف بعد المعالجة. إليكَ كيفية الحفاظ على سير العمل بسلاسة:

- البقع السطحية: الأسباب المحتملة: تراكم كبريتات الألومنيوم غير المذابة على الأسطح، أو انخفاض الرقم الهيدروجيني إلى مستوى منخفض جداً. ما يجب القيام به: قم دائماً بإذابة كبريتات الألومنيوم بشكل كامل ووزعها بالتساوي. قم بريّ الموقع جيداً بعد التطبيق، خاصة في المسابح والحدائق. تجنب التطبيق عندما يكون الماء بارداً جداً.

- انسداد المرشح: الأسباب المحتملة: الفشل في شفط التجلطات إلى المصرف أو تشغيل المرشح أثناء فترة الترسيب. ما يجب القيام به: بعد استقرار الترسبات، قم بتفريغها كنفاية قبل إعادة تشغيل الفلترة. قم بغسيل المرشحات عكسياً حسب الحاجة.

إدارة استجابة التربة والنبات

عند الاستخدام كبريتات الألومنيوم للحدائق ، قد يكون من المغري استخدام كمية أكبر لتحقيق نتائج أسرع - لكن المبالغة قد تؤدي إلى نتائج عكسية. تخيل تحول أوراق الهدرانج إلى اللون البني أو ظهور نمو بطيء على التوت الأزرق. هذه علامات لزيادة الحموضة أو سمية الألومنيوم، خاصة إذا تجاهلت اختبار التربة.

- حروق الأوراق أو نمو محدود: الأسباب المحتملة: الاستخدام المفرط أو انخفاض الرقم الهيدروجيني تحت مستوى تحمل النبات. ما يجب القيام به: قم دائمًا باختبار الرقم الهيدروجيني للتربة قبل كل تطبيق. استهدف نطاق 4.5–5.5 للنباتات المحبة للحمضية. طبق الكمية بكميات صغيرة، اروِ النباتات جيدًا، وأعد قياس الرقم الهيدروجيني بعد بضعة أسابيع ( أليانس كيميكل ).

- تظل التربة شديدة القلوية: الأسباب المحتملة: كمية غير كافية من المنتج، أو تطبيق غير متساوٍ، أو احتفاظ التربة الثقيلة بالتعادل. ما يجب القيام به: كرر الاستخدامات الصغيرة ذات الفواصل الزمنية، واخلط كبريتات الألومنيوم في الستة بوصات العلوية من التربة للحصول على أفضل النتائج.

قائمة أفضل الممارسات

- قم باختبار الرقم الهيدروجيني قبل وبعد كل تطبيق — لا تحصل على تخمين

- استخدم الجرعات التدريجية وراقب النتائج قبل إعادة التطبيق

- امزج جيدًا وأضف الماء بكمية كافية لتجنب بقايا على السطح

- قم بتشغيل مرشح التصفية العكسي أو تنظيف المرشحات بعد معالجة المياه

- في البستنة، استخدم كبريتات الألومنيوم مع المواد العضوية لدعم صحة التربة

باتباعك لهذه الخطوات لحل المشكلات وأفضل الممارسات، ستتمكن من تحقيق أقصى استفادة من كبريتات الألومنيوم — سواء كنت تقوم بتنقية المياه، أو صيانة المسبح، أو العناية بالنباتات المحبة للحمضية. هل أنت جاهز لإعادة التلخيص والحصول على مصادر موثوقة إضافية؟ انتقل بعد ذلك إلى الملخص والدليل المرجعي.

الملخص والموارد ذات الصلة

النقاط الرئيسية والموارد الموثوقة

- كبريتات الألومنيوم - والمعروفة أيضًا باسم الملح الألمنيزي، Al 2(SO 4)3, أو كبريتات الألومنيوم - هي ملح غير عضوي متعدد الاستخدامات تُستخدم في معالجة المياه، وصناعة الورق، وصباغة النسيج، وتحمض التربة، وحتى في التطبيقات الطبية والغذائية.

- ما هو الاستخدام الأكثر شيوعًا لكبريتات الألومنيوم؟ إن وظيفتها الأساسية هي استخدامها كعامل تجلط لتنقية مياه الشرب، ومعالجة مياه الصرف الصحي، وإزالة الشوائب من المسابح والعمليات الصناعية ( EPA ).

- إن تحديد الجرعة المناسبة، والتحكم في درجة الحموضة، وتحديد الشكل المناسب (سائل أو جاف) من العوامل الأساسية للحصول على نتائج آمنة وفعالة - سواء كنت تقوم بتنقية المياه، أو تعديل درجة حموضة التربة، أو تثبيت الأصباغ على الأقمشة.

- قم دائمًا بالتحقق من الدرجة النوعية، ونوع الهيدرات، والوثائق الداعمة (ورقة البيانات الأمنية/شهادة التحليل) عند الحصول على كبريتات الألومنيوم للاستخدام في التطبيقات الحرجة.

- ليست كبريتات الألومنيوم كيميائيًا فحسب، بل هي عنصر مُمَكِّن أساسي في التصنيع المستدام، خاصة في المجالات التي تتداخل فيها معالجة المياه مع مكونات الألومنيوم المتوافقة.

حلول ألمنيوم ذات صلة للمهندسين

إن المهندسين والمشترين الذين يعملون مع أنظمة معالجة المياه أو الذين يحددون معدات تعتمد على الألومنيوم، عليهم أن يربطوا بين المعرفة الكيميائية وتصنيع المواد. إن دورة تصنيع واستخدام مكونات الألومنيوم - مثل الإطارات والهياكل أو قطع السيارات - تتطلب في كثير من الأحيان إدارة رشيدة للمياه والمجاري. كون كبريتات الألومنيوم مادة تجفيف رئيسية في هذه العمليات، فإنها تساعد في ضمان الامتثال البيئي والكفاءة التشغيلية.

- مورد قطع المعادن Shaoyi – مزود رئيسي ومتكامل لحلول قطع السيارات المعدنية الدقيقة في الصين. إن قطع ألومنيوم للطحن هي مثالية لإطارات معدات معالجة المياه والتطبيقات الخاصة بالسيارات، حيث تسد الفجوة بين الكيمياء والحلول الهندسية.

- Affinity Chemical: تركيب كبريتات الألومنيوم واستخداماته – نظرة شاملة على استخدامات كبريتات الألومنيوم والسلامة والرؤى الصناعية.

- EPA: ملف سلسلة توريد كبريتات الألومنيوم – إرشادات سلسلة التوريد والتنظيمية من قبل جهة موثوقة لمستخدمي القطاع الصناعي والبلديات.

- كيمتريد: بيانات منتج كبريتات الألومنيوم (ألوم) - تفاصيل حول الدرجات والشهادات ونصائح التطبيق للمشترين الصناعيين.

لماذا يجب وضع هذه الإرشادات في الإشارات المرجعية؟

- يمكنك بسرعة الرجوع إلى قائمة السلامة وبروتوكولات اختبار الجرّة للمستقبل.

- ابقَ على اطلاع بأحدث الممارسات المتبعة في معالجة المياه وإدارة التربة وتوافق المواد.

- شارك هذه الموارد مع الزملاء أو الفرق التي تدير عمليات المعالجة الكيميائية وشراء مكونات الألومنيوم.

لأي شخص يسأل 'ما استخدام كبريتات الألومنيوم؟' أو يستكشف الاستخدامات العديدة للاستعمالات ألوم ، يربط هذا الدليل بين النظرية والممارسة الواقعية - من تنقية المياه إلى التصنيع المتقدم. فهم كيمياء المادة مع استخدامات الألومنيوم و استخدامات الألمنيوم في الصناعة يمكّنك من اتخاذ قرارات أكثر أمانًا وذكاءً واستدامة.

الأسئلة الشائعة حول كبريتات الألومنيوم

1. ما هي كبريتات الألومنيوم ولماذا تُستخدم؟

كبريتات الألومنيوم هي ملح غير عضوي، Al2(SO4)3، ويُستخدم على نطاق واسع كعامل تجلط في معالجة المياه وبرك السباحة وتحميض التربة وصناعة الورق. فهو يساعد في إزالة الشوائب من الماء وتعديل درجة حموضة التربة للنباتات التي تحتاج إلى التربة الحمضية.

2. هل كبريتات الألومنيوم هي نفسها ملح الشبة؟

بينما يستخدم الكثير من الناس مصطلح "ملح الشبة" للإشارة إلى كبريتات الألومنيوم، فإن مصطلح "ملح الشبة" يشير تقنيًا إلى مجموعة من الأملاح الكبريتية المزدوجة. تُسمى كبريتات الألومنيوم أحيانًا بملح الشبة على الملصقات، ولكن من المهم التحقق من الصيغة الكيميائية لضمان شراء المنتج الصحيح.

3. كيف يمكنني التعامل مع كبريتات الألومنيوم بشكل آمن وكيفية تخزينها؟

ارتدِ قفازات ونظارات واقية وملابس حماية. أضف كبريتات الألومنيوم دائمًا إلى الماء (وليس العكس)، وتجنّب استنشاق الغبار، واحفظه في وعاء مُلصَق ومُجفَّف بعيدًا عن المواد غير المتوافقة. راجع ورقة بيانات السلامة الخاصة بالمنتج للحصول على تعليمات السلامة المفصّلة.

٤. ما الذي يجب أن أتحقّق منه عند شراء كبريتات الألومنيوم؟

تحقّق من الدرجة (تقنية، أو لمياه الشرب، أو للأغذية) ونوع الهيدرات وشهادات الجودة المطلوبة. اطلب ورقة بيانات السلامة المعتمدة وشهادة التحليل الخاصة بالمنتج، ووثّق تفاصيل التغليف والتركيز المناسبة لتطبيقك. يوفّر الموردون الموثوق بهم وثائق واضحة ودعمًا فنيًا.

٥. لماذا تعتبر كبريتات الألومنيوم مهمة في التصنيع الصناعي؟

تُعدّ كبريتات الألومنيوم ضرورية لمعالجة مياه الصرف في الصناعات التحويلية، خاصةً في عمليات البثق الألومنيومي حيث تكون المياه النظيفة ضرورية. يضمن استخدامها الامتثال للمعايير البيئية ويدعم الإنتاج المستدام لمكونات معدنية.

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —