المواد الأساسية لقوالب الصب بالضغط وأجزائها

باختصار

يتمثل اختيار المواد المناسبة للقالبة بالضغط في فئتين مختلفتين. تُصنع القوالب، أو الأدوات، من فولاذ أدوات عالي المقاومة للحرارة مثل H13 وP20 لتحمل درجات الحرارة والضغوط الشديدة. أما الأجزاء نفسها فتُشكَّل عن طريق حقن سبائك غير حديدية منصهرة—وخصوصًا الألومنيوم والزنك والمغنيسيوم—في هذه القوالب. ويُعد فهم هذا التمييز أمرًا بالغ الأهمية للتصنيع الناجح.

مواد القالب مقابل مواد الصب: تمييز بالغ الأهمية

نقطة شائعة من الالتباس في صب القوالب هي الفرق بين المادة المستخدمة في صنع القالب والمادة المستخدمة في إنتاج الجزء النهائي. إن توضيح هذه النقطة هو الخطوة الأولى نحو اتخاذ قرارات هندسية مدروسة. فكلا المادتين تؤديان وظائف مختلفة تمامًا وتتميزان بخصائص مختلفة جوهريًا. فالقالب هو أداة متينة وقابلة لإعادة الاستخدام، في حين أن مادة الصب هي المادة الأولية التي تتحول إلى المنتج النهائي.

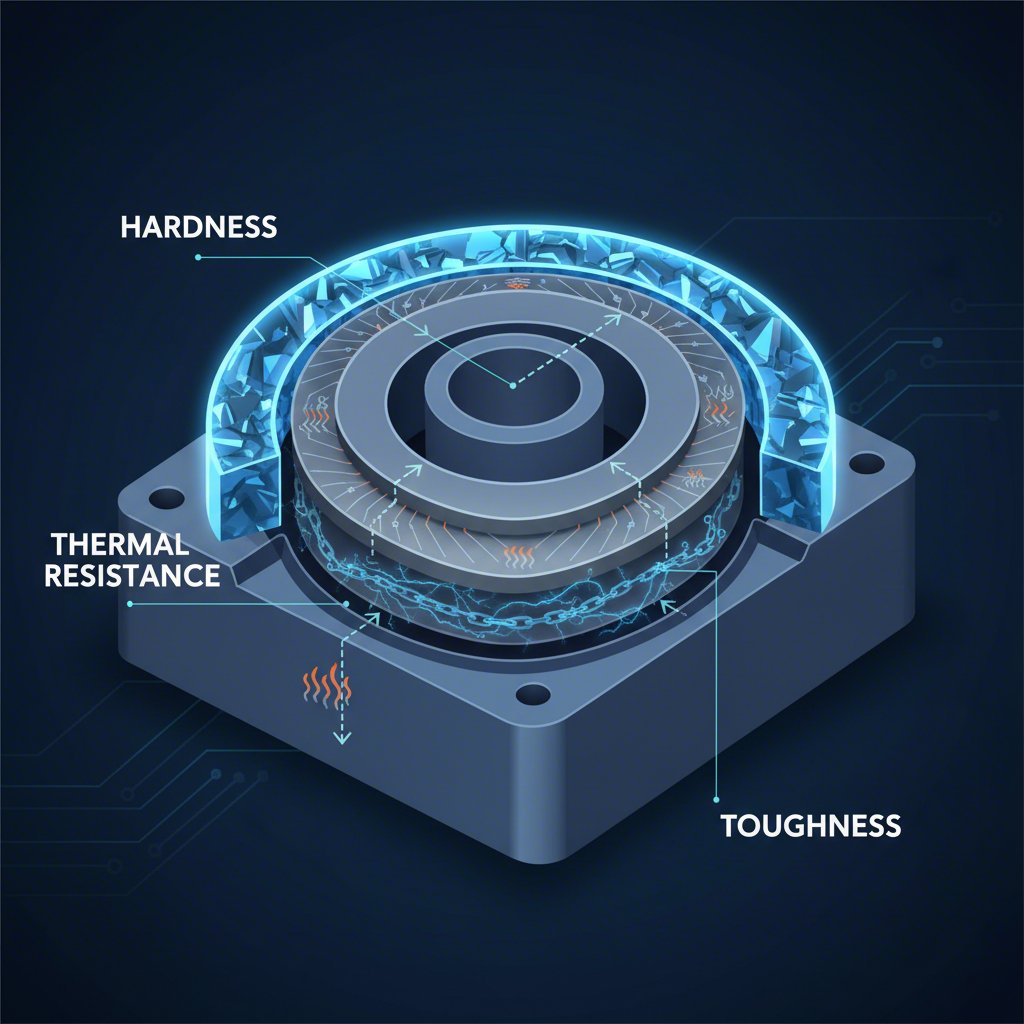

يجب أن تكون مادة القالب قوية بشكل استثنائي. فدورها الأساسي هو احتواء المعدن المنصهر تحت ضغط هائل والقدرة على تحمل آلاف الدورات الحرارية دون أن تشوه أو تتشقق أو تتآكل. ولهذا السبب، يعتمد المصنعون على فولاذ أدوات عمل ساخن متخصص. وقد تم تصميم هذه الفولاذات لتتميز بصلابة عالية، ومقاومة ممتازة لتعب الحرارة، ومتانة عند درجات الحرارة المرتفعة. وكما ورد في الأدلة من HLC Metal Parts ، فإن عمر التشغيل والدقة في عملية الصب بالقالب بأكملها تعتمد على جودة فولاذ القالب.

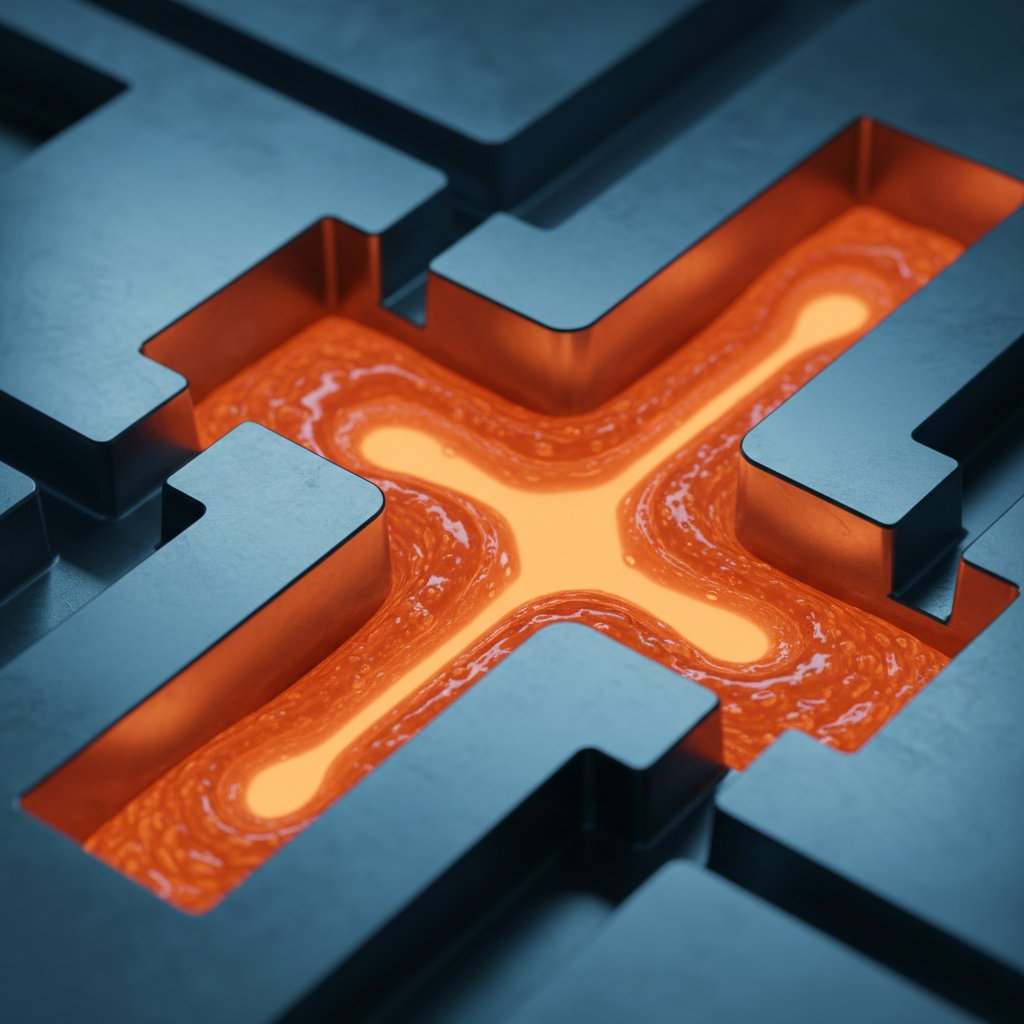

على النقيض، يتم اختيار مادة الصب بناءً على الخصائص المطلوبة للمكوّن النهائي. وعادةً ما تكون هذه المواد سبائك غير حديدية تُعرف بخصائص مثل السيولة الممتازة عند انصهارها، ونقاط الانصهار المنخفضة، والوزن الخفيف، ومقاومة التآكل. والهدف هو اختيار سبيكة تتدفق بسهولة داخل تجاويف القالب المعقدة لإنتاج جزء دقيق الأبعاد ولديه القوة الميكانيكية المطلوبة ونهاية السطح المناسبة. وتتعلق متطلبات أداء مادة الصب بكافة الجوانب المتعلقة باستخدام المنتج النهائي، وليس متانة أداة التصنيع.

قد يؤدي الخلط بين هذين الأمرين إلى أخطاء كبيرة في التصميم والإنتاج. على سبيل المثال، تحديد سبيكة صب شائعة لاستخدامها في قالب سيؤدي إلى فشل فوري، لأنها ستذوب بمجرد ملامستها لمادة الصب. ويوضح الجدول أدناه هذا الفرق الأساسي من خلال أمثلة شائعة.

| الفئة | الدور الأساسي | الخصائص الرئيسية | أمثلة شائعة |

|---|---|---|---|

| مواد القوالب | لتشكيل الأداة القابلة لإعادة الاستخدام (القالب) | صلابة عالية، ومقاومة للحرارة، وقوة ضد إجهاد التعب الحراري | فولاذ الأداة H13، فولاذ P20 |

| مواد الصب | لتشكيل الجزء النهائي | سيولة جيدة، ونسبة قوة إلى وزن محددة، ومقاومة للتآكل | الألومنيوم (A380)، الزنك (Zamak 3)، المغنيسيوم (AZ91D) |

تحقيق أعمق: فولاذ عالي الأداء لقوالب الصب بالضغط

المواد المستخدمة في بناء قوالب الصب بالضغط هي الأبطال المجهولون في عملية التصنيع. ويجب أن تعمل هذه المواد بموثوقية تحت بعض الظروف الصناعية الأكثر صرامة. وتتمثل الفئة الأساسية للمواد المستخدمة في هذا الغرض في فولاذ الأدوات للعمل الساخن، وهو نوع من السبائك المصممة خصيصًا للحفاظ على قوتها وصلابتها واستقرارها البُعدي عند درجات الحرارة العالية جدًا. وتعتبر هذه السبائك ضرورية لضمان عمر طويل للقالب وإنتاج أجزاء متسقة وعالية الجودة عبر عشرات الآلاف من الدورات.

المواد الأكثر استخدامًا على نطاق واسع في قوالب الصب بالضغط هي فولاذ الأداة H13. ووفقًا لتحليل تفصيلي من Neway Precision ، توفر H13 توازنًا استثنائيًا بين الصلابة والمرونة ومقاومة التعب الحراري. تتكون هذه المادة من الكروم والموليبدينوم والفاناديوم، ما يمكنها من تحمل الصدمات الحرارية الناتجة عن ملئها مرارًا بالمعدن المنصهر. ويجعل منها هذا الخيار المفضل لسبك سبائك الألومنيوم والزنك. ومن المواد الشائعة الأخرى فولاذ P20، الذي يُستخدم غالبًا بشكل مسبق التصلب. وعلى الرغم من أن مقاومته للحرارة العالية ليست بنفس مستوى H13، إلا أن فولاذ P20 أسهل في التشغيل ويُعد خيارًا اقتصاديًا للقوالب المستخدمة في التطبيقات منخفضة الحرارة أو في دفعات إنتاج قصيرة.

يعتمد اختيار فولاذ الأدوات المحدد بشكل كبير على التطبيق. بالنسبة للمهام شديدة الطلب التي تنطوي على هندسات معقدة أو أحجام إنتاج عالية، قد يلجأ المصنعون إلى مواد أكثر تقدمًا مثل فولاذ الماراجينج أو سبائك النيكل الفائقة، والتي توفر قوة ومتانة متفوقة بتكلفة أعلى. في قطاع السيارات، حيث تكون الدقة والمتانة أمرًا بالغ الأهمية، يكون اختيار المادة أمرًا حاسمًا. وشركات تصنيع متخصصة مثل Shaoyi (Ningbo) Metal Technology Co., Ltd. تُظهر خبرتها في إنتاج قوالب ختم السيارات عالية الدقة، وهي عملية تعتمد على فولاذ أدوات قوي بالمثل لضمان اتساق القطع وطول عمر الأداة بالنسبة لموردي المعدات الأصلية (OEM) والموردين من الدرجة الأولى.

لتعزيز الأداء بشكل أكبر، غالبًا ما تتلقى أسطح القوالب علاجات متخصصة. على سبيل المثال، يؤدي النترجة إلى تكوين طبقة سطحية صلبة جدًا تقاوم البلى والتآكل الناتج عن تدفق المعدن المنصهر. ويمكن أيضًا تطبيق طلاء الكروم الصلب لتحسين صلابة السطح وتسهيل إخراج القطعة. يمكن أن تُطيل هذه العلاجات عمر القالب التشغيلي بشكل كبير، مما يحمي الاستثمار الكبير الذي تم بذله في تصنيعه. فيما يلي مقارنة بين فولاذ الأدوات الشائع المستخدم في قوالب الصب بالقالب.

| درجة الصلب | الصلابة النموذية (HRC) | الخصائص الرئيسية | التطبيقات النموذجية |

|---|---|---|---|

| H13 | 52-54 | توازن ممتاز بين المتانة، ومقاومة الحرارة، ومقاومة التعب الحراري. | غرض عام للسباكة بالألومنيوم والزنك والمغنيسيوم. |

| ص20 | ~30-36 (مسبق التصلب) | سهولة تشغيل جيدة، وقوة معتدلة. مقاومة حرارية أقل من H13. | قوالب للسباكة بالزنك، قوالب نموذجية، ودورات إنتاج قصيرة. |

دليل حول السبائك الشائعة لأجزاء الصب بالقالب

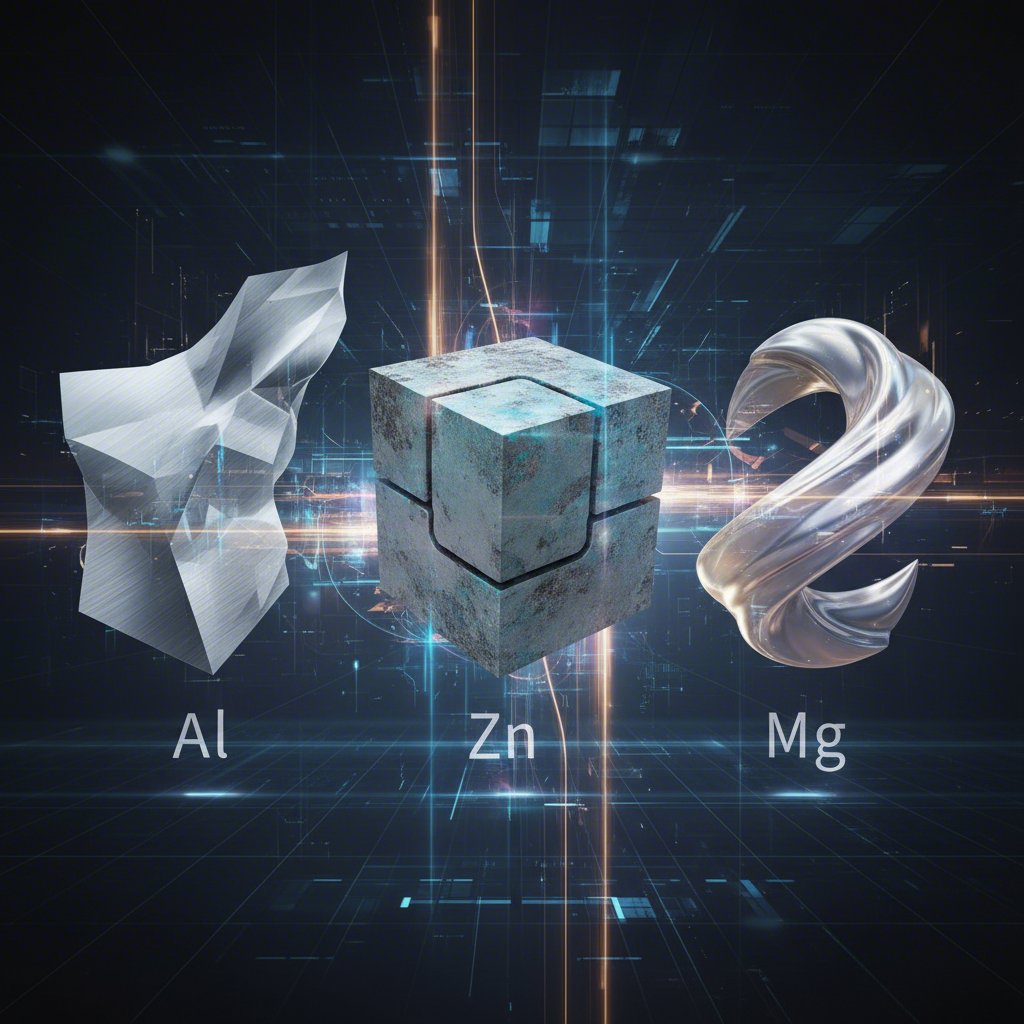

بينما يوفر القالب الشكل، فإن سبيكة الصب تمنح القطعة النهائية مادتها ووظيفتها. يتم تصنيع الغالبية العظمى من قطع الصب بالضغط باستخدام ثلاث عائلات رئيسية من السبائك غير الحديدية: الألومنيوم، والزنك، والمغنيسيوم. وتتميز كل سبيكة بملف خصائص فريد، مما يجعلها مناسبة لتطبيقات مختلفة. ويُعد اختيار السبيكة قرارًا حاسمًا في التصميم، حيث يؤثر على وزن القطعة وقوتها ومتانتها وتكلفتها.

سبائك الألومنيوم

يُعد الألومنيوم المادة الأكثر شيوعًا في صب القوالب، ويُقدَّر لما يتمتع به من نسبة ممتازة بين القوة والوزن، ومقاومته للتآكل، والتوصيل الحراري الجيد. وكما ورد في دليل منشور من قبل القياس تُعد سبائك مثل A380 شديدة التنوع، وتُستخدم في مجموعة واسعة من المنتجات، بدءًا من كتل محركات السيارات وصولاً إلى أغلفة الإلكترونيات وأدوات التشغيل الكهربائية. وتُعرف درجة أخرى شائعة، ADC12، بقابليتها الفائقة للصهر، ما يمكنها من ملء قوالب معقدة ذات جدران رقيقة. وتوفر سبائك الألومنيوم حلاً اقتصاديًا لإنتاج مكونات خفيفة الوزن ولكنها قوية.

سبائك الزنك

تُعد سبائك الزنك، ولا سيما تلك المنتمية إلى عائلة زاماك (مثل زاماك 3 وزاماك 5)، حجر زاوية آخر في صناعة الصب بالقالب. وتشمل مزاياها الرئيسية نقطة انصهار منخفضة جداً، مما يقلل من تكاليف الطاقة ويُطيل عمر القالب، بالإضافة إلى سيولة استثنائية. تتيح هذه السيولة إمكانية إنتاج أجزاء ذات تفاصيل دقيقة للغاية وحوائط رقيقة جداً، وغالباً ما تكون ذات تشطيب سطحي متفوق ولا تحتاج سوى إلى حد أدنى من المعالجة الثانوية. تتميز سبائك الزنك بكثافة أعلى من الألومنيوم، ولكن قوتها وصلابتها تجعلها مثالية للتطبيقات مثل مقابض أبواب السيارات، والأجهزة الزخرفية، والتروس، وموصلات الإلكترونيات.

سبائك المغنيسيوم

عندما يكون الحد الأدنى المطلق للوزن مطلوبًا، يلجأ المصممون إلى سبائك المغنيسيوم. وباعتباره أخف المعادن الهيكلية على الإطلاق، يوفر المغنيسيوم أفضل نسبة قوة إلى الوزن. وتُستخدم سبائك مثل AZ91D على نطاق واسع في التطبيقات التي يكون فيها تقليل الوزن أمرًا بالغ الأهمية، مثل مكونات الطيران والفضاء، والأجزاء السيارات عالية الجودة، والأجهزة المحمولة مثل هياكل أجهزة الكمبيوتر المحمولة وأجسام الكاميرات. وعلى الرغم من أن تكلفته أعلى من الألومنيوم أو الزنك، فإن الخصائص الفريدة للمغنيسيوم تبرر استخدامه في التطبيقات المتميزة التي تكون فيها الأداء والوزن الخفيف شرطًا لا يمكن التنازل عنه.

| عامل | سبائك الألومنيوم | سبائك الزنك | سبائك المغنيسيوم |

|---|---|---|---|

| الوزن | ضوء | ثقيل | الأخف وزناً |

| القوة | قوة جيدة عند درجات الحرارة العالية | قوة تأثير عالية وصلابة | نسبة قوة إلى وزن ممتازة |

| مقاومة للتآكل | ممتاز | جيدة جدًا | جيدة (مع المعالجة السطحية المناسبة) |

| نقطة الانصهار | أعلى (~600°م) | الأدنى (~380°م) | أعلى (~600°م) |

| التكلفة النسبية | معتدلة | منخفض إلى متوسط | مرتفع |

معايير الاختيار الرئيسية: اختيار المادة المناسبة لتطبيقك

يتطلب اختيار المادة المثلى لكل من قوالب الصب بالضغط والجزء النهائي تحليلًا دقيقًا للعوامل الميكانيكية والحرارية والاقتصادية. إن عملية اتخاذ القرار هذه لا تدور حول إيجاد مادة واحدة هي "الأفضل"، بل حول تحديد الأنسب لتطبيق معين. ويضمن النهج المتوازن أن يستوفي المنتج النهائي أهداف الأداء مع الحفاظ على انخفاض تكلفة التصنيع.

عوامل اختيار مادة القالب

يتحدد اختيار فولاذ الأداة للقالب بشكل أساسي وفقًا لظروف الصب ومتطلبات الإنتاج. وتشمل الاعتبارات الرئيسية التي حددها الخبراء في Ace Mold تشمل:

- درجة حرارة سبيكة الصب: كلما زادت نقطة انصهار سبيكة الصب (مثل الألومنيوم مقابل الزنك)، كان لا بد من أن تكون مادة القالب أكثر مقاومة للحرارة. ولهذا السبب يُعد H13 هو المعيار للألمنيوم، بينما يمكن أن يكون P20 كافيًا للزنك.

- حجم الإنتاج: بالنسبة للتشغيل عالي الحجم الذي يبلغ مئات الآلاف، فإن استخدام فولاذ أداة أكثر متانة وتكلفة يعد استثمارًا حكيمًا، لأنه سيكون له عمر أطول ويقلل من التوقف عن العمل. وبالنسبة للنماذج الأولية أو الإنتاج بكميات صغيرة، قد يكون الفولاذ الأقل متانة والأكثر سهولة في التشغيل أكثر اقتصاداً.

- تعقيد القطعة: يمكن أن تؤدي الهندسات المعقدة ذات الجدران الرقيقة إلى مناطق عالية الإجهاد في القالب. ومن الضروري استخدام فولاذ أقوى يتمتع بمقاومة عالية للتآكل لمنع التشقق المبكر والفشل.

عوامل اختيار مادة الصب

عند اختيار السبيكة الخاصة بالقطعة نفسها، يتحول التركيز إلى بيئة الاستخدام النهائي ومتطلبات الأداء. والأساسية التي يجب مراعاتها هي:

- الخصائص الميكانيكية: هل ستتعرض القطعة لإجهاد عالٍ أو صدمات أو تآكل؟ توفر سبائك الزنك صلابة قوية ومدى جيداً ضد الصدمات، في حين يوفر الألومنيوم توازناً أفضل للمكونات الهيكلية.

- بيئة التشغيل: هل سيتم تعريض القطعة للرطوبة أو المواد الكيميائية أو درجات الحرارة القصوى؟ إن مقاومة الألومنيوم الطبيعية للتآكل تجعله مثاليًا للعديد من البيئات الخارجية أو القاسية. وقد يحتاج المغنيسيوم إلى طلاءات واقية.

- متطلبات الوزن: هل يُعد تقليل الوزن هدفًا رئيسيًا في التصميم؟ يُعد المغنيسيوم الخيار الأفضل بوضوح للتطبيقات مثل صناعة الطيران والإلكترونيات المحمولة، يليه الألومنيوم.

- الميزانية: إن التكلفة لكل قطعة عامل رئيسي مهم. عمومًا، تكون سبائك الزنك والألومنيوم أكثر اقتصادية من المغنيسيوم. كما أن تعقيد القطعة وعمليات التشطيب المطلوبة تؤثر بشكل كبير في التكلفة النهائية.

لتوجيه هذه العملية، ينبغي للمصمم طرح سلسلة من الأسئلة قبل الانتهاء من اختيار المواد. يمكن أن تُعد القائمة التالية نقطة بداية عملية لأي مشروع صب بالقالب الدقيق.

- ما هو حجم الإنتاج الكلي المتوقع لهذه القطعة؟

- ما هي درجات الحرارة القصوى والدنيا التي ستتعرض لها القطعة أثناء التشغيل؟

- ما الأحمال الهيكلية أو التأثيرات التي يجب أن يتحملها الجزء أثناء عمره الافتراضي؟

- هل يُعد وزن الجزء قيدًا تصميميًا حرجًا؟

- ما مستوى مقاومة التآكل المطلوب؟

- ما متطلبات التشطيب السطحي والمظهر الجمالي للمنتج النهائي؟

- ما التكلفة المستهدفة لكل جزء؟

الأسئلة الشائعة

1. ما المادة المستخدمة في قوالب الصب بالضغط؟

تُصنع قوالب الصب بالضغط بشكل رئيسي من فولاذ أدوات عالي الجودة، وبشكل خاص فولاذ الأدوات للعمل الساخن. ويُعد فولاذ H13 الخيار الأكثر شيوعًا وتنوعًا، حيث يوفر مزيجًا ممتازًا من المتانة ومقاومة البلى والمقاومة ضد الإجهاد الحراري. ولتطبيقات درجات الحرارة المنخفضة أو لإنتاج كميات أقل، يُعد فولاذ P20 أيضًا خيارًا شائعًا.

ما هي المادة الأنسب لصب القوالب؟

يعتمد اختيار المادة الأنسب للجزء المصبوب بالكامل على متطلبات التطبيق. تُعد سبائك الألومنيوم، مثل A380، هي الأكثر شيوعًا بشكل عام نظرًا لتوازنها الممتاز بين القوة والوزن الخفيف ومقاومة التآكل والتكلفة. ومع ذلك، فإن سبائك الزنك تكون أفضل للقطع التي تتطلب تفاصيل دقيقة وقوة صدم عالية، في حين يُعد المغنيسيوم الخيار الأفضل عندما يكون تقليل الوزن هو الأولوية القصوى.

3. أي من المواد التالية تُستخدم عادةً في إعداد قوالب الصب بالضغط؟

من بين المواد الشائعة، تُعد فولاذ الأدوات هو المعيار لإعداد قوالب الصب بالضغط. تم تصميم درجات مثل H13 وP20 خصيصًا لتحمل الضغوط العالية والصدمات الحرارية الناتجة عن عملية الصب بالضغط. وتضمن هذه المواد متانة القالب ودقة أبعاده عبر العديد من دورات الصب.

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —

دُفعات صغيرة، معايير عالية. خدمتنا لتطوير النماذج الأولية بسرعة تجعل التحقق أسرع وأسهل —